Novel-structured glass fiber reinforced plastic chimney

A glass fiber reinforced plastic chimney and structural sub-layer technology, applied in the field of chimneys, can solve the problem of no large thermal power plant FRP chimney engineering examples, etc., and achieve the effects of easy construction and quality control, good axial mechanical properties, and good hoop mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The preparation method of FRP chimney of the present invention comprises the following steps:

[0072] (a) provide inner lining functional layer;

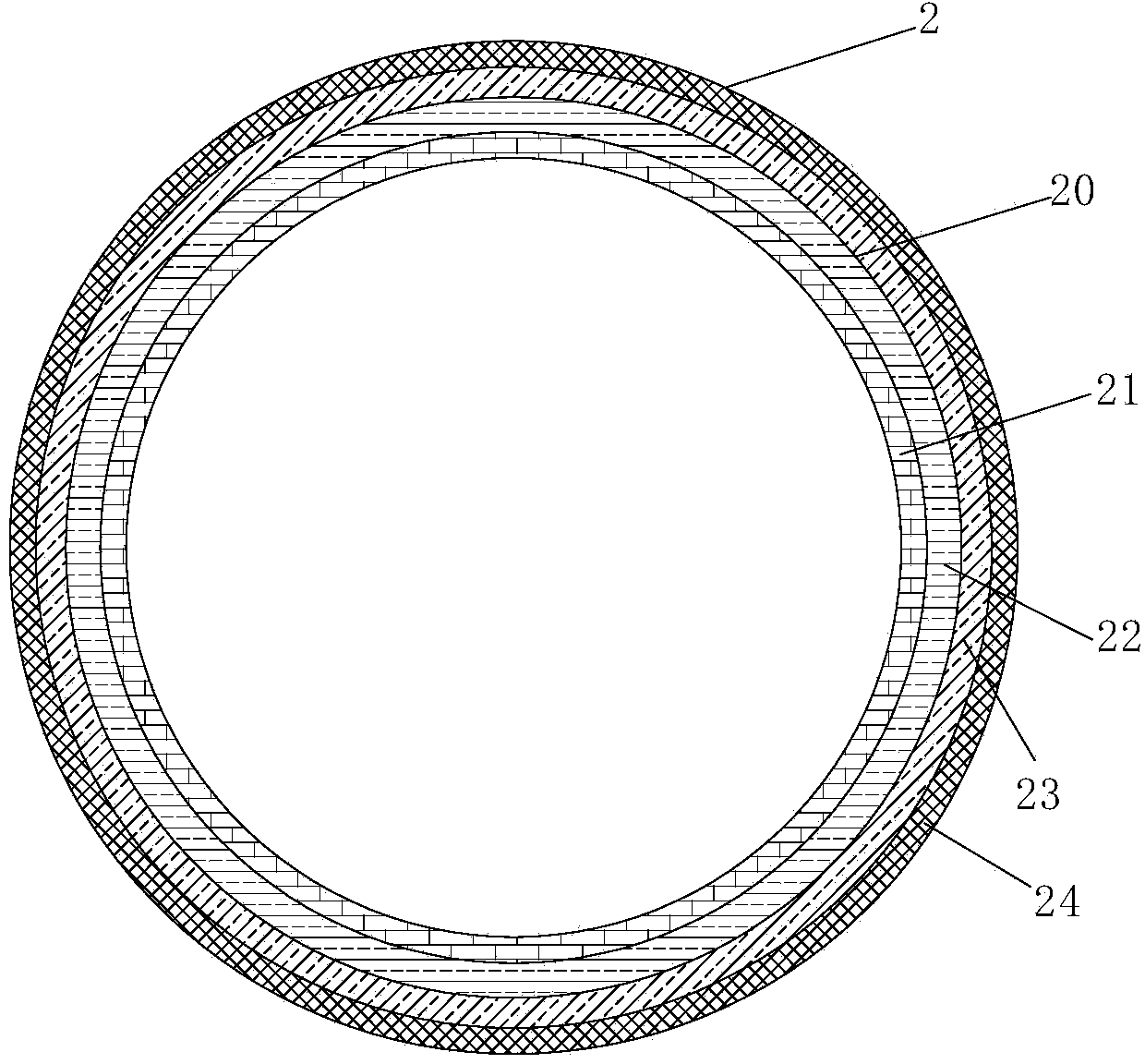

[0073] (b) laying (making) the intermediate structural layer outside the inner lining functional layer, and optionally

[0074] (c) laying (making) the outer protection layer outside the intermediate structure layer to obtain the glass fiber reinforced plastic chimney;

[0075] or include the following steps:

[0076] (a) providing an inner liner functional layer, an intermediate structural layer, and an optional outer protective layer;

[0077] (b) Assembling the inner lining functional layer, intermediate structural layer, and optional outer protective layer into the FRP chimney. The fiberglass chimney of the present invention has one or more of the following features:

[0078] (1) The hoop tensile strength is greater than 235MPa, the modulus is greater than 19.0GPa, the axial tensile strength is greater than 110MPa, a...

