Plastic panel, concrete pipe coating plastic panel and plastic panel processing device

A technology for processing equipment and plastic plates, applied in mechanical equipment, pipes, rigid pipes, etc., can solve the problems of poor penetration resistance, corrosion of steel skeleton, short service life, etc., to achieve strong penetration resistance, high processing efficiency, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

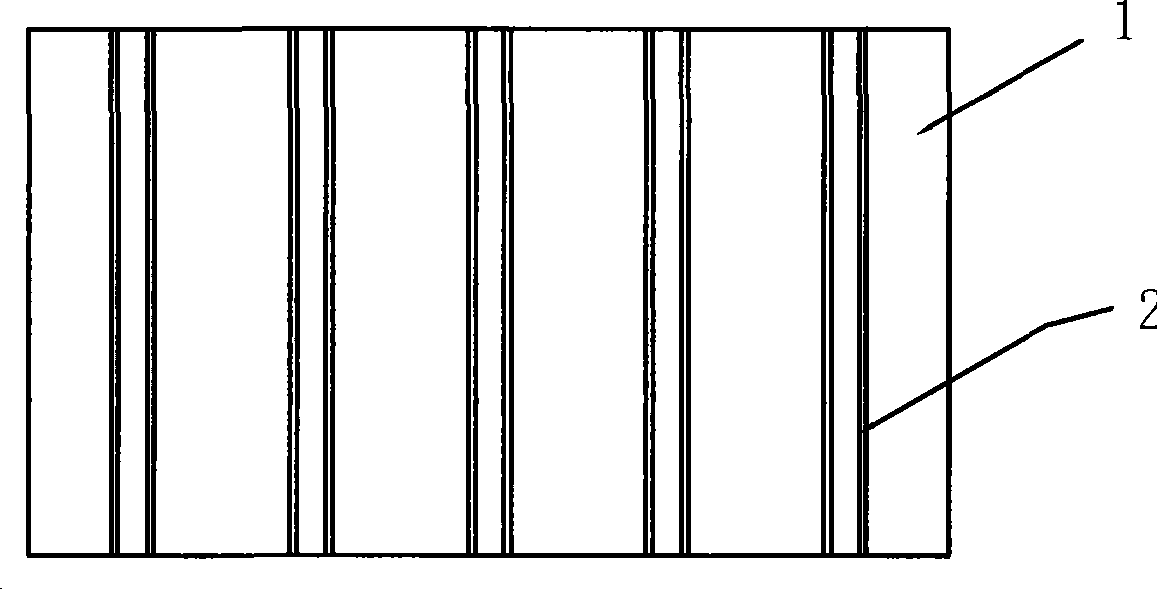

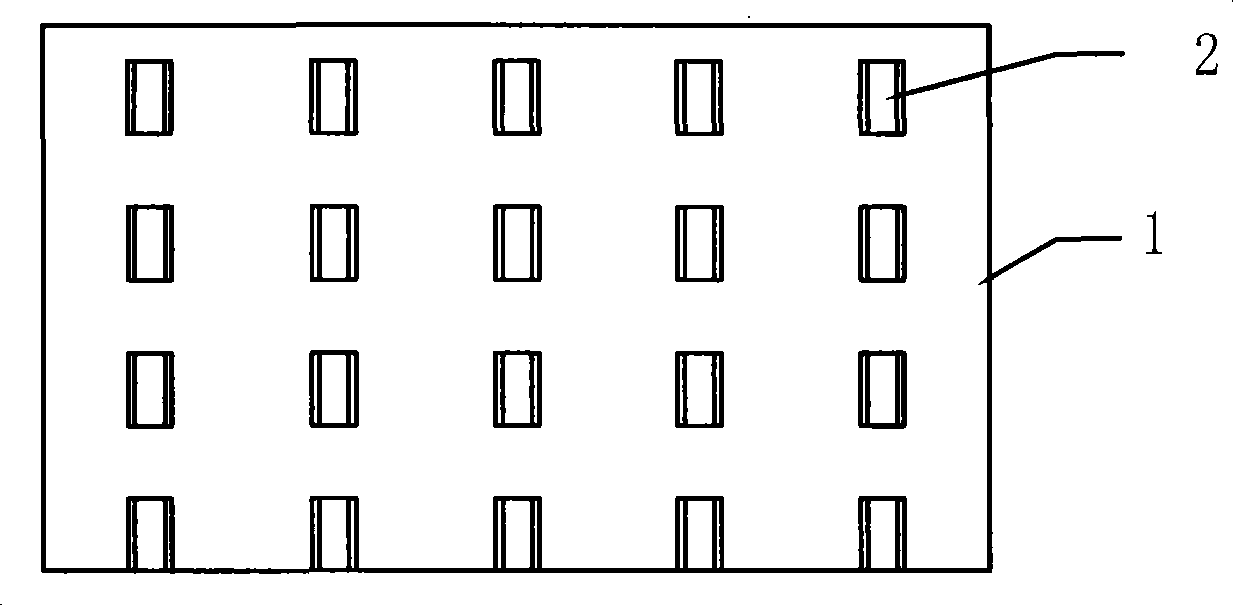

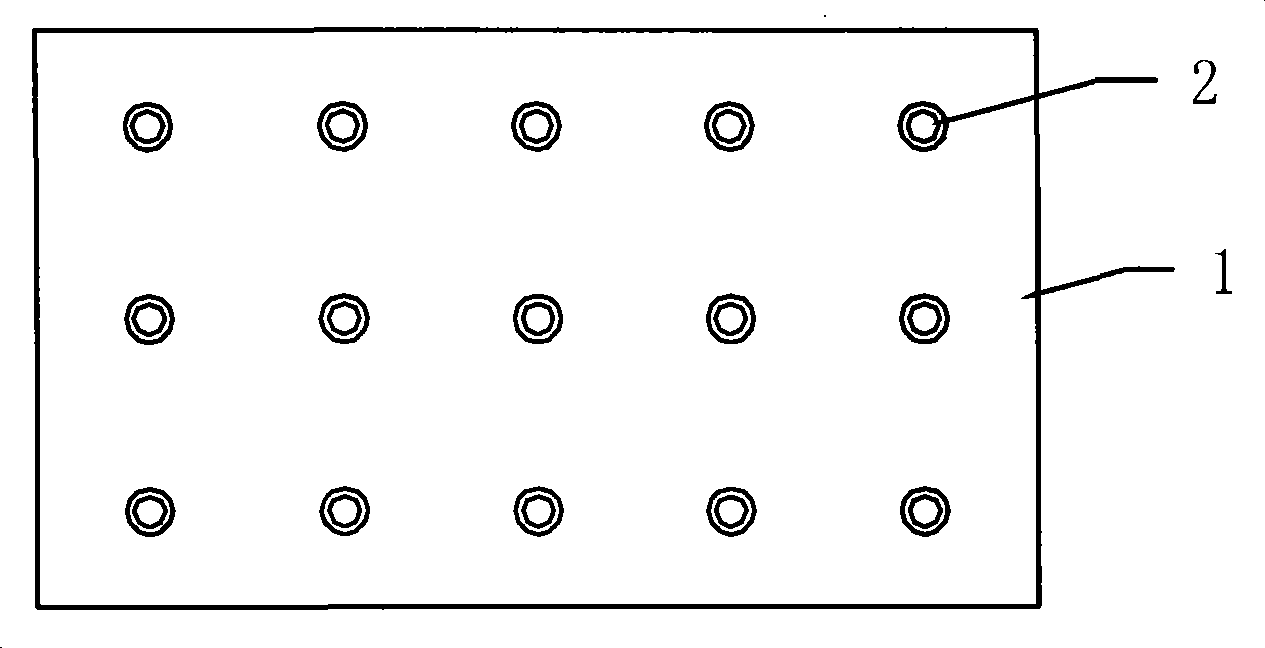

[0055] Figure 1a-Figure 1e Shown is the plastic board of the present invention, which includes a base material 1 and a plurality of fixing claws 2 arranged on one side of the base material 1, and the width of the base of the fixing claws 2 is smaller than that of the ends.

[0056] Such as Figure 1a As shown, the fixing claws 2 can be strip-shaped, and each strip-shaped fixing claw 2 is arranged in parallel along the longitudinal direction of the plastic plate substrate 1 and has a T-shaped cross section.

[0057] Such as Figure 1b As shown, the fixing claws 2 can also be block-shaped, and each block-shaped fixing claw 2 is regularly arranged horizontally and vertically along the plastic plate substrate 1, and its longitudinal section is T-shaped.

[0058] Such as Figure 1c , Figure 1d and Figure 1e As shown, the fixing claws 2 can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com