Patents

Literature

31results about How to "Good fluidity of molten pool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

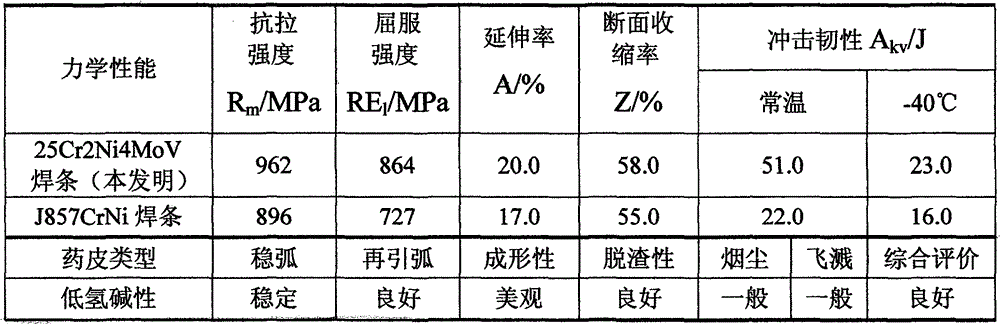

Low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding

InactiveCN101890594AGood arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFerrosiliconFerrotitanium

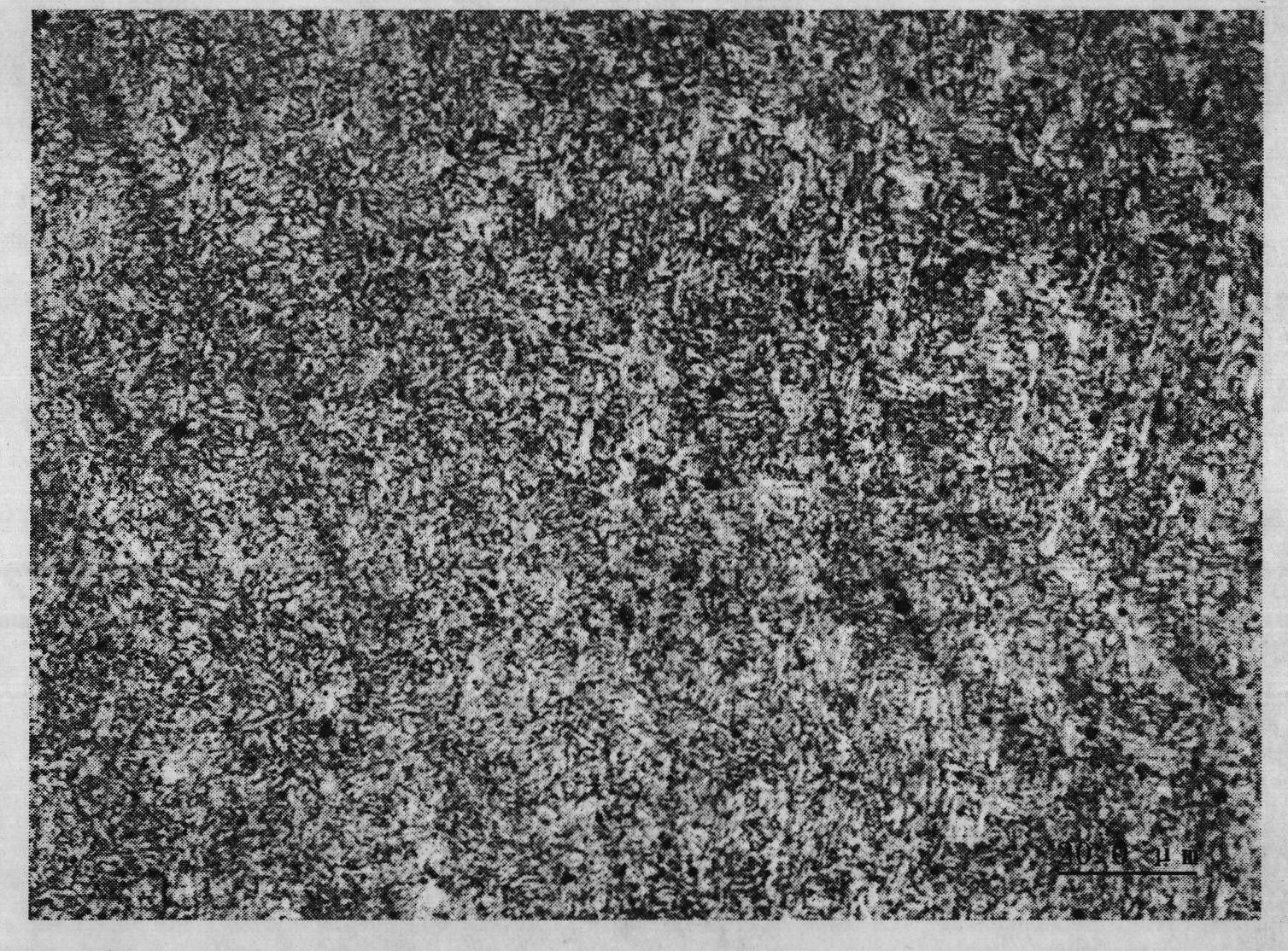

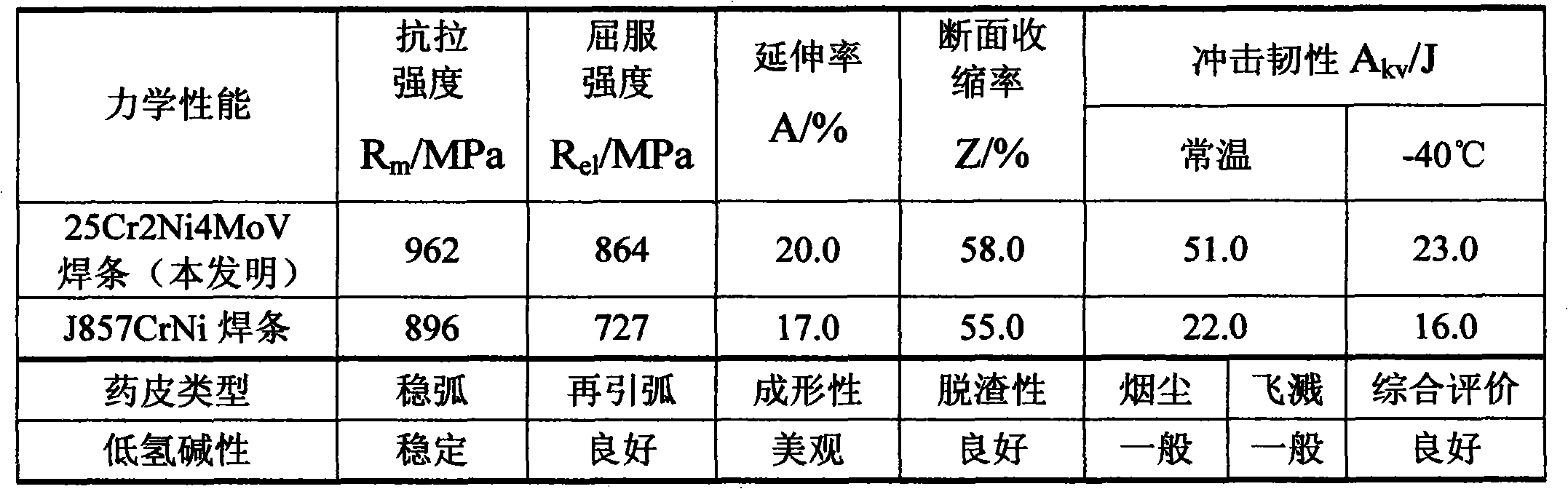

The invention discloses a low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding, which comprises a core wire and a coating, wherein the coating is prepared from the following materials in percentage by weight: 40-47% of marble, 16-24% of fluorite, 3-6% of quartz, 3-6% of zircon sand, 4-12% of rutile, 6-11% of ferrotitanium, 4-8% of low-carbon ferromanganese, 