Embodiment 1

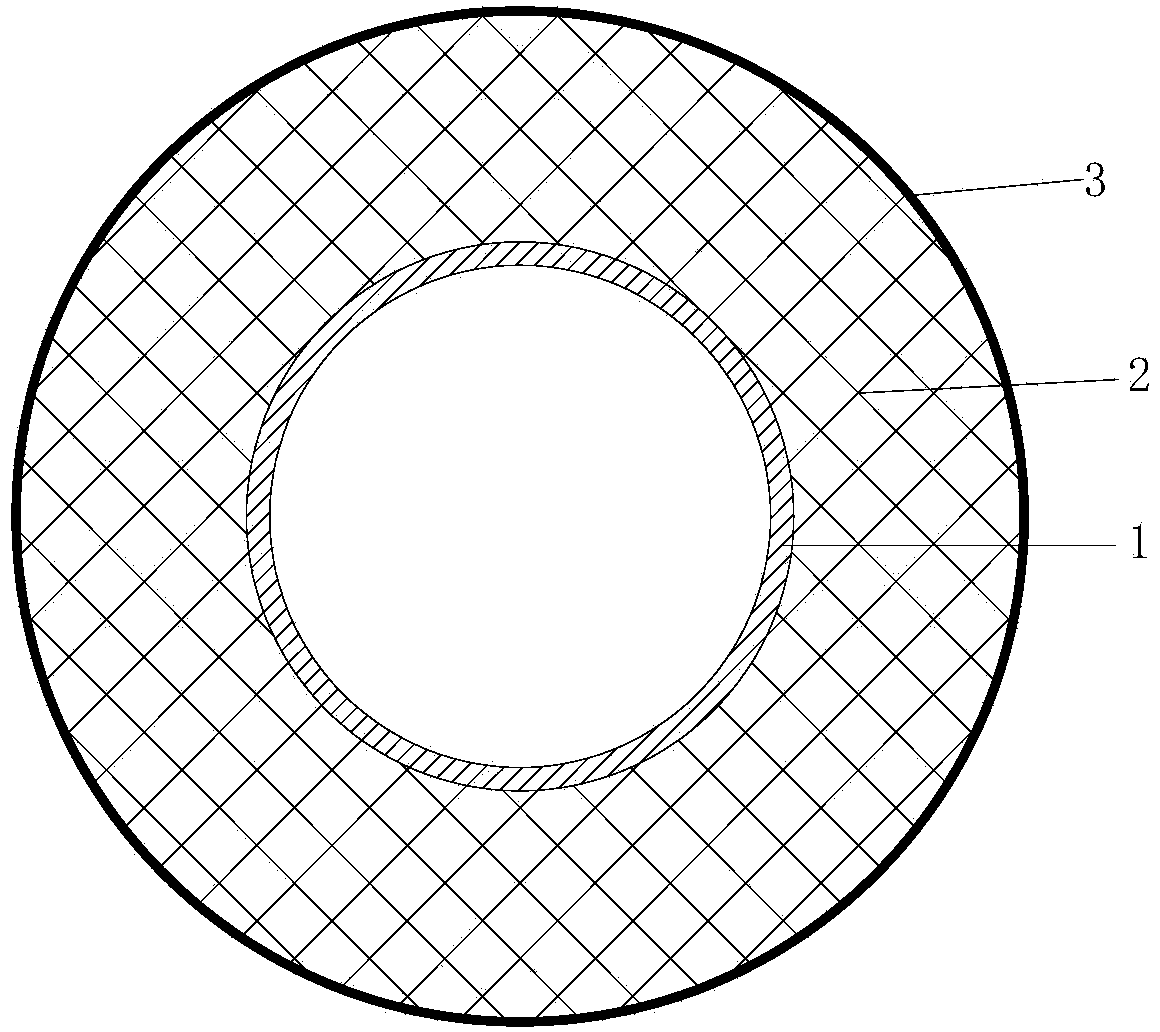

[0175] In the FRP chimney of this embodiment, the tube wall includes an inner lining functional layer, an intermediate structural layer and an outer protective layer, and the diameter is 7.2 meters.

