Patents

Literature

52results about How to "Small and uniform pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super electrolytic capacitor paper

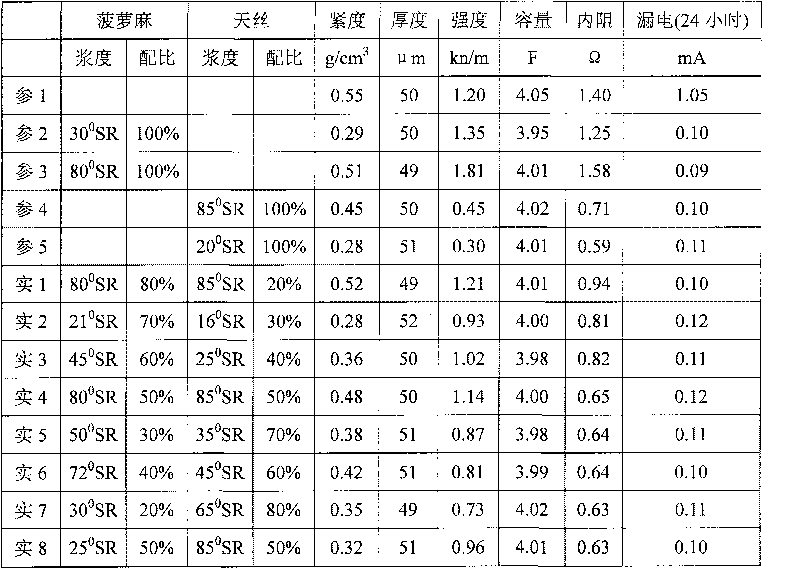

ActiveCN101696558ALow paper tightnessGood strengthPlastic/resin/waxes insulatorsFlax fiberPapermaking

The invention relates to an electrolytic capacitor paper, in particular to a super electrolytic capacitor paper. The super electrolytic capacitor paper consists of the following components in percentage by weight: 10 to 80 percent of pineapple flax fiber and 20 to 90 percent of tencel papermaking. The super electrolytic capacitor paper has low paper tightness, high strength and small and uniform pore diameter; the capacitor paper is low in consumption due to the low paper tightness, and an internal resistance of a super capacitor is not increased; the capacitor paper is suitable for the processing of the super capacitor due to the high strength; and the super capacitor is small in leakage current due to the small pore diameter, so that the super capacitor paper is suitable for storing energy and is applied to the super capacitor.

