Nano silicon window layer with gradient band gap characteristic and preparation method thereof

A nano-silicon and window layer technology, applied in nanotechnology, nanotechnology, nano-optics, etc., can solve the problems of difficult to obtain wide bandgap, i/p interface damage, interface bombardment damage, etc., to reduce interface carrier recombination , small particle bombardment, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

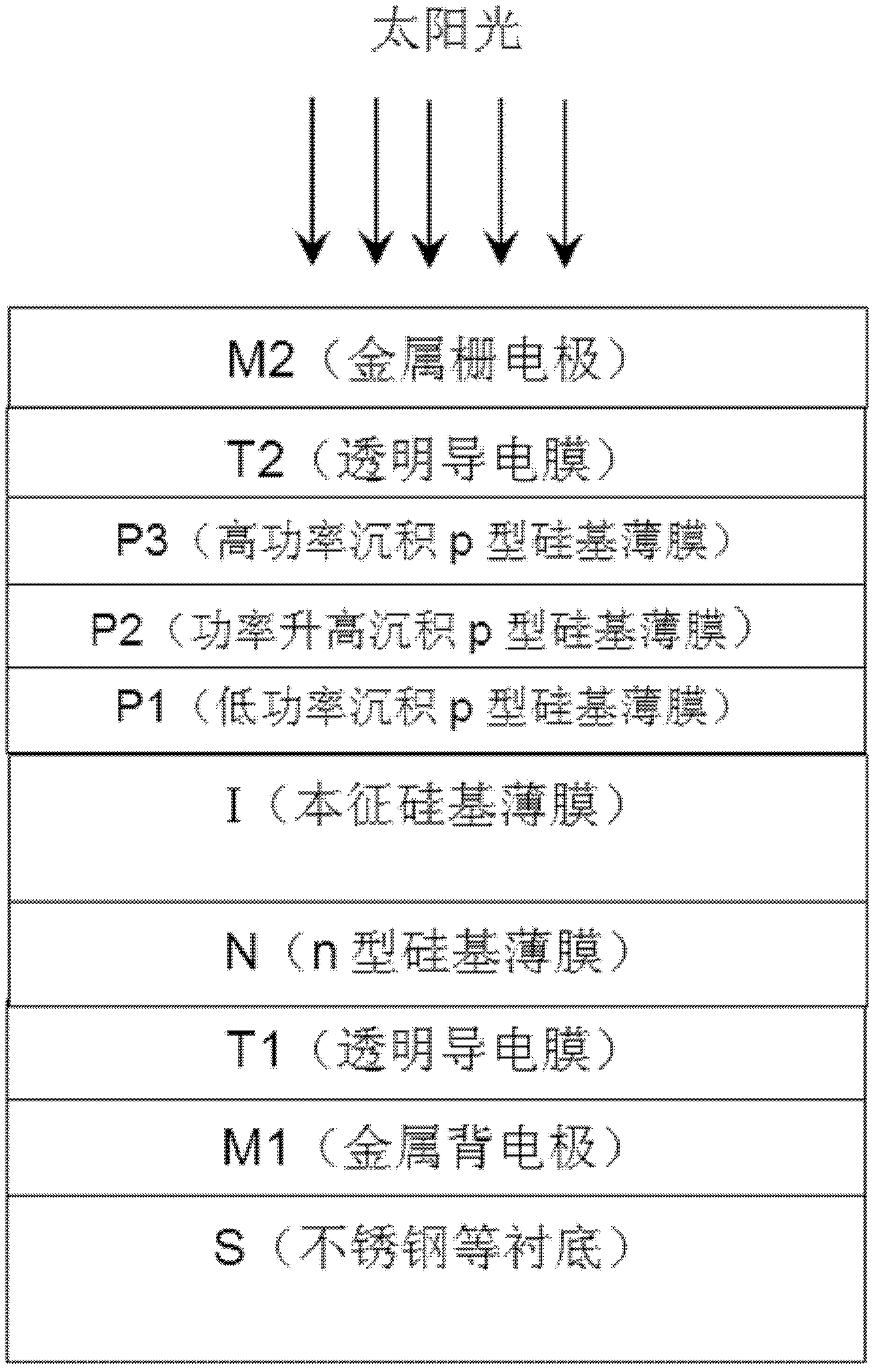

[0030] A preparation method of a nano-silicon window layer with gradient bandgap characteristics, comprising the following steps:

[0031] 1) Put the sample to be treated with the metal back electrode M, the transparent conductive back electrode T1, the n-type silicon-based film N and the intrinsic silicon-based film I stacked in sequence on the substrate into a plasma-enhanced chemical vapor phase of 13.56MHz-100MHz In the PECVD deposition equipment, the surface temperature of the sample to be processed is 150°C, and the background vacuum is 2×10 -4 Pa, into the reaction gas, the source gas in the reaction gas is silane SiH 4 ; The diluent gas is H 2 ; Doping gas is B 2 h 6 ; The ratio of dopant atoms to silicon atoms is 1%; the flow rate ratio of diluent gas to source gas is 250:1, the reaction gas pressure is 2Torr, and the glow power density is 0.08W / cm 2 A silicon film P1 with a thickness of 1.5nm was glow-deposited under the conditions;

[0032] 2) Change the glow p...

Embodiment 2

[0038] A preparation method of a nano-silicon window layer with gradient bandgap characteristics, comprising the following steps:

[0039] 1) Put the sample to be treated with the metal back electrode M, the transparent conductive back electrode T1, the n-type silicon-based film N and the intrinsic silicon-based film I stacked in sequence on the substrate into a plasma-enhanced chemical vapor phase of 13.56MHz-100MHz In the PECVD deposition equipment, the surface temperature of the sample to be processed is 150°C, and the background vacuum is 2×10 -4 Pa, into the reaction gas, the source gas in the reaction gas is silane SiH 4 ; The diluent gas is H 2 ; Doping gas is B 2 h 6 ; The ratio of dopant atoms to silicon atoms is 1%; the flow rate ratio of diluent gas to source gas is 250:1, the reaction gas pressure is 2Torr, and the glow power density is 0.08W / cm 2 A silicon film P1 with a thickness of 1.5nm was glow-deposited under the conditions;

[0040] 2) Change the glow p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com