Powder coating material for metal corrosion prevention, preparation method and application method thereof

A powder coating and metal anti-corrosion technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as poor layer compactness, and achieve the effects of high compactness, improved service life, and excellent adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

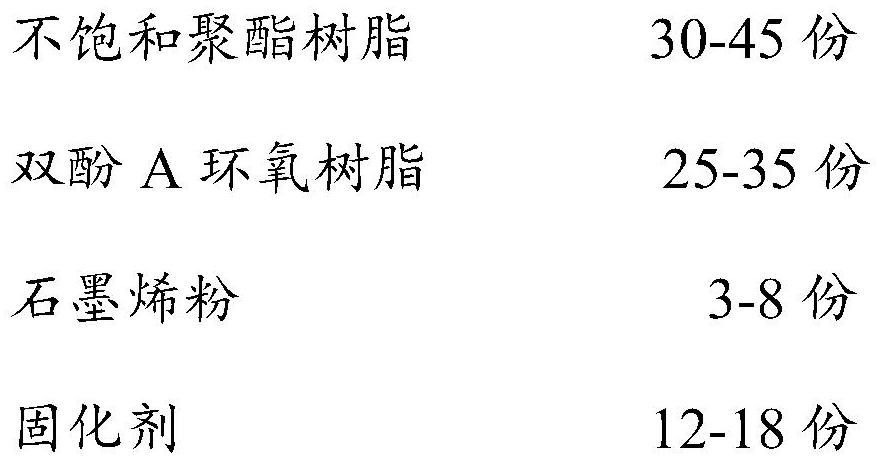

[0035] A method for preparing a powder coating for metal anticorrosion, the method comprising:

[0036] Grinding the unsaturated polyester resin and bisphenol A epoxy resin to 100-200 mesh to obtain a mixed resin;

[0037] Add graphene powder, curing agent, leveling agent, benzoin and mixed resin into a high-speed mixer, mix at a temperature of 40-60°C and a speed of 500-800r / min for 10-20min to obtain a mixture;

[0038] Add the mixture to a twin-screw extruder with a rotating speed of 200-300r / min, the temperature of the extruder cavity is 100-120°C, the temperature of the outlet is 115-125°C, and melt extrusion;

[0039] After the molten material is cooled, it is crushed to 250-300 mesh to obtain a powder coating.

[0040] A method of applying a powder coating for metal corrosion protection by:

[0041] Pass the powder coating through a 200-300 mesh sieve;

[0042] Spray the powder paint on the surface-treated metal plate with an electrostatic spray gun, the paint film t...

specific Embodiment 1

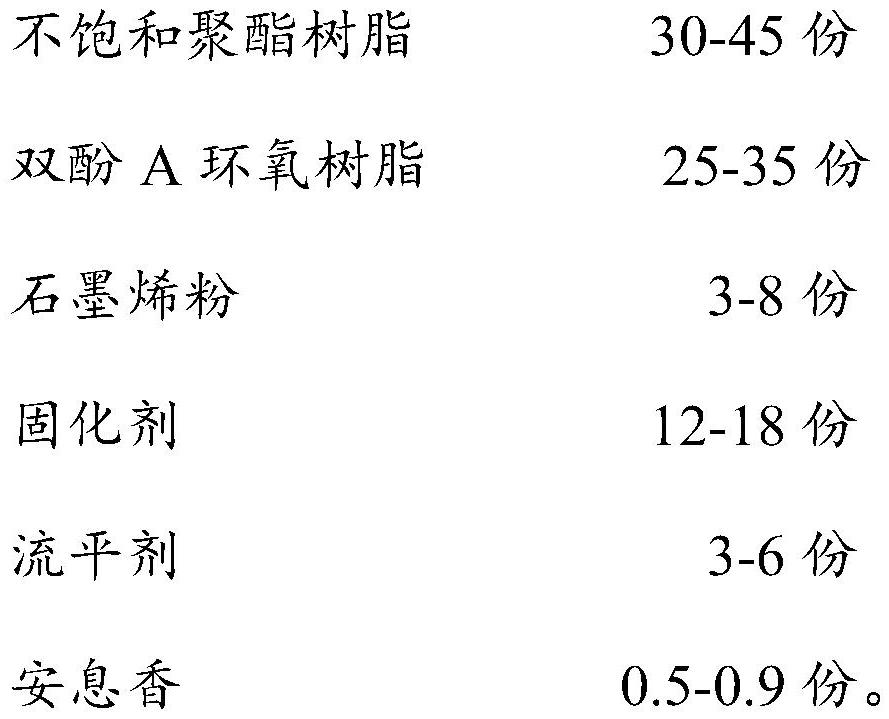

[0044] A kind of powder coating that is used for metal anticorrosion, raw material comprises by weight component:

