Carbon fiber automobile air conditioner filter

A technology for automotive air conditioners and filters, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation methods, which can solve the problems of unsatisfactory filtration performance and achieve good chemical resistance, small pore size, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

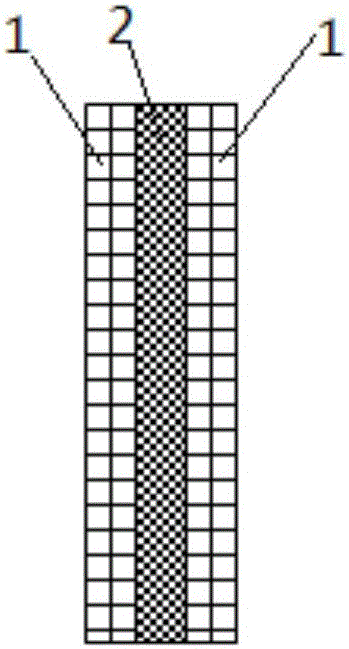

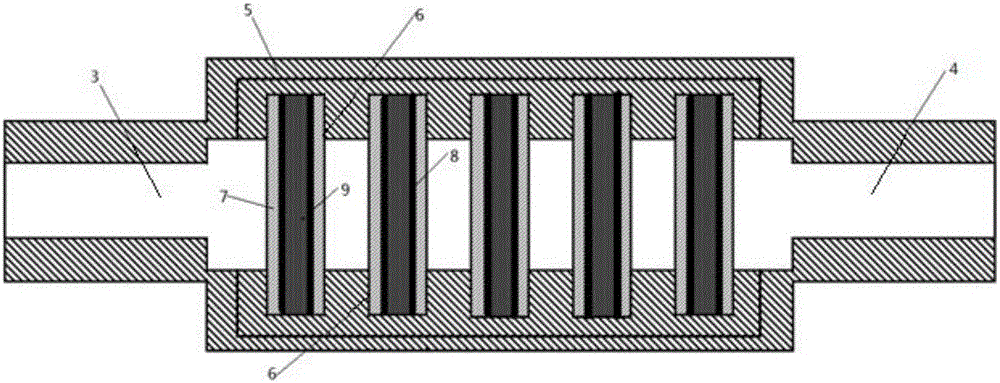

[0020] Such as figure 1 Shown, a kind of portable detachable car air conditioner filter with multi-stage carbon fiber adsorption layer structure, comprises filter box 5, and described filter box 5 has air inlet 3 and air outlet 4, and described filter box 5 interior is set There are five slots 6, each slot 6 is inserted with a filter frame 7, the two sides of the filter frame 7 are respectively provided with magnetic suction strips 8, and a filter core is arranged between the magnetic suction strips 8 on both sides Material 9, the filter core material 9 includes a non-woven fabric layer 1 that is imitated by mixing organic fibers and activated carbon fiber filaments on both sides of the surface and an activated carbon fiber felt filter adsorption layer 2 in the middle.

[0021] The preparation of the portable and detachable automotive air-conditioning filter with a multi-stage carbon fiber adsorption layer structure first prepares a carbon fiber filter core material with a lam...

Embodiment 2

[0026] Such as figure 1 Shown, a kind of portable detachable car air conditioner filter with multi-stage carbon fiber adsorption layer structure, comprises filter box 5, and described filter box 5 has air inlet 3 and air outlet 4, and described filter box 5 interior is set There are five slots 6, each slot 6 is inserted with a filter frame 7, the two sides of the filter frame 7 are respectively provided with magnetic suction strips 8, and a filter core is arranged between the magnetic suction strips 8 on both sides Material 9, the filter core material 9 includes a non-woven fabric layer 1 that is imitated by mixing organic fibers and activated carbon fiber filaments on both sides of the surface and an activated carbon fiber felt filter adsorption layer 2 in the middle.

[0027] The preparation of the portable and detachable automotive air-conditioning filter with a multi-stage carbon fiber adsorption layer structure first prepares a carbon fiber filter core material with a lam...

Embodiment 3

[0031] Such as figure 1 Shown, a kind of portable detachable car air conditioner filter with multi-stage carbon fiber adsorption layer structure, comprises filter box 5, and described filter box 5 has air inlet 3 and air outlet 4, and described filter box 5 interior is set There are five slots 6, each slot 6 is inserted with a filter frame 7, the two sides of the filter frame 7 are respectively provided with magnetic suction strips 8, and a filter core is arranged between the magnetic suction strips 8 on both sides Material 9, the filter core material 9 includes a non-woven fabric layer 1 that is imitated by mixing organic fibers and activated carbon fiber filaments on both sides of the surface and an activated carbon fiber felt filter adsorption layer 2 in the middle.

[0032] The preparation of the portable and detachable automotive air-conditioning filter with a multi-stage carbon fiber adsorption layer structure first prepares a carbon fiber filter core material with a lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com