Owner:浙江凯恩新材料有限公司 +1

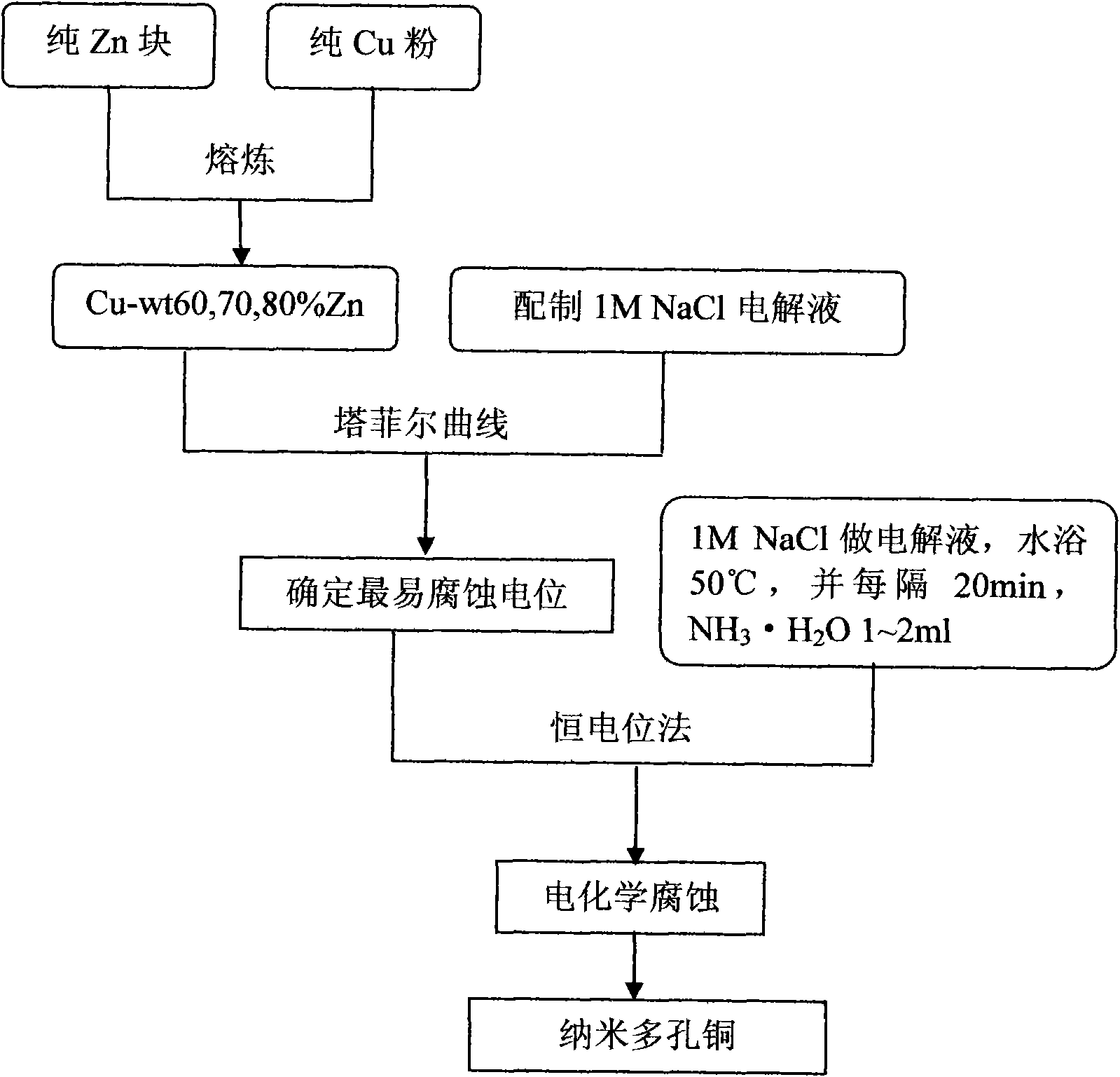

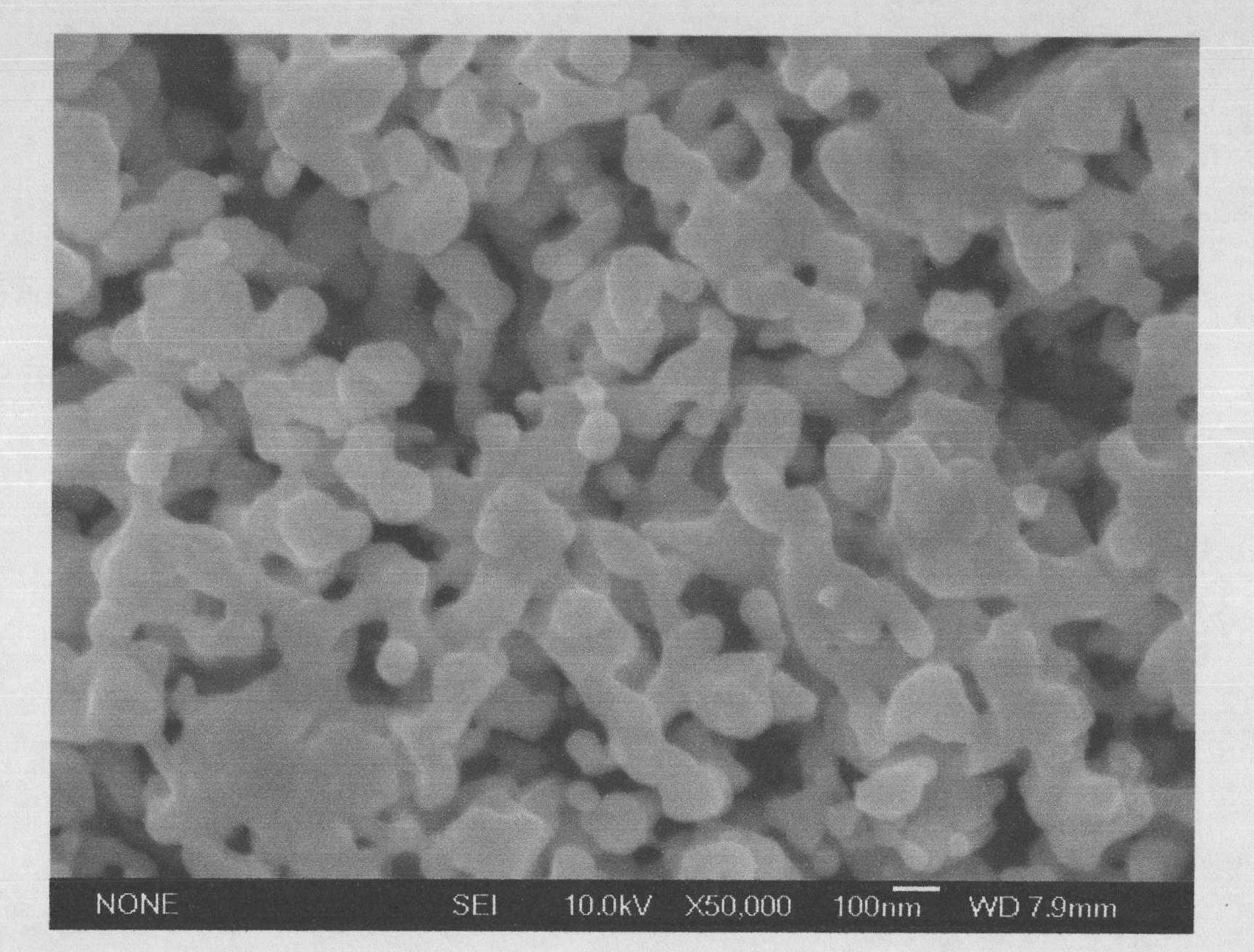

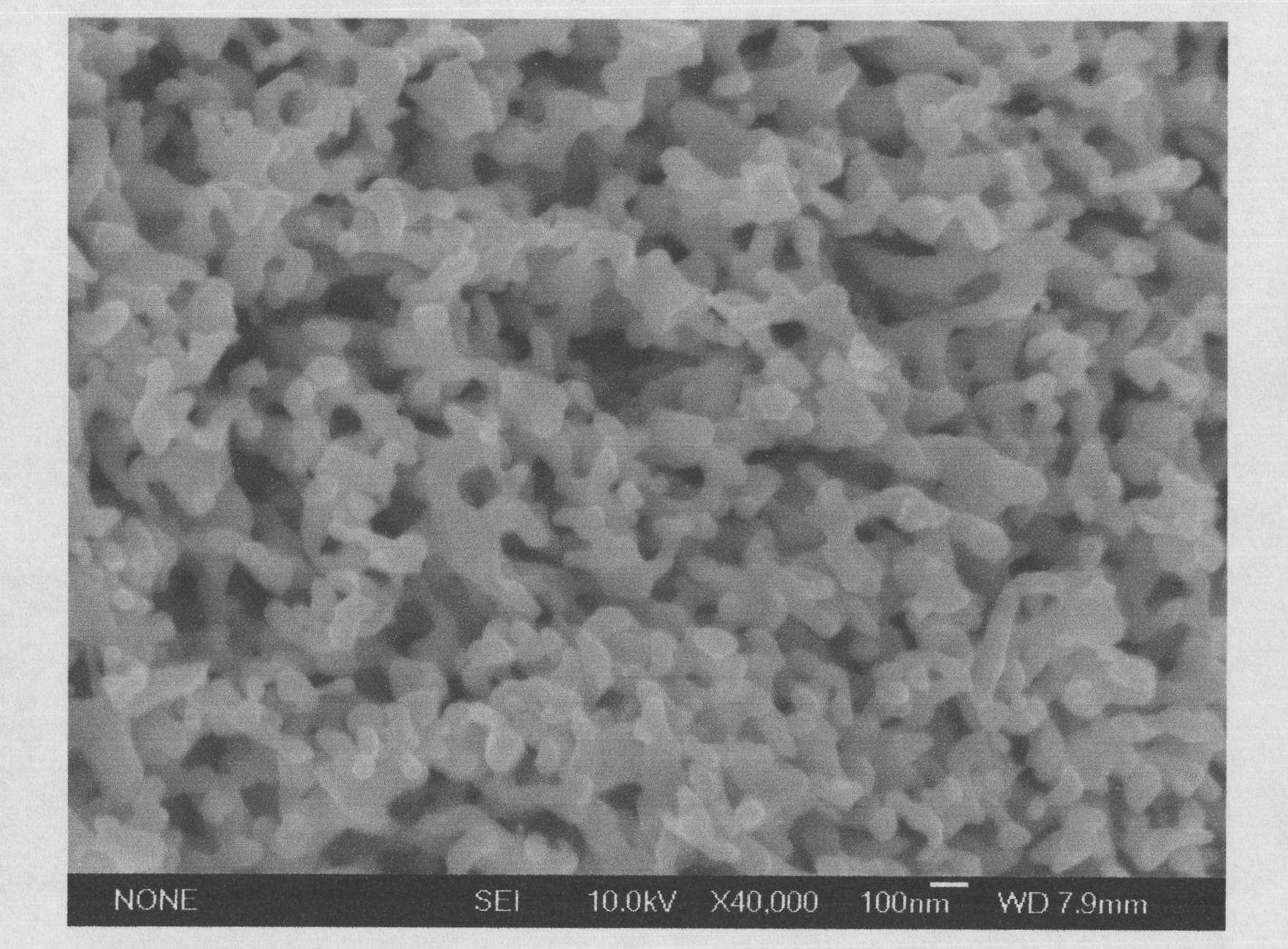

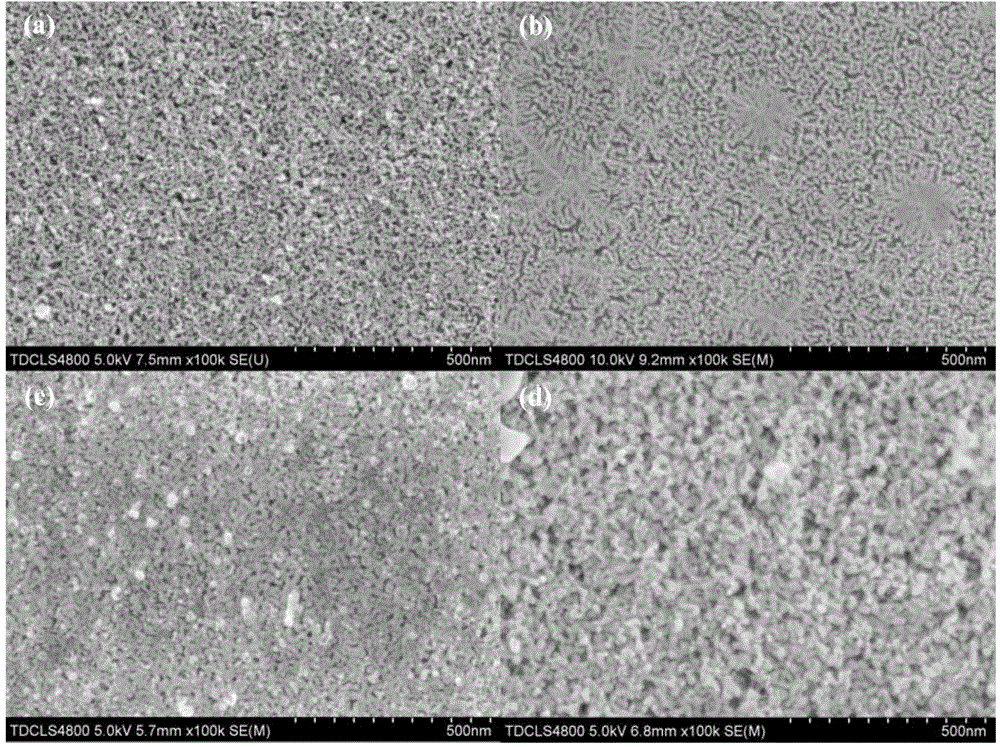

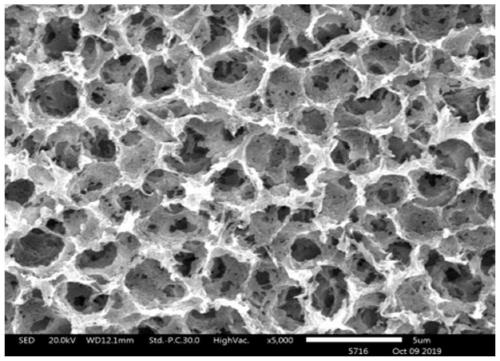

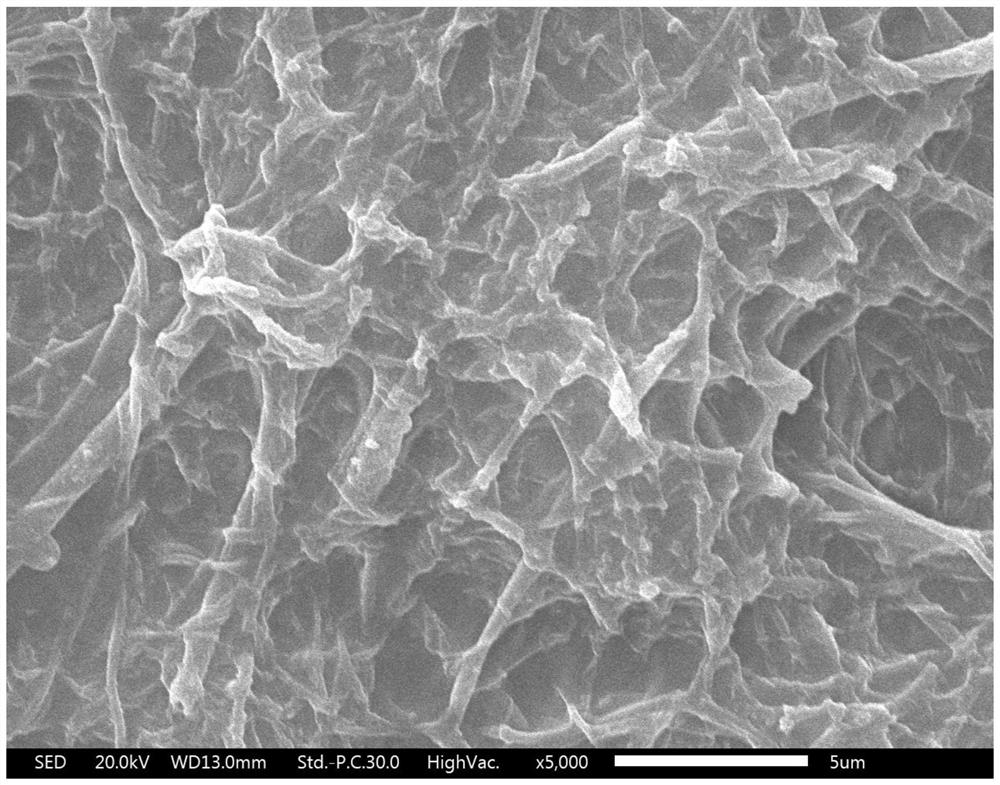

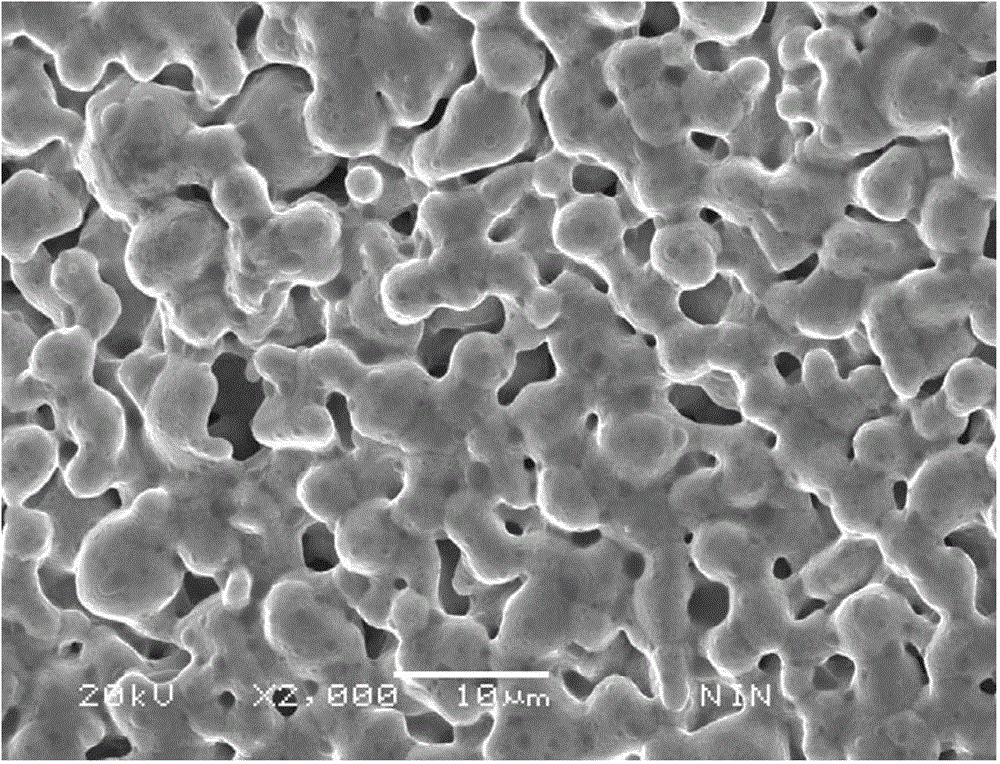

Method for preparing nano porous copper by adopting Cu-Zn alloy

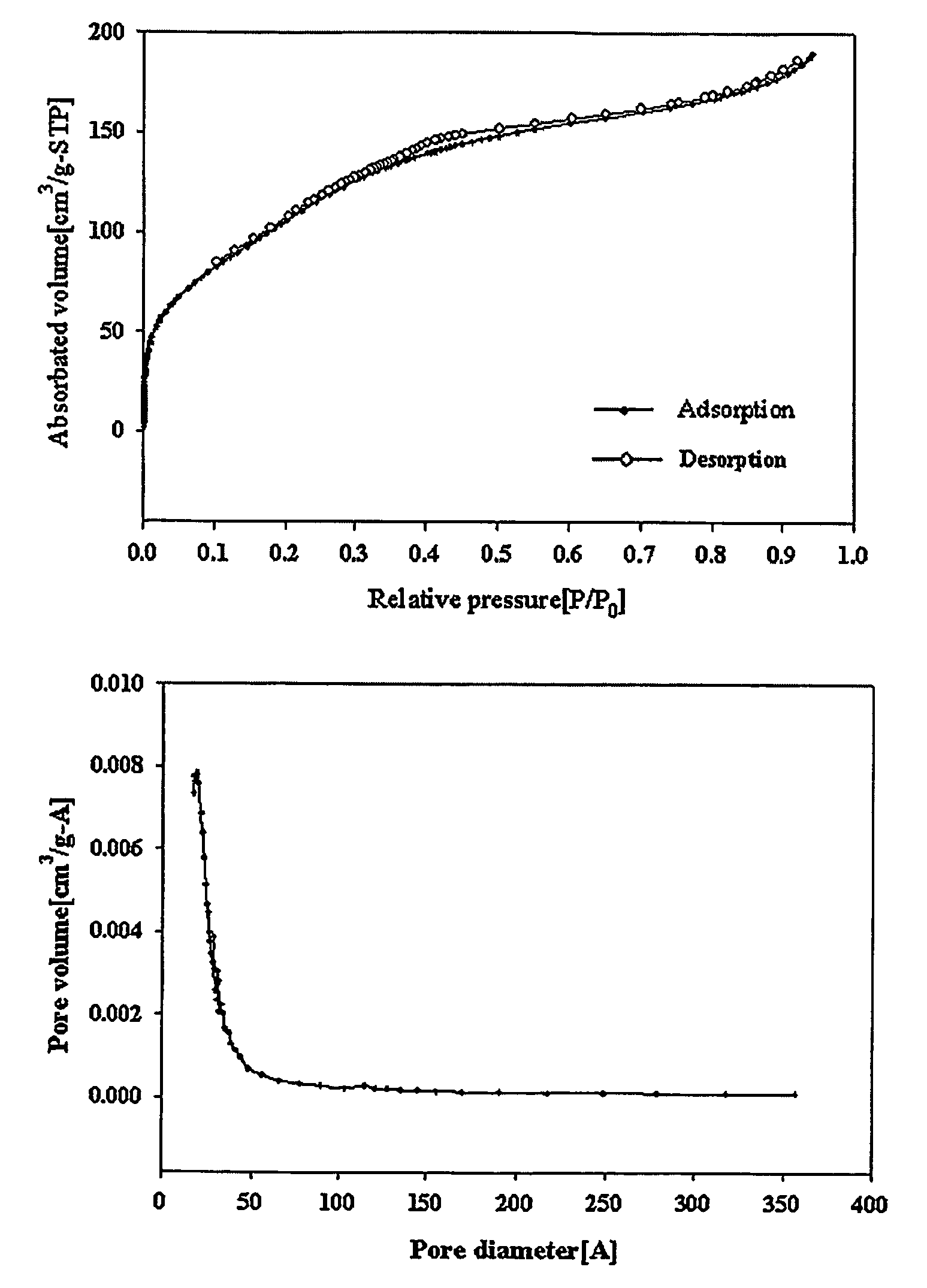

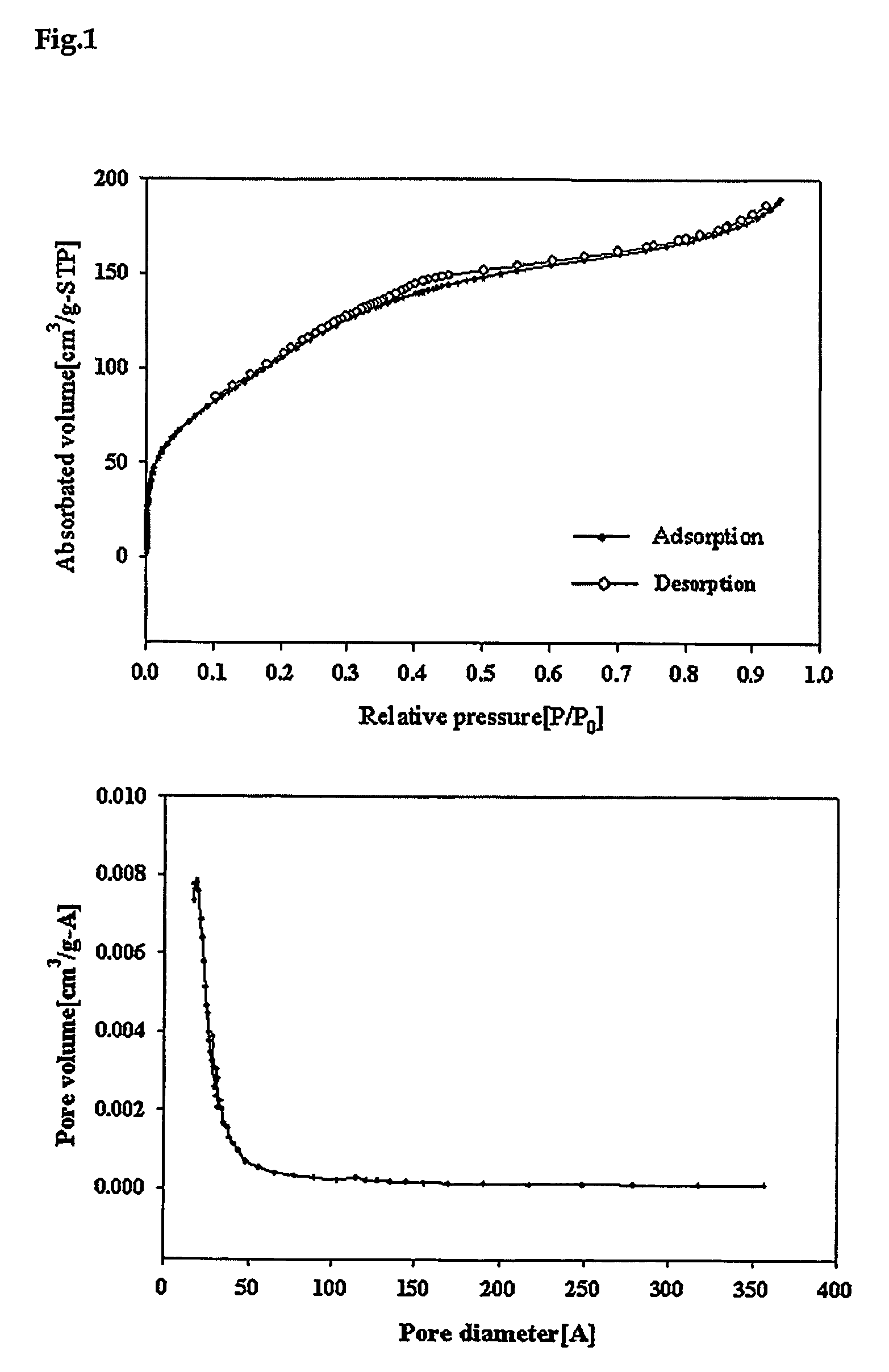

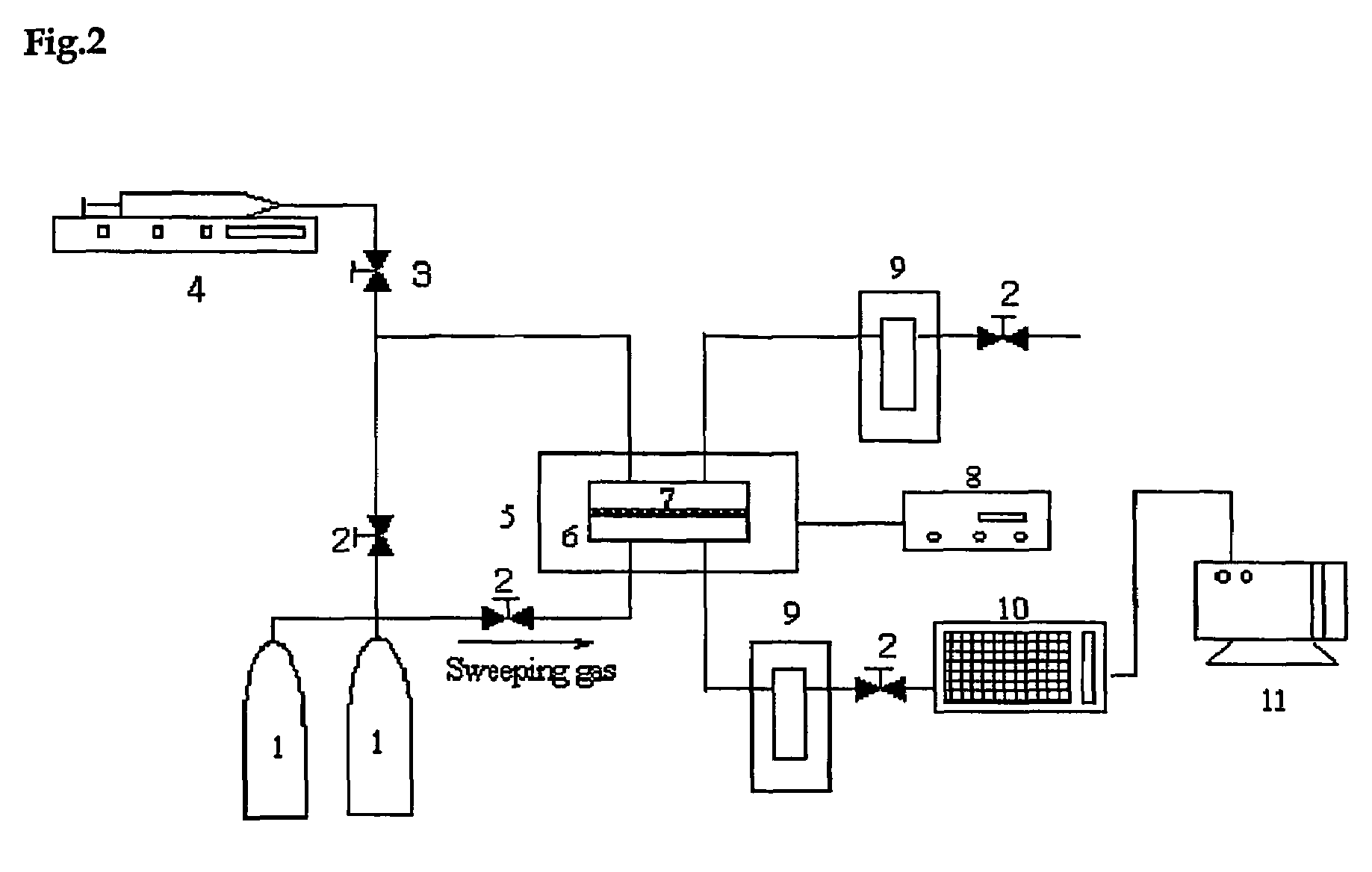

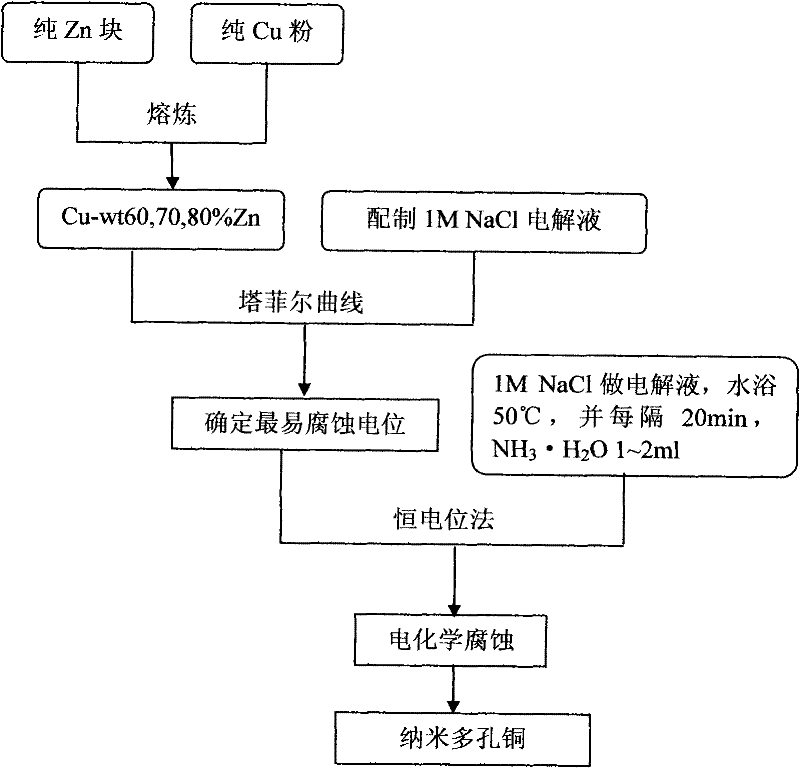

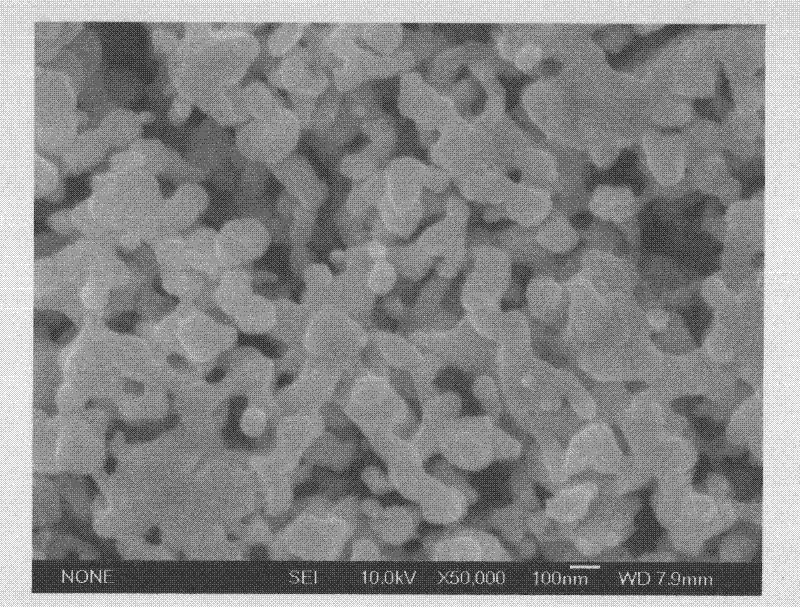

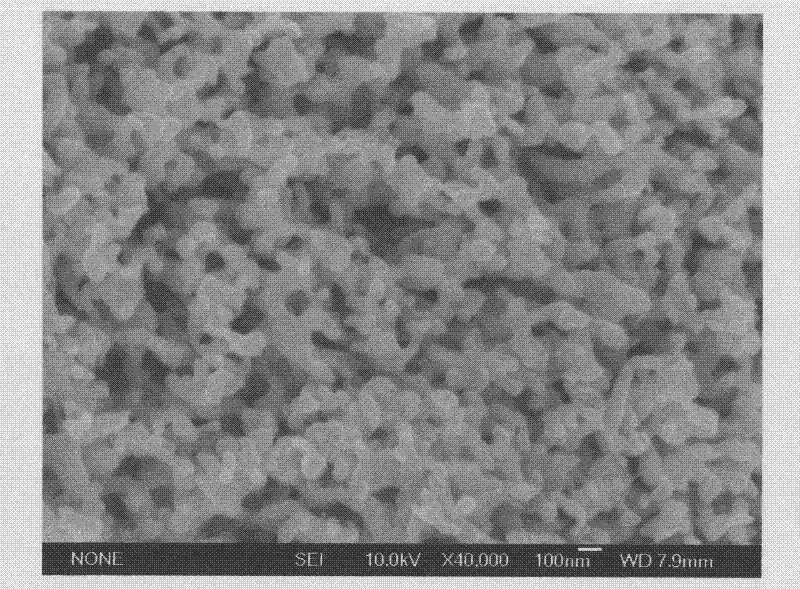

The invention discloses a method for preparing nano porous copper by adopting Cu-Zn alloy. The method comprises the following steps of: preparing copper and zinc in a proportion that the copper is 60 weight percent or 70 weight percent or 80 weight percent of the zinc under the protection of nitrogen to obtain alloys by adopting a smelt technology; carrying out Tafel curve testing by taking a 1M NaCl solution as an electrolyte and utilizing a three-electrode method to obtain easies corrosion voltages of different alloys; carrying out water bath at 50-70 DEG C in the 1M NaCl solution under the condition that the volume ratio of corrosive liquid to the alloy volume is (1,000-1,500):1; carrying out electrochemical corrosion on the alloys under the easies corrosion voltages; dropwise adding 1-2ml of concentrated NH3.H2O solution every other 20 minutes to ensure that the electrolyte contains certain complex compounds to promote the reaction; and stopping the reaction until the cathode does not discharge obvious bubbles any more to obtain the nano porous copper. The nano porous copper prepared through the method has the advantages that the aperture is fine and small, the ligament outline is clear, the aperture is 50-200nm, and the ligament width is 70-100nm.

