Single-layer high-reliability detonating tube and preparation method thereof

A detonating tube and reliability technology, which is applied in the field of single-layer high-reliability detonating tubes and their preparation, can solve problems such as breakdown, potential safety hazards, blind shots, etc., and achieves low manufacturing cost, easy acquisition, and breakdown resistance. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares nonel of the present invention

[0027] The components and ratios of the raw materials for preparing the nonel of the present invention are as follows: the percentage of low-density polyethylene accounting for the total raw material mass is 40% to 60%, and the percentage of linear low-density polyethylene accounting for the total raw material mass is 30% to 50%. %, ethylene copolymer accounts for 5% to 20% of the total raw material mass. The density of linear low density polyethylene is 0.915~0.920g / cm 3 , Melt index in 2 ~ 5g / 10min. The ethylene copolymer is one or more mixtures of ionomers of ethylene-vinyl acetate copolymer (EVA) or ethylene-acrylate copolymer (EMA) or ethylene acrylic acid copolymer (EAA). The AA content in EAA is less than 10%, the VA content in EVA is less than 5%, and the MA content in EMA is less than 10%.

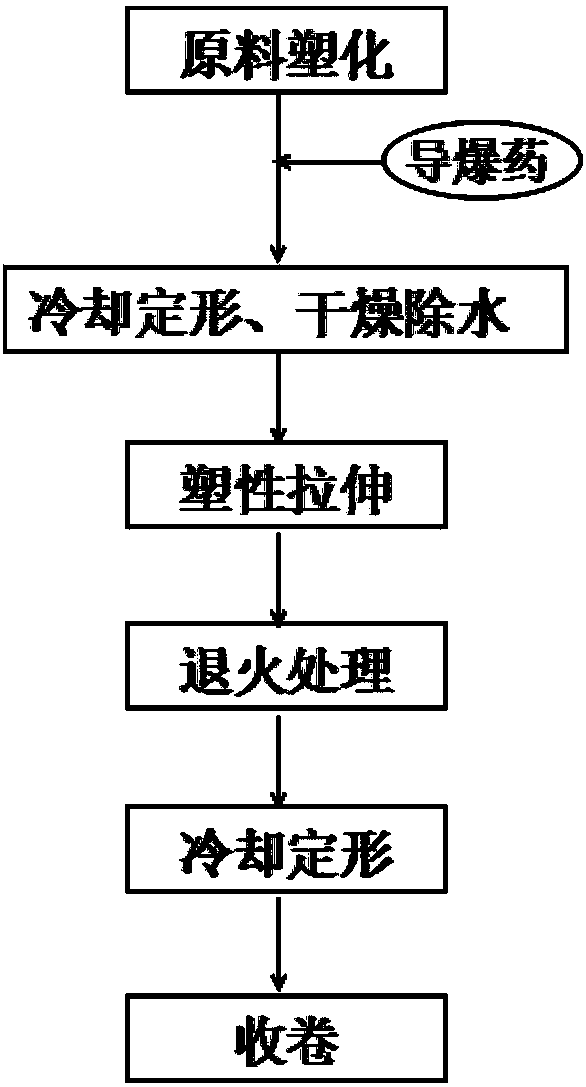

[0028] Follow the steps below to operate (the process flow is as follows figure 1 shown):

[0029] A single-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com