Drum type air treating machine set

An air handling unit, cylindrical technology, applied in heating mode, air conditioning system, space heating and ventilation, etc., can solve the problem of filter, surface cooler and muffler efficiency reduction, performance can not fully reach the highest efficiency, affecting the unit performance and life, to achieve the effects of easy cleaning and maintenance, low resistance, and strong resistance to breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

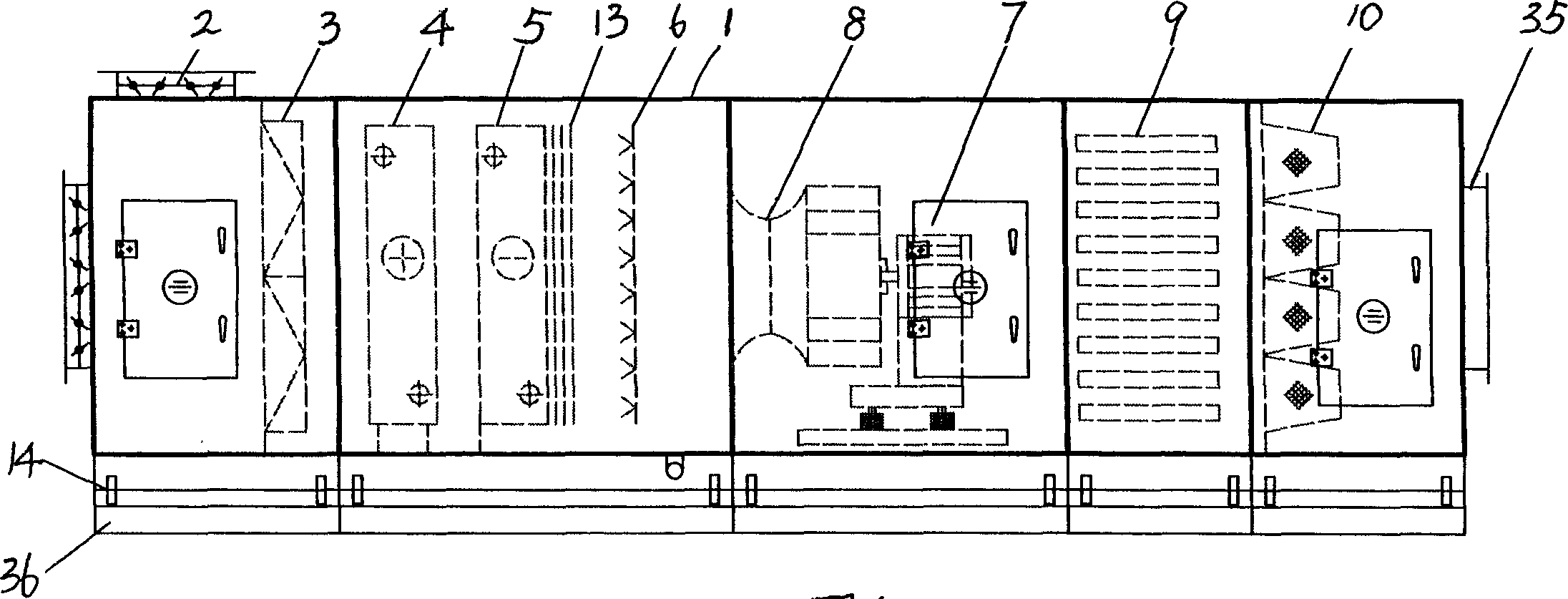

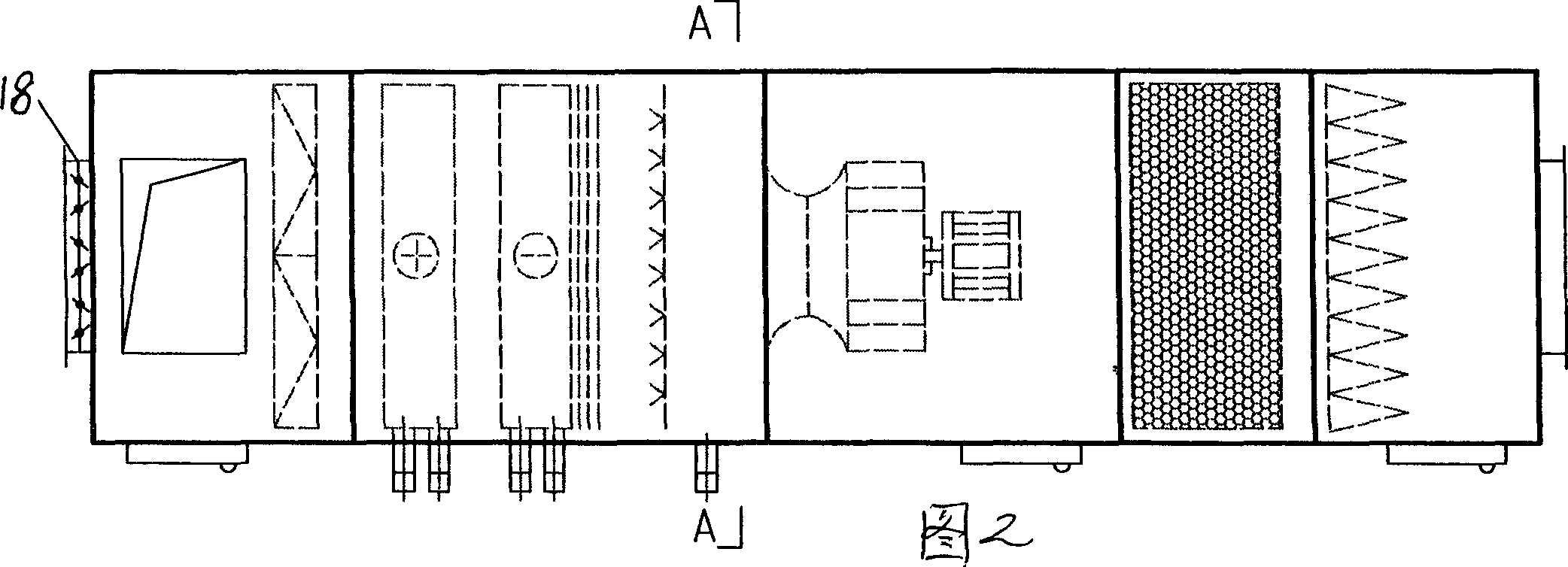

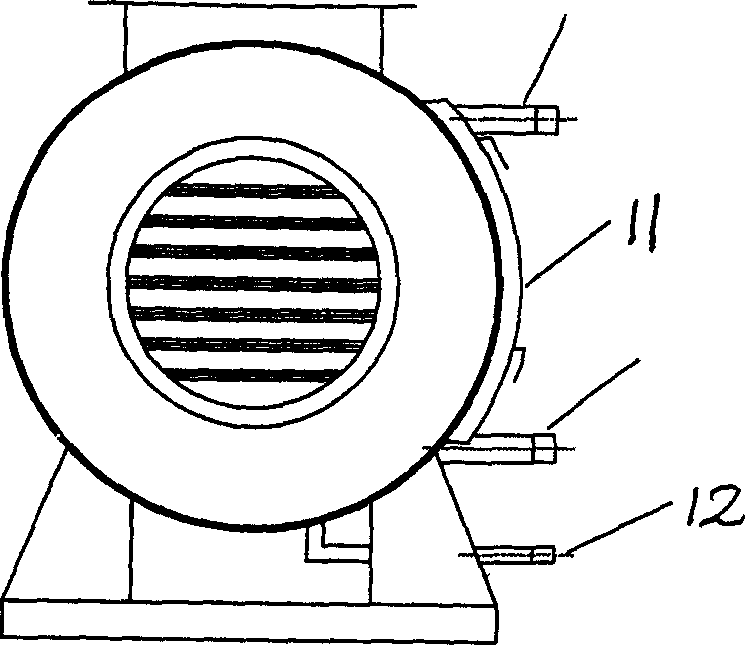

[0026] A cylindrical air handling unit has a cylindrical horizontal casing 1, and a circular multi-leaf air valve (including a circular multi-leaf fresh air valve 2 and a circular multi-leaf return air valve) is arranged at the air inlet end of the casing 1. 18), the fan-shaped primary effect filter 3 (or cartridge type primary effect filter) is arranged in the housing behind the circular multi-leaf air valve, and the circular surface heater 4 is arranged after the primary effect filter 3, and the circular surface After the heater 4, set the surface cooler 5 with the primary effect filter, set the humidifier 6 behind the surface cooler 5 with the primary filter, set the fan 8 driven by the motor 7 after the humidifier 6, and set the cylindrical muffler 9 behind the fan 8 , After the cylindrical muffler 9, a cylindrical or circular medium-efficiency filter 10 is set, an arc-shaped inspection door 11 is set on the shell 1, and a condensation water pipe 12 is set at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com