[0045]

[0046] Unsaturated polyester resin is polymerized by styrene, acrylate and vinyl acetate; the molecular weight of bisphenol A epoxy resin is 4000-5000; the particle size of graphene powder is 600 mesh; the curing agent is a tertiary amine curing agent ; The leveling agent is polydimethylsiloxane.

[0047] A method for preparing a powder coating for metal anticorrosion, the method comprising:

[0048] Pulverizing the unsaturated polyester resin and the bisphenol A epoxy resin to 100 mesh to obtain a mixed resin;

[0049] Add graphene powder, curing agent, leveling agent, benzoin and mixed resin into a high-speed mixer, mix at a temperature of 40°C and a speed of 800r / min for 20min to obtain a mixture;

[0050] Add the mixture to a twin-screw extruder with a rotating speed of 200r / min, the temperature of the extruder cavity is 100°C, the temperature o...

specific Embodiment 2

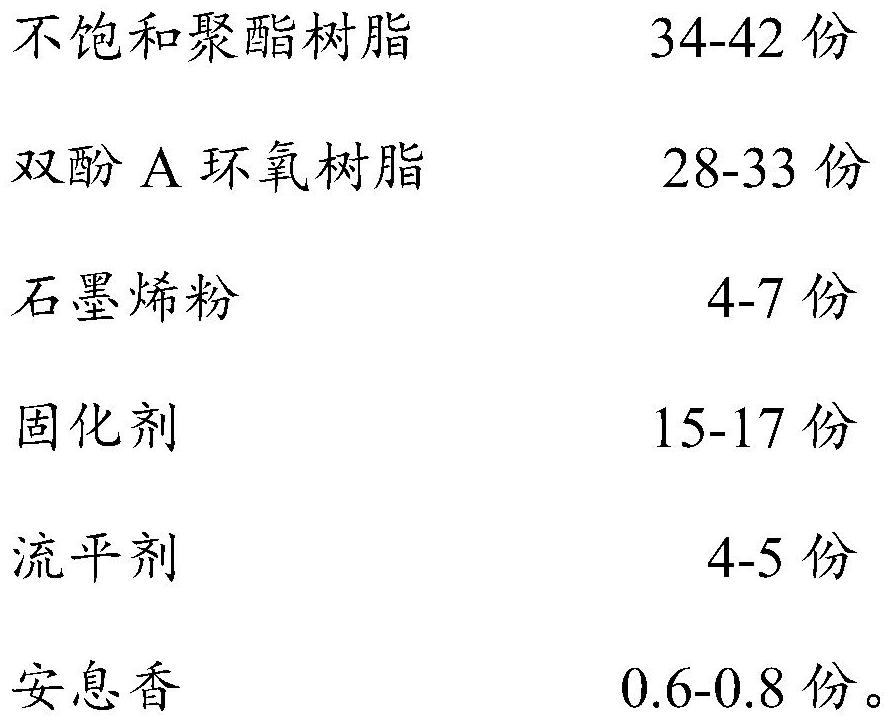

[0056] A kind of powder coating that is used for metal anticorrosion, raw material comprises by weight component:

[0057]

[0058] Unsaturated polyester resin is polymerized by styrene, acrylate and vinyl acetate; the molecular weight of bisphenol A epoxy resin is 5000-6000; the particle size of graphene powder is 400 mesh; the curing agent is imidazole curing agent; The leveling agent is polyether polyester modified organosiloxane.

[0059] A method for preparing a powder coating for metal anticorrosion, the method comprising:

[0060] Pulverizing the unsaturated polyester resin and the bisphenol A epoxy resin to 200 mesh to obtain a mixed resin;

[0061] Add graphene powder, curing agent, leveling agent, benzoin and mixed resin into a high-speed mixer, mix at a temperature of 60°C and a speed of 500r / min for 10 minutes to obtain a mixture;

[0062] Add the mixture to a twin-screw extruder with a rotation speed of 300r / min, the temperature of the extruder cavity is 120°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com