Ceramic tile polishing mud and kieselguhr-based microporous thermal insulation material as well as preparation method thereof

A technology of thermal insulation materials and polishing mud, which is applied in the field of building materials, can solve the problems of low space wall strength, inability to adapt to industrial production, and low damage rate, and achieve the effects of improving acid-base environment, small pore size, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

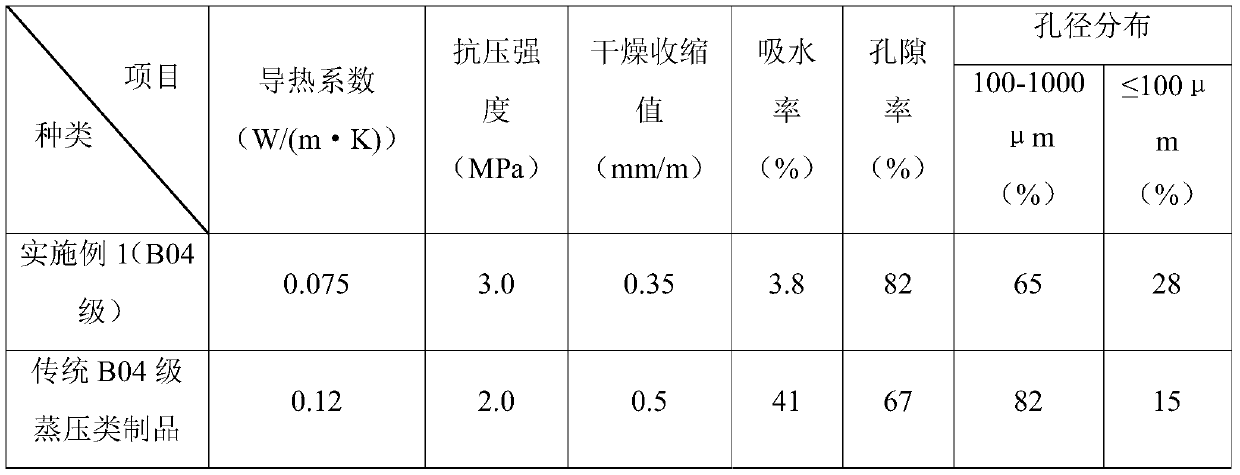

Embodiment 1

[0058] (1) Wash the ceramic tile polishing mud with water in the sedimentation tank, stir for 5 minutes, let it stand for 1 hour, remove the surface water, repeat twice, sieve the bottom mud to remove large particles in the mud, put it into the pulping tank, and get Modified ceramic tile polishing mud;

[0059] (2) Mix fluorine gypsum and quicklime evenly according to the mass ratio of 6:1, and after crushing, sieving and grinding, make the particle size 0.30mm to obtain modified fluorine gypsum;

[0060] (3) Carrying out dehydration and roasting the calcium carbide slag, the roasting temperature is 550°C, the roasting time is 1h, and the modified calcium carbide slag is obtained by grinding to a particle size of 0.18mm;

[0061] (4) Mix the modified ceramic tile polishing mud, diatomaceous earth, and modified fluorogypsum in a mass ratio of 6:2:3 to obtain a siliceous component, and set aside;

[0062] Mix quicklime and modified calcium carbide slag evenly at a mass ratio of...