Owner:XIAN UNIV OF TECH

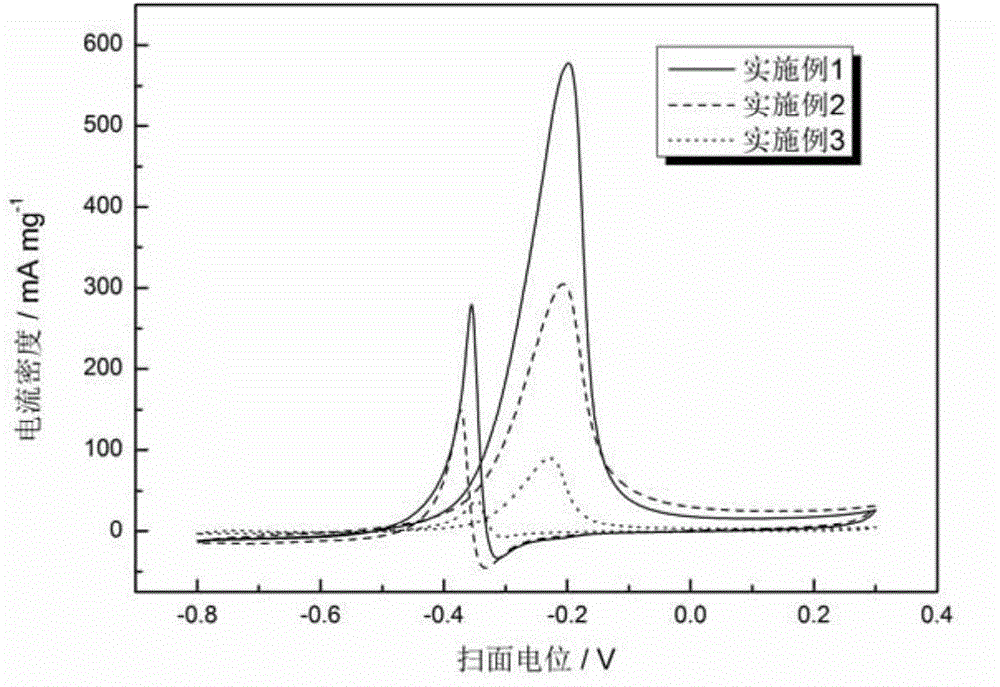

Method for preparing Pd/CuO composite nanometer porous material by using amorphous alloy for dealloying

InactiveCN104475125AReduce manufacturing costEasy to operateCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNanometreAqueous solution

The invention discloses a method for preparing a Pd / CuO composite nanometer porous material by using amorphous alloy. The method comprises: preparing Ti-Cu-Pd amorphous alloy according to the following atomic percent content: 20%-30% of Ti, 40%-65% of Cu, and 5%-20% of Pd; cutting the Ti-Cu-Pd amorphous alloy into a strip with the thickness of 10 mu m-30 mu , the width of 15 mm-20 mm and the length of 1 cm-3 cm; performing ultrasonic processing in anhydrous ethanol for 5 min, cleaning with deionized water, and drying for usage; putting the strip and a hydrochloric acid aqueous solution with the molar ratio of 1.25 M-5 M in an enclosed container for reaction, and controlling the reaction temperature to be 70 DEG C-180 DEG C and the reaction time of 4 h-10 h, flushing the prepared sample after the reaction is finished, and drying, so as to obtain the Pd / CuO composite nanometer porous material. The Pd / CuO composite nanometer porous material has a composite nanometer porous structure with large specific surface area and electrocatalytic activity. The method is low in enforcement cost, simple to operate and short in time consumption, and is efficient and economic.

Owner:TIANJIN UNIV

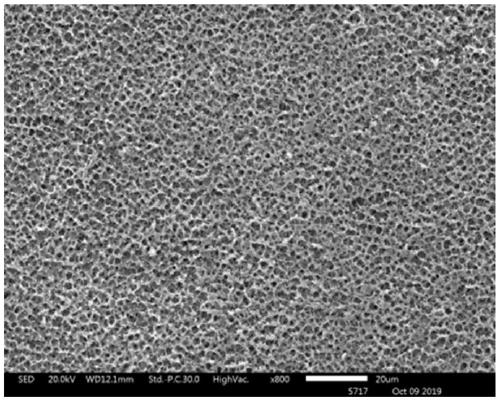

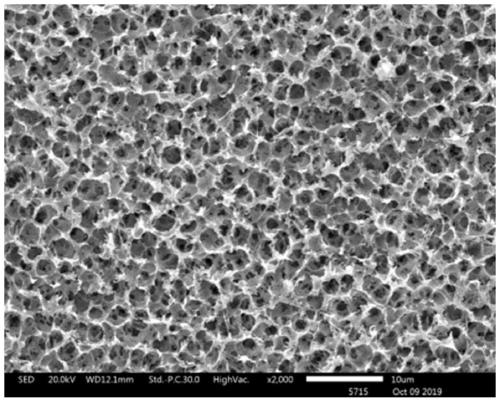

Polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and preparation method thereof

ActiveCN111346522AImprove controllabilityImprove uniformitySemi-permeable membranesMembranesPolyvinyl alcoholPorous membrane

The invention provides a polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and a preparation method thereof. The preparation method comprises the following steps: firstly, a polyvinyl alcohol-ethylene copolymer is dissolved in a mixed solvent of isopropanol and water in a mass ratio of (1: 2)-(2: 1) to prepare a polyvinyl alcohol-ethylene copolymer solution with the mass fraction of 7%-12%; then, after a polyvinyl alcohol-ethylene copolymer film is prepared through spin coating, heat treatment is conducted at the temperature 1 to 10 DEG C lower than the boiling point of an azeotrope of isopropanol and water, a solvent phase is removed, and a honeycomb-shaped porous film is formed; and finally, annealing treatment is carried out to obtain the polyvinyl alcohol-ethylene copolymer honeycomb porous membrane. The molecular chain of the selected polyvinyl alcohol-ethylene copolymer comprises a hydrophilic polyvinyl alcohol chain segment and a hydrophobic polyethylene chain segment, and the honeycomb porous membrane with uniform distribution, small pore diameter and uniform pore diameter is prepared through multi-stage solvent volatilization by utilizing the difference of solubility and boiling points of isopropanol and water on the polyvinyl alcohol-ethylene copolymer.

Owner:武汉维晨科技有限公司

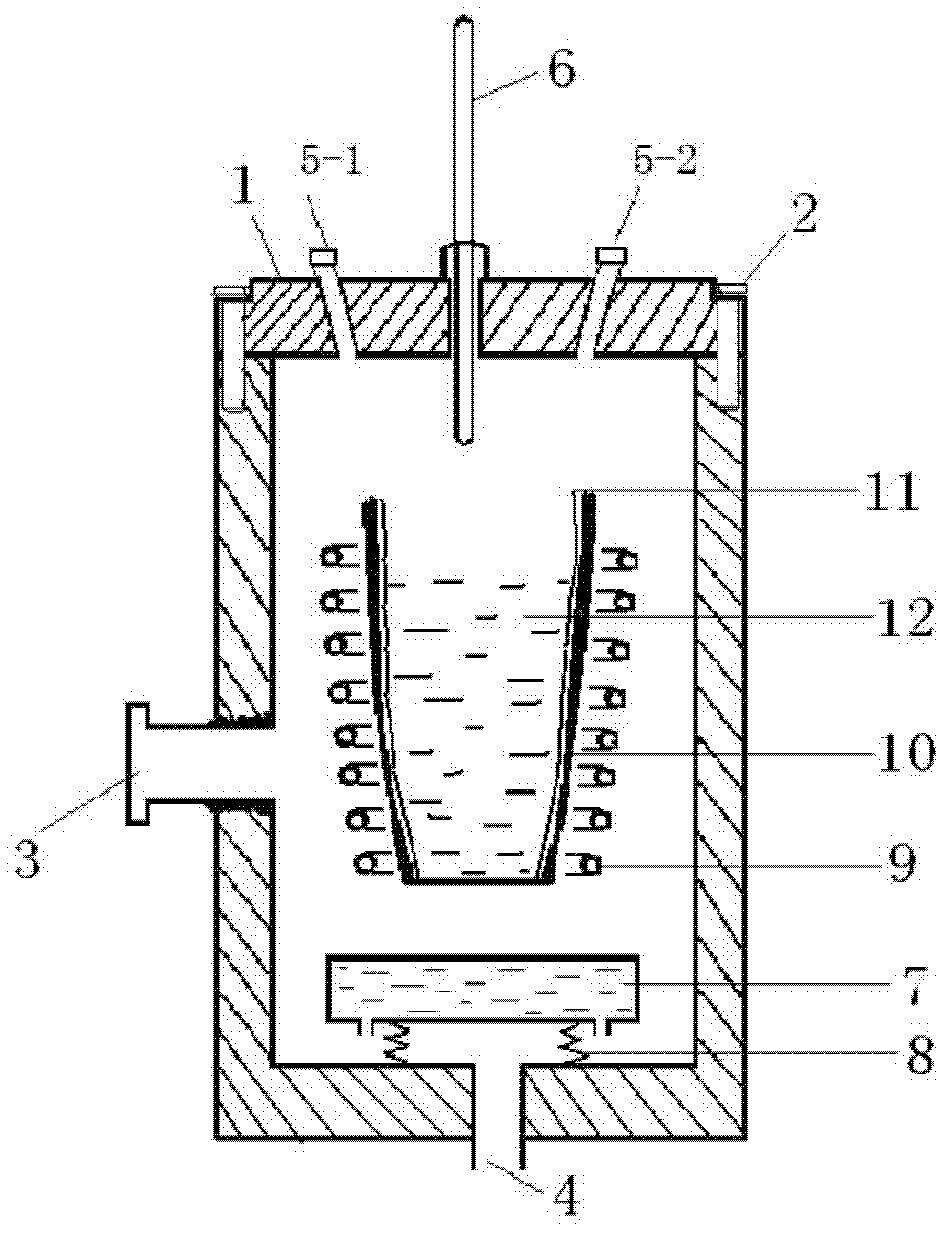

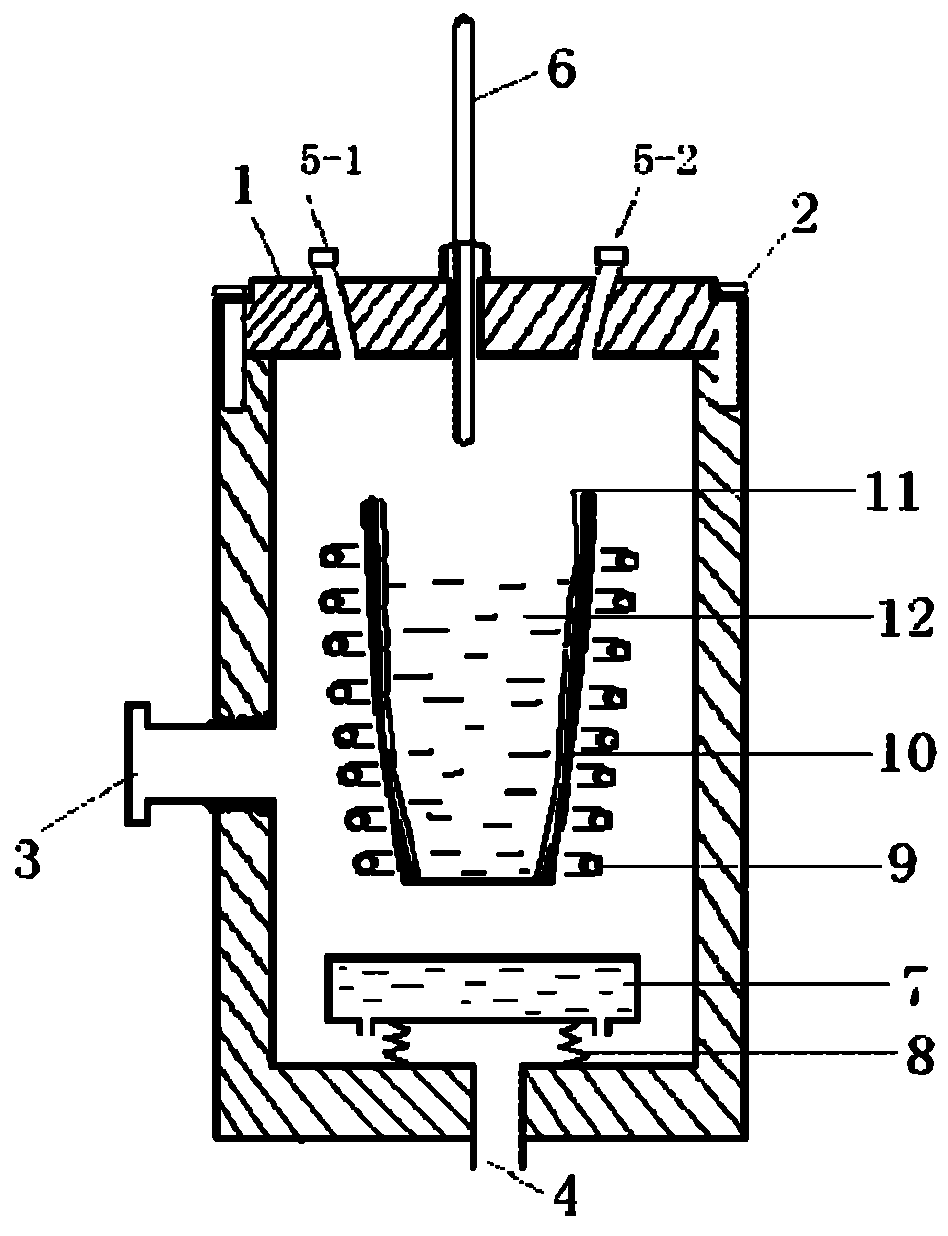

Vacuum-positive pressure smelting and solidifying equipment

The invention relates to equipment for manufacturing porous metal and alloy equipment with a vertical bottom surface porous structure by adopting a smelting and bottom-oriented solidification process under vacuum and high-pressure atmospheres. According to the invention, a smelting crucible and an oriented solidifying casting mould are the same device, the lateral wall of the device has conical degree, an insulated ceramic coating is coated inside the device, or a heat-insulation ceramic sleeve is lined in the device in a close fit way, and the device and a water-cooled induction coil wound on the periphery of the device are separated by a puddling material; and a water-cooled crystallizer is arranged below the smelting crucible and has an automatic lifting function. During smelting, the water-cooled crystallizer is far away from the smelting crucible, namely the oriented solidification casting mould; and during solidifying, the surface of the water-cooled crystallizer and the bottom surface of the smelting crucible, namely the oriented solidification casting mold are closely jointed. The water flow velocity in the water-cooled crystallizer is controlled through pressure; after the oriented solidification is finished, the equipment can obliquely rotate for 120DEG through an external tilting mechanism, and a porous metal ingot is taken out. The vacuum-positive pressure smelting and solidifying equipment can be used for producing porous metal materials used for fields of aircraft industry, electronics, medicines and biochemical and metallurgical machinery, petroleum chemical engineering, energy environment protection, national defense and war industry, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

