A kind of enzyme-modified freeze-dried instant tofu and its preparation method

A production method and modification technology, which are applied in the field of enzyme-modified freeze-dried instant tofu and its production, can solve the problems of high production conditions, increased viscosity of soybean milk, difficult equipment cleaning, etc. Effects requiring low solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

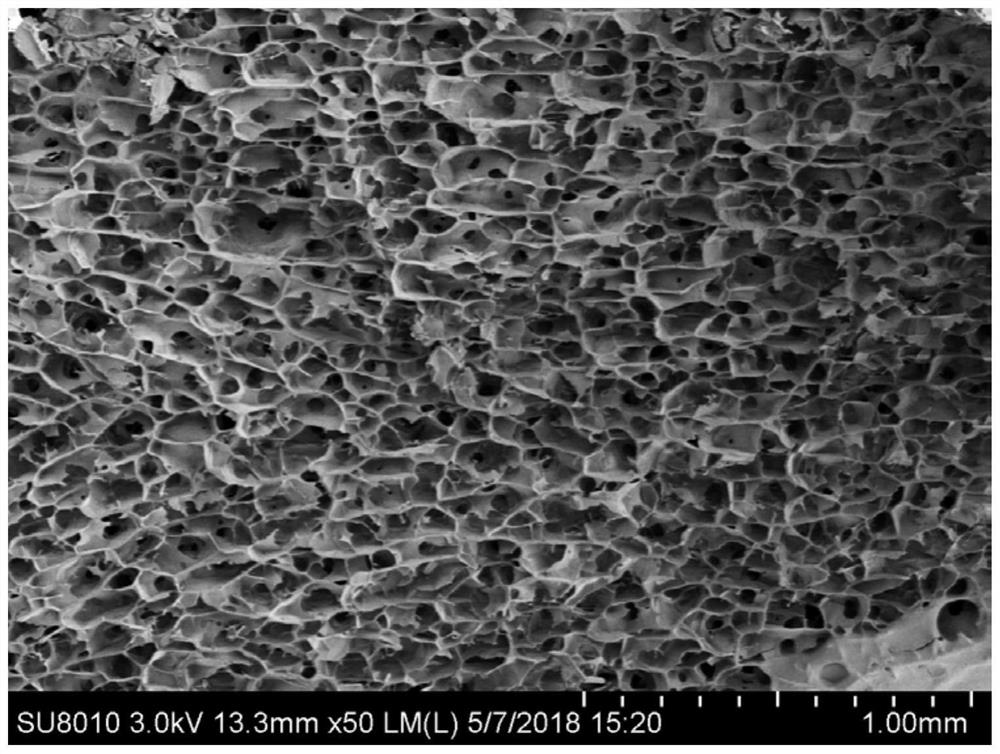

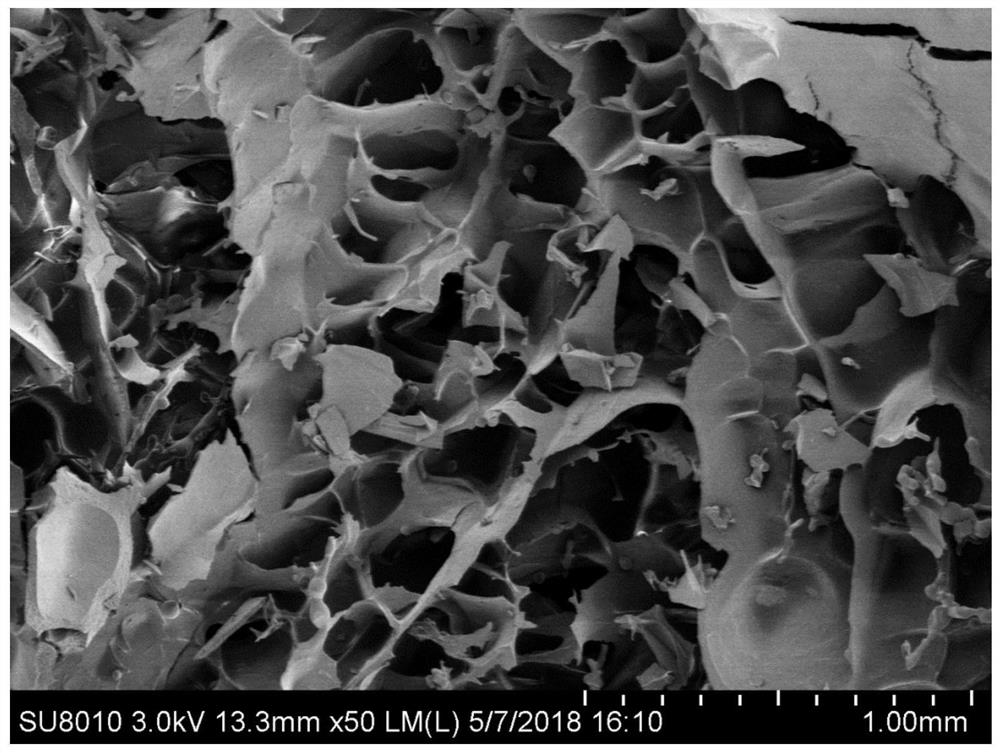

Embodiment 1

[0039] After the soybeans are fully soaked, beating at a mass ratio of 1:7, adding a defoamer and standing for 5 minutes, removing the bean dregs to obtain soybean milk with a solid content of 9°Brix. Heat the soy milk, when the central temperature reaches 95°C, maintain it for 5 minutes. After boiling the pulp, add 1.6% gelatin aqueous solution of soybean milk quality (the consumption of water is 8 times of gelatin quality). After the soymilk is cooled to about 45°C, add 0.02% of the mass of soymilk neutral protease (enzyme activity is 0.8AU / g), stir evenly and immediately add 0.2U / g transglutaminase (enzyme activity is 200U / g), Then put it in a 45°C water bath for 50min to carry out enzyme modification. After taking it out, add 0.3% D-glucono-δ-lactone in the mass of soybean milk, and put it in a water bath at 90°C for 30 minutes to make the soybean milk coagulate. The tofu obtained after heating and coagulating as described above was subjected to cooling treatment at 4°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com