2-5% of ferrosilicon, 1-3% of rare earth ferrosilicon, 2.8-3.2% of synthetic mica and 0.5-1.5% of soda ash, and the sum of the weight percentage of all the components is 100%.The electrode prepared from the coating has the advantages of high arc stabilizing performance, good molten pool fluidity, fine splashing particles, easier deslagging after welding, uniform slag covering and delicate and attractive molded weld. Besides, the diffusible hydrogen content of the deposited metal of the prepared electrode is effectively limited.

Owner:XIAN UNIV OF TECH

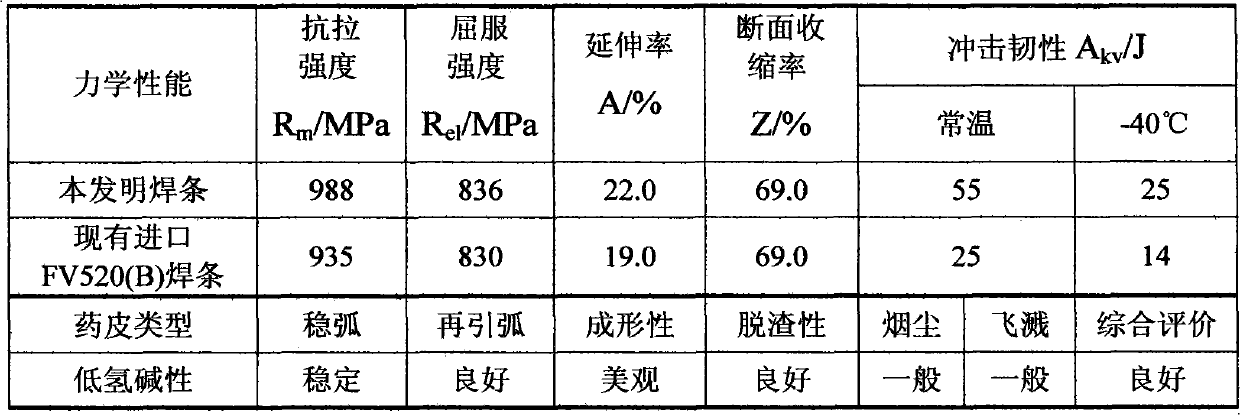

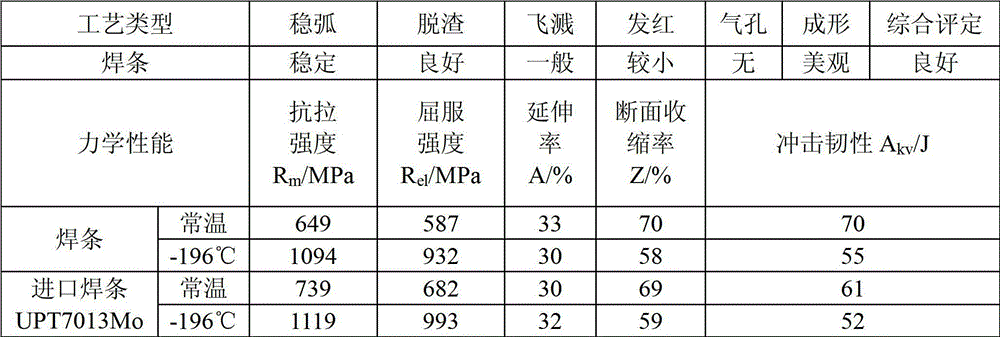

Low-hydrogen basic electrode for welding FV520 (B) stainless steel

ActiveCN101905395AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagMolten bath