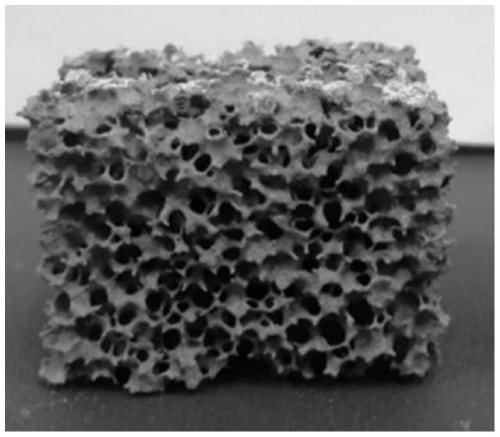

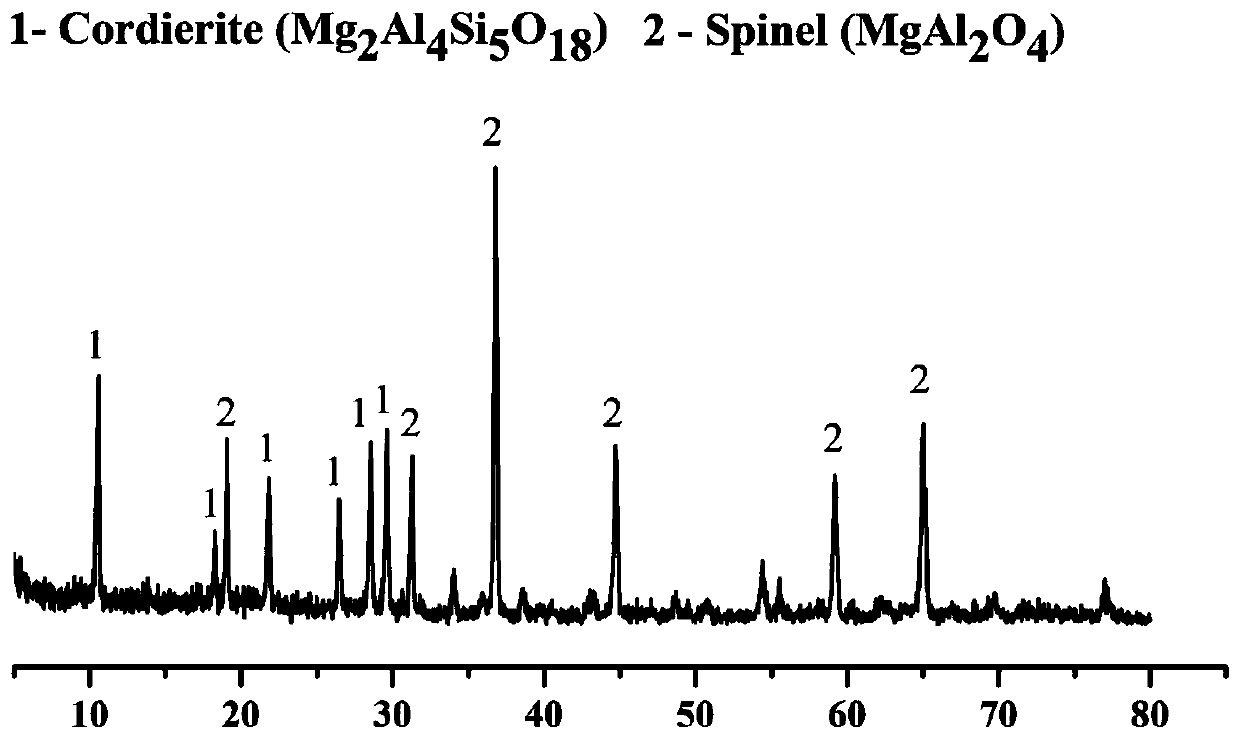

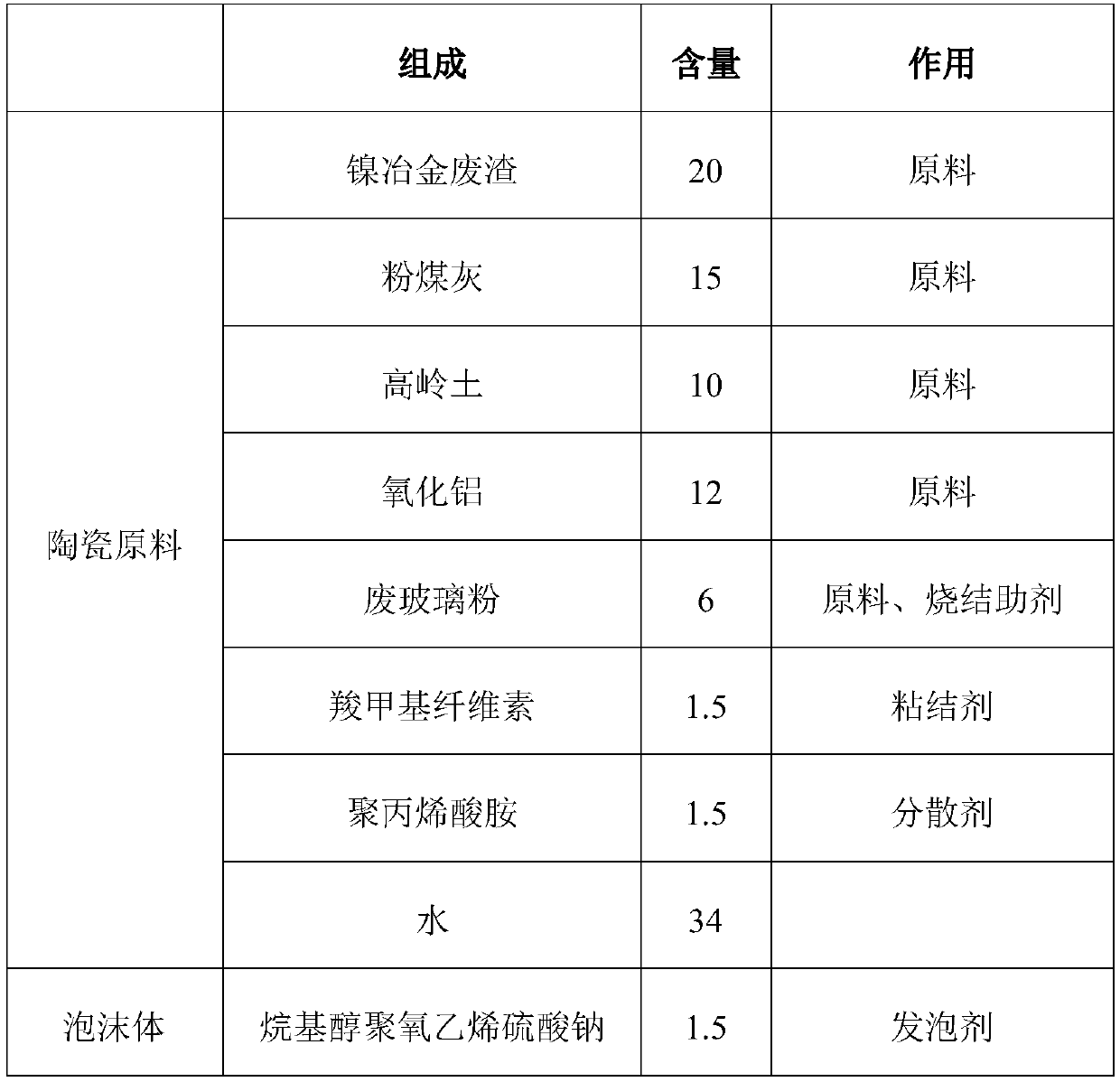

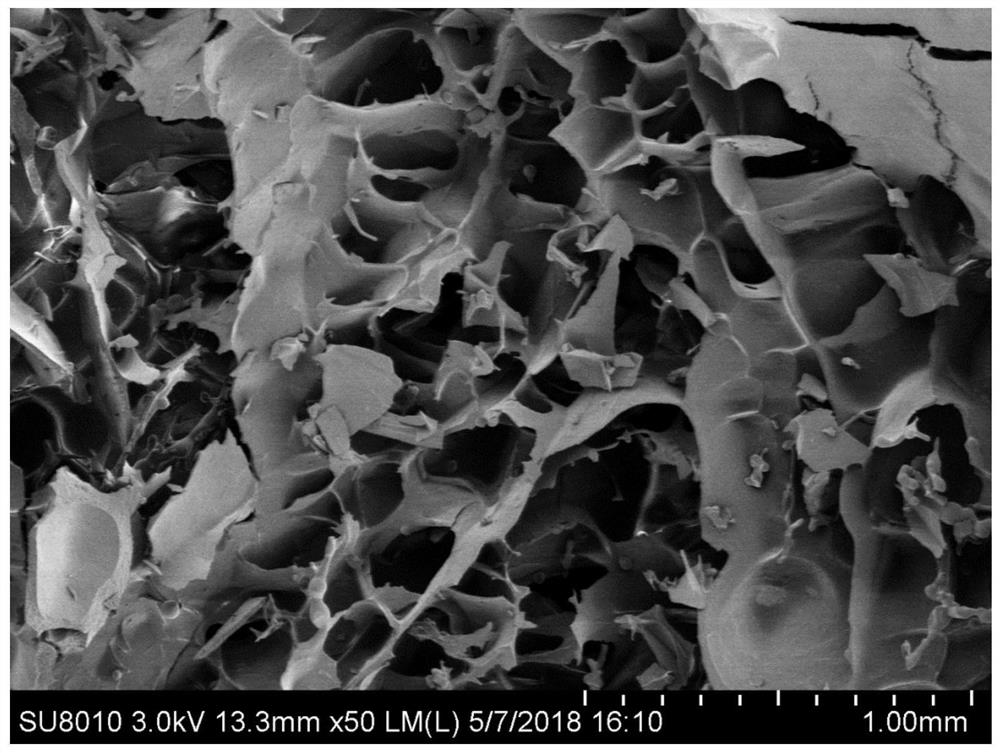

Three-dimensional reticulated spinel-cordierite porous ceramic with high porosity and preparation method thereof

ActiveCN110423099APromote generationHigh porosityCeramic materials productionCeramicwareCordieritePorous ceramics

The invention discloses three-dimensional reticulated spinel-cordierite porous ceramic with high porosity and a preparation method thereof. Raw materials comprise a polyurethane sponge template, a foam ceramic raw material and a foam body; and the foam ceramic raw material comprises the following components in percentage by weight: 10-20% of nickel metallurgical waste residues, 7-17% of fly ash, 5-10% of kaolin, 8-13% of alumina, 5-10% of waste glass powder, 0.5-2% of carboxymethyl cellulose, 0.5-2% of polyacrylic acid amine and 36-40% of water; and the foam body comprises the following components in percentage by weight: 1-2% of a foaming agent, 0.5-1% of a foam stabilizer and the balance of water. According to the invention, the three-dimensional reticulated spinel-cordierite porous ceramic with high porosity is prepared by a compound pore forming method by using the foaming agent and an organic foam impregnation method, so that compound pore forming is carried out on an existing three-dimensional reticulated structure by using the foaming agent to obtain a porous structure with small and uniform pore diameters, and porosity of the porous ceramic is improved.

Owner:YANCHENG INST OF TECH

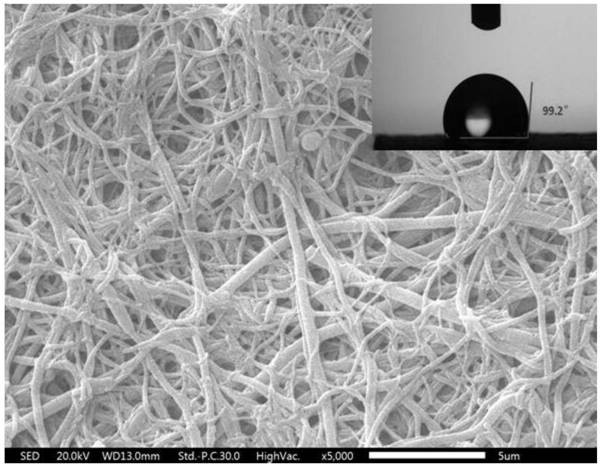

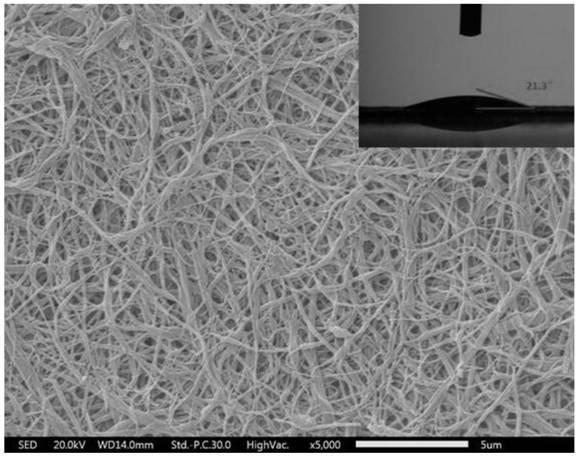

High-hydrophilicity nanofiber coating-based nanofiltration membrane and preparation method thereof

ActiveCN111644080AImprove hydrophilicityCompact structureMembranesSemi-permeable membranesPolymer scienceNanofiber

The invention provides a high-hydrophilicity nanofiber coating-based nanofiltration membrane and a preparation method thereof. The high-hydrophilicity nanofiber coating-based nanofiltration membrane is formed by compounding a high-hydrophilicity nanofiber coating base membrane and a nanofiltration separation layer loaded on the surface of the high-hydrophilicity nanofiber coating base membrane. The preparation method comprises the following steps: firstly, carrying out wet coating on an ethylene-vinyl alcohol copolymer nanofiber dispersion liquid on a non-woven fabric base layer to prepare a nanofiber coating base film; then carrying out alkali treatment and plasma treatment, and carrying out functional modification on the base membrane to obtain the high-hydrophilicity coating base membrane; and finally, carrying out interfacial polymerization to obtain the high-hydrophilicity nanofiber coating-based nanofiltration membrane. The composite nanofiltration membrane prepared by the invention is compact in structure, has high hydrophilicity, can realize synergistic improvement of flux and retention rate, and also has an excellent filtering effect. The preparation method provided by theinvention can optimize the interfacial polymerization process, and the preparation process is simple and controllable, green and pollution-free, and low in cost, and has a great industrial application prospect.

Owner:WUHAN TEXTILE UNIV

Carbon fiber automobile air conditioner filter

ActiveCN105854431AImprove mechanical propertiesSmall mechanical propertiesHuman health protectionDispersed particle filtrationActivated carbonCarbon fibers

The invention discloses a carbon fiber automobile air conditioner filter which comprises a filter cartridge, wherein the filter cartridge is provided with an air inlet and an air outlet, a plurality of slots are formed in the filter cartridge, and a filter frame is inserted into each slot. The carbon fiber automobile air conditioner filter is characterized in that magnetic attraction strips are arranged on the two inner sides of each filter frame respectively, wherein filter core materials are arranged between the magnetic attraction strips on the two sides; each filter core material comprises nonwoven fabric layers arranged on the surfaces of the two sides and blended from organic fiber filaments and activated carbon fiber filaments and a middle activated carbon fiber felt filtration and adsorption layer; the surface density of the blended nonwoven fabric layers is 30 to 200g / m<2>, and the surface density of the activated carbon fiber felt filtration and adsorption layers is 60 to 400g / m<2>. According to the carbon fiber automobile air conditioner filter, harmful substances in haze can be adsorbed and filtered in a targeted manner; with the adoption of a matched pluggable structure, a filter element can be flexibly replaced; moreover, a purification level can be freely regulated according to hazy weather, so that air quality in an automobile in different climatic environments can be effectively improved.

Owner:SHANDONG UNIV

Sound-absorbing ceramsite as well as preparation method and application thereof

ActiveCN111470790ALow densityReduce dosageSolid waste managementCompressive strengthUltimate tensile strength

