Self-circulating three-winding autotransformer and manufacturing method thereof

A technology of autotransformer and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, transformers, fixed transformers, etc., can solve the problems of complex overvoltage protection, poor heat dissipation conditions of dry-type transformers, and small loss, and achieve improved volume resistance High efficiency, excellent solid heat transfer efficiency, poor functional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

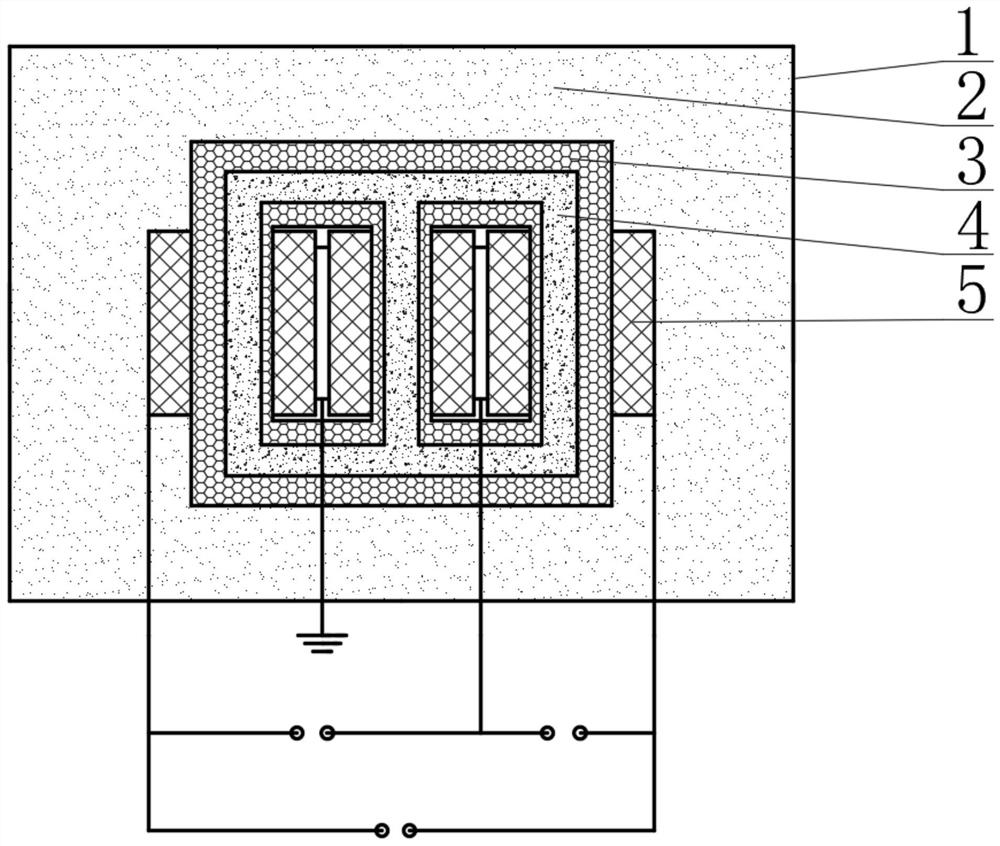

[0040] Such as figure 1 A self-circulating three-winding autotransformer is shown, including a skeleton, a winding 5, a magnetic core 4, a shield 1, and a packaging material, wherein the skeleton is an alumina-based porous foam ceramic skeleton 3 with a porosity of 20%-30% ; Winding 5 adopts copper wire with 1140 epoxy polyester insulating varnish; Magnetic core 4 is a Japanese-shaped silicon steel sheet magnetic core 4; The gap between shielding cover 1 and other components is filled with self-circulating insulating heat transfer filler 2, said The self-circulating insulating heat transfer filler 2 is a mixture of alumina-based porous foam ceramics, non-vulcanized silica gel and gum rosin; the shielding cover 1 is made of aluminum alloy and is packaged in a fully enclosed structure.

[0041] The manufacturing method of the three-winding autotransformer comprises the following steps:

[0042] 1) Selection and preparation of various components

[0043] ① The skeleton is made ...

Embodiment 2

[0070] The whole is consistent with Example 1, the difference is:

[0071] The manufacturing method of the three-winding autotransformer comprises the following steps:

[0072] 2) Manufacturing method of self-circulating insulating heat transfer filler 2

[0073] ① Mix aluminum chloride hexahydrate with an appropriate amount of pure water, stir and filter impurities, adjust to obtain an aluminum chloride solution with a mass percentage of 65%, and add sodium silicate with a weight of 55% aluminum chloride hexahydrate into the aluminum chloride solution , stir until dissolved evenly;

[0074] ③ After step ② is completed, continue to vibrate at high frequency for 40 minutes, then place the obtained solution in a constant temperature environment of 30°C, and stir it mechanically for 40 minutes to obtain a prefabricated solution;

[0075] ④ Slowly add dilute hydrochloric acid solution dropwise to the prefabricated solution obtained in step ③ and stir until the pH value of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com