High specific volume electrolytic capacitor roll core isolation assembling method

A technology of electrolytic capacitors and assembly methods, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of low pass rate of high specific volume aluminum electrolytic capacitors, high manufacturing cost, explosion of high specific volume aluminum electrolytic capacitors, etc., and achieve unexpected loss The effect of small probability, low paper tightness and small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

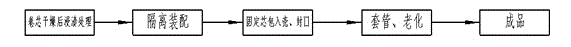

[0027] Such as figure 1 As shown, a high specific capacitance electrolytic capacitor roll core isolation assembly method includes the following steps:

[0028] (1) Impregnation treatment after the core is dried: dry the wound cylindrical core according to the conventional steps and put it into the fixative solution for 3~5 minutes;

[0029] (2) Isolation assembly: According to the size of the core obtained in step (1), wrap a layer of capacitor paper on the outside of the core. The diameter of the bottom of the capacitor paper is consistent with the cross-sectional diameter of the core, and the top of the capacitor paper is located under the side surface of the core. 1 / 2~4 / 5;

[0030] (3) Fixing the core into the shell and sealing: according to the conventional process, fix the packaged core into the corresponding capacitor shell and seal it;

[0031] (4) Casing and aging: According to the conventional process steps, put the sealed capacitor into the aluminum tube and pu...

Embodiment 2

[0036] On the basis of Embodiment 1, a high specific capacitance electrolytic capacitor winding core isolation assembly method includes the following steps:

[0037] (1) Impregnation treatment after the core is dried: dry the wound cylindrical core according to the conventional steps and put it into the fixative solution for 3~5 minutes;

[0038] (2) Isolation assembly: According to the size of the core obtained in step (1), wrap 3 layers of capacitor paper on the outside of the core. The diameter of the bottom of the capacitor paper is consistent with the cross-sectional diameter of the core, and the top of the capacitor paper is located under the side surface of the core. 1 / 2~4 / 5;

[0039] (3) Fixing the core into the shell and sealing: according to the conventional process, fix the packaged core into the corresponding capacitor shell and seal it;

[0040] (4) Casing and aging: According to the conventional process steps, put the sealed capacitor into the aluminum tube and ...

Embodiment 3

[0043] On the basis of embodiment 1 or embodiment 2, a high specific capacitance electrolytic capacitor winding core isolation assembly method includes the following steps:

[0044] (1) Impregnation treatment after the core is dried: dry the wound cylindrical core according to the conventional steps and put it into the fixative solution for 3~5 minutes;

[0045] (2) Isolation assembly: According to the size of the core obtained in step (1), wrap 2 layers of capacitor paper on the outside of the core. The diameter of the bottom of the capacitor paper is consistent with the cross-sectional diameter of the core, and the top of the capacitor paper is located under the side surface of the core. 1 / 2~4 / 5;

[0046] (3) Fixing the core into the shell and sealing: according to the conventional process, fix the packaged core into the corresponding capacitor shell and seal it;

[0047] (4) Casing and aging: According to the conventional process steps, put the sealed capacitor into the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com