Porous alumina preparation method

A technology of porous alumina and alumina powder, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of high impurity content, low material strength, irregular pores, etc., and achieve low impurity content and low impurity content in products , Small and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

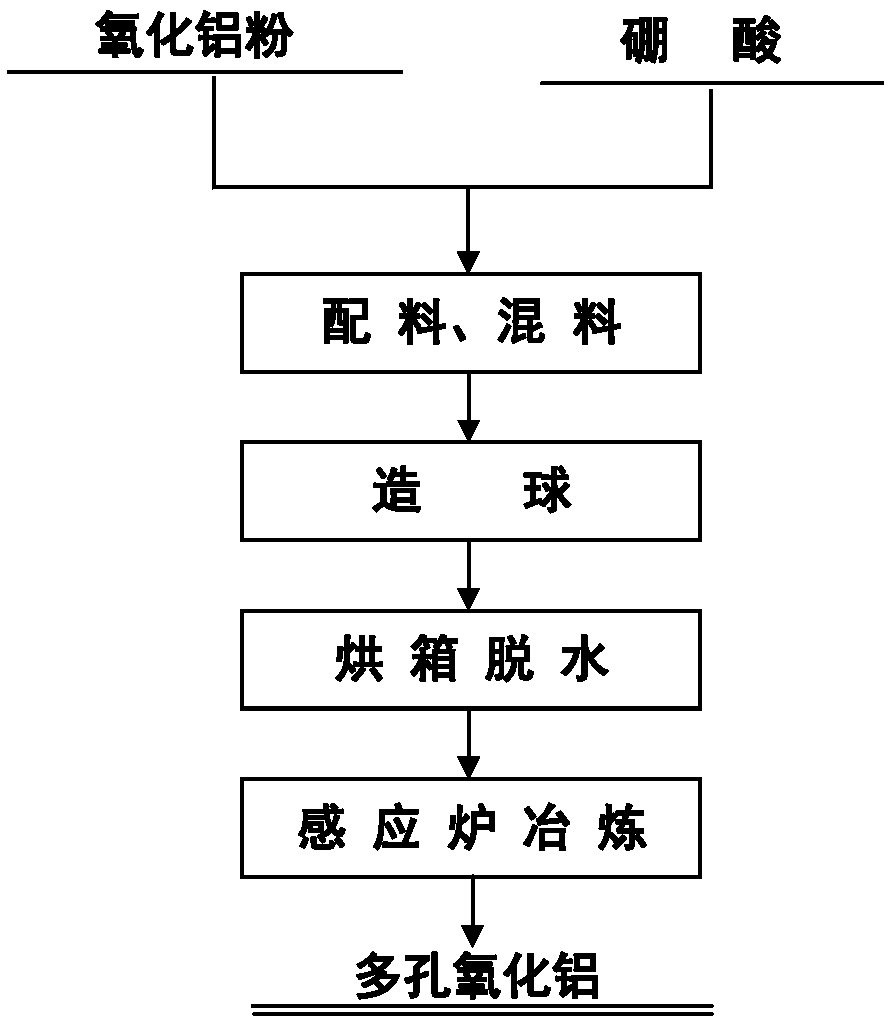

[0029] 1. Batch and mix boric acid powder and alumina powder according to a certain quality: 30% boric acid, 70% alumina;

[0030] 2. Add 7% water of the mass of the raw material to the raw material, further mix it and press it into a pellet under a pelletizing pressure of 20 MPa;

[0031] 3. Dry the pressed pellet wet material, the drying temperature is 100°C, and the drying time is 9 hours;

[0032] 4. Put the dried pellets into the induction furnace for high temperature (1500°C) smelting for 40 minutes;

[0033] 5. After the smelting is finished, cool the product to room temperature in air.

