Cell separator manufacturing method, cell separator and alkaline storage battery using said separator

A manufacturing method and storage battery technology, which are applied in the manufacture of battery separators, battery separators and alkaline storage batteries using such separators, can solve the problems of increased battery impedance and difficulty in uniform sulfonation as a whole, and achieve The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0068] A slurry containing commercially available spherical nickel hydroxide powder with an average particle size of about 15 μm, a small amount of fluororesin powder, and conductive substance powder is coated on a nickel foil with a thickness of 30 μm having numerous bumps and concaves by a known method. , was dried by a known method and then pressed to obtain a positive electrode with a thickness of 400 μm. By cutting, a thin and long positive electrode with a width of 40mm, a length of 170mm and a theoretical capacity of about 1700mAh was produced.

manufacture example 2

[0070] Except using common foamed metal with a thickness of 0.7 mm as the positive electrode and cutting it into a width of 40 mm and a length of 85 mm, the positive electrode was made in the same way as in the positive electrode manufacturing example 1.

[0071] (Negative electrode production example 1)

[0072] Contain commercially available AB with an average particle size of about 10 μm 5 An aqueous solution slurry of a hydrogen storage alloy was applied by a known method to a 30 μm thick nickel foil having numerous unevennesses, dried by a known method and then pressed to obtain a negative electrode with a thickness of 240 μm. Then it is cut into a long-sized electrode with a width of 40 mm and a length of 230 mm to make a negative electrode with a theoretical capacity of about 2400 mAh.

[0073] (Negative electrode production example 2)

[0074] Except for using a common slurry-type hydrogen storage alloy negative electrode with a thickness of 0.35 mm and cutting it in...

