Device and method for continuously washing and purifying polyether sulfone/polyether ketone resin

A polyether ketone resin and purification device technology, which is applied in the field of continuous washing and purification devices for polyether sulfone/polyether ketone resin, can solve the problems of incomplete impurity removal, complicated equipment, and high cost, and achieve convenient operation, Production cost reduction and performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

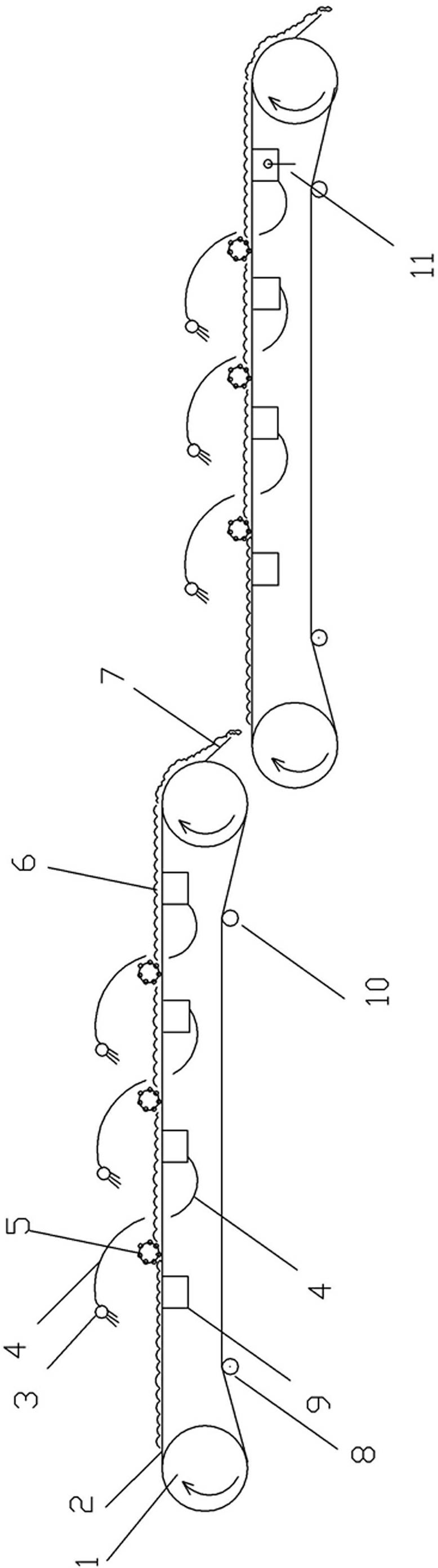

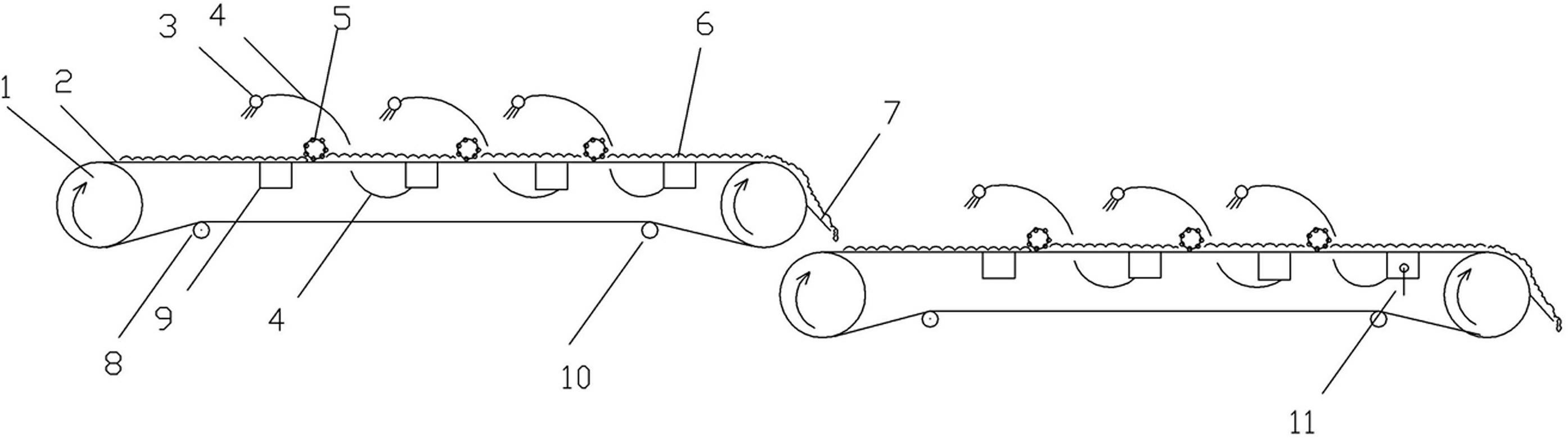

Embodiment 1

[0030] Polyether ether ketone resin polymer prepared with sulfolane as solvent, particle size 50μm~1mm, material thickness 10mm, width 3m, each group length 6m, nylon mesh transmission track 300 mesh (aperture 48μm), divided into 3 groups, with Deionized water is used as detergent, and a continuous washing bed with 8 rows of nozzles and vacuum suction filter boxes is evenly arranged above and below each group of conveyor belts to wash and purify the solvent sulfolane and by-product NaF in the polymer, because the solubility of NaF in water is not sensitive to temperature, so Use normal temperature water to wash, the conveying speed is 0.3m / min, and the F of the final washing liquid is measured by an online ion meter. - The concentration is 0.15ppm, the production capacity of this method is about 100Kg / h, and the water consumption is about 500Kg / h, and the water consumption per kilogram of material is 5Kg, and the normal temperature treatment greatly saves energy.

Embodiment 2

[0034] Polyethersulfone resin polymer prepared with sulfolane as a solvent, particle size 0.2mm ~ 4mm, material thickness 10mm, width 3m, each group length 6m, copper mesh transmission track 150 mesh (aperture 106μm), divided into 2 groups, with Normal temperature deionized water is used as detergent, and a continuous washing bed with 8 rows of nozzles and vacuum suction filter boxes is evenly arranged above and below each group of conveyor belts to wash and purify the solvent sulfolane and by-product NaCl in the polymer, because the solubility of NaCl in water is not sensitive to temperature. Therefore, normal temperature water is used for washing, and the conveying speed is 0.2m / min. The final lotion is 1.3μs / cm measured by the online conductivity meter. The production capacity of this method is about 60Kg / h, and the water consumption is about 400Kg / h. One kilogram of material consumes 7Kg / Kg of water, and the normal temperature treatment greatly saves energy.

Embodiment 3

[0038] The polyether ether ketone resin polymer prepared with diphenyl sulfone as a solvent, with a particle size of 10 μm to 500 μm, is washed in two steps. First, it enters the first treatment system. The thickness of the material is 5mm, and the width is 3m, and the length is 15m. Stainless steel mesh Conveyor track 1500-mesh single-group sealed washing equipment with exhaust pipe, use ethanol as detergent to remove diphenyl sulfone, 20 rows of nozzles evenly distributed above and below the conveyor belt and a continuous washing bed of vacuum suction filter box to wash and purify the polymer Solvent diphenyl sulfone, because the solubility of diphenyl sulfone in ethanol is sensitive to temperature, so it is washed with hot ethanol at 60-70 °C, and the conveying speed is 0.1m / min. At the same time, the material enters the second set of washing system, with a width of 3m, each group of 6m in length, nylon mesh transmission crawler 1500 mesh, divided into 3 groups, using deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com