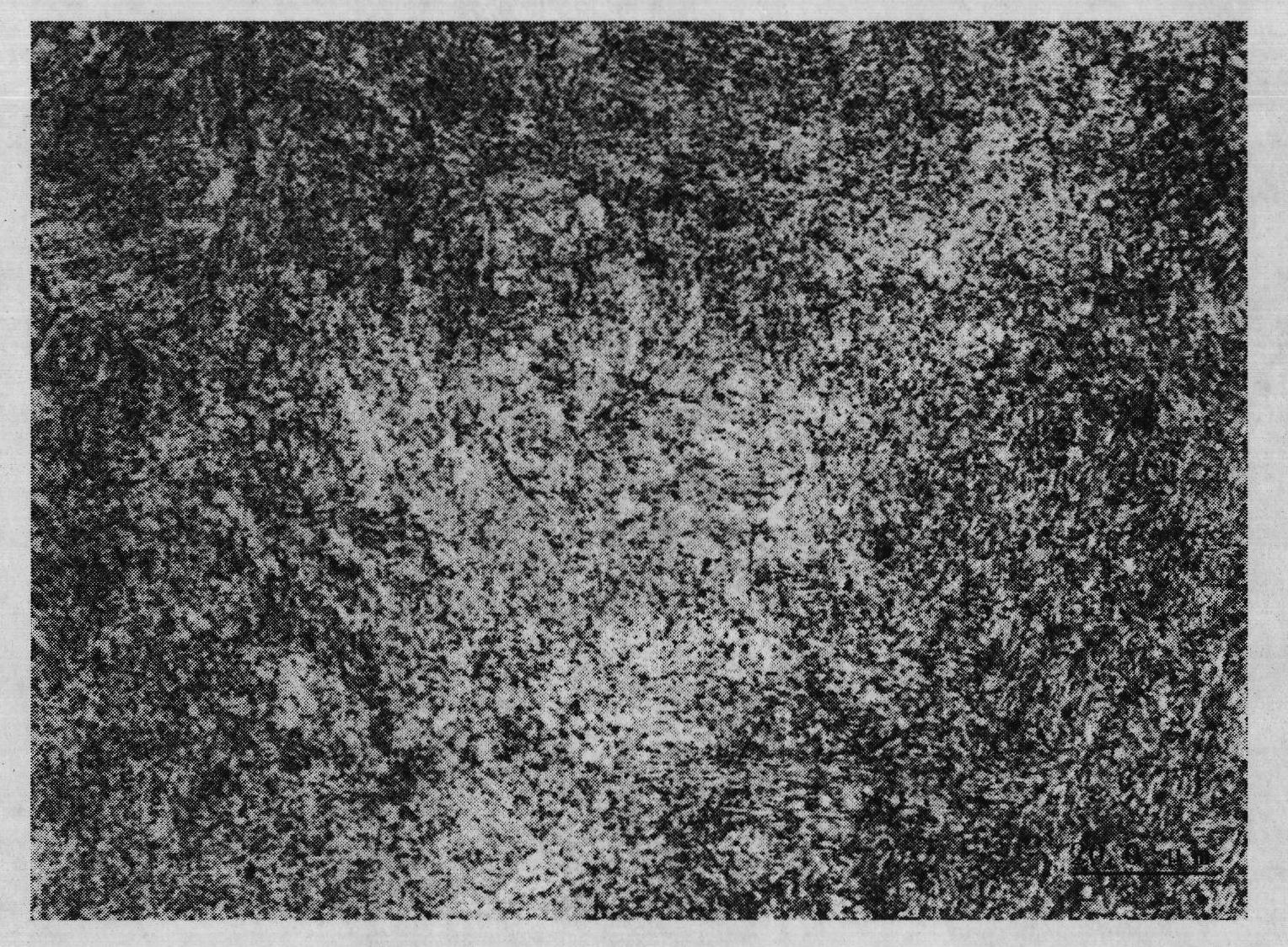

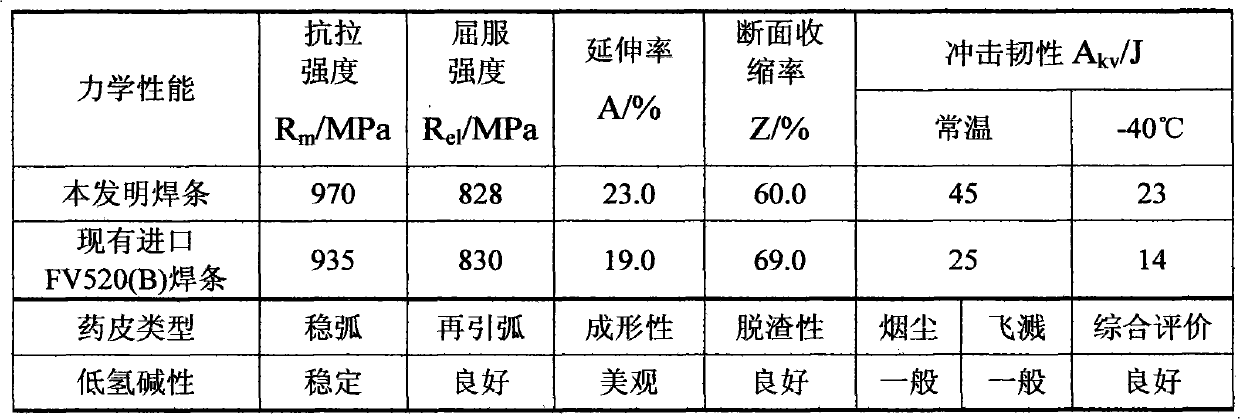

The invention discloses a low-hydrogen basic electrode for welding FV520 (B) stainless steel, comprising a core wire and an electrod covering, wherein the electrode covering comprises the following materials in weight percentage: 35%-45% of marble, 18%-26% of fluorite, 6%-9% of quartz, 3%-6% of zircon sand, 6%-12% of rutile, 1%-3% of ferrosilicon, 6%-10% of ferrotitanium, 5%-11% of low-carbon ferromanganese, 1%-3% of rare-earth ferrosilicon and 0.5%-1.5% of sodium carbonate, and the sum of the weight percentages of the components is 100%. Compared with the traditional special imported electrode for the FV520 (B) stainless steel, the electrode made of the electrode covering has the advantages of favorable arc stabilization performance, good fluidity of a molten bath, less splash and dust, easier slag removal after welding, uniform slag coverage, and delicate and attractive welding joint formation. The content of diffusible hydrogen generated by using the developed electrode for depositing metal is effectively controlled and meets the requirements of low-carbon contents.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

