Shield conversion lead of parallel composite strip

A technology of transposition wires and composite tapes, applied in the direction of conductors, insulated conductors, flat/ribbon cables, etc., can solve the problems of uncontrollable product performance, influence of shielding wire effect, difficult production operation, etc., and achieve excellent short-circuit resistance performance , Excellent insulation effect and strong breakdown resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

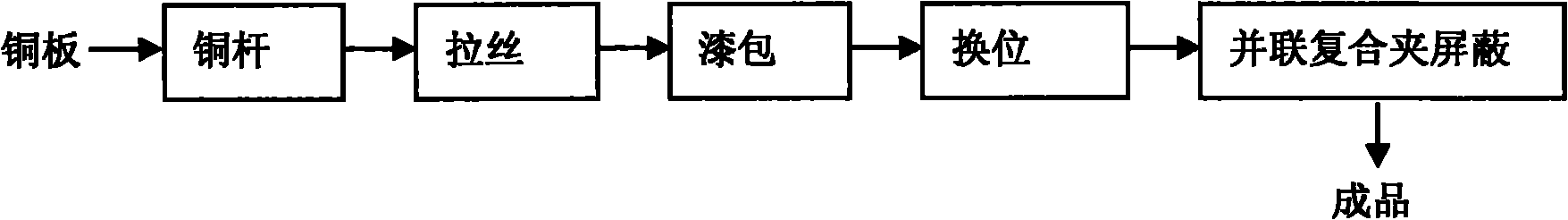

Method used

Image

Examples

Embodiment Construction

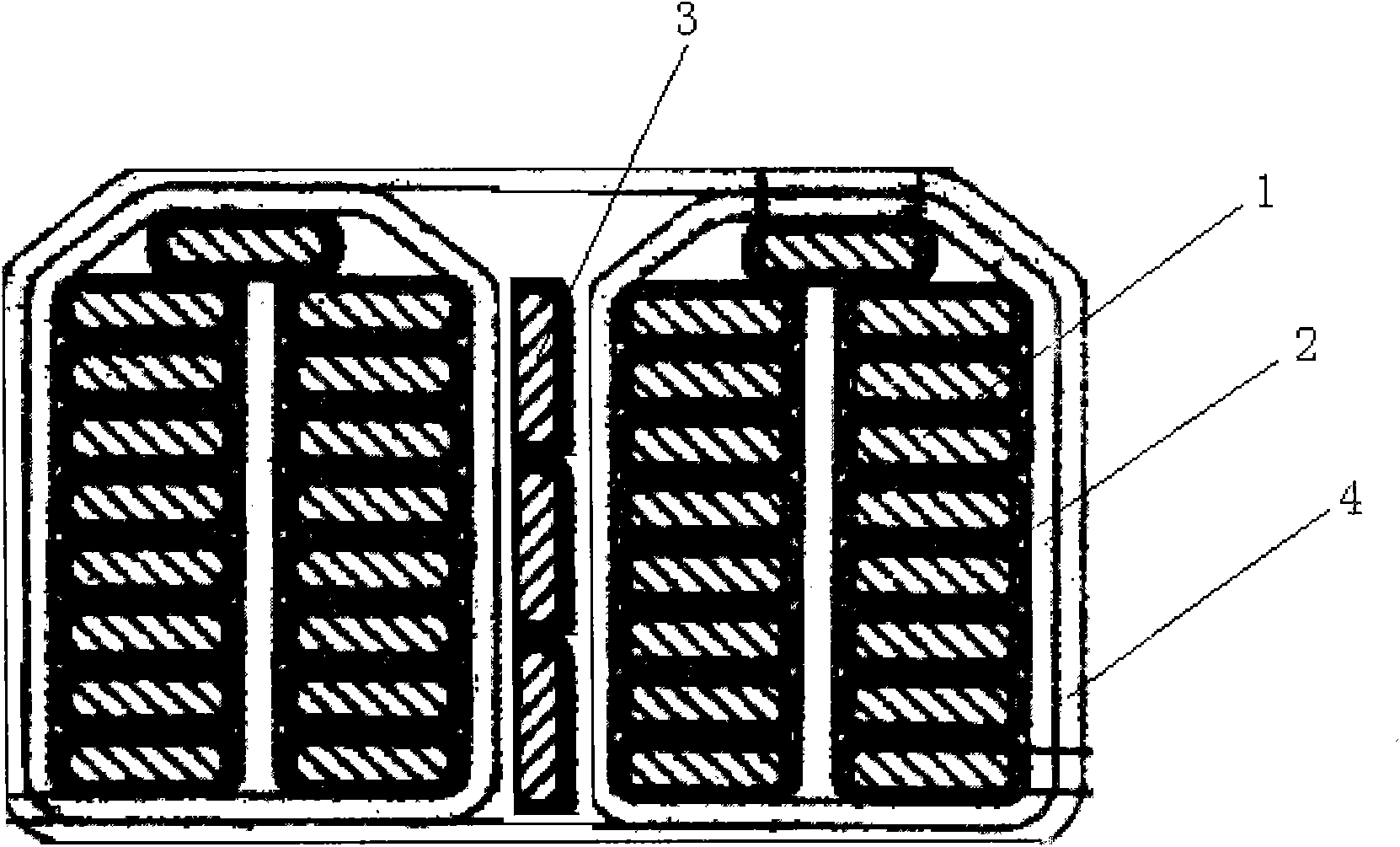

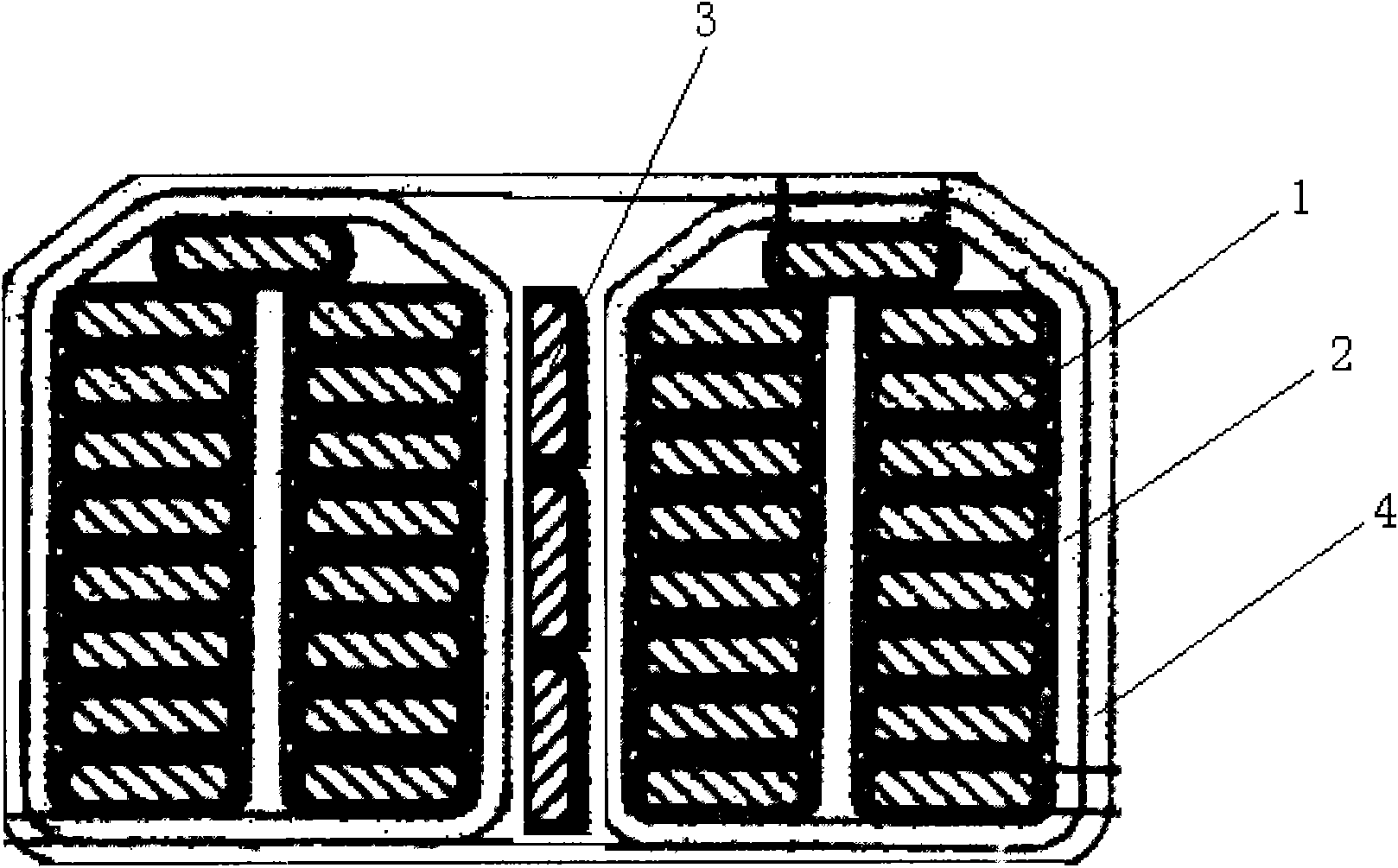

[0013] A kind of parallel composite tape shielding transposition wire according to the present invention, see figure 2 , the composite shielded transposition conductor includes two sets of copper flat wires 1, and the inner insulating paper layer 2 is coated on the outside of the single set of copper flat wires 1; the two sets of copper flat wires 1 are axially arranged side by side; A shielded wire 3 is provided between them, and an outer insulating paper layer 4 is covered outside the two sets of flat copper wires 1 and the shielded wire 3 .

[0014] There are three shielded wires 3 , and the narrow sides of a single shielded wire 3 overlap, and the height after overlapping is smaller than the height of a single set of flat copper wires 1 . The single-group copper flat wire 1 is composed of a plurality of ordinary enamelled flat wires, and the single-group copper flat wire 1 is a single transposed wire composed of ordinary enamelled flat wires. For the best insulation effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com