Six phase electrode electric melting furnace

An electric melting furnace and electrode technology, which is applied in the direction of electric furnace heating, furnace, crucible furnace, etc., can solve the problems of affecting product output and quality, high energy consumption of electric fused magnesium production, slow furnace temperature rise, etc., to achieve uniform and stable product quality, Energy saving, fast furnace temperature rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

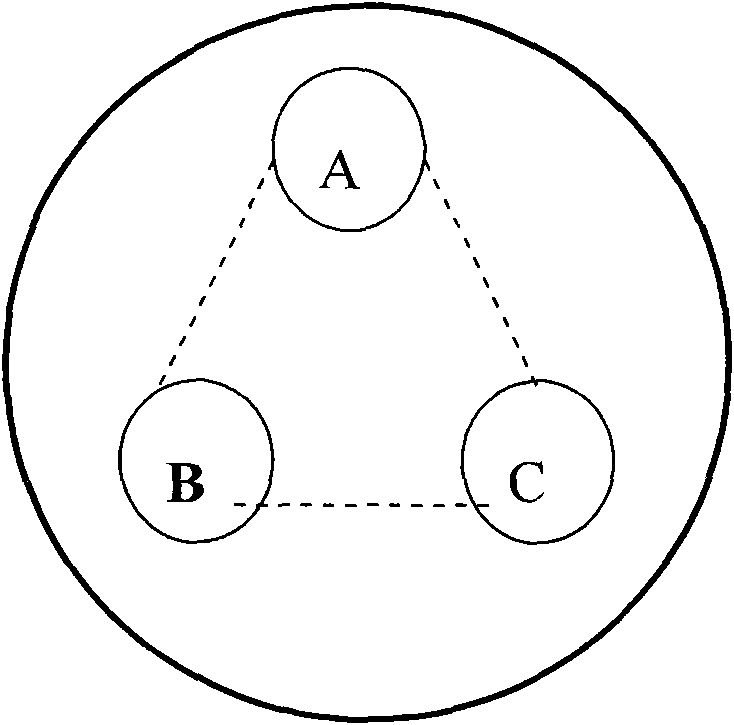

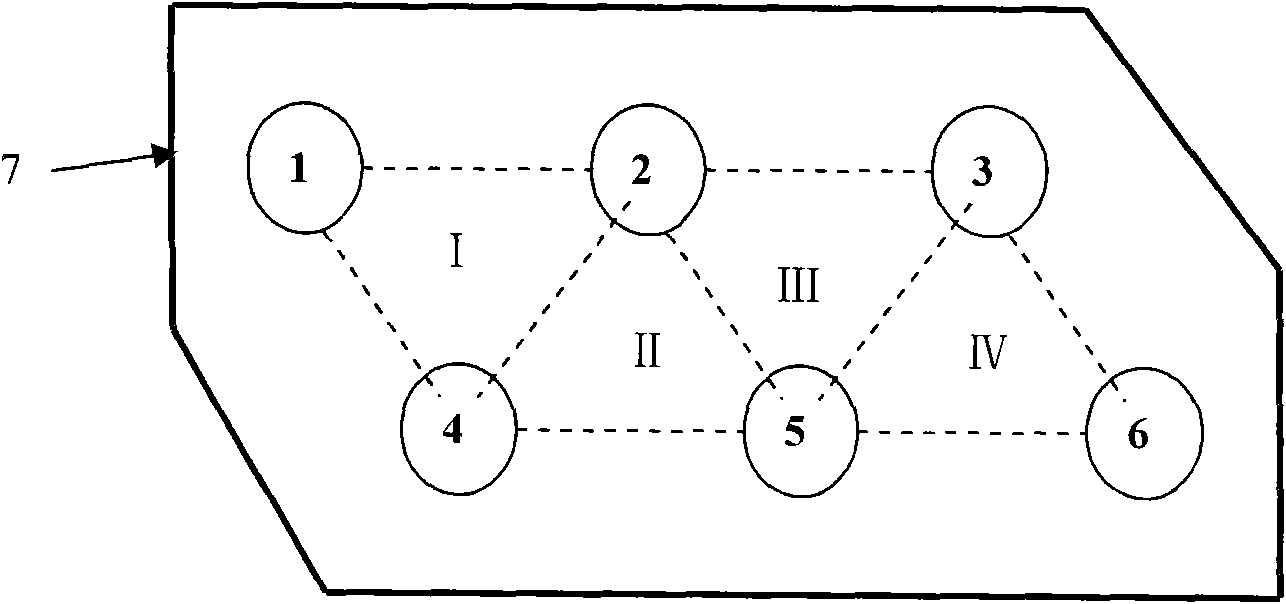

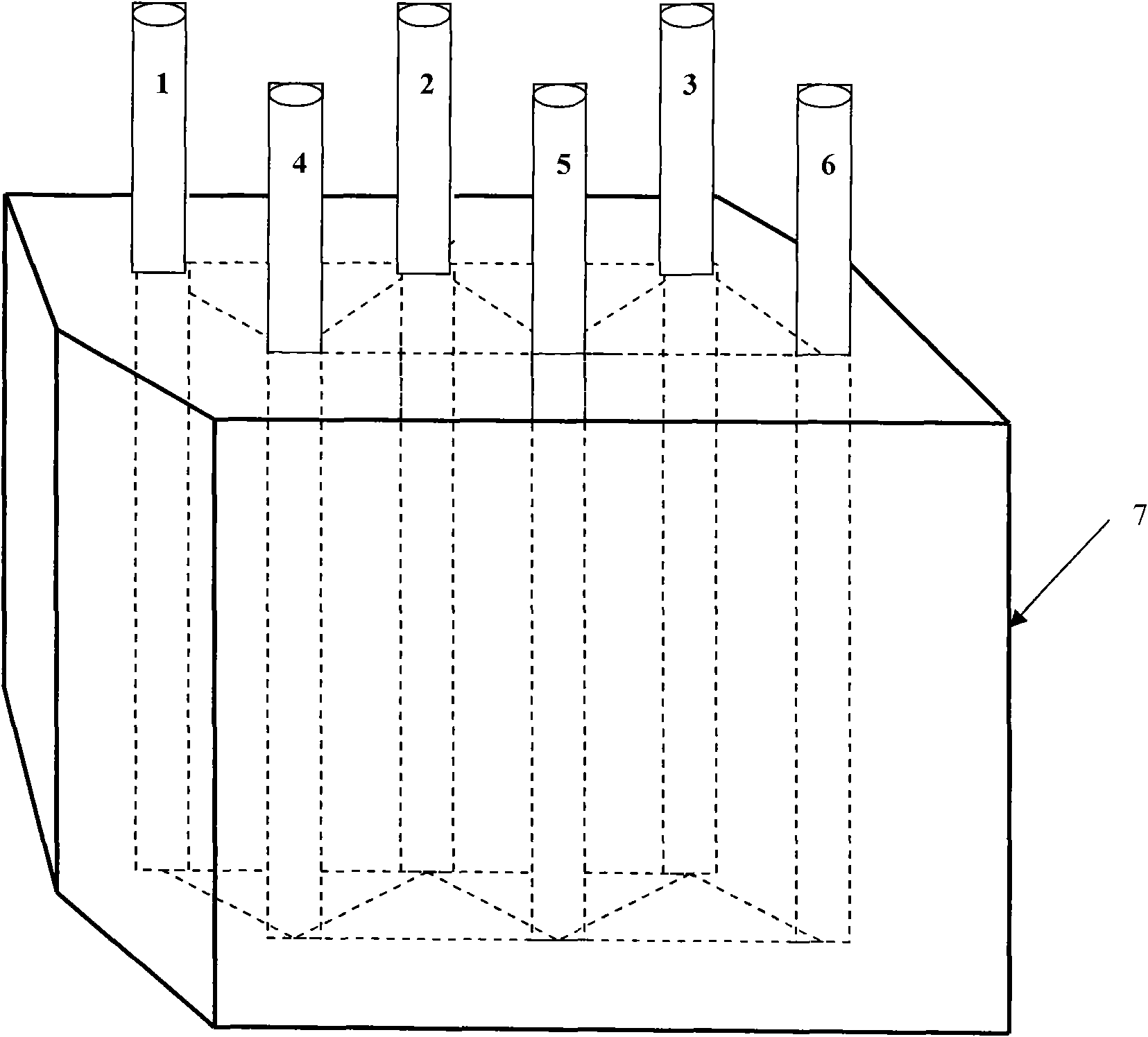

[0008] The six-phase electrode electric melting furnace includes a hexagonal column furnace body 7, and a first electrode 1, a second electrode 2, a third electrode 3, a fourth electrode 4, a fifth electrode 5, and a sixth electrode 6 are inserted in the furnace body 7 , wherein the first electrodes 1, the second electrodes 2, and the third electrodes 3 are placed in a row at equal intervals, the fourth electrodes 4, the fifth electrodes 5, and the sixth electrodes 6 are placed in a row at equal intervals, and the electrodes of the two rows are in the shape of a parallelogram as a whole. Respectively by the first electrode 1, the second electrode 2, the fourth electrode 4, the second electrode 2, the fourth electrode 4, the fifth electrode 5, the second electrode 2, the third electrode 3, the fifth electrode 5, the third electrode 3. The fifth electrode 5 and the sixth electrode 6 constitute four equilateral triangular heating regions I, II, III, and IV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com