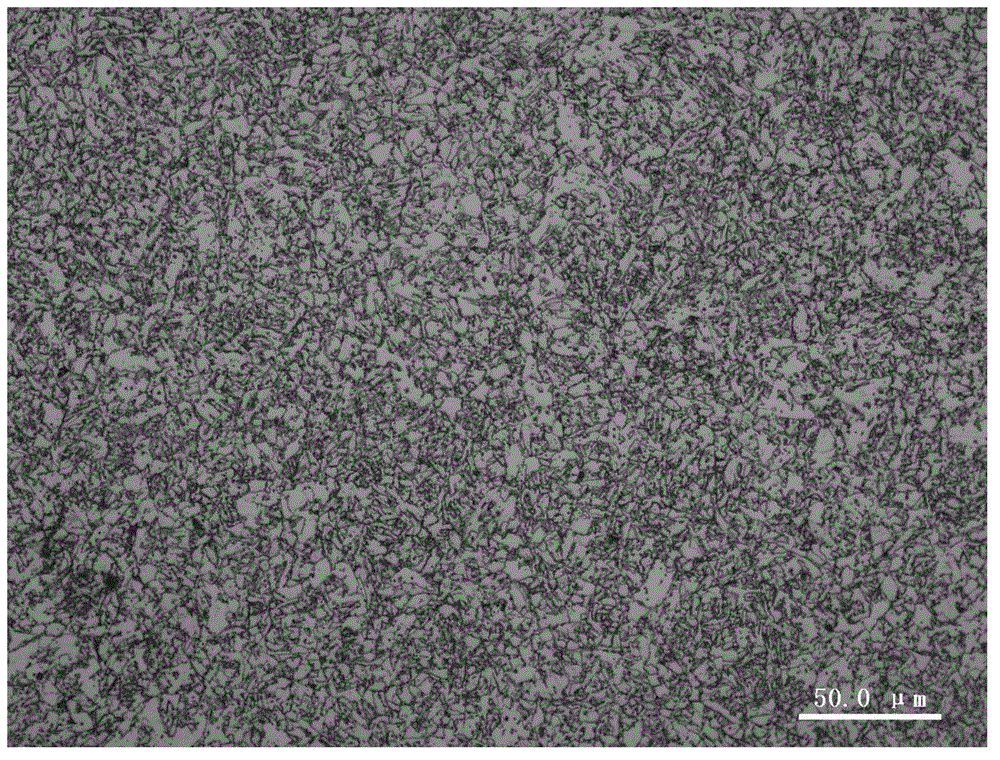

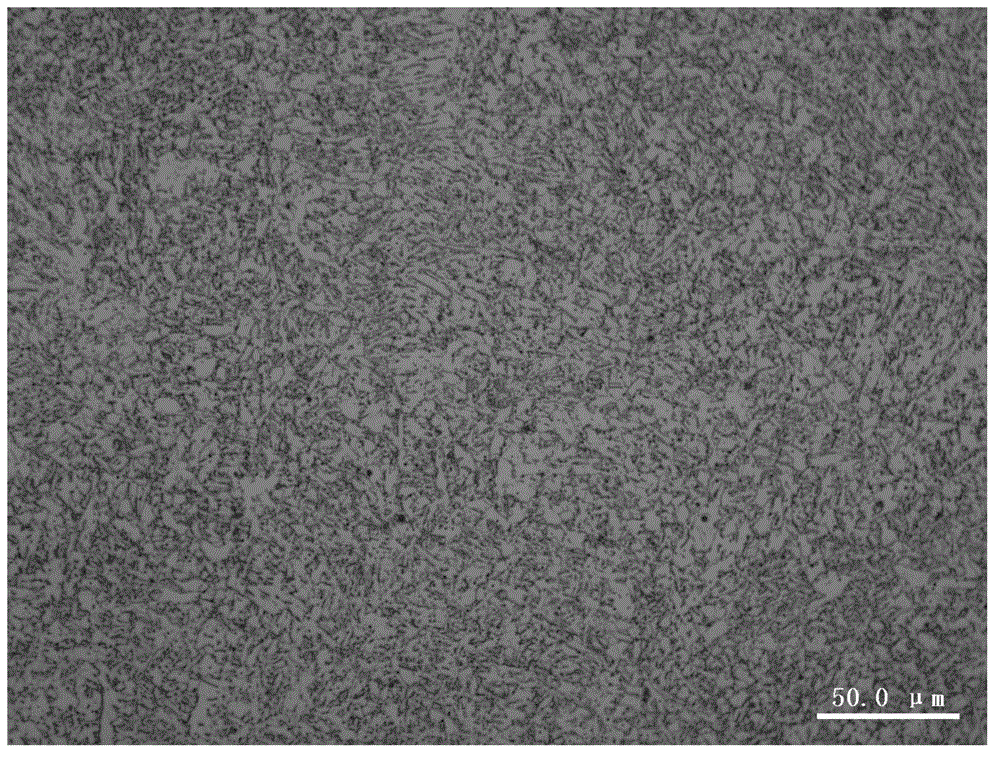

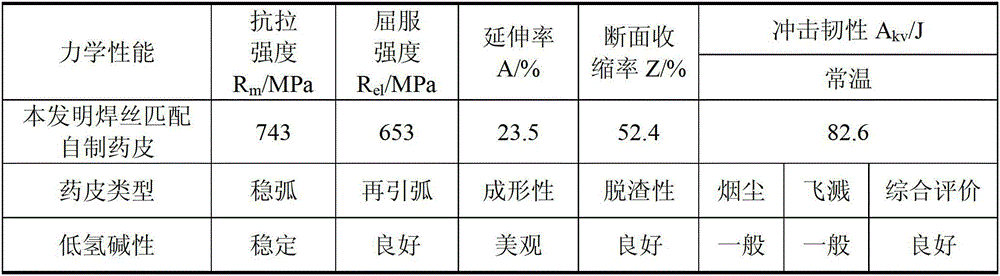

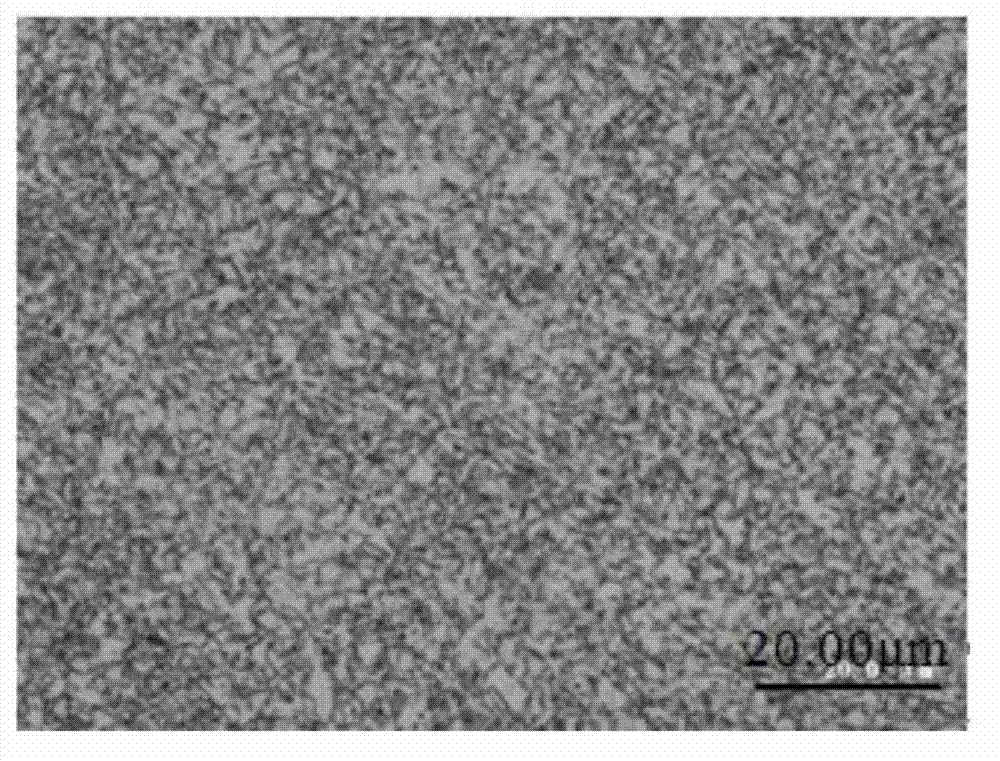

Welding wire for welding FV520B martensitic stainless steel and manufacturing method thereof

InactiveCN103990918AGood soldering requirementsImprove self-protection performanceWelding/cutting media/materialsWelding/soldering/cutting articlesSlagMartensitic stainless steel

A welding wire for welding FV520B martensitic stainless steel comprises a powder core and an outer skin. The powder core is composed of, by mass, 15 percent to 35 percent of rutile, five percent to 15 percent of zircon sand, two percent to five percent of quartz, four percent to 10 percent of feldspar, two percent to five percent of sodium carbonate, two percent to five percent of aluminum oxide, six percent to 12 percent of aluminum magnesium alloy, five percent to 10 percent of electrolytic manganese metal, 18 percent to 25 percent of chromium powder, six percent to 10 percent of nickel powder, two percent to six percent of ferroniobium and one percent to 10 percent of molybdenum powder, and the sum of the mass percent of all the components is 100 percent. The welding wire is good in arcing and arc stabilizing performance, good in molten pool fluidity, fine in splashed particle and even in postwelding slag coverage, and enables deslagging to be easy, welding joint forming is meticulous and attractive, the welding wire is suitable for large linear energy welding, the organization and performance obtained through the prewelding preheating and postwelding heat treatment process can meet actual production needs, and the welding requirement for FV520B martensitic stainless steel is met.

Owner:XIAN UNIV OF TECH

Low-hydrogen alkaline electrode for online welding of X80 pipeline steel

InactiveCN102873473AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFerrosiliconFerrotitanium

