Sodium battery comprising asymmetric modification layer and preparation method thereof

A technology of sodium battery and modification layer, which is applied in the field of energy materials, can solve the problem that the interface behavior between the positive and negative electrodes and the solid electrolyte cannot be solved well, and achieve the simple and easy processing method, low cost, and strong raw material selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

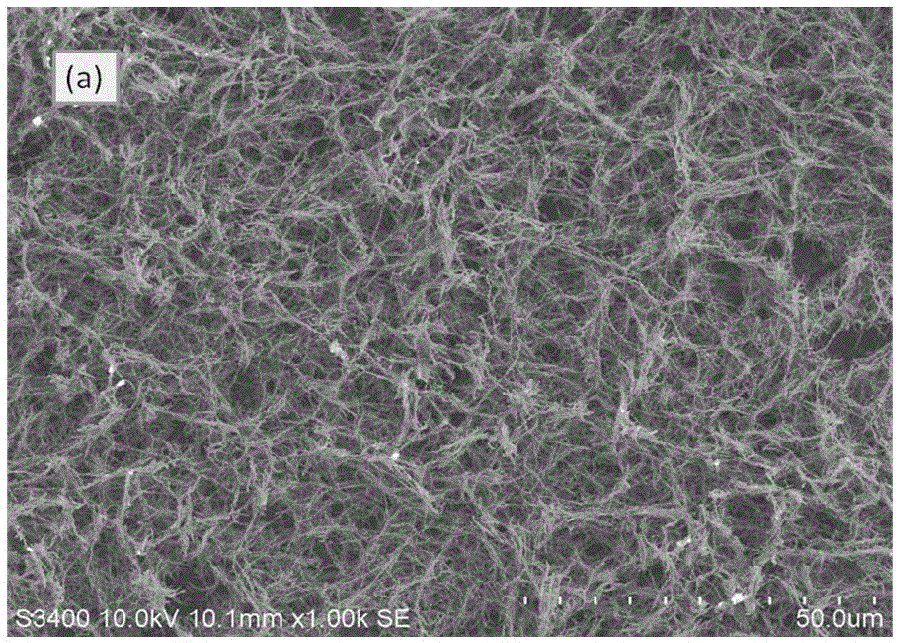

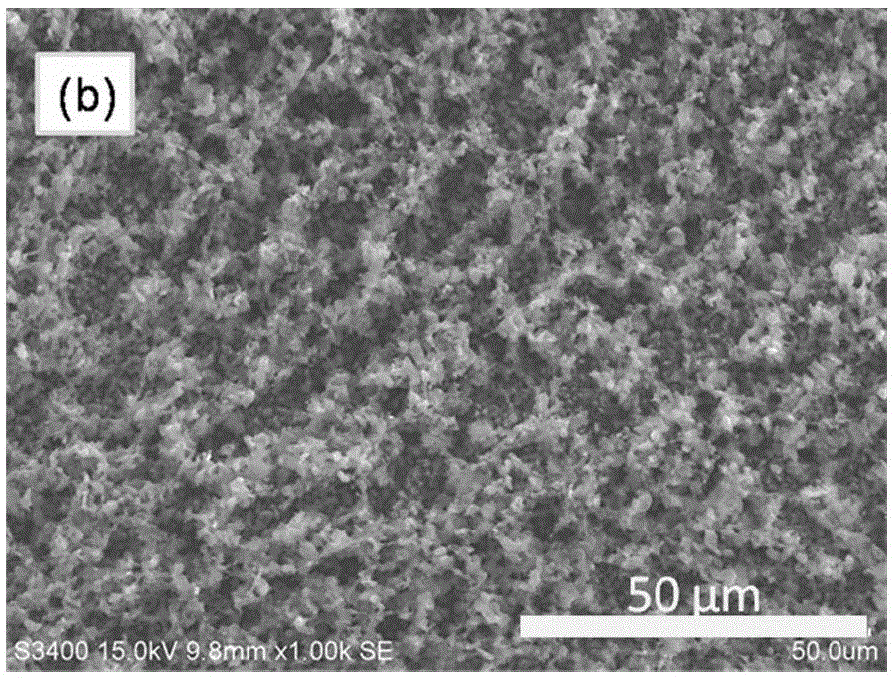

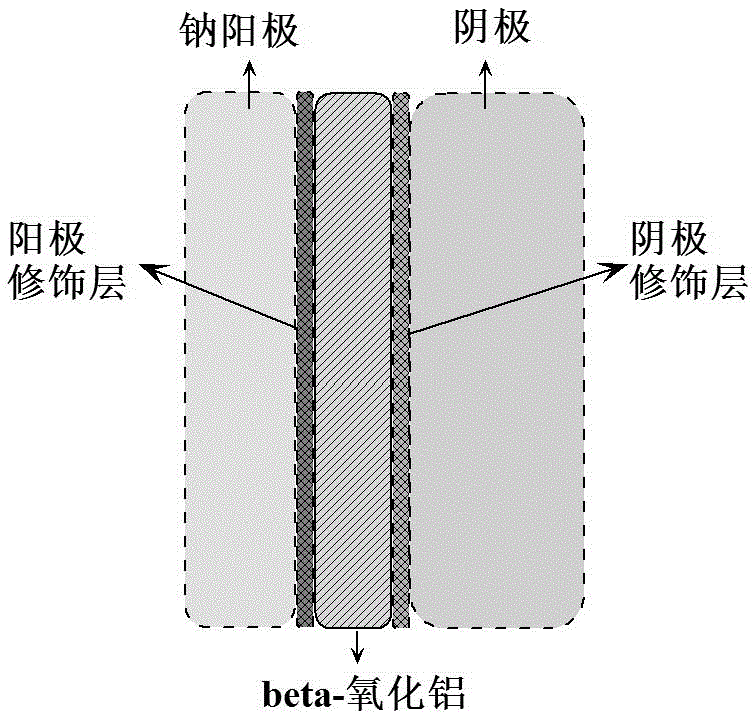

[0049] The porous nickel layer (11 μm) and the porous carbon layer (6 μm) were modified on the inner and outer surfaces of the β″-alumina solid electrolyte by sol-gel coating method and wet chemical coating method, and then the modified β″-alumina Assemble a sodium-nickel chloride battery with a design capacity of 15Ah. The sodium negative electrode contacts the porous carbon layer, and the nickel chloride positive electrode contacts the porous nickel layer. Figure 2 shows the scanning electron microscope pictures of the porous carbon layer and the porous nickel layer. Then test the charge and discharge curve of the battery under constant current (0.5A), such as image 3 , found that the first charge and discharge polarization voltage of the battery was as low as 0.05V. Polarization was significantly improved compared to unmodified cells.

Embodiment 2

[0053] The porous nickel layer (11 μm) and metal tin layer (200 μm) were modified on the inner and outer surfaces of the β″-alumina solid electrolyte by sol-gel coating method and evaporation method, and then the modified β″-alumina oxide was used to assemble the design A sodium-nickel chloride battery with a capacity of 15Ah. The sodium negative electrode contacts the metal tin layer, and the nickel chloride positive electrode contacts the porous nickel layer. After testing the charge and discharge curve of the battery under constant current (0.5A), it was found that the first charge and discharge polarization voltage of the battery was as low as 0.08V. Polarization was significantly improved compared to unmodified cells.

Embodiment 3

[0055] The porous iron layer (5 μm) and porous nickel layer (11 μm) were modified on the inner and outer surfaces of the β″-alumina solid electrolyte by the template coating method and the sol-gel coating method, and then assembled with the modified β″-alumina solid electrolyte A sodium-ferric chloride battery with a design capacity of 15Ah. The sodium negative electrode contacts the porous nickel layer, and the ferric chloride positive electrode contacts the porous iron layer. After testing the charge and discharge curve of the battery under constant current (0.5A), it was found that the first charge and discharge polarization voltage of the battery was as low as 0.06V. Polarization was significantly improved compared to unmodified cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com