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

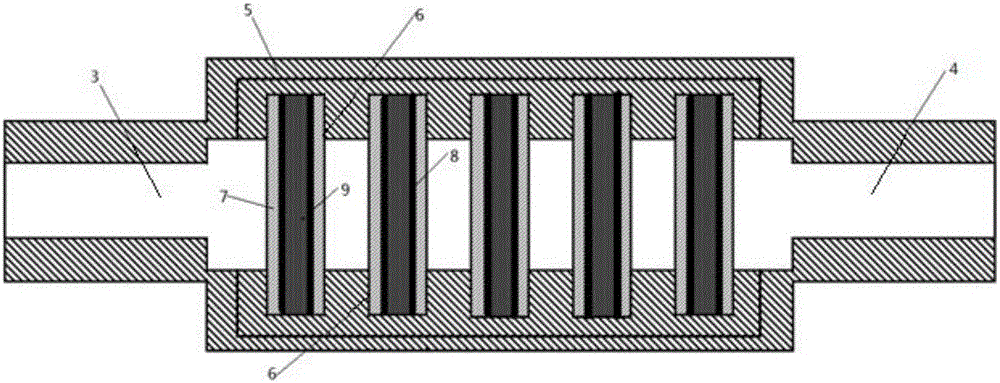

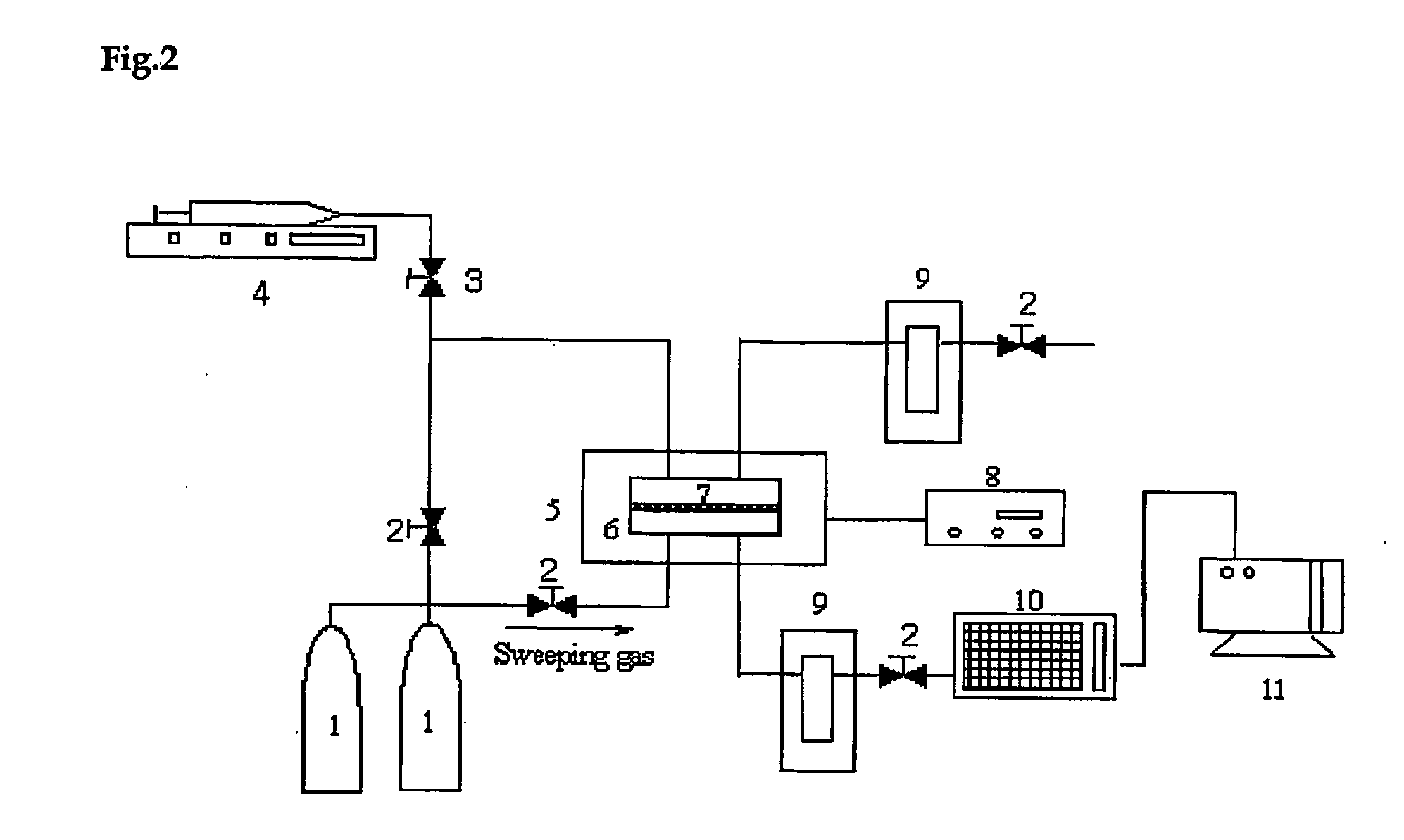

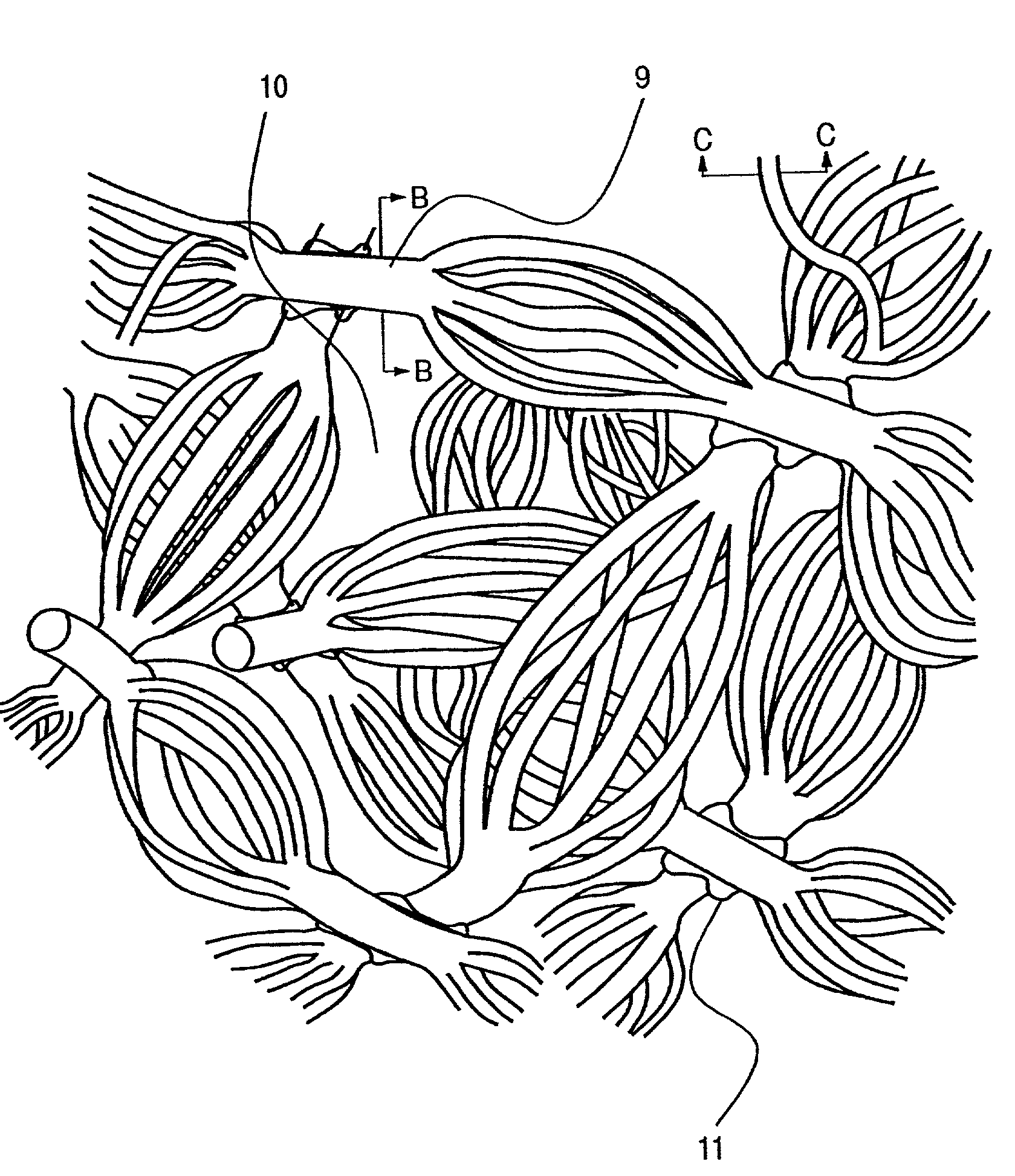

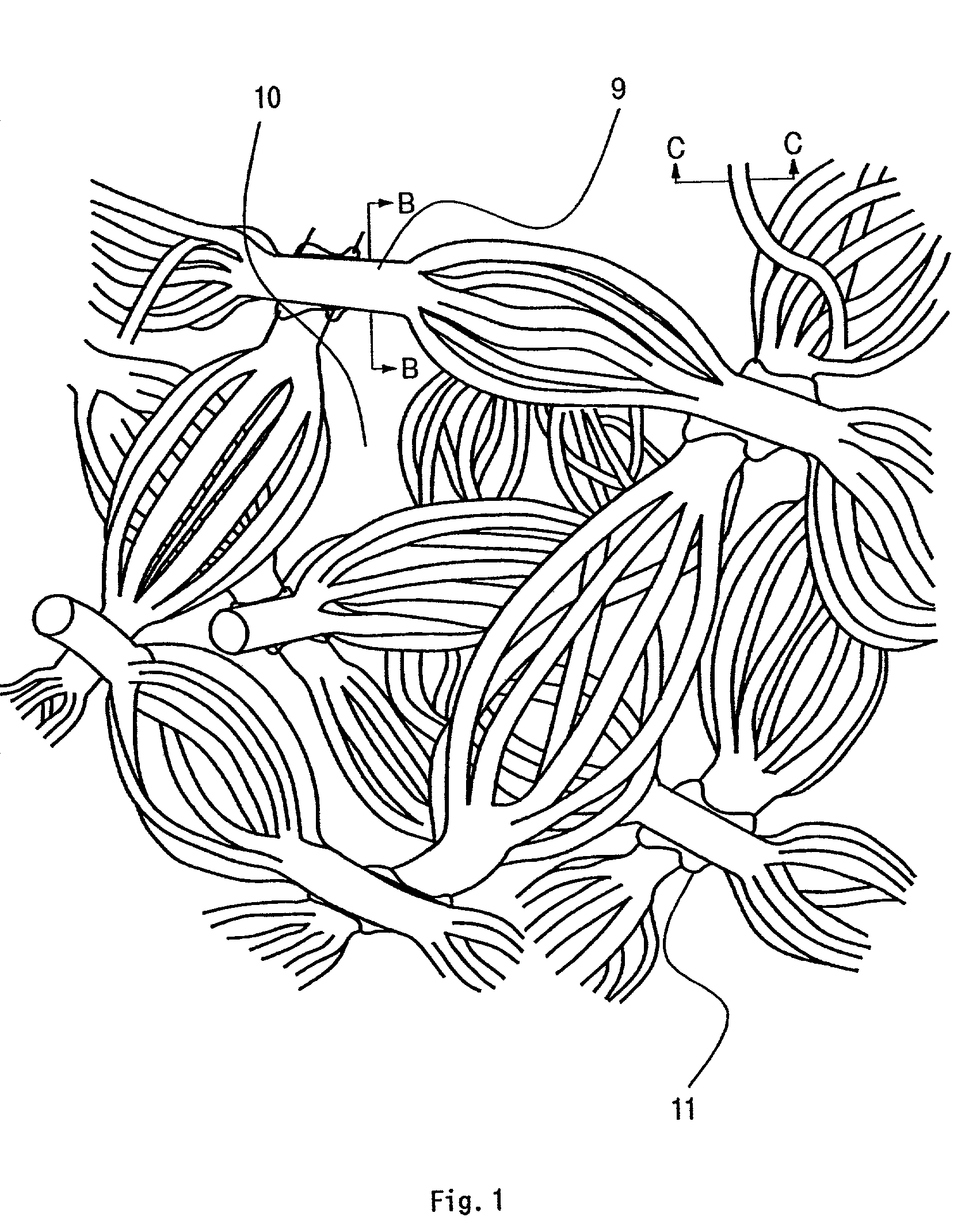

Cell separator manufacturing method, cell separator and alkaline storage battery using said separator

InactiveCN1380706ASmall and uniform pore sizeImprove reliabilityFinal product manufactureFibre treatmentPolyolefinWater vapor

The invention provides a method for manufacturing separators for batteries. At least the vicinity of the fiber surface of the non-woven fabric is sulfonated, and the sulfonation process includes the pretreatment of exposing the non-woven fabric to a water vapor stream with a nearly saturated humidity. process and the process of immediately exposing the nonwoven fabric subjected to the pretreatment process to an air stream containing SO3 gas, and the nonwoven fabric composed of fibers mainly made of polyolefin resin characterized by the above-mentioned sulfonation process is A method for manufacturing a battery separator based on a base fabric, a separator manufactured by the manufacturing method, and a battery using the separator.

Owner:松本 功

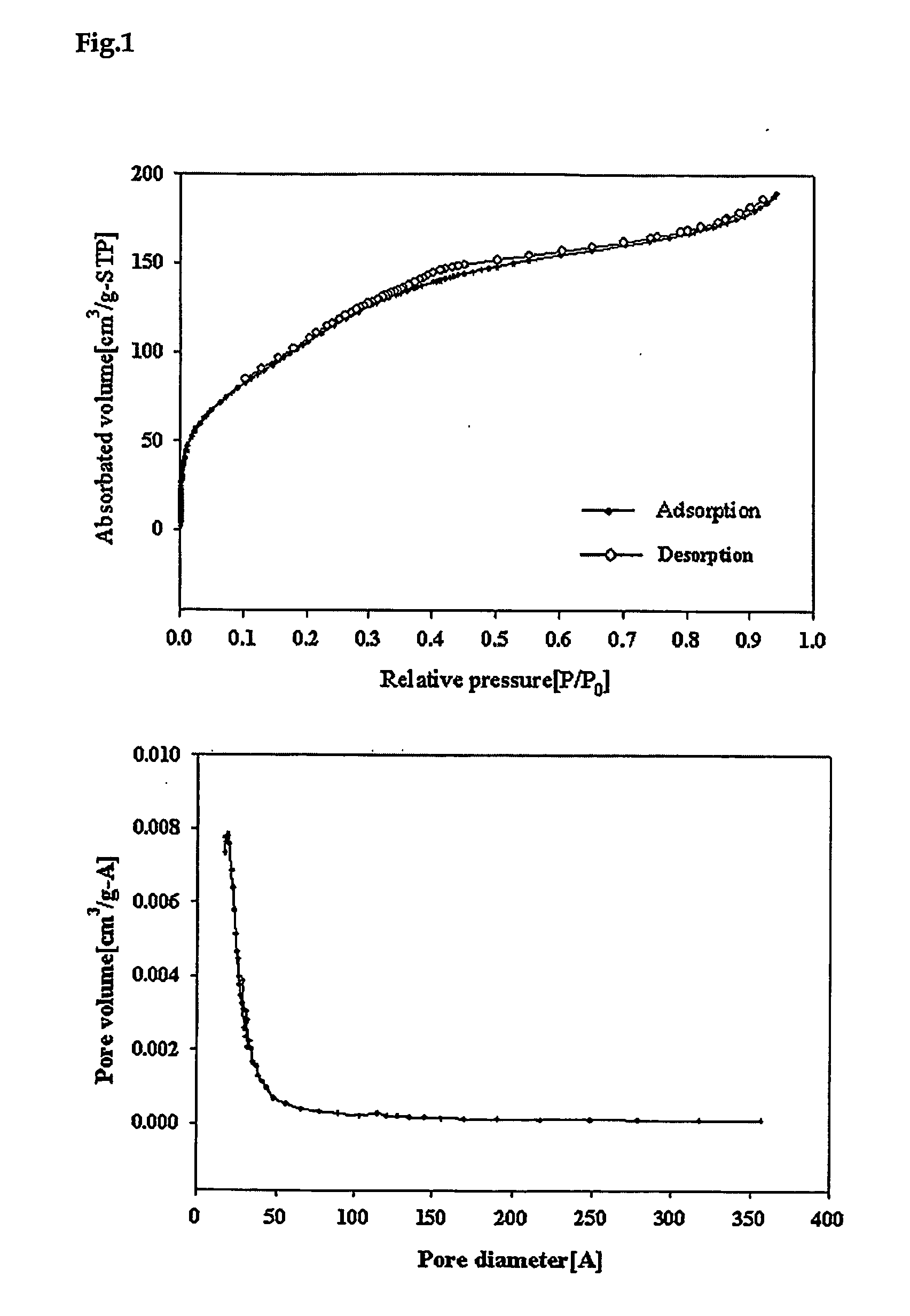

Titania composite membrane for water/alcohol separation, and preparation thereof

InactiveUS20070059514A1Improve thermal stabilityHigh-temperature and mechanical strengthMembranesSynthetic resin layered productsSurface layerAlcohol

The present invention relates to a titania composite membrane for separating water / alcohol mixtures and a method of preparation thereof, and more particularly to the titania composite membrane and the method of preparation thereof, wherein a surface of a porous support is modified with silica xerogel and γ-alumina sol and titania sol is coated on the modified surface to form a titania surface layer and then the obtained titania surface layer is dried and calcined to optimize performance of separation and promote thermal stability. The titania composite membrane of the present invention has excellent properties such as thermal stability, mechanical strength and good perm-selectivity for water molecule in water / alcohol mixtures due to the hydrophilic property of the titania surface layer, thus being applicable to the membrane for separating water / alcohol mixtures.

Owner:KOREA RES INST OF CHEM TECH

Gypsum-based foam concrete and preparation method thereof

ActiveCN112679185ASmall and uniform pore sizeImprove water resistanceCeramicwareFoam concreteAluminate

The invention belongs to the technical field of building materials, and provides gypsum-based foam concrete and a preparation method of the gypsum-based foam concrete. The concrete comprises the following components in parts by weight: 50-65 parts of gypsum, 22-28 parts of Portland cement, 1-2 parts of sulphoaluminate cement, 1-2 parts of quick lime and / or slaked lime, 13-18 parts of fly ash, 4-8 parts of SiO2 aerogel, 0.2-0.4 part of graphene oxide, 0.2-0.4 part of a water reducing agent, 0.05-0.1 part of a waterproof agent and 0.09-0.2 part of a foaming agent. Each component can play a synergistic role in specific proportions, can significantly improve the water resistance of the gypsum-based foam concrete, and the water absorption rate of the gypsum-based foam concrete is obviously reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Process for producing separator for batteries, the separator for batteries, and alkaline storage batteries using the same

InactiveUS6994935B2Improve hydrophilicityHigh degree of sulfonationFinal product manufactureFibre treatmentPolyolefinSulfur

The present invention relates to the separator for batteries wherein the non-woven cloth comprising fibers mainly composed of polyolefin type resin is provided with hydrophilic property on the fiber surface at least by sulfuric compound and characterized as follows:(a) the ratio of atomic mass of sulfur to atomic mass of carbon (S / C) is 5×10−3 to 30×10−3 (b) the tensile strength is not less than 3 kg / cm2 and the preparation method of this separator. The present invention also relates to the secondary batteries using this separator.

Owner:MATSUMOTO

AGM partition plate capable of preventing electrolyte from being layered

ActiveCN106299201AAvoid stratificationInhibition densityFinal product manufactureCell component detailsPorosityFiber

The invention discloses an AGM partition plate capable of preventing an electrolyte from being layered. The AGM partition plate is prepared from the following raw materials based on percent by weight: 5-10% of polyester fiber, 3-5% of polyethylene oxide, 5-10% of modified bamboo fiber, 10-15% of water-soluble polyvinyl alcohol fiber, 30-35% of high alkali glass fiber with diameter of 0.5-0.7 micrometer with the balance being high alkali glass fiber with diameter of 3-4 micrometers. By the AGM partition plate, a traditional pure glass fiber formula is abandoned, various fibers are creatively adopted and are interwoven in a mixed way to form the AGM partition plate, higher electrolyte absorption quantity, high wettability and high electrolyte maintaining capability are achieved by means of synergistic matching among fibers, the electrolyte is uniform in distribution, high in porosity and uniform in air gap, and has excellent integral performance, the performance of a battery is favorably improved, and the service lifetime of the battery is favorably prolonged.

Owner:ZHEJIANG CHANGTONG SCI & TECH

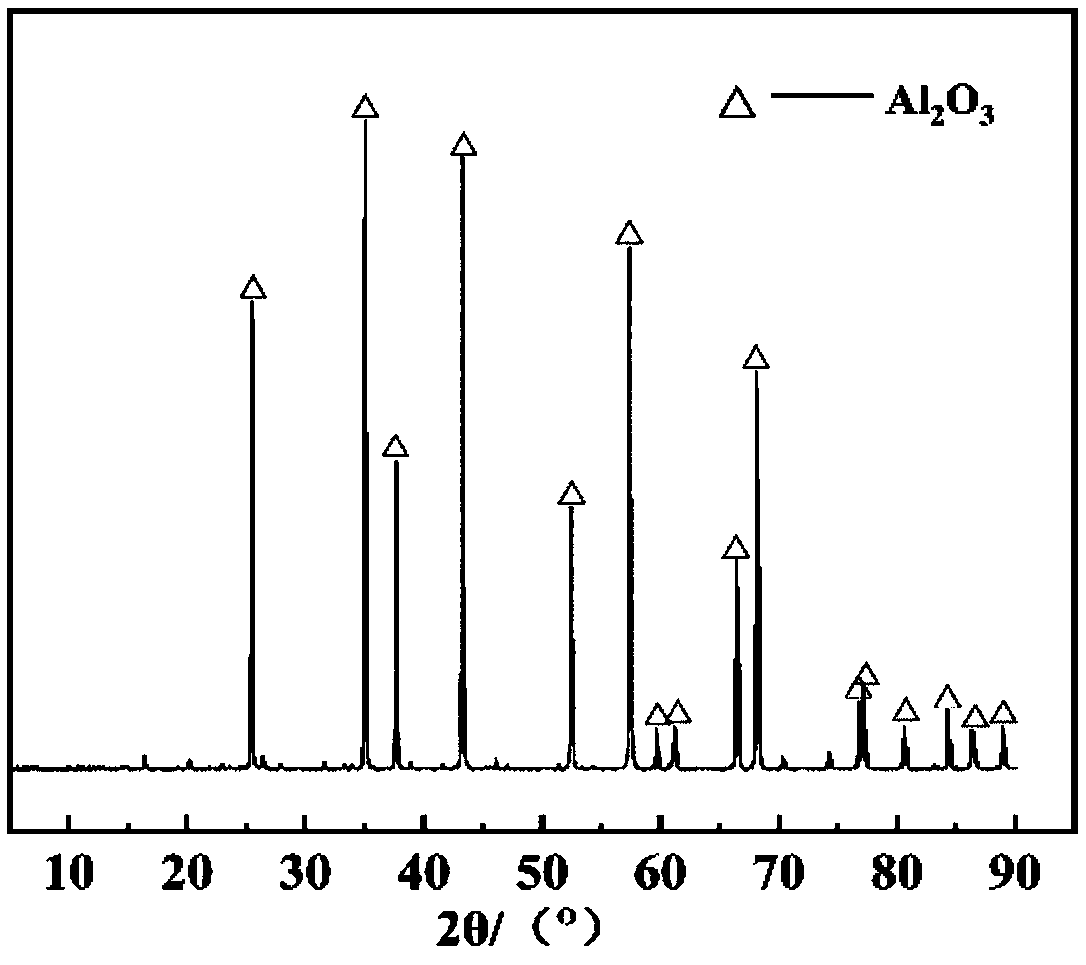

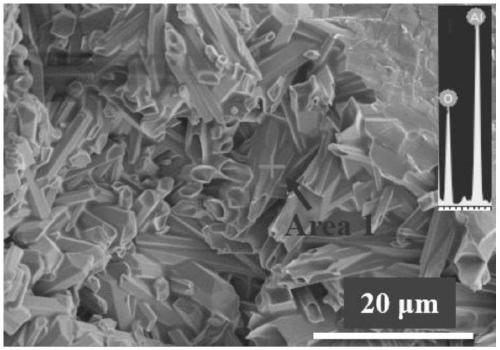

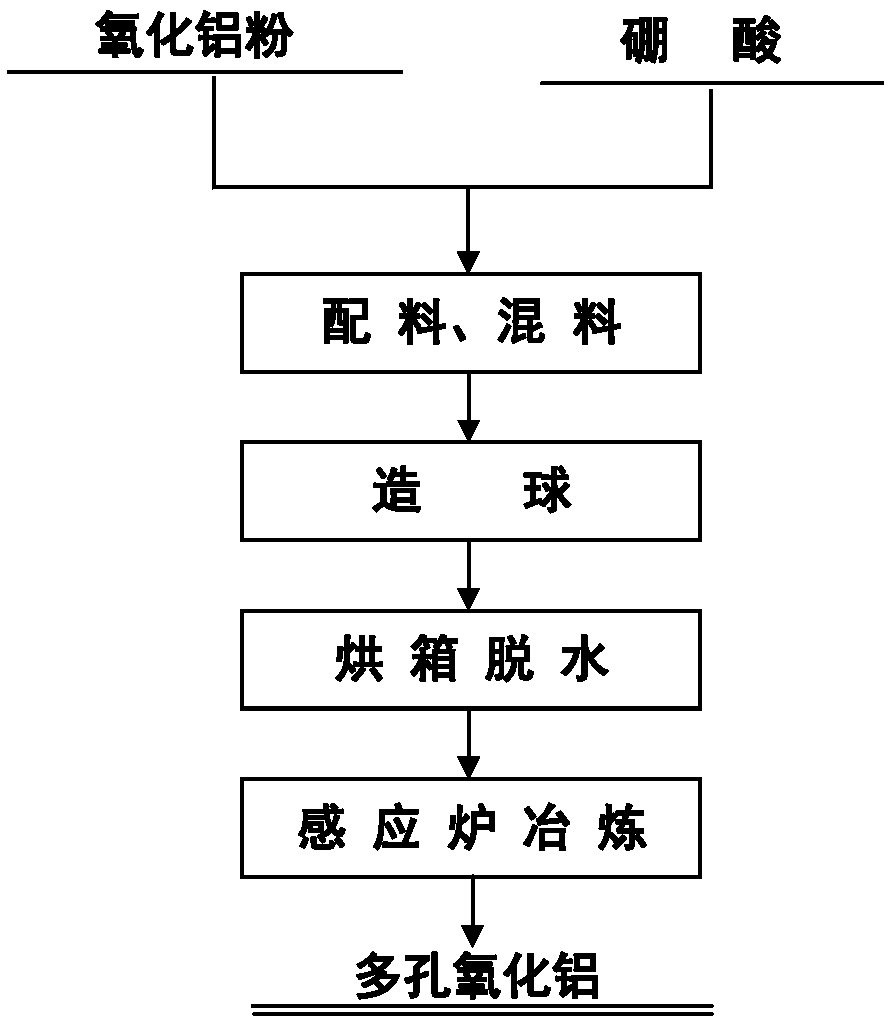

Porous alumina preparation method

ActiveCN109133976ASimple processSmall and uniform pore sizeCeramicwareMaterials preparationRoom temperature

The invention belongs to the field of porous material preparation, and discloses a porous alumina preparation method which particularly includes the steps: (1) dispensing and mixing boric acid powderand alumina according to a certain proportion; (2) adding an appropriate amount of water into raw materials and further blending and pressing the raw materials into pellets; (3) placing the pellets into a vacuum drying oven for drying; (4) placing the pellets into an induction furnace for high-temperature smelting; (5) performing air cooling on products to reach room temperature after smelting. Compared with a traditional porous alumina preparation method, the porous alumina preparation method has the advantages that a large number of complicated process steps are omitted, production cost andenergy consumption are remarkably reduced, and generated porous alumina is high in purity and free from other impurities and accordingly has better chemical corrosion resistance.