The invention discloses a low-hydrogen alkaline electrode for online welding of X80 pipeline steel. The low-hydrogen alkaline electrode comprises a core wire and a coating. The coating comprises, by weight, from 40% to 45% of marble, from 15% to 20% of fluorite, from 2% to 4% of titanium dioxide, from 6% to 10% of rutile, from 7% to 10% of ferrotitanium, from 4% to 7% of low-carbon ferromanganese, from 2% to 5% of ferrosilicon, from 6% to 10% of iron powder, from 2.5% to 3% of synthetic mica, from 1.8% to 2.2% of rare earth and from 2% to 2.4% of microcrystal fibers, and the sum of the weight percents of the components is 100%. The electrode made from the coating is good in arc stabilization performance, a molten pool is good in flowability, splashing particles are tiny, post-welding slag detachability is good, slag coverage is uniform, and formed weld joints are delicate and attractive. Besides, the content of diffusible hydrogen in deposited metal of the manufactured electrode is effectively controlled.

Owner:XIAN UNIV OF TECH

High-tenacity low-hydrogen alkaline welding rod and preparation method thereof

InactiveCN103084757AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberMisch metal

The invention discloses a high-tenacity low-hydrogen alkaline welding rod which comprises a coating and a welding core, wherein the coating comprises, by weight, 38%-44% of marble, 20%-25% of fluorite, 3%-5% of zircon sand, 1%-5% of ferrosilicon, 10%-15% of ferrotitanium, 5%-7% of mid-carbon ferromanganese, 2%-4% of titanium dioxide, 3%-6% of mica, 1.5%-2% of microcrystalline fiber, 1.2%-1.8% of nickel powder, and 1%-1.5% of misch metal, wherein sum of weight percentages of all components is 100%. The invention further discloses a preparation method of the high-tenacity low-hydrogen alkaline welding rod. The preparation method of the high-tenacity low-hydrogen alkaline welding rod includes the steps: enabling coating materials and K-Na mixing water glass to be mixed, crushing the mixture into a power ball with a cylindrical shape, putting the power ball into a pressing coating machine, coating the power ball with the cylindrical shape on a H08A welding core to form the welding rod, and then grinding the head and the tail and getting the high-tenacity low-hydrogen alkaline welding rod after drying. When the high-tenacity low-hydrogen alkaline welding rod is used for welding high-strength steel, no preheating is needed before welding, no heat treatment is needed after welding, content of diffusible hydrogen of deposited metal is controlled effectively, and the preparation method is simple.

