Bottom-layer anticorrosive paint, preparation method and application thereof

An anti-corrosion coating and bottom layer technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low cathodic disbondment resistance and low heat release, and can extend the storage period, increase heat release, and resist penetration. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of bottom anticorrosion paint, comprises following components, by weight parts:

[0039]

[0040] The epoxy resin is the epoxy resin E-12 of Shengli Oilfield Fangyuan Anticorrosion Material Co., Ltd.

[0041] The heterocyclic phenolic curing agent is GP-04 (melting range: 126°C-140°C) from Zibo Yizhou Paint Filler Technology Co., Ltd.

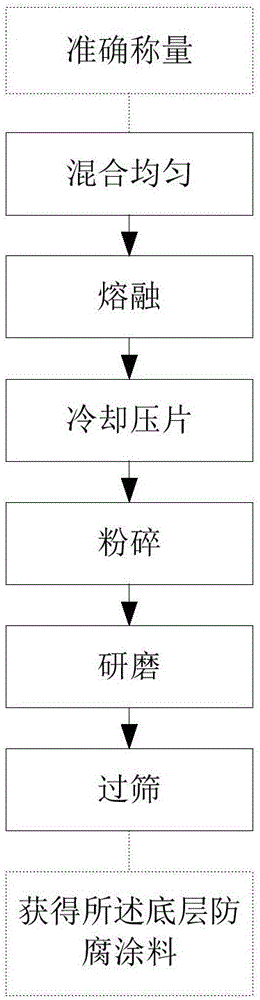

[0042] Preparation method: First, accurately weigh the raw materials according to the composition of the formula components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 95-110°C, passed through a cooling roll, pressed into a tablet, cooled, and then the tablet was crushed (including coarse crushing and finely crushed), ground, sieved, and finally obtained a uniform particle size ( 40-80 μm) powder coating, namely obtain described primer anticorrosion c...

Embodiment 2

[0048] A kind of bottom anticorrosion paint, comprises following components, by weight parts:

[0049]

[0050] The epoxy resin is GESR904 (epoxy equivalent of 780-850g / eq, viscosity of 45-80P / 150°C, softening point of 92-102°C) produced by Hongchang Electronic Materials Co., Ltd.

[0051] The heterocyclic phenolic curing agent is GP-04 (melting range: 126°C-140°C) from Zibo Yizhou Paint Filler Technology Co., Ltd.

[0052] Preparation method: First, accurately weigh the raw materials according to the composition of the formula components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 95-110°C, passed through a cooling roll, pressed into a tablet, cooled, and then the tablet was crushed (including coarse crushing and finely crushed), ground, sieved, and finally obtained a uniform particle size ( 40-8...

Embodiment 3

[0055] A kind of bottom anticorrosion paint, comprises following components, by weight parts:

[0056]

[0057]

[0058] The epoxy resin is epoxy 014F (epoxy equivalent of 730-850g / eq, softening point of 93-105° C.) produced by Langfang Nuoerxin Chemical Co., Ltd.

[0059] The heterocyclic phenolic curing agent is GP-04 (melting range: 126°C-140°C) from Zibo Yizhou Paint Filler Technology Co., Ltd.

[0060] Preparation method: First, accurately weigh the raw materials according to the composition of the formula components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 95-110°C, passed through a cooling roll, pressed into a tablet, cooled, and then the tablet was crushed (including coarse crushing and finely crushed), ground, sieved, and finally obtained a uniform particle size ( 40-80 μm) powder c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat release | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com