Polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and preparation method thereof

An ethylene copolymer and polyvinyl alcohol technology, which is applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of difficult to precisely control the morphology, pore size and uniformity of porous membranes, and achieve uniformity and repeatability. Good performance and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of polyvinyl alcohol-ethylene copolymer honeycomb porous membrane, comprises the following steps:

[0035] S1. Add polyvinyl alcohol-ethylene copolymer to a mixed solvent of isopropanol and water with a mass ratio of 1:2 to 2:1, heat it to 70 to 85°C, and dissolve it completely to obtain a mass fraction of 7 %~12% polyvinyl alcohol-ethylene copolymer solution.

[0036] The polyvinyl alcohol-ethylene copolymer molecular chain includes a hydrophilic polyvinyl alcohol segment and a hydrophobic polyethylene segment, which is soluble in hot aqueous solution. It is difficult to dissolve polyvinyl alcohol with isopropanol alone. The volatility of water is poor, which is not conducive to the formation of honeycomb porous structure when removing the solvent phase. And because isopropanol and water are miscible, so choose volatile isopropene and water as mixed solvent, utilize the difference of both to polyvinyl alcohol-ethylen...

Embodiment 1

[0049] A polyvinyl alcohol-ethylene copolymer honeycomb porous membrane is prepared by a phase separation spin coating method, comprising the following steps:

[0050] S1. Add polyvinyl alcohol-ethylene copolymer to a mixed solvent of isopropanol and water with a mass ratio of 1:1, heat to 80°C to dissolve it completely, and obtain polyvinyl alcohol with a mass fraction of 8%- Ethylene copolymer solution;

[0051] The molecular weight of the polyvinyl alcohol-ethylene copolymer is about 50,000; the content of polyvinyl alcohol in the polyvinyl alcohol-ethylene copolymer is 80%; the alcohol content of polyvinyl alcohol in the polyvinyl alcohol-ethylene copolymer The resolution is 88%.

[0052] S2. Put the silicon wafer on the turntable of the homogenizer, set the rotating speed to 2000 rpm, and the rotation time is 60s, start the homogenizer, and drop 0.05ml of the polyvinyl alcohol-ethylene copolymer solution obtained in step S1 On the silicon chip, until the glue homogenize...

Embodiment 2~8 and comparative example 1~5

[0057] The polyvinyl alcohol-ethylene copolymer honeycomb porous membrane that embodiment 2~8 and comparative example 1~5 provide, compare with embodiment 1, difference is that, preparation condition is as shown in table 1, other and embodiment 1 They are basically the same and will not be repeated here.

[0058] The preparation conditions of table 1 embodiment 2~8 and comparative examples 1~5

[0059]

[0060]

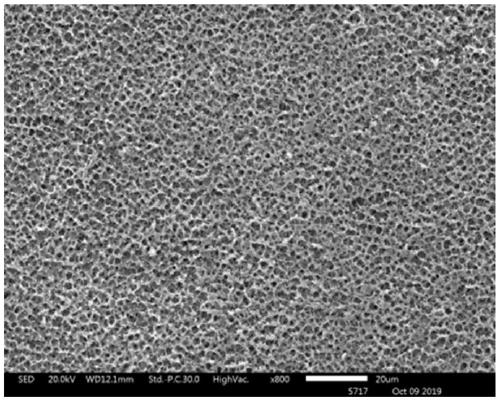

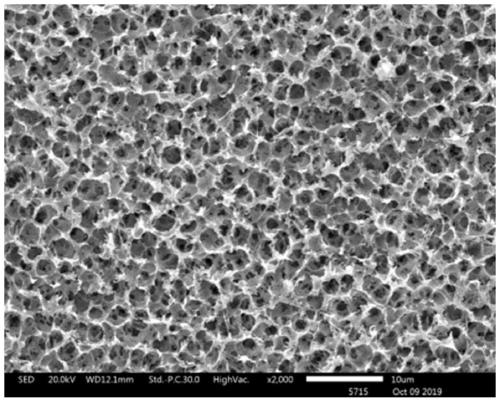

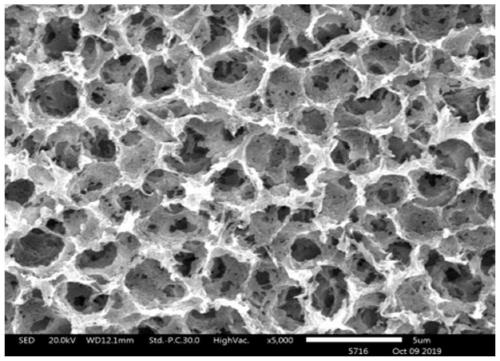

[0061] see Figure 4 As shown, it can be seen that when the mass fraction of the polyvinyl alcohol-ethylene copolymer solution was 6%, the polyvinyl alcohol-ethylene copolymer film prepared in Comparative Example 3 did not form a honeycomb porous structure, which may be because the solution concentration was too high. When the viscosity is low, the viscosity decreases and the content of the solvent phase is large. When the solvent phase is removed, a large amount of solvent volatilizes, resulting in an increase in the content of condensed water, making it diffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com