A novel synthetic thickener for dye printing and its preparation method and application

A technology for synthesizing thickeners and dyes, used in dyeing, textile and papermaking, etc., can solve the problems of poor electrolyte resistance and impermeability of thickeners, and achieve increased electrolyte resistance, improved electrolyte resistance, and improved electrolyte resistance. The effect of improving the impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method for a synthetic thickener for novel dye printing, comprising the following steps:

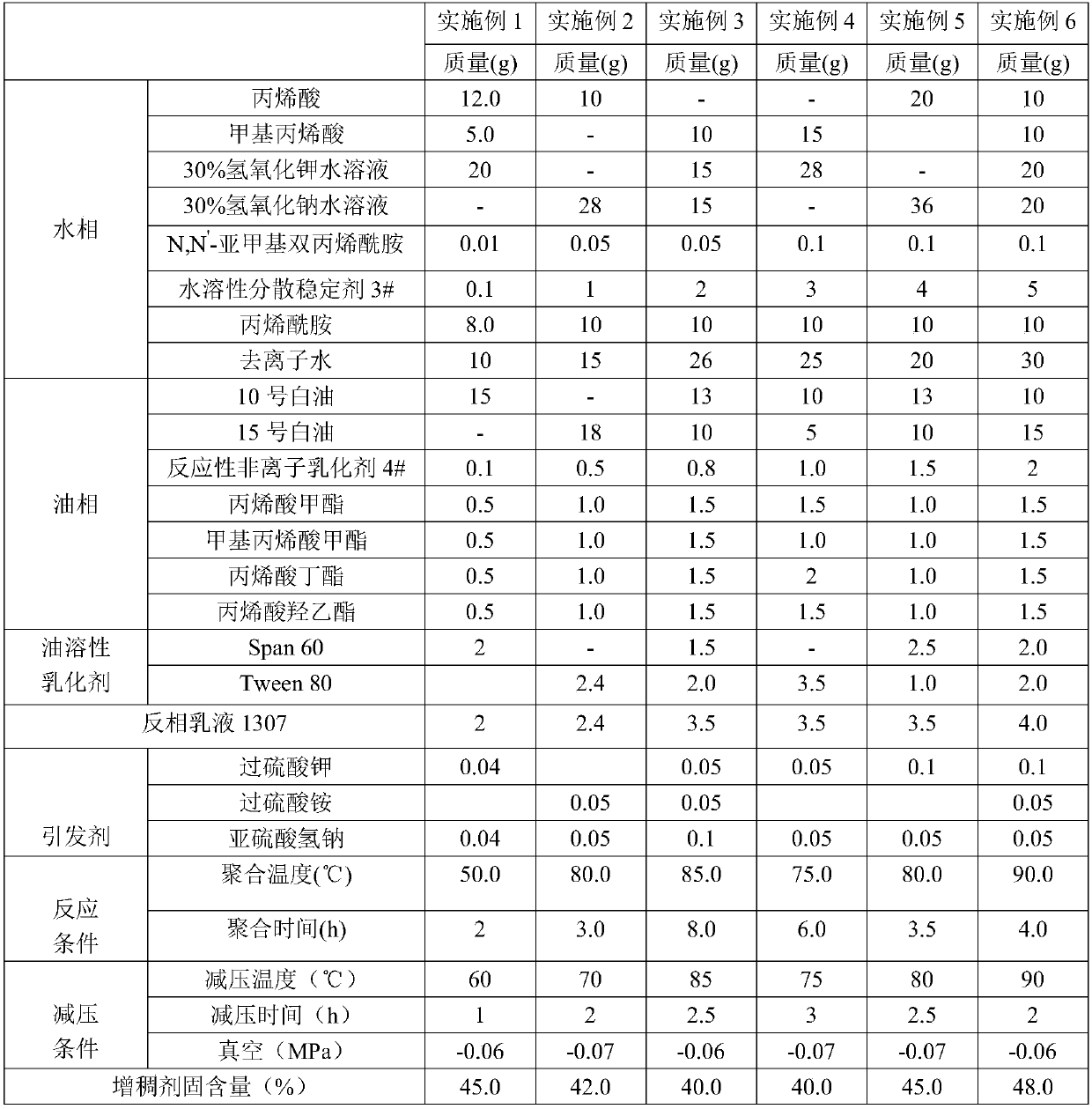

[0066] 1), 12 parts by weight of acrylic acid and 5 parts by weight of methacrylic acid are neutralized with 20 parts by weight of a neutralizer (30% potassium hydroxide aqueous solution) to obtain a neutralized solution with a pH value of 6.0 to 6.2, and the neutralized solution is mixed with 8 parts by weight of acrylamide, 0.01 part by weight of a cross-linking monomer (N,N'-methylenebisacrylamide), 0.1 part by weight of a water-soluble dispersion stabilizer and 10 parts by weight of deionized water are uniformly mixed to obtain an aqueous phase;

[0067] 2), add 15 parts by weight of No. 10 white oil, 2 parts by weight of oil-soluble emulsifier (Span60), 0.1 part by weight of reactive nonionic emulsifier and 2 parts by weight of oil-soluble monomer (methyl acrylate, methyl acrylate) in the reactor methyl acrylate, butyl acrylate and hydroxyethyl acrylate) to form...

Embodiment 2

[0083] This example is based on Example 1, and the difference from the example is that the raw materials for preparing the synthetic thickener, the ratio between the raw materials and the parameters are adjusted, as shown in Table 3,

[0084] The synthetic thickener prepared by the method described in this embodiment is composed of the following parts by weight:

[0085] 0.5 parts by weight of reactive nonionic emulsifier, 1 part by weight of water-soluble dispersion stabilizer, 20 parts by weight of water-soluble monomer, 4 parts by weight of oil-soluble monomer, 0.05 part by weight of crosslinking monomer, 28 parts by weight of neutralizer, 2.4 parts by weight of oil-soluble emulsifier, 2.4 parts by weight of inverse emulsion, 0.10 parts by weight of initiator, 18 parts by weight of white oil, and 15 parts by weight of deionized water.

Embodiment 3

[0087] This example is based on Example 1, and the difference from the example is that the raw materials for preparing the synthetic thickener, the ratio between the raw materials and the parameters are adjusted, as shown in Table 3,

[0088] The synthetic thickener prepared by the method described in this embodiment is composed of the following parts by weight:

[0089] 0.8 parts by weight of reactive nonionic emulsifier, 2 parts by weight of water-soluble dispersion stabilizer, 20 parts by weight of water-soluble monomer, 6 parts by weight of oil-soluble monomer, 0.05 parts by weight of cross-linking monomer, 30 parts by weight of neutralizer, 3.5 parts by weight of oil-soluble emulsifier, 3.5 parts by weight of inverse emulsion, 0.2 parts by weight of initiator, 23 parts by weight of white oil, and 26 parts by weight of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com