Owner:XIAN UNIV OF TECH

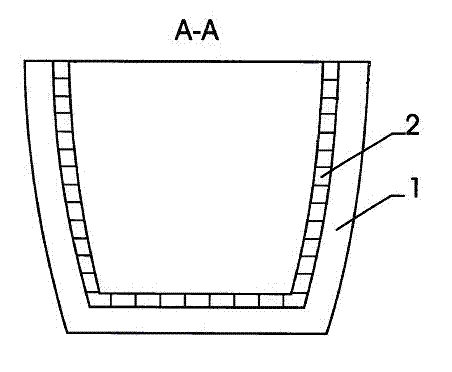

Molten titanium and titanium alloy crucible and preparation method thereof

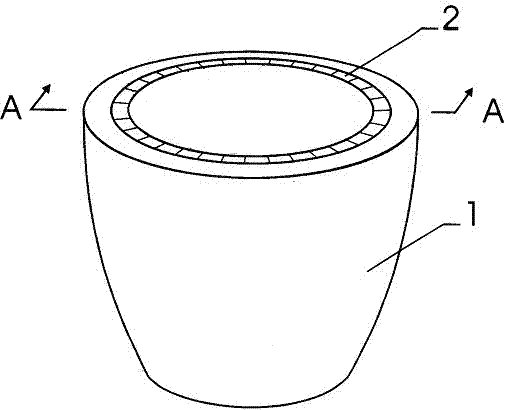

InactiveCN103922769AEliminate defects that are prone to cracksEasy to replace and maintainCrucibleTitanium

The invention discloses a molten titanium and titanium alloy crucible which is at least formed by combining a crucible shell and a crucible lining, wherein the crucible lining is of an opened structure capable of holding a melt and is made of a composite material; the crucible shell is made of a high-temperature-resistant material with a high melting point and is of a force bearing structure capable of bearing pressure generated by titanium melts and titanium alloy melts; the crucible lining is made of a sintered composite prepared by mixing the following main components: 45-70wt% of barium oxide, 30-50wt% of zirconium oxide and 0-5wt% of fluxing agent, wherein the fluxing agent is titanium oxide, aluminum oxide or boron oxide. The invention also discloses a preparation method of the crucible; the crucible lining is assembled in a way of stacking and combining sintered bricks and can be disassembled in a decomposition way. An inner layer material of the crucible disclosed by the invention does not react with titanium; in addition, the crucible is nonstick, capable of meeting the requirements of industrialization, large capacity, low cost, easiness for maintenance and long service life, reasonable in structure and mature in preparation process.

Owner:SHANGHAI UNIV

Welding stick for all-position welding of X100 pipeline steel and manufacturing method thereof

InactiveCN103962743AGood arc start and arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaOxideMetallic Nickel

A welding stick for the all-position welding of X100 pipeline steel comprises a flux core and a covering. The flux core comprises, by mass, 40-60% of fluoride, 10-20% of oxide, 2-6% of carbonates, 12-16% of Al-Mg alloy powder, 2-10% of nickel powder, 2-5% of chromium powder, 3-8% of molybdenum powder, 5-10% of electrolytic manganese metal and 0-3% of ferroniobium, and the sum of the mass percents of the components is 100%. According to the welding stick for the all-position welding of the X100 pipeline steel, adding of a denitrification agent and a deoxidizing agent (namely the Al-Mg alloy powder and ferromanganese) is controlled, the slagging and gas making functions of the fluoride and the carbonates are matched, and the good slag-gas-metal triune self-protection effect is achieved. The arcing and arc stability properties are good, the fluidity of a weld pool is good, splashing particles are small, postwelding slag coverage is even, slag removal is easy, and the appearance of weld seams is delicate and attractive.