Owner:NORTHEASTERN UNIV

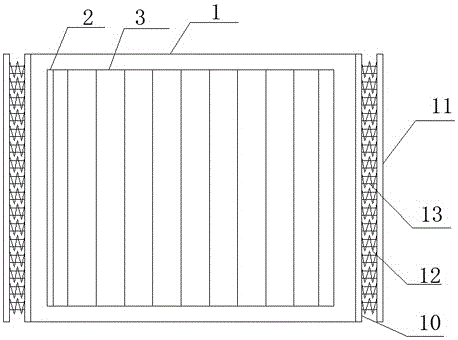

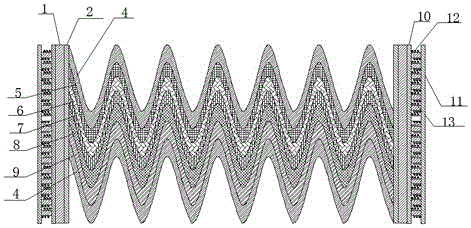

Automobile air conditioner filter with sealing device

InactiveCN106731279AGood mechanical propertiesImprove mechanical propertiesAir-treating devicesGas treatmentBacterial virusActivated carbon

The invention relates to the technical field of automobile parts, in particular to an automobile air conditioner filter with a sealing device. The automobile air conditioner filter with the sealing device comprises a hollow shell, two magnetic suction strips, two elastic sealing pads and a wavy filter element, wherein the two magnetic suction strips are symmetrically arranged on the inner walls of a left side plate and a right side plate of the hollow shell; the two elastic sealing pads are symmetrically arranged on the outer walls of the left side plate and the right side plate of the hollow shell; the wavy filter element is arranged between the two magnetic suction strips; two layers of metal supporting nets matched with the wavy filter element are arranged between the two magnetic suction strips; and the wavy filter element is arranged between the two layers of metal supporting nets in a matched way. The automobile air conditioner filter with the sealing device is simple in structure, reasonable in design and high in sealing property, can eliminate dust and harmful substances which enter an air-conditioning system, sterilize the air, prevent bacterial virus from entering the automobile and reduce disease propagation, and has large effective filtering surface; meanwhile, due to the regeneration characteristic of activated carbon, the service life can be effectively prolonged.

Owner:济源市万荣商贸有限公司

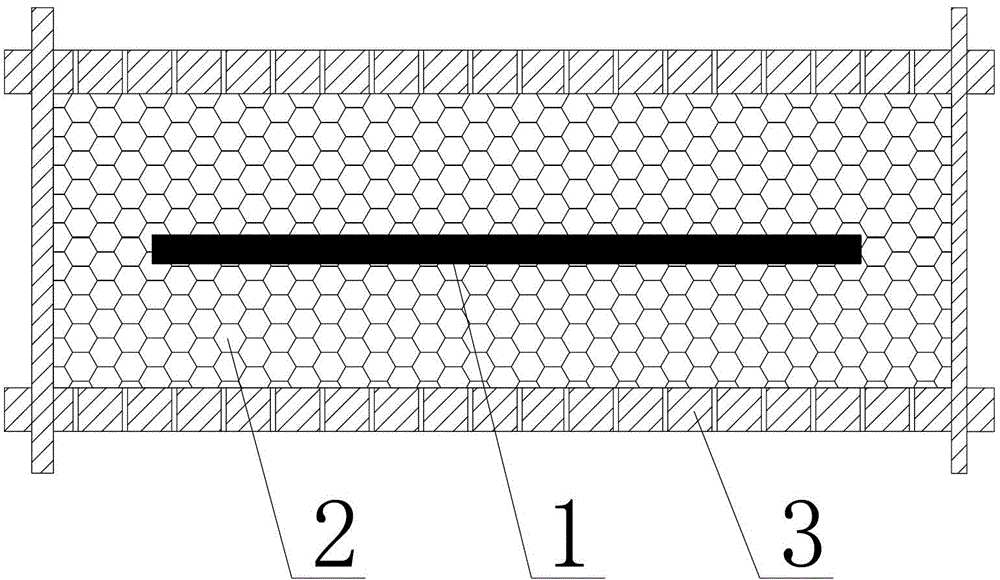

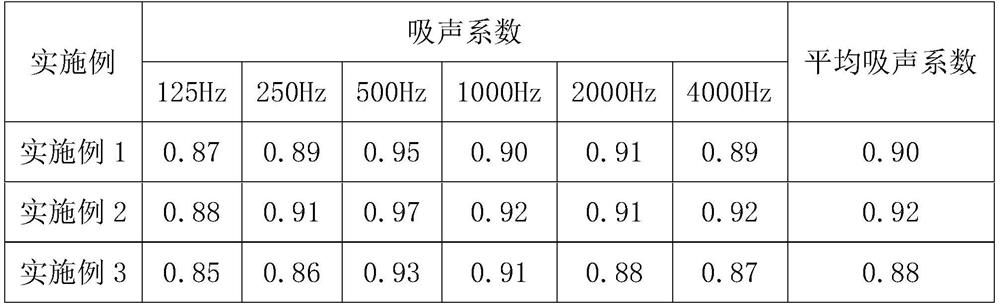

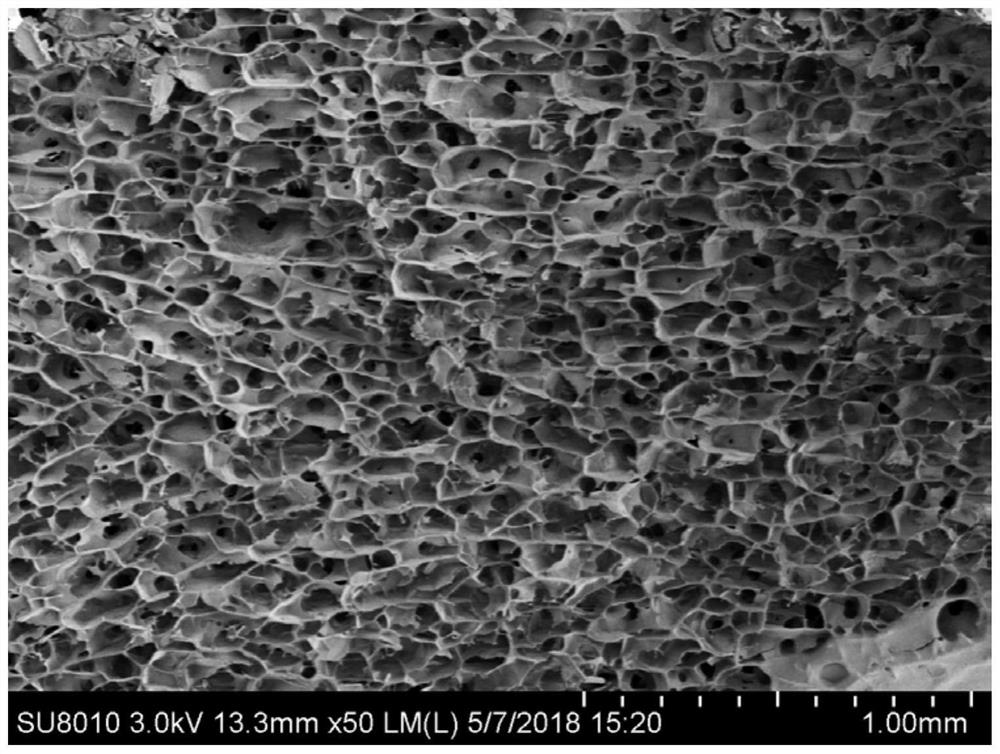

Foamed aluminum sound-absorbing plate capable of effectively reducing urban traffic noises and preparation method thereof

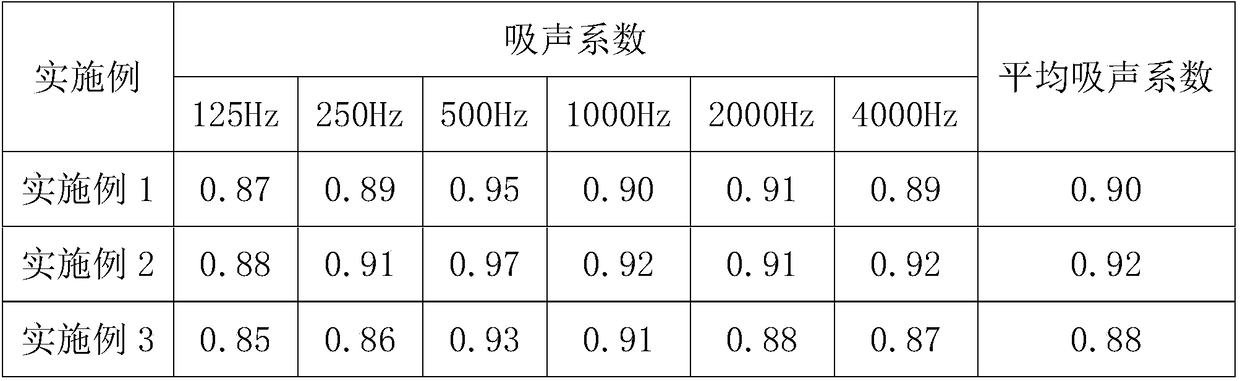

ActiveCN108608687AIncreased through-hole porosityReduced via hole sizeTransportation and packagingMetal-working apparatusPorosityEpoxy

The invention discloses a foamed aluminum sound-absorbing plate capable of effectively reducing urban traffic noises. The foamed aluminum sound-absorbing plate comprises an aluminum plate body, wherein foamed aluminum materials are adhered to the two side surfaces of the aluminum plate body; the foamed aluminum material comprises the following raw materials: aluminum scrap, deionized water, ultrapure water, absolute ethanol, a dispersant, a plasticizer, an adhesive and a foaming agent; the adhesive comprises the following raw materials: starch, polyvinyl alcohol, polyurethane, butyl rubber, vinyl acetate resin and waterborne organosilicone epoxy resin; the foaming agent comprises the following raw materials: azodicarbonamide, sodium hydrogen carbonate, carbon black, n-hexane, trichlorofluoromethane and sodium lauryl sulfate; the foamed aluminum material has the through hole porosity of 98.5-99.8% and the average through hole size of 0.75-0.85mm; the foamed aluminum materials adhered tothe two side surfaces of the aluminum plate body have the thickness of 20-25mm; the foamed aluminum sound-absorbing plate has the sound-absorbing coefficient of 0.88-0.92. The technical problems of nonuniform through pore size, relatively large through hole size and relatively low through hole porosity of the existing foamed aluminum material are solved.