Embodiment 1

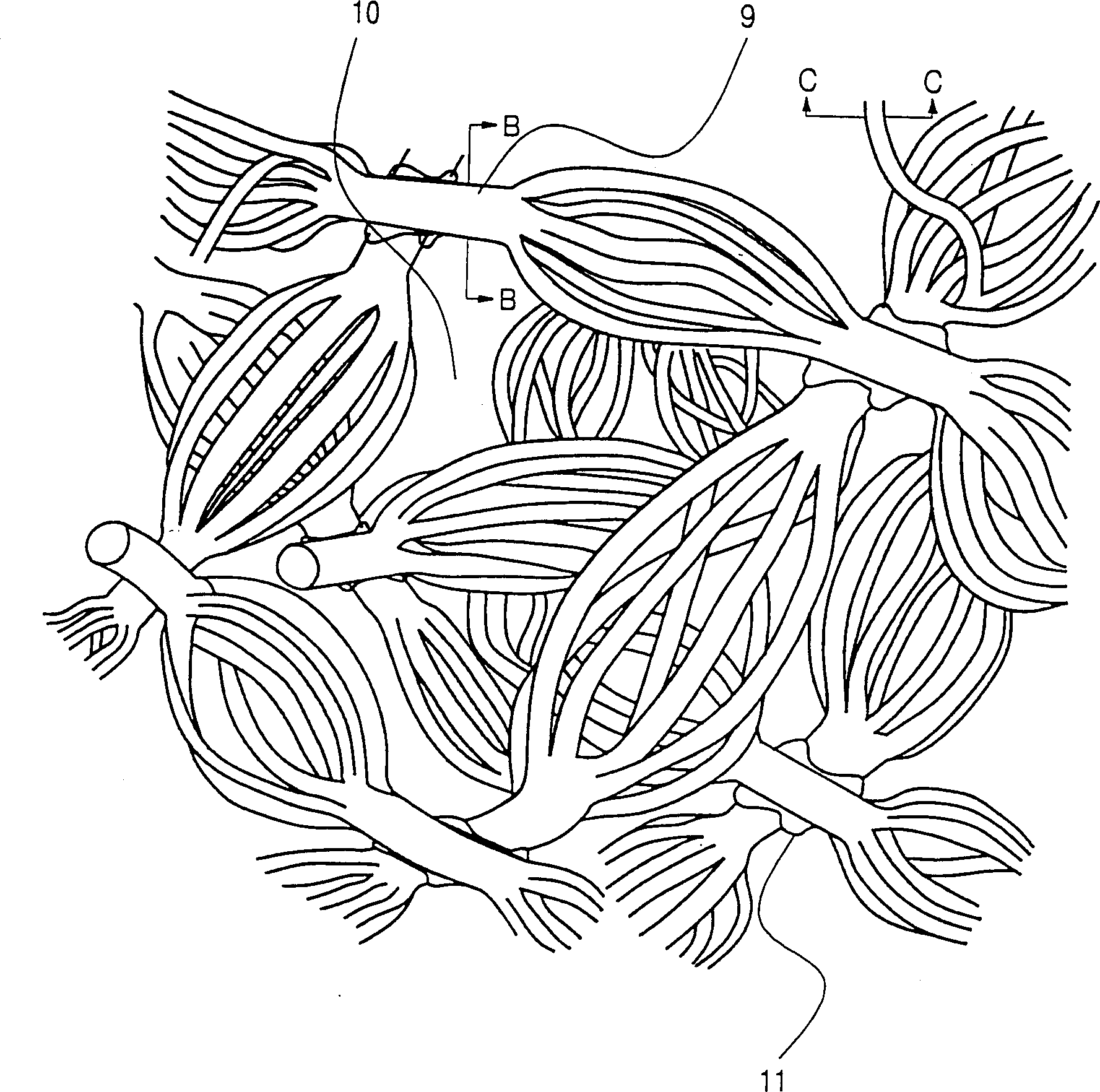

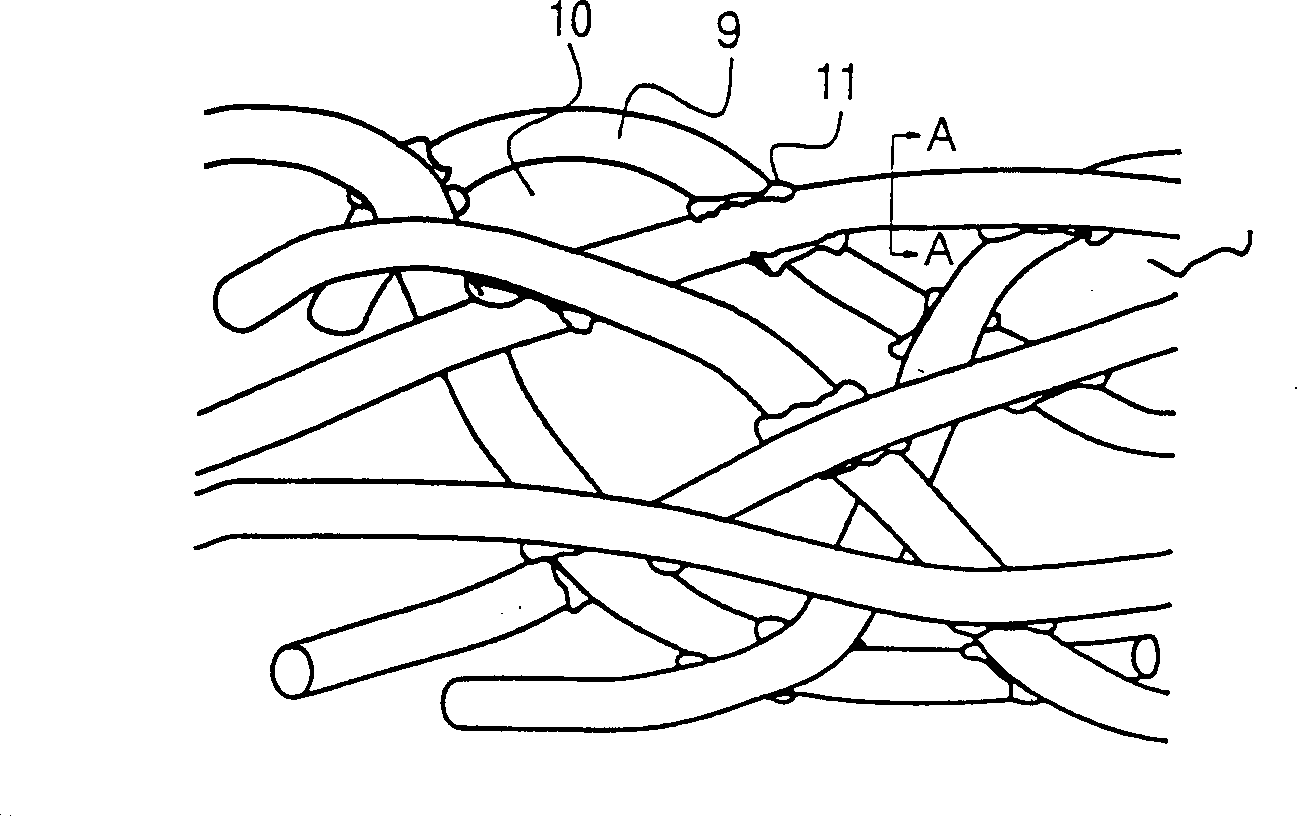

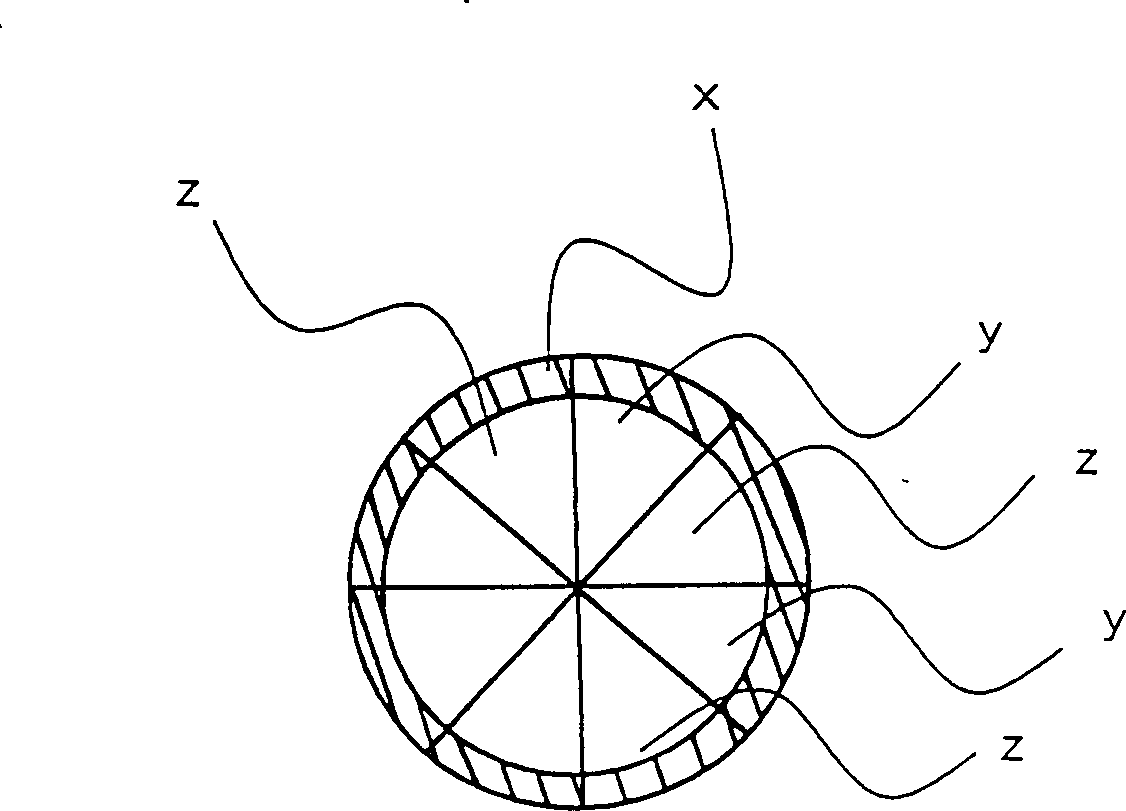

[0076] image 3 The microfibers shown in which polyolefin fibers and polyethylene fibers are divided into 8 strands are integrated bundled fibers, that is, polyolefin microfibers and polyethylene microfibers are alternately arranged in the circumferential direction of the cross section of the bundled fibers. Fibers (diameter 10 μm) are joined with low-melting polyethylene at the intersections, and the average thickness is 100 μm, the porosity is 60%, and the tensile strength is 6.2 kg / cm 2 of non-woven fabrics. By impacting the non-woven fabric with a high-speed water flow, each ultra-fine fiber is divided at the unjoined part of the bundled fibers constituting the non-woven fabric, and then passed between hot rolls at about 80°C to make the thickness of the non-woven fabric Adjust to 70 ~ 80μm, get figure 1 The final hoop-shaped nonwoven is shown. Then the final hoop-shaped non-woven fabric is placed on the Figure 5 Expose for about 10 seconds in the atmosphere of a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com