Owner:XIAN UNIV OF TECH

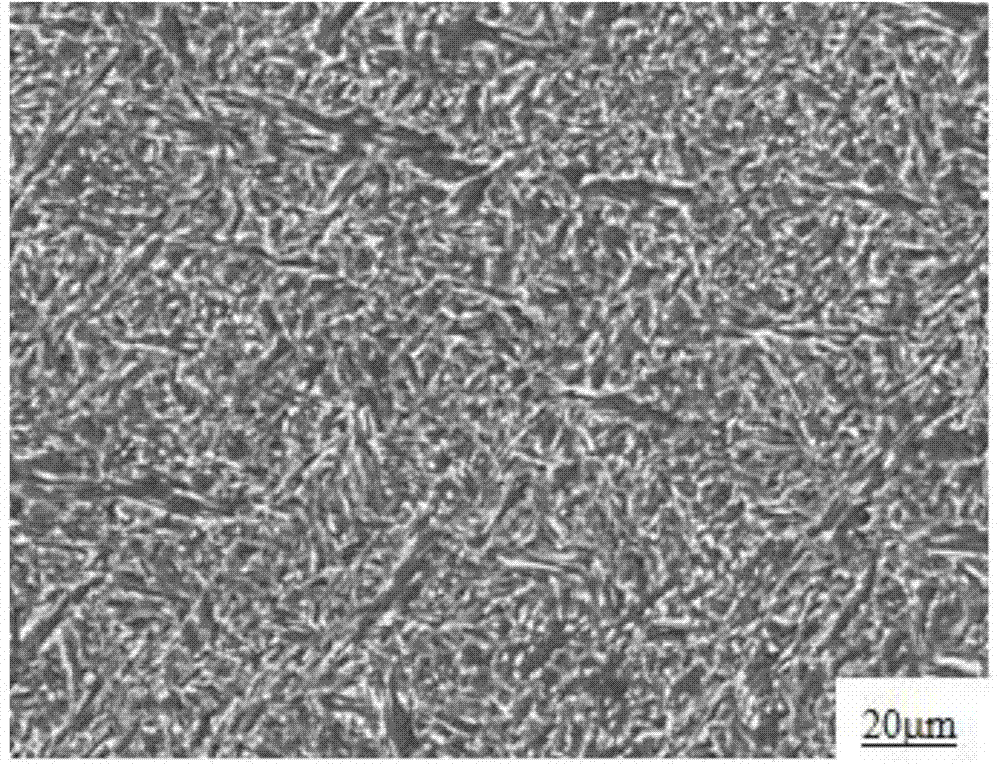

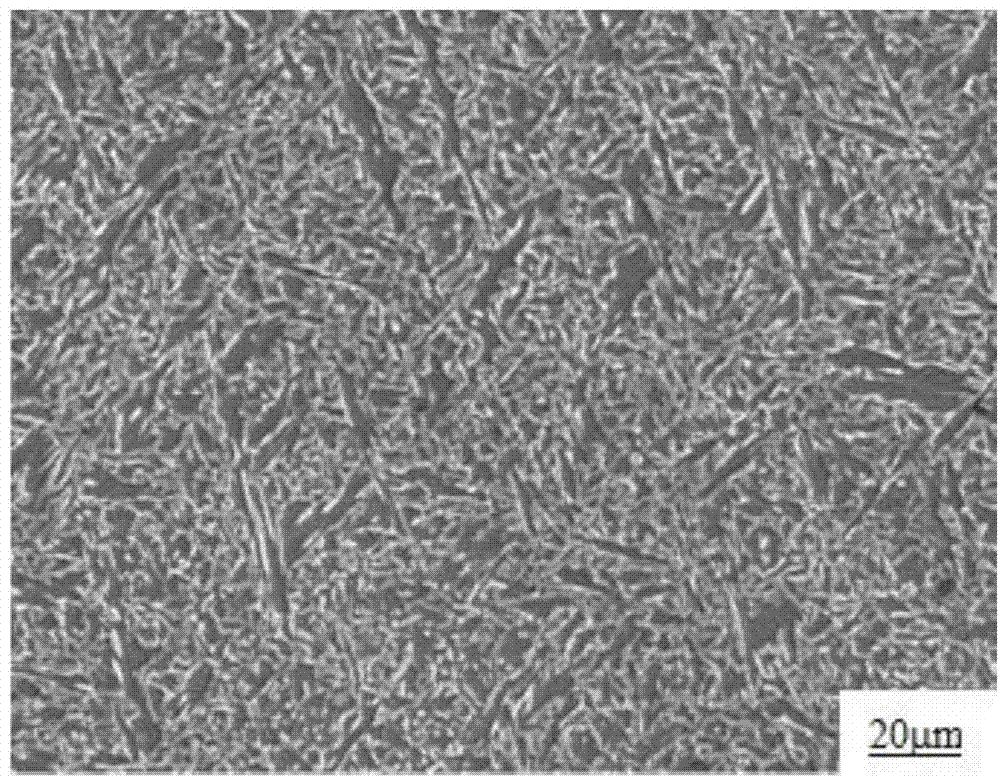

Low-hydrogen basic electrode for 1Ni9 low-temperature steel welding and preparation method of low-hydrogen basic electrode

InactiveCN103433642AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention provides a low-hydrogen basic welding electrode for 1Ni9 low-temperature steel welding. The low-hydrogen basic welding electrode comprises a welding core and a coating, wherein the welding core consists of the following components in percentage by mass: 0.01 to 0.03 percent of carbon, 0.5 to 0.9 percent of manganese, 0.2 to 0.4 percent of silicon, 21 to 24 percent of chromium, 2.5 to 3.5 percent of iron, 8.5 to 9.5 percent of molybdenum, 0.02 to 0.04 percent of titanium, 4 to 4.5 percent of niobium, 0.15 to 0.20 percent of nitrogen, at most 0.01 percent of sulfur, at most 0.01 percent of phosphorus and the balance of nickel; the coating comprises the following components in percentage by mass: 34 to 48 percent of marble, 17 to 24 percent of fluorite, 2 to 6 percent of zircon sand, 1 to 4 percent of ferrosilicon, 5 to 12 percent of ferrotitanium, 3 to 5 percent of mid-carbon ferromanganese, 2 to 5 percent of titanium dioxide, 2 to 5 percent of rutile, 2 to 6 percent of mica, 0.7 to 1 percent of alkali and 1 to 3 percent of mixed rare earth, and the sum of the mass percentage of the components is 100 percent. The low-hydrogen basic electrode provided by the invention solves the problems of poorer performance and high import price of existing welding electrodes.

Owner:XIAN UNIV OF TECH

Flux-cored wire for welding X90 pipeline steel and preparing method thereof

InactiveCN104741834AImprove self-protection performanceGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a flux-cored wire for welding X90 pipeline steel. The flux-cored wire for welding the X90 pipeline steel comprises a flux core and skin. The flux core comprises, by mass, 30%-55% of fluoride, 10%-20% of oxide, 2%-5% of carbonate, 7%-10% of Al-Mg, 8%-15% of nickel powder, 0.5%-2.5% of chromium powder, 3%-6% of molybdenum powder, 1%-3% of copper powder, 10%-15% of electrolytic manganese metal, 1%-4% of ferrocolumbium, 0.5-1.5% of ferrotitanium, and 2%-4% of ferrosilicon. According to the flux-cored wire for welding the X90 pipeline steel, through control over the addition of the denitrfying agent and the oxygen agent and the slag making function and the gas making function of the fluoride, a good slag-gas-metal triune self-protection function is achieved; the arcing performance and the arc stabilizing performance are good, the fluidity of a molten bath is high, splashed particles are fine and small, slag is evenly covered after welding, slag removal is easy, and formed weld joints are delicate and attractive.

