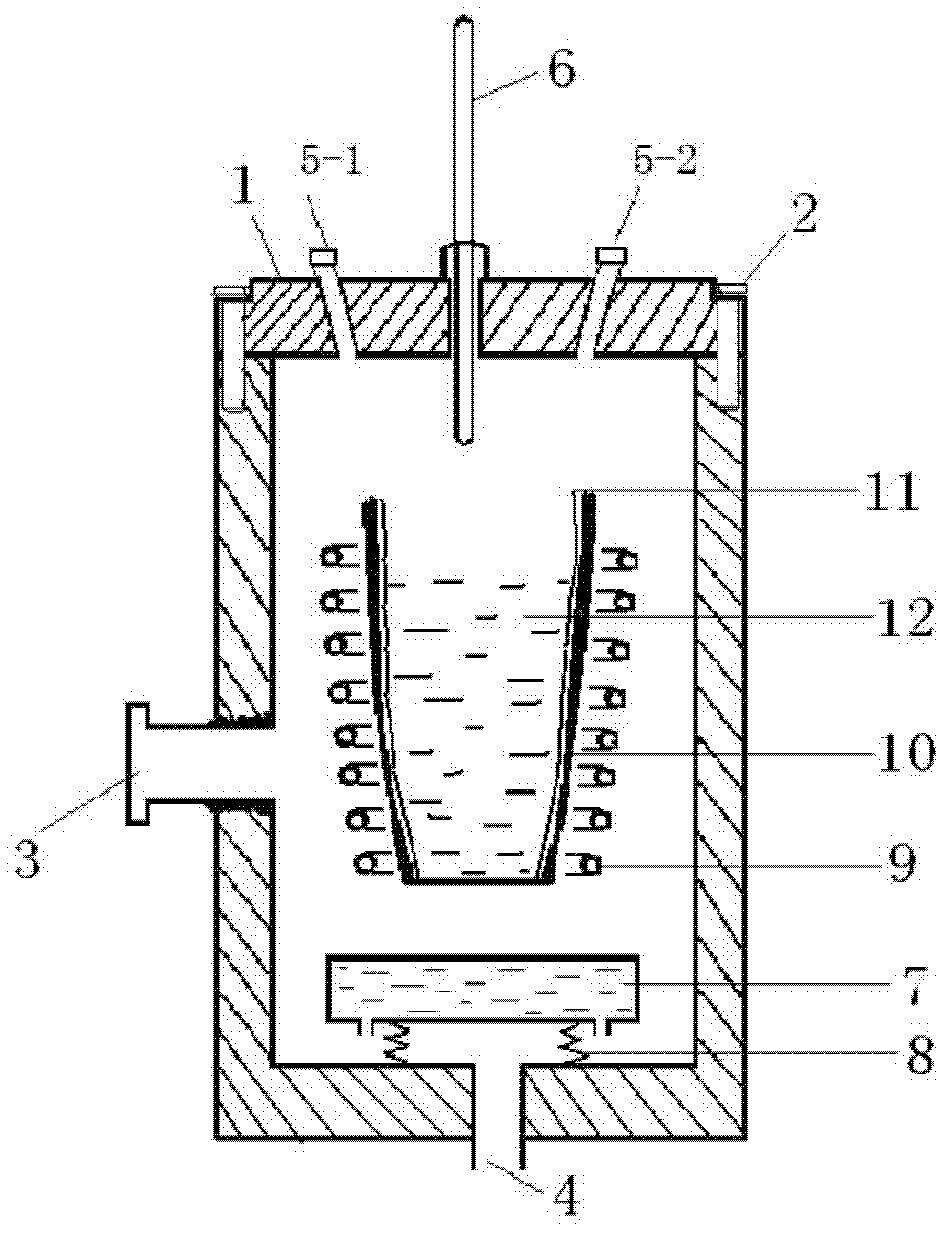

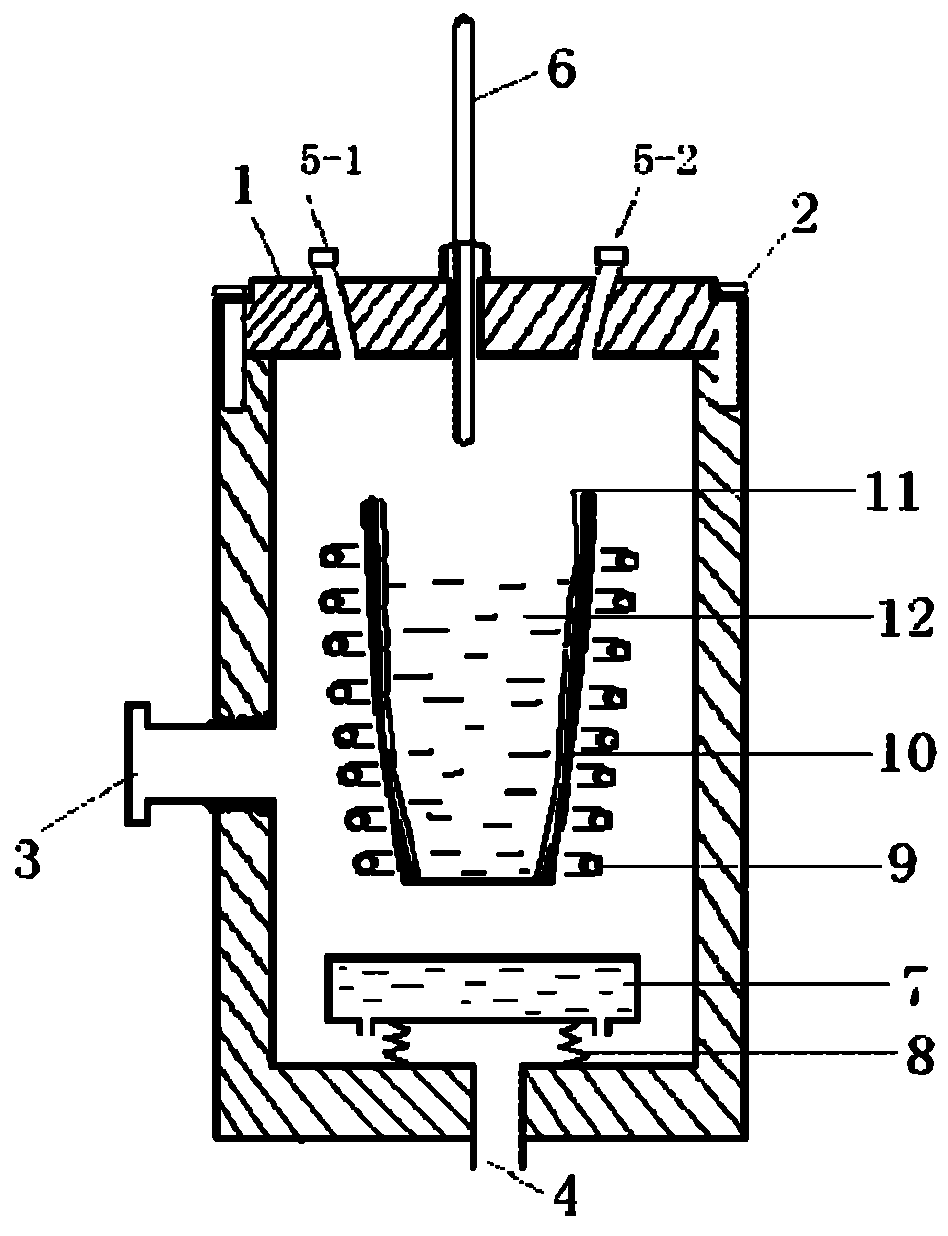

Vacuum-positive pressure smelting and solidifying equipment

A vacuum and equipment technology, applied in the field of vacuum-positive pressure smelting directional solidification equipment, can solve the problems of poor controllability, uneven porous metal structure, etc., and achieve the effect of simple operation, uniformity and controllability, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of High Strength Oriented Porous Copper

[0034] The device is in the vertical state of the smelting crucible and the directional solidification mold 10. Open the sealing flange 1, put metal copper into the smelting crucible and the directional solidification mold 10, close and tighten the sealing flange 1, and lower the water-cooled crystallizer to the melting crucible and the directional solidification mold 10. The bottom of the directionally solidified casting mold 10 is separated. Turn on the water cooling system of the device, turn on the vacuum system to evacuate the whole device through interface 3, when the pressure in the furnace reaches 3×10 -2 Turn on the power supply of the heating coil 9 of the smelting furnace at Pa, start to heat the metal material in the smelting crucible and directional solidification mold 10 and observe the smelting process through the observation window I5-1 or the observation window II5-2. At this stage, what t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com