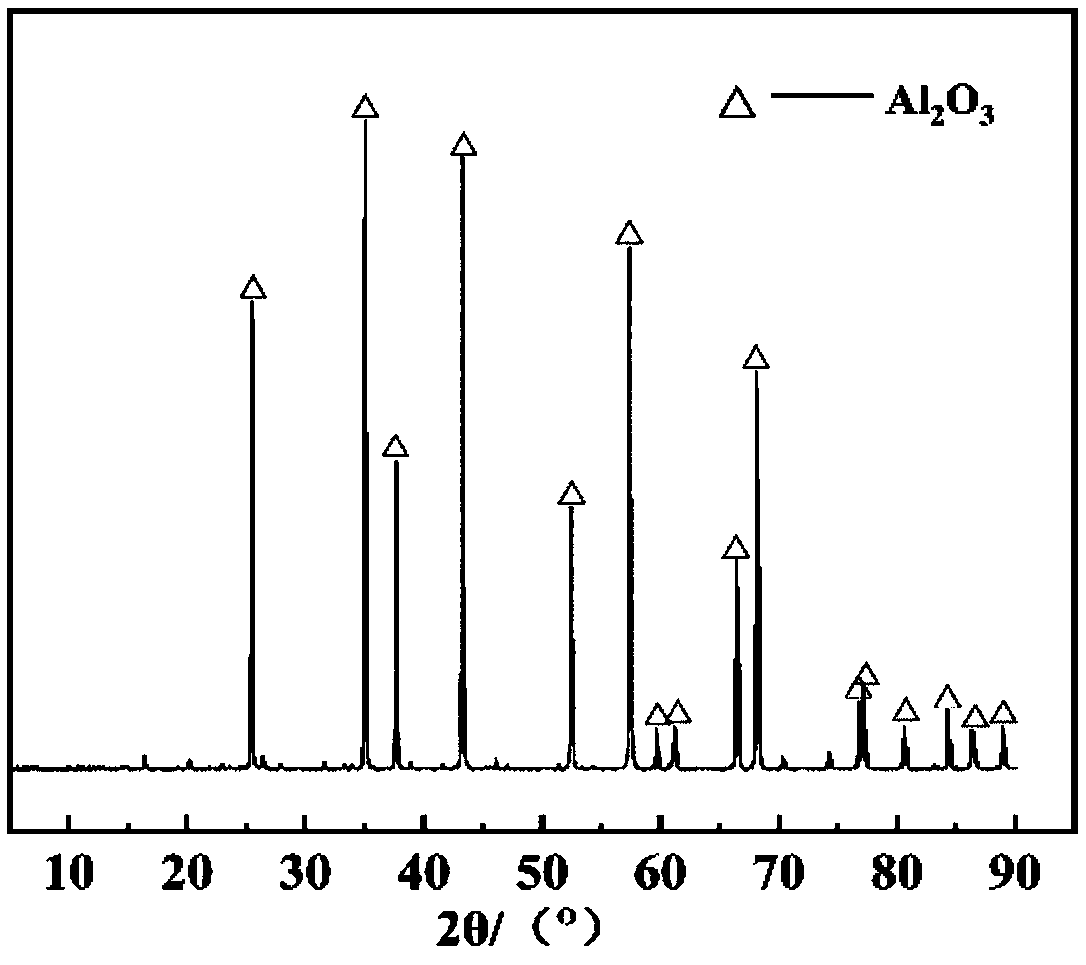

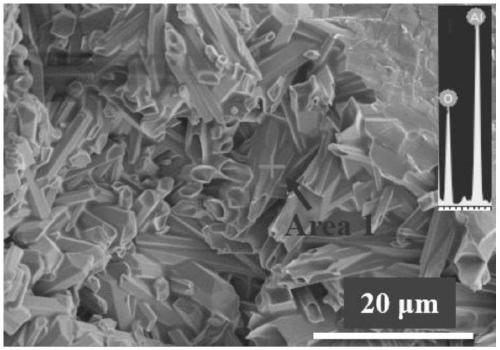

[0034] from figure 1 -XRD and figure 2 -EDS analysis results show that the smelted product is high-purity alumina with almost no other impurities. It can be seen from the scanning electron microscope image that the obtained product is porous, and the pore size is uniformly distributed, and the particle size is about 1 μm.

Embodiment 2

[0036] 1. Batch and mix boric acid powder and alumina powder according to a certain quality: 40% boric acid, 60% alumina;

[0037] 2. Add 10% water of the mass of the raw material to the raw material, further mix it and press it into a pellet under a pelletizing pressure of 20 MPa;

[0038] 3. Dry the pressed pellet wet material, the drying temperature is 100°C, and the drying time is 9 hours;

[0039] 4. Put the dried pellets into the induction furnace for high temperature (1600°C) smelting for 40 minutes;

[0040] 5. After the smelting is finished, cool the product to room temperature in air.

Embodiment 3

[0042] 1. Batch and mix boric acid powder and alumina powder according to a certain quality: 50% boric acid, 50% alumina;

[0043] 2. Add 15% water of the mass of the raw material to the raw material, further mix it and press it into a pellet under a pelletizing pressure of 10 MPa;

[0044] 3. Dry the pressed pellet wet material, the drying temperature is 110°C, and the drying time is 8 hours;

[0045] 4. Put the dried pellets into the induction furnace for high temperature (1800°C) smelting for 40 minutes;

[0046] 5. After the smelting is finished, cool the product to room temperature in air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com