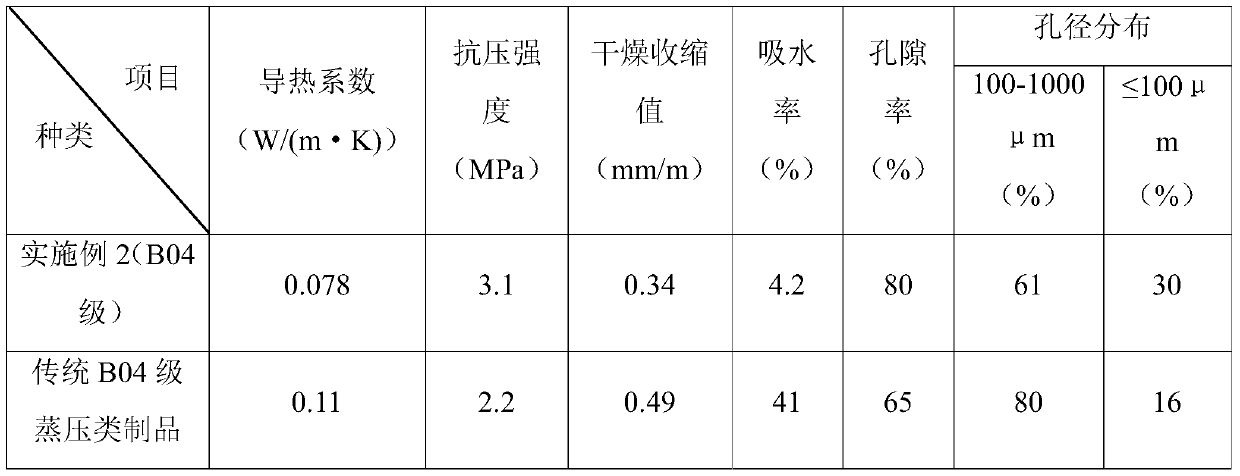

Embodiment 2

[0079] (1) Wash the ceramic tile polishing mud in the sedimentation tank, stir for 10 minutes, let it stand for 0.5 hours, remove the surface water, repeat 3 times, sieve the bottom mud, remove the large particles in the mud, put it into the pulping tank, Obtain modified ceramic tile polishing mud;

[0080] (2) Mix fluorine gypsum and quicklime uniformly at a mass ratio of 5:1, and after crushing, sieving and grinding, make the particle size 0.20mm to obtain modified fluorine gypsum;

[0081] (3) Carrying out dehydration and roasting the calcium carbide slag, the roasting temperature is 350°C, the roasting time is 2h, and the modified calcium carbide slag is obtained by grinding to a particle size of 0.15mm;

[0082] (4) Mix the modified ceramic tile polishing mud, diatomaceous earth, and modified fluorogypsum in a mass ratio of 10:3:6 to obtain a siliceous component, and set aside;

[0083] Mix quicklime and modified calcium carbide slag evenly at a mass ratio of 1:6 to obta...

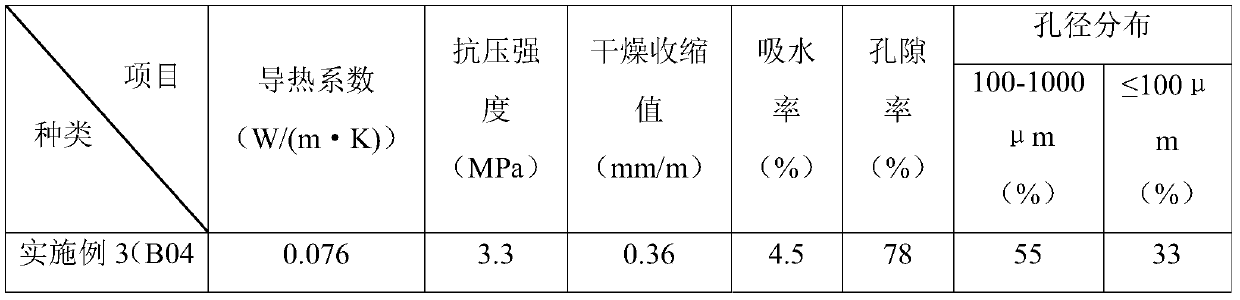

Embodiment 3

[0100] (1) Wash the ceramic tile polishing mud in the sedimentation tank, stir for 7 minutes, let it stand for 0.8 hours, remove the surface water, repeat 4 times, sieve the bottom mud, remove large particles in the mud, put it into the pulping tank, Obtain modified ceramic tile polishing mud;

[0101] (2) Mix fluorine gypsum and quicklime uniformly at a mass ratio of 10:1, and after crushing, sieving and grinding, make the particle size 0.15mm to obtain modified fluorine gypsum;

[0102] (3) Carrying out dehydration and roasting the calcium carbide slag, the roasting temperature is 600°C, the roasting time is 0.5h, and the modified calcium carbide slag is obtained by grinding to a particle size of 0.30mm;

[0103] (4) Mix the modified ceramic tile polishing mud, diatomaceous earth, and modified fluorogypsum in a mass ratio of 7:2:5 to obtain a siliceous component, and set aside;

[0104] Mix quicklime and modified calcium carbide slag evenly at a mass ratio of 1:5 to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com