Owner:常州市驰义塑胶制品有限公司

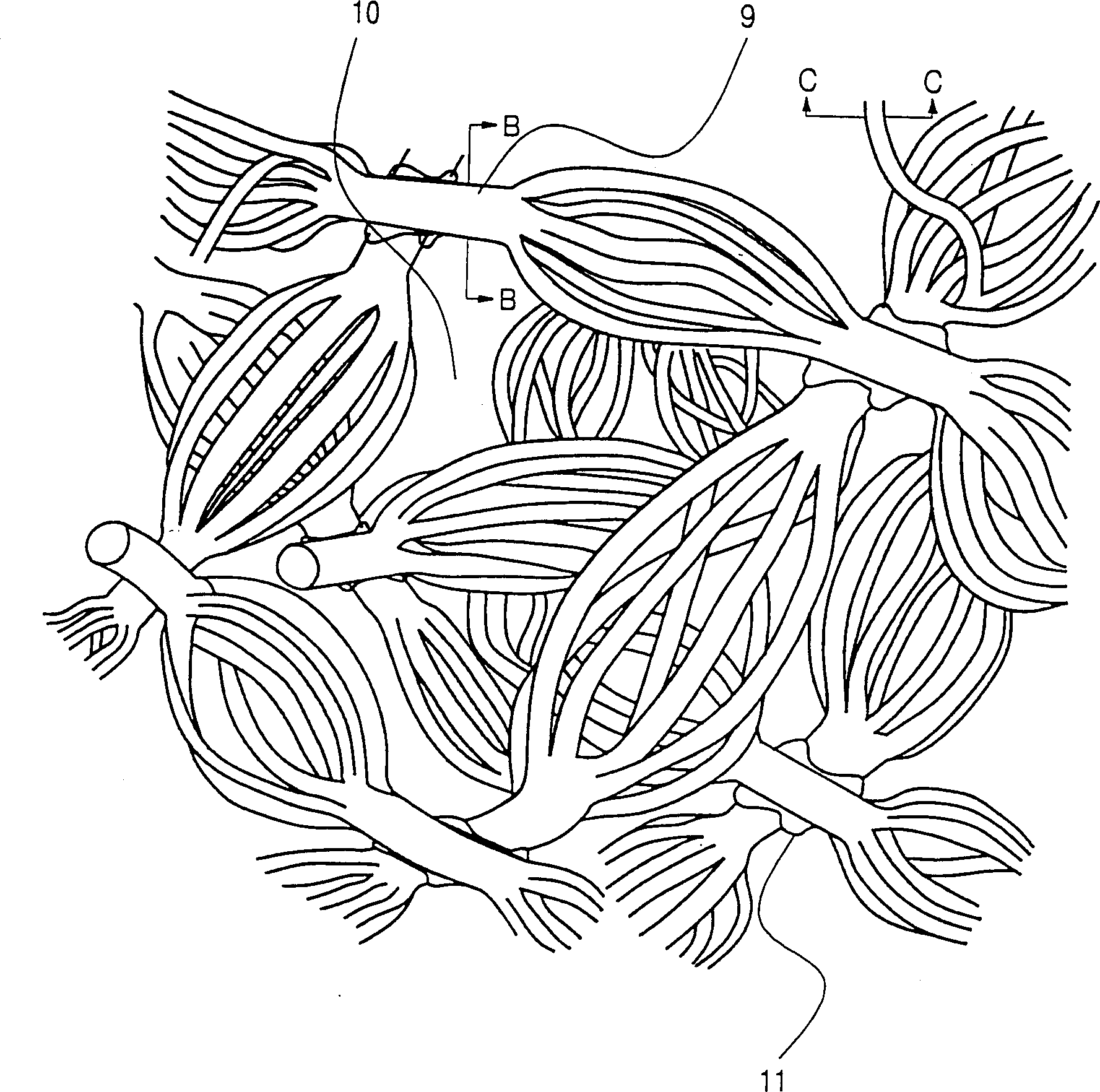

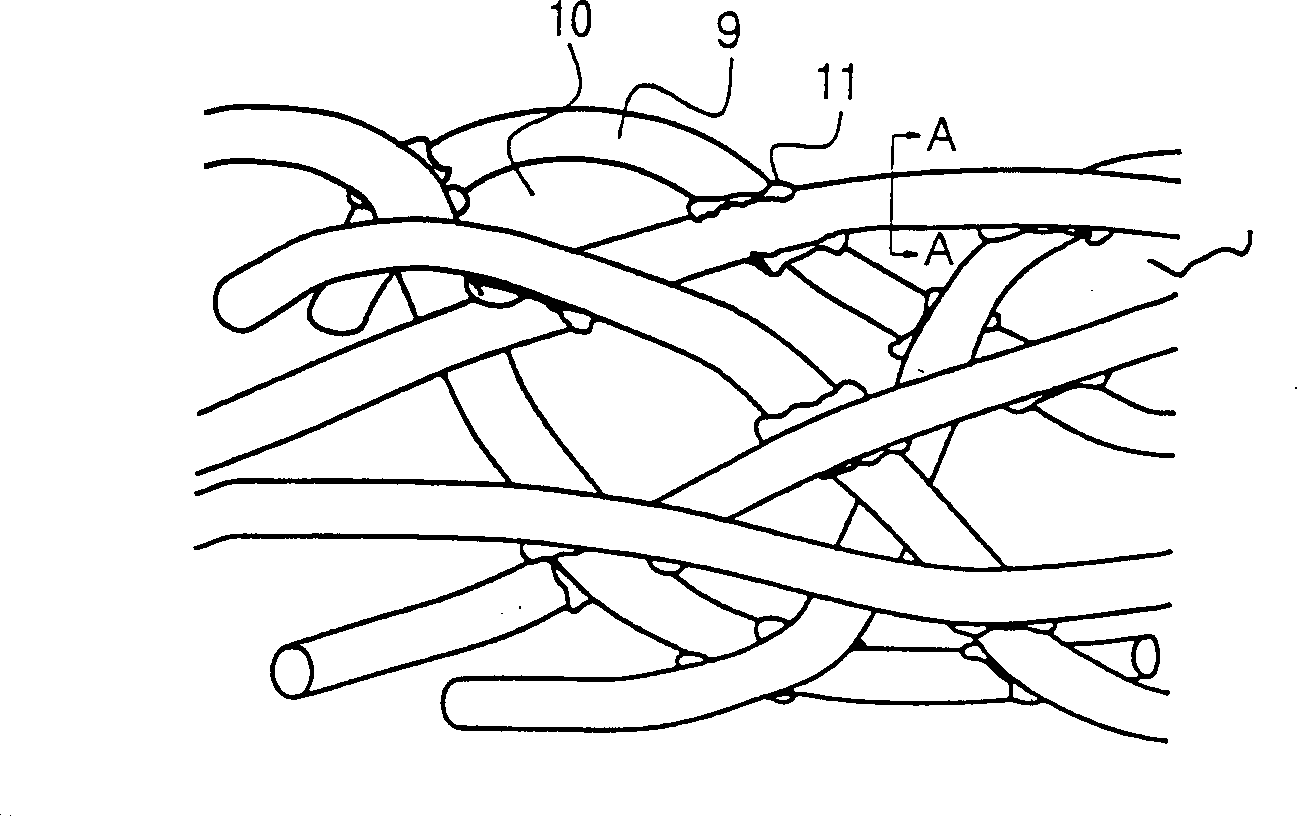

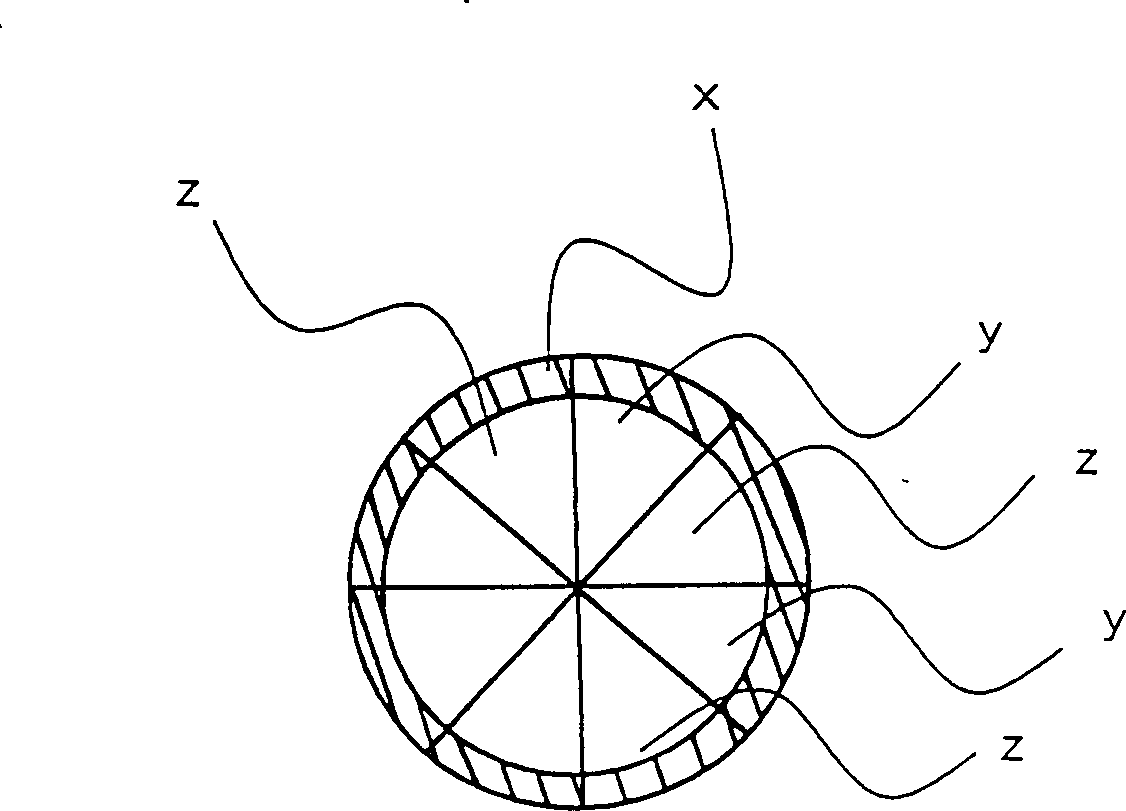

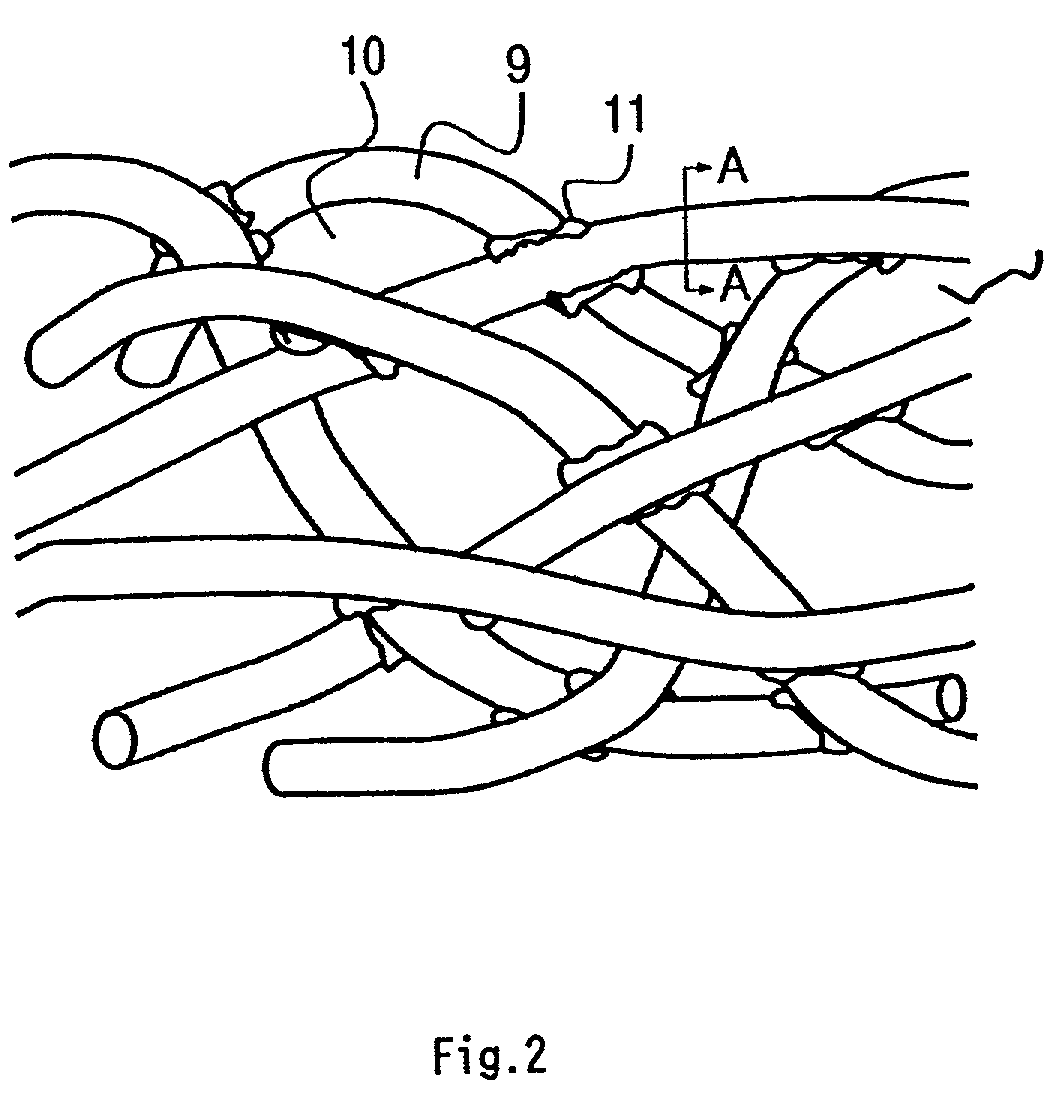

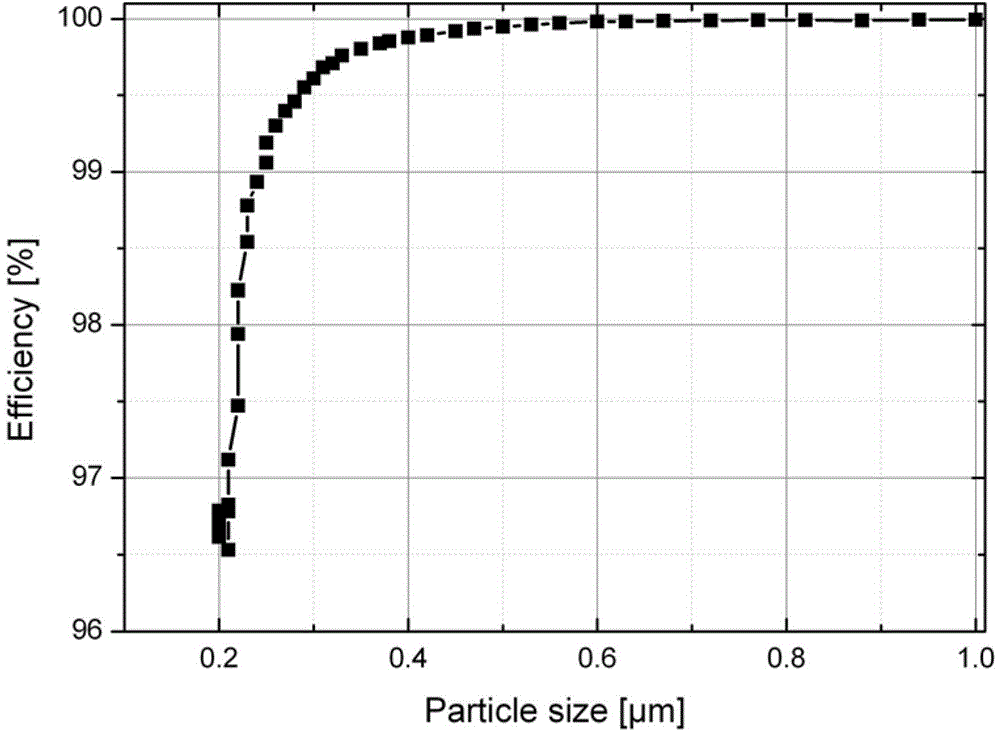

High-performance pps fiber structure and production method and use thereof (as amended)

InactiveUS20180251920A1Small and uniform pore sizeImprove air tightnessPhysical treatmentWoven fabricsMethods of productionMaterials science

The present invention discloses a high-performance PPS fiber structure and production method and use thereof. The high-performance PPS fiber structure is woven fabric made from PPS fibers in 0.1 to 12 μm cross sectional diameter, and the maximum pore size of the PPS fiber structure is 20 μm or smaller. The PPS fiber structure disclosed in the present invention has the advantages of high gas impermeability and good hydrophilicity, also has the advantages of simple process, low energy consumption and zero environmental pollution, and can be used in diaphragms for electrolytic apparatuses, high-temperature liquid filter materials and insulating materials.

Owner:TORAY IND INC

Support-free perforated metal film preparation method

ActiveCN103386486BSolve the problem of difficult forming and uncontrollableImprove filtration efficiencyLow demandPolyvinyl alcohol

The invention provides a support-free perforated metal film preparation method, comprising the steps of 1, uniformly mixing metal powder and poval in a ball-milling mode to obtain slurry; 2, coating the slurry onto a basal body face, and stripping after drying to obtain a support-free metal film blank; 3, placing ceramic padding and the support-free metal film blank into a sintering die, enabling the ceramic padding to fully wrap the support-free metal film blank, and then performing processes of pre-sintering preprocessing, pre-sintering, sintering and cooling to obtain the support-free perforated metal film. The support-free perforated metal film preparation method is simple in process and low in production cost, has lower demands on production equipment, and is suitable for large-scale industrial production; and the support-free perforated metal film produced according to the preparation method is small and uniform in aperture, high in porosity, and far higher in filtering efficiency compared with a traditional metal film, and can be widely applied in industrial fields such as petroleum industry, bio-pharmaceuticals, food, beverage and water treatment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Titania composite membrane for water/alcohol separation, and preparation thereof

InactiveUS7655277B2Improve thermal stabilityHigh-temperature and mechanical strengthMembranesSynthetic resin layered productsAlcoholSurface layer

Owner:KOREA RES INST OF CHEM TECH

Method for preparing nano porous copper by adopting Cu-Zn alloy

The invention discloses a method for preparing nano porous copper by adopting Cu-Zn alloy. The method comprises the following steps of: preparing copper and zinc in a proportion that the copper is 60 weight percent or 70 weight percent or 80 weight percent of the zinc under the protection of nitrogen to obtain alloys by adopting a smelt technology; carrying out Tafel curve testing by taking a 1M NaCl solution as an electrolyte and utilizing a three-electrode method to obtain easies corrosion voltages of different alloys; carrying out water bath at 50-70 DEG C in the 1M NaCl solution under the condition that the volume ratio of corrosive liquid to the alloy volume is (1,000-1,500):1; carrying out electrochemical corrosion on the alloys under the easies corrosion voltages; dropwise adding 1-2ml of concentrated NH3.H2O solution every other 20 minutes to ensure that the electrolyte contains certain complex compounds to promote the reaction; and stopping the reaction until the cathode does not discharge obvious bubbles any more to obtain the nano porous copper. The nano porous copper prepared through the method has the advantages that the aperture is fine and small, the ligament outline is clear, the aperture is 50-200nm, and the ligament width is 70-100nm.

Owner:XIAN UNIV OF TECH

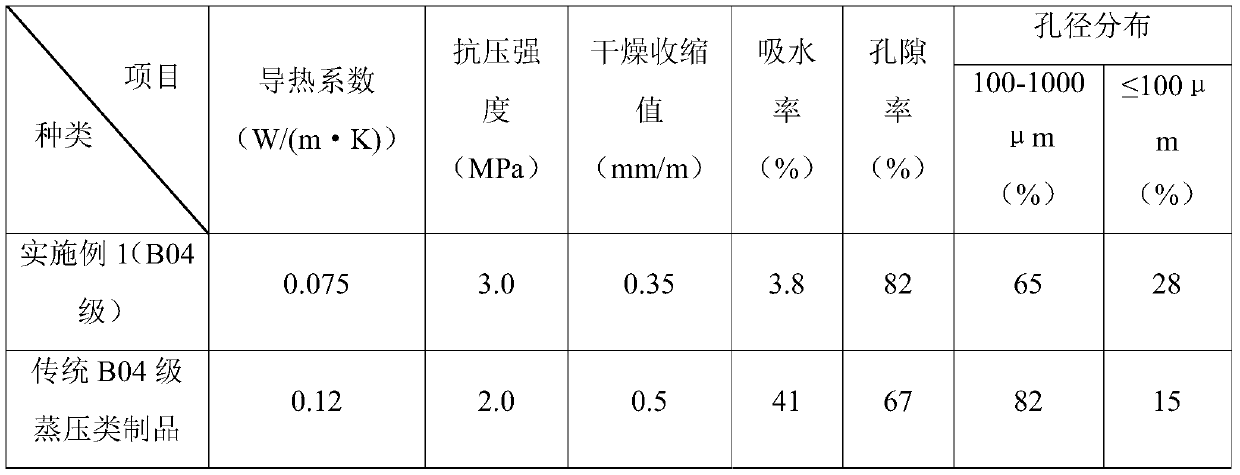

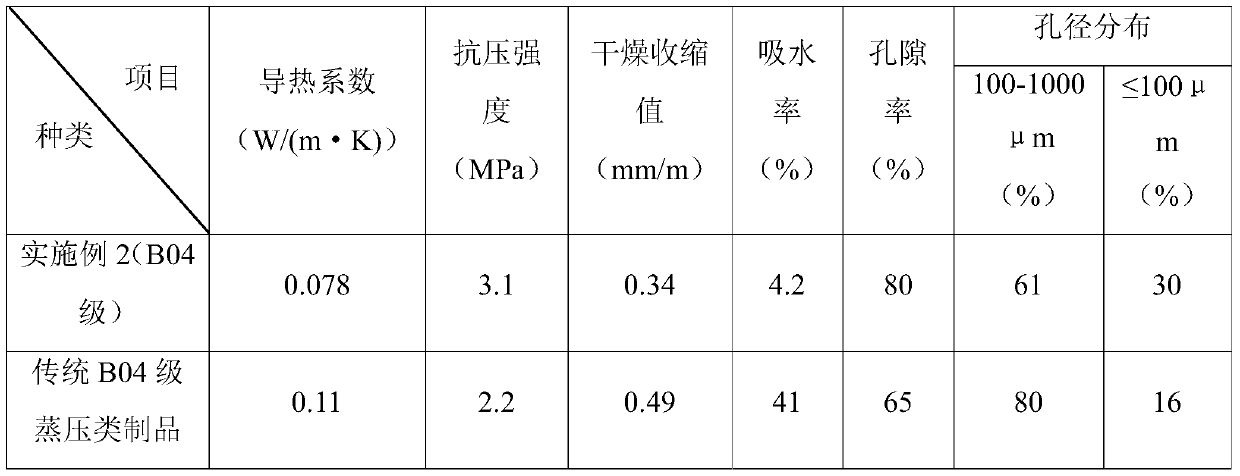

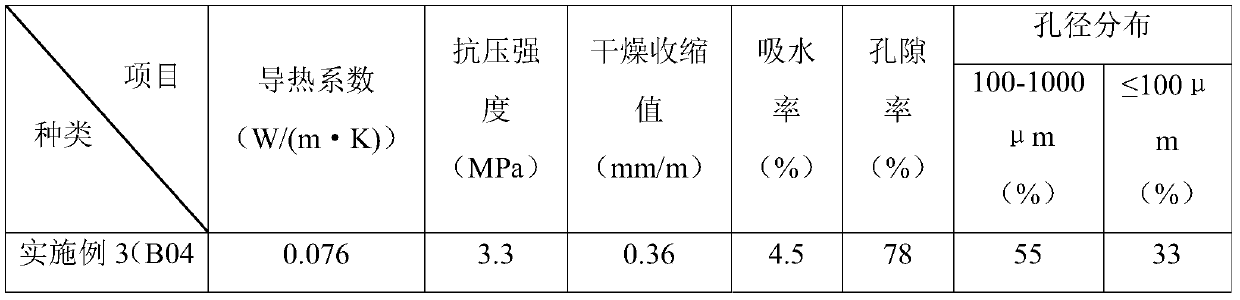

Ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material as well as preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material as well as a preparation method thereof. The ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material is prepared from a siliceous component, a calcareous component, a coagulated component, a gas-forming component, a gas-guiding component, a hydrophobic component and water; the siliceous component is prepared from modified ceramic tile polishing mud, kieselguhr and modified fluorogypsum; and the calcareous component is prepared from quicklime and modified carbide slag. According to the thermal insulation material provided by the invention, the waste utilization rate is high, the ceramic tile polishing mud, the fluorgypsum and the carbide slag can be resourcefully utilized, in the product structure, the porosity is high, the aperture is small and uniform, macro holes and micro holes coexist, the heat conductivity coefficient is low, the mechanical property is high, the water absorption rate is low, and therefore, the thermal insulation material can be widely applied tocivil buildings and industrial buildings in thermal insulation.

Owner:SHANDONG ZIJIAN GRP

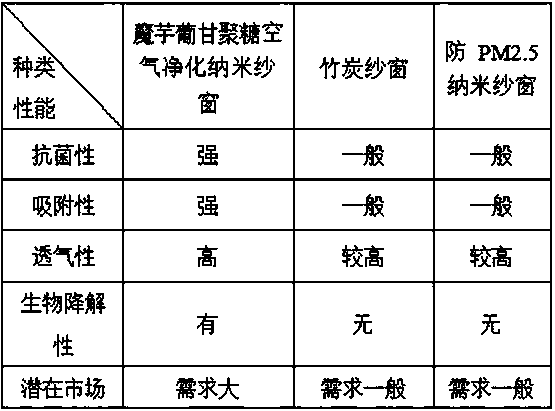

Konjac glucomannan air purifying nano screen window and preparation method thereof

ActiveCN108386120ASmall and uniform pore sizeImprove breathabilityInsect protectionFilament/thread formingAdditive ingredientEngineering

The invention relates to a konjac glucomannan air purifying nano screen window and a preparation method thereof. The preparation method of the konjac glucomannan air purifying nano screen window comprises the following steps of preparing a film stock solution, preparing a non-woven fabric, making a spinning solution, and preparing a nano window screen by using an electrospinning machine. The konjac glucomannan air purifying nano screen window provided by the invention adopts konjac glucomannan as a main material, and has higher tensile strength and higher antibacterial effect than a polyethylene material, and can keep the indoors clean and hygienic for a long time; nano cobalt ferrite is added to enhance the adsorption effect of the screen window to particles, enhance the weather resistance and toughness, improve the weathering resistance and prolong the service life; the non-woven fabric and a filter membrane layer are both made of natural ingredients, so that the screen window can becompletely biodegraded after being discarded, and is environmentally friendly and low carbon. The konjac glucomannan air purifying nano screen window provided by the invention has the advantages of small and uniform pore size, large tensile strength, good toughness, good gas permeability, anti-aging, convenience in material obtaining, low price and long service life.