[0176] Wherein, the lining functional layer includes a surface felt layer and a sprayed yarn layer from the inside to the outside, with a thickness of 1.2mm.

[0177] The middle structural layer is composed of 4 structural sub-layers 1 from inside to outside, 2 additional structural single layers and 1 outermost structural single layer. The structure is S1-S1-F2-F2-S1-S1-Y2, with a total thickness of 14.2mm .

[0178] The outer protective layer is a gel coat layer with a thickness of 0.25mm.

Embodiment 2

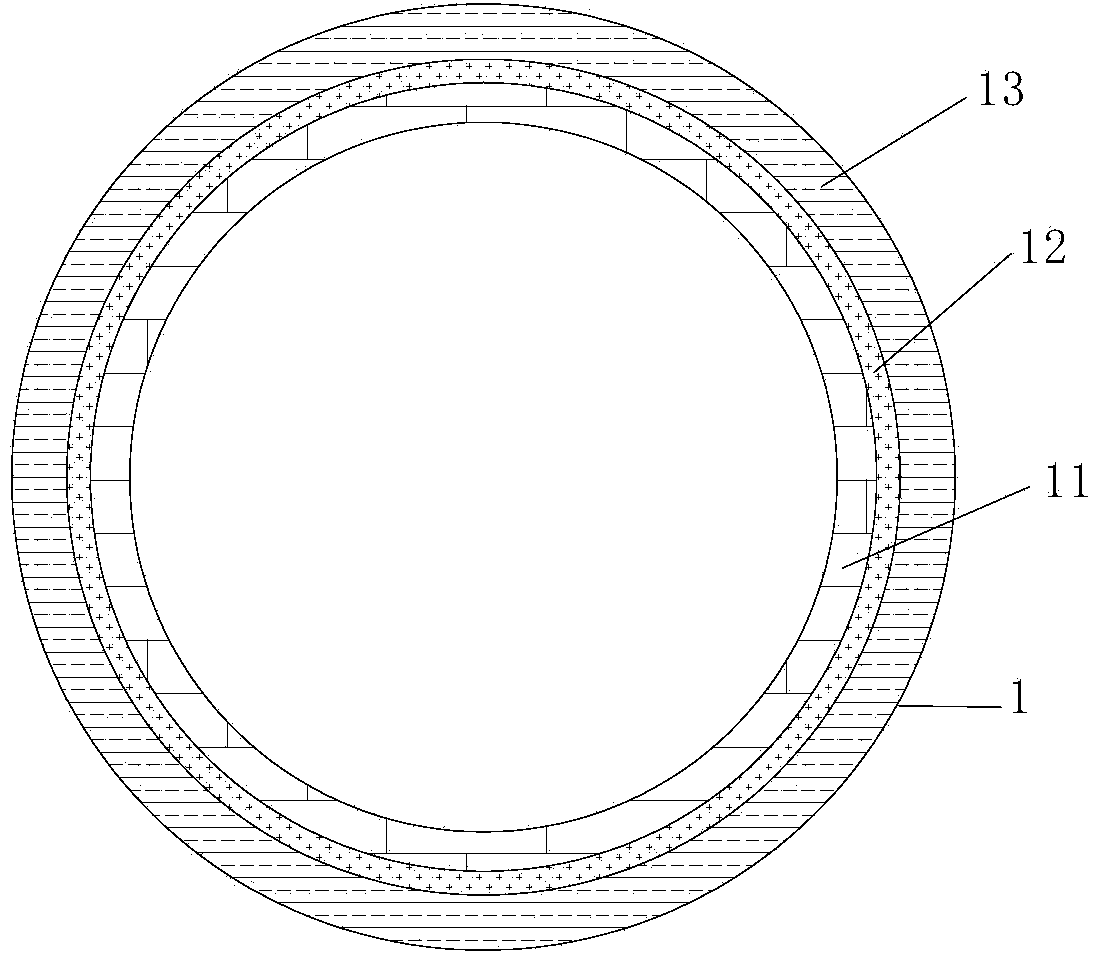

[0180] In the FRP chimney of this embodiment, the tube wall includes an inner lining functional layer, an intermediate structural layer and an outer protective layer, and the diameter is 7.2 meters.

[0181] Among them, the lining functional layer is composed of carbon fiber felt layer, surface felt layer and jet yarn layer from inside to outside, with a thickness of 1.5mm.

[0182] The structure of the middle structure layer from inside to outside is S1-S1-F1-S1-S2-F1-F2-S1-S4, and the total thickness of the middle structure layer is 16.5mm.

[0183] The outer protective layer is a gel coat layer with a thickness of 0.25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com