Owner:XIAN UNIV OF TECH

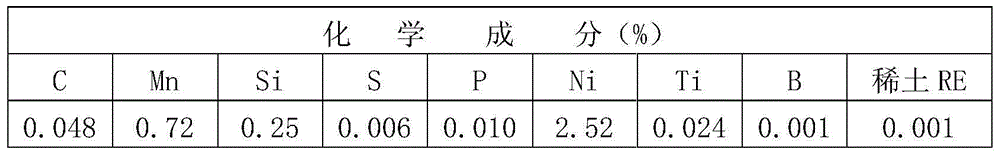

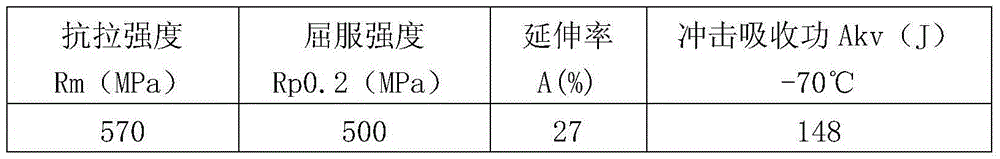

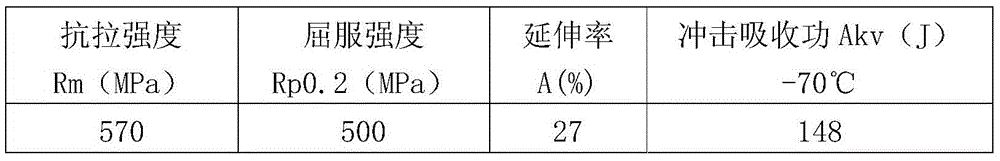

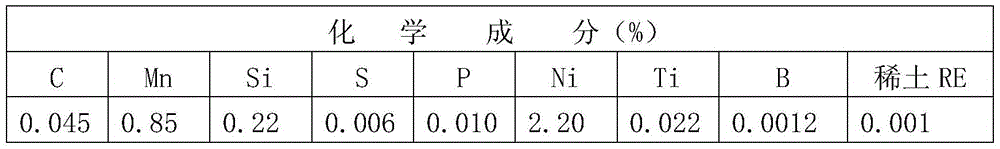

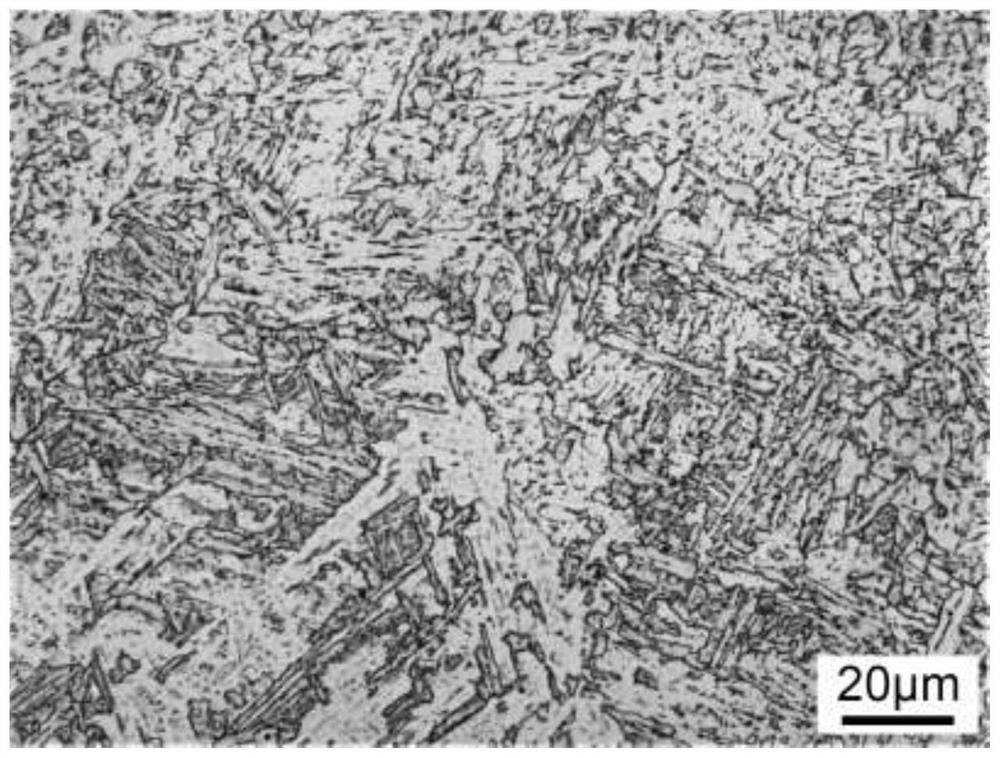

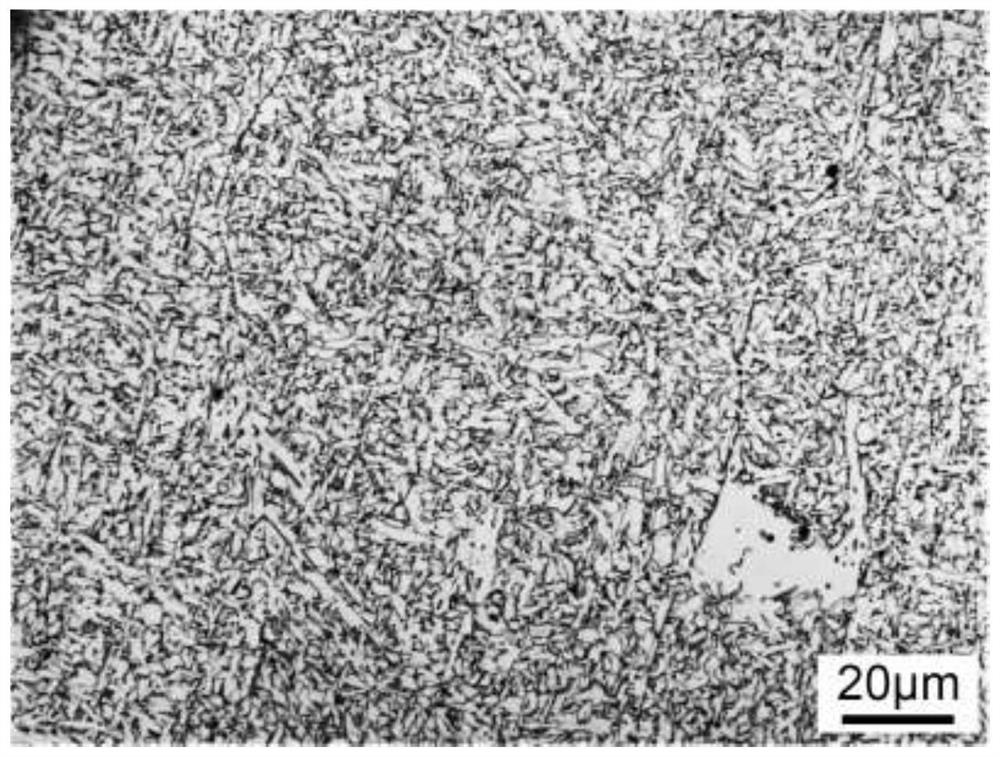

-70 degrees centigrade low-temperature steel welding bar

ActiveCN104551455AReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

A weather-resistant gas-shielded welding wire for a coating-free weather-resistant steel bridge

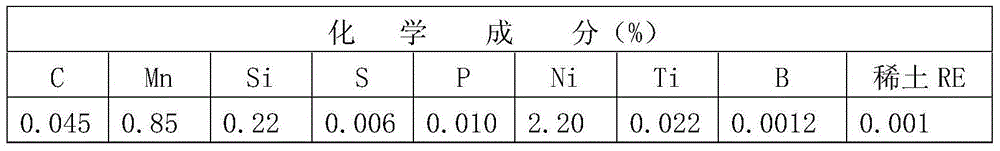