Owner:FUJIAN AGRI & FORESTRY UNIV

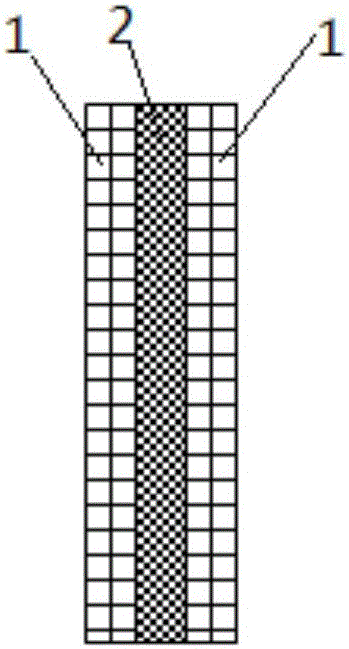

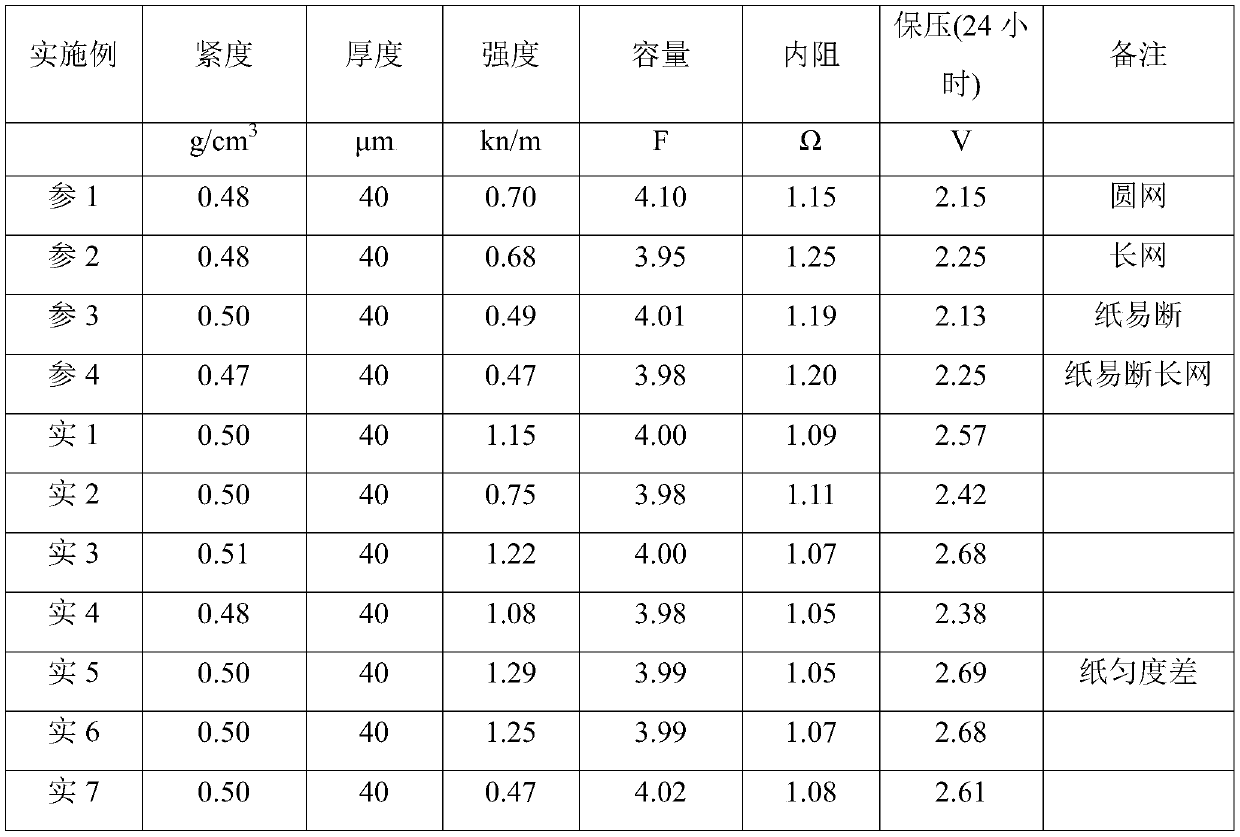

Super capacitor paper and preparation method and application thereof

InactiveCN111254745AHigh strengthHigh porosityHybrid capacitor separatorsSpecial paperSupercapacitorPaper sheet

The invention provides super capacitor paper. The super capacitor paper is composed of the components in percentage by weight: 5-30% of PET fibers, 70-95% of tencel fibers and the balance being a drystrength agent; the dry strength agent accounts for 0.3-1% of the total weight of the PET fibers and the tencel fibers; the weight ratio of PET fiber pulp is 5-30%; if the weight ratio is higher than30%, the tensile strength of a paper sheet is low and cannot meet the requirements of super capacitor processing; when the weight ratio is lower than 5%, the tearing strength and the elongation of thepaper sheet are low, so that the paper sheet is difficult to meet the strength requirement in the assembly process of the super capacitor and has adverse effects on the loss, and part of the fine denier PET fibers can improve the loss performance of the super capacitor.

Owner:浙江辰龙特种材料有限公司

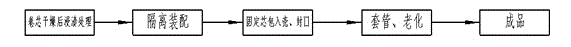

High specific volume electrolytic capacitor roll core isolation assembling method

InactiveCN104882280AEradication of explosive phenomenaDoes not increase internal resistanceElectrolytic capacitorsInternal resistanceEngineering

The invention discloses a high specific volume electrolytic capacitor roll core isolation assembling method; a dipped roll core is isolated from a fixing liquid, and a specific method is to wrap a capacitor paper layer outside the dipped roll core, so black glue and the capacitor roll core can be isolated in the fixing liquid, and copper, iron, chloride ion and impurity in the black glue cannot dip into an anode and a cathode of the capacitor roll core, thus preventing conduction and reaction under high temperature, hydrogen cannot be generated, so blast phenomenon can be eradicated. The capacitor paper is low in tightness, high in intensity, small and uniform in hole diameter, has small accident loss probability in usage, and capacitor internal resistance is not added; the leakage current is small, energy storage effect is good, and capacitor production can be convenient.

Owner:NANTONG HUAYU ELECTRONICS

A foamed aluminum sound-absorbing panel that can effectively reduce urban traffic noise and its preparation method

ActiveCN108608687BIncreased through-hole porosityReduced via hole sizeTransportation and packagingMetal-working apparatusSodium bicarbonateEpoxy

The invention discloses an aluminum foam sound-absorbing panel that can effectively reduce urban traffic noise. It comprises an aluminum plate body, and foamed aluminum materials are pasted on both sides of the aluminum plate body. The foamed aluminum material includes the following raw materials: aluminum chips, deionized Water, ultrapure water, absolute ethanol, dispersant, plasticizer, adhesive, foaming agent; the adhesive is composed of the following raw materials: starch, polyvinyl alcohol, polyurethane, butyl rubber, vinyl acetate resin, water-based Silicone epoxy resin; blowing agent consisting of the following raw materials: azodicarbonamide, sodium bicarbonate, carbon black, n-hexane, trichlorofluoromethane, sodium lauryl sulfate; through-hole porosity of aluminum foam material 98.5%-99.8%, the average hole diameter is 0.75-0.85mm; the thickness of the foamed aluminum material pasted on both sides of the aluminum plate body is 20-25mm; the sound absorption coefficient of the foamed aluminum sound-absorbing board is 0.88-0.92. The invention solves the technical problems of non-uniform through-hole diameter, large through-hole diameter and low through-hole porosity in the existing aluminum foam material.

Owner:常州市驰义塑胶制品有限公司

A kind of high strength agm separator

A high-strength AGM separator plate is disclosed. The separator plate is prepared from, by mass, 1-3% of modified nanometer silicon nitride, 3-5% of polyoxyethylene, 5-10% of modified basalt mineral fibres, 10-15% of water-soluble poly(vinyl alcohol) fibers, and 30-35% of high-alkalinity glass fibers the diameter of which is 0.5-0.7 mum, with the balance being high-alkalinity glass fibers the diameter of which is 3-4 mum. A traditional pure glass fiber formula is abandoned, and a raw material formula of the separator plate is optimized. The separator plate is scientific and reasonable in formula, good in mechanical strength and heat radiation performance, fine and uniform in pore size, proper in porosity, and capable of effectively preventing short circuits of cells and facilitating prolongation of lifetimes of cells.

Owner:ZHEJIANG CHANGTONG SCI & TECH

A kind of production method of high-strength AGM clapboard

ActiveCN106299202BRaise the zeta potentialIncrease repulsionMaterial nanotechnologyCell component detailsPorosityMaterials preparation

The invention discloses a production method of a high-strength AGM partition plate. The production method comprises the following steps of (1) preparation of modified nanometer silicon nitride; (2) preparation of modified basalt mineral fiber; (3) material preparation; (4) pulping; (5) papermaking and forming; (6) primary drying; (7) rolling; and (8) secondary drying. The production method of the high-strength AGM partition plate is simple in step, low in production cost and high in maneuverability, the produced partition plate is high in mechanical strength and heat dissipation performance, fine and uniform in aperture and moderate in porosity size, and lead dendrite can be prevented from penetrating through the partition plate to cause chronic short circuit.

Owner:ZHEJIANG CHANGTONG SCI & TECH

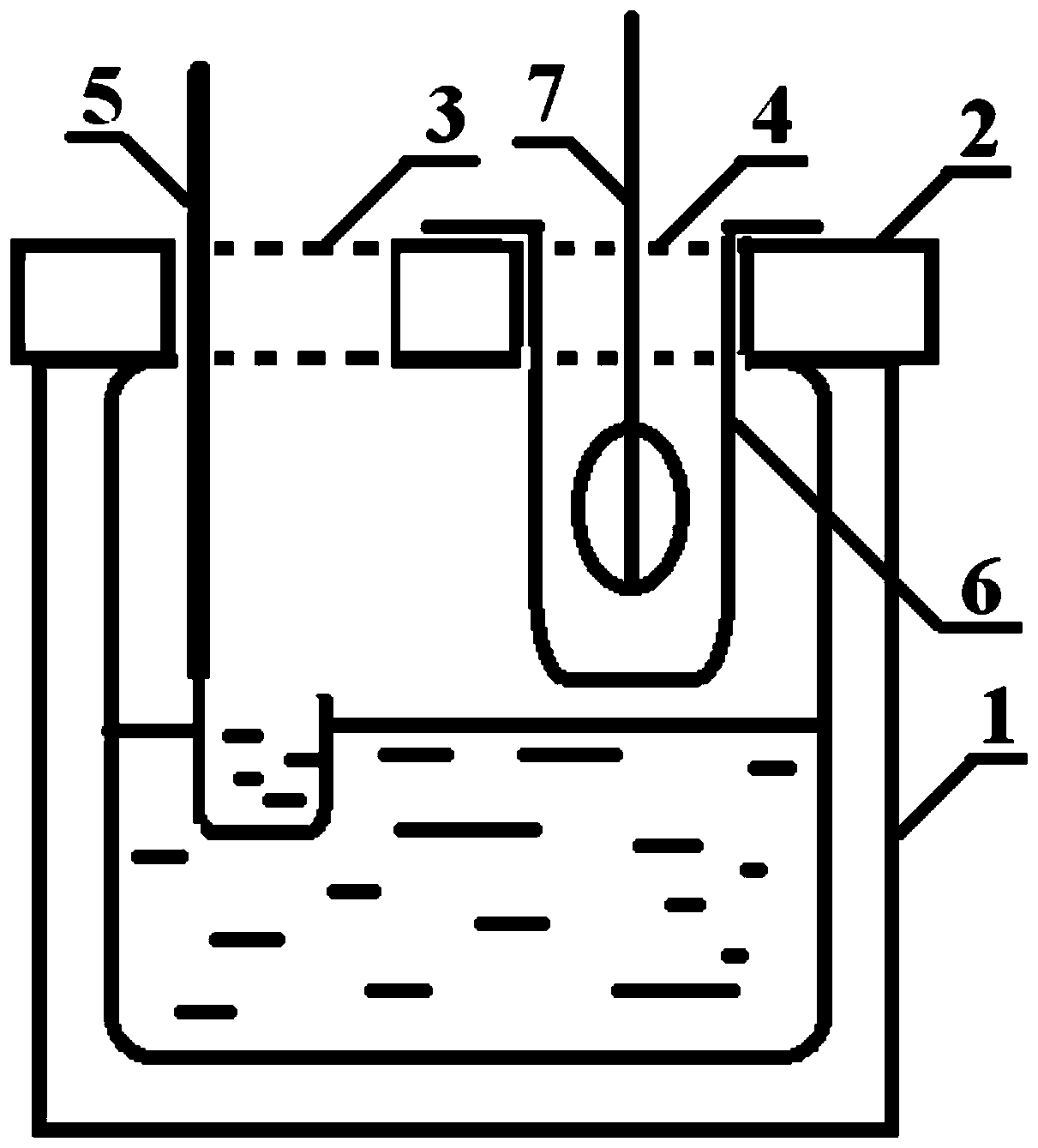

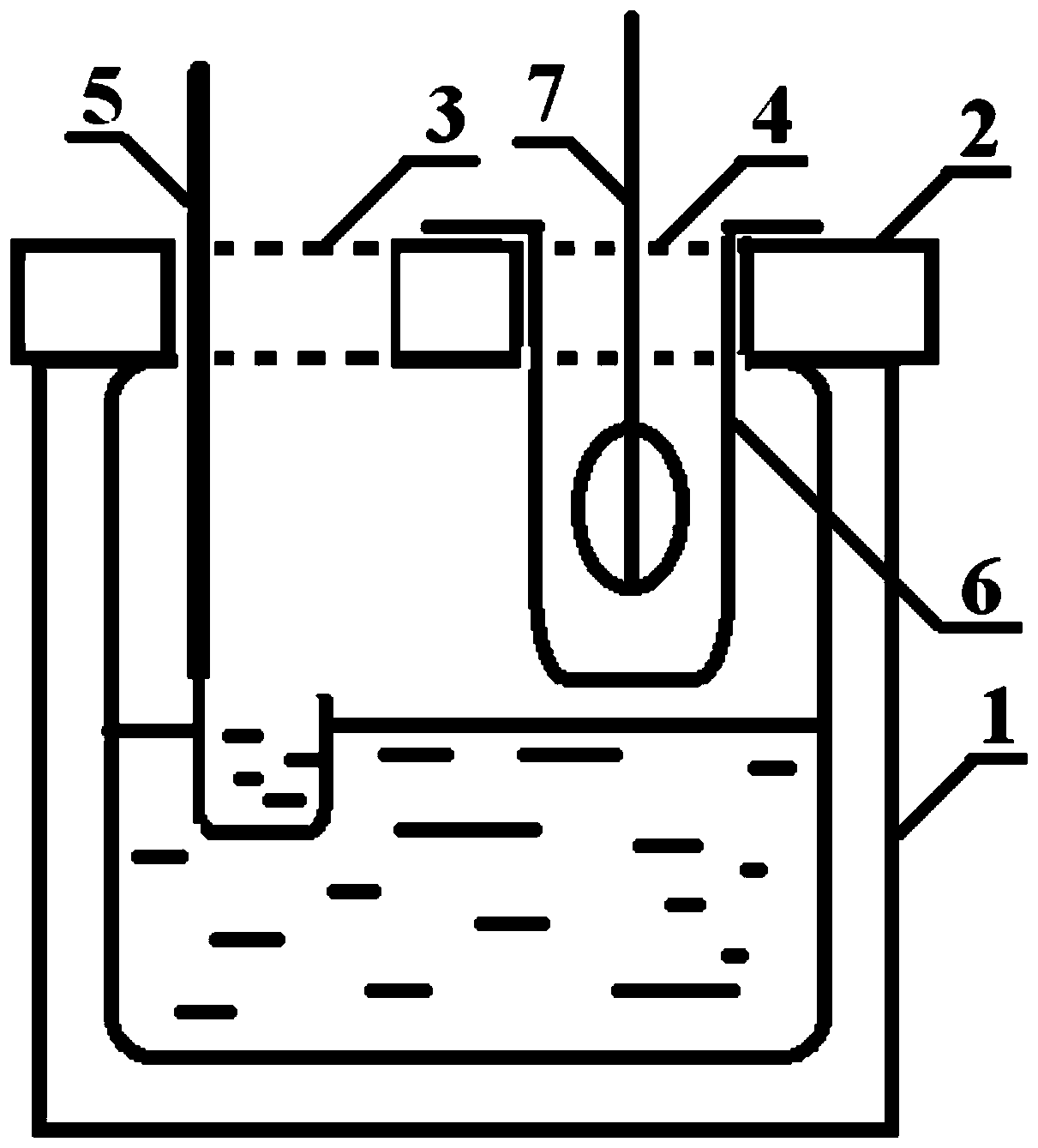

Foaming device and method for a porous magnesium alloy

The present invention provides a porous magnesium alloy foaming device, comprising: a melting furnace; a furnace cover arranged on the top of the melting furnace, the furnace cover is provided with a first through hole and a second through hole; A pipetting spoon with a through hole; a foaming mold fixed in the second through hole, the foaming mold is suspended inside the melting furnace; a stirrer arranged in the foaming mold. The foaming device provided by the invention can realize foaming in a short process, saves the addition of tackifier and heat preservation and foaming, and does not stir for a long time in a semi-solid state. On the one hand, it will not change the existing alloy composition, and has little impact on product performance. On the other hand, the foaming process is suitable for most magnesium alloys and has good formability. On the other hand, the foaming time is shortened and the foaming efficiency is improved; and the structure design of the melting furnace and the foaming mold can make the foaming agent decompose. The speed matches the cooling and viscosity increasing speed of the magnesium alloy liquid, so as to prevent the precipitated bubbles from aggregating and overflowing, and the obtained porous magnesium alloy has a small and uniform pore size.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of enzyme-modified freeze-dried instant tofu and its preparation method

ActiveCN109527113BLow solid content requirementsHigh yieldCheese manufactureFood scienceBiotechnologyFreeze-drying

The invention discloses an enzyme-modified freeze-dried instant tofu and a preparation method thereof. This method can control the freezing deterioration of tofu, and the product is still smooth and delicate after rehydration, which is suitable for the development of convenience food. The method comprises the following steps: soaking beans, beating, filtering and removing slag, boiling, modifying soybean milk, coagulating, quick-freezing, and vacuum freeze-drying. The process of the method is simple, and the pore diameter of the prepared freeze-dried tofu section is small and uniform, which is only 1 / 5-1 / 2 of that of ordinary freeze-dried tofu; there is no crack after rehydration, and the hardness is only 40-70% of the latter, soft and soft. Moderate hardness, fine cross-section, few pores, pore size is only 1 / 6-1 / 4 of the pore size of ordinary tofu, the taste is close to that of fresh tofu, the solid content of soy milk is low, the yield of tofu is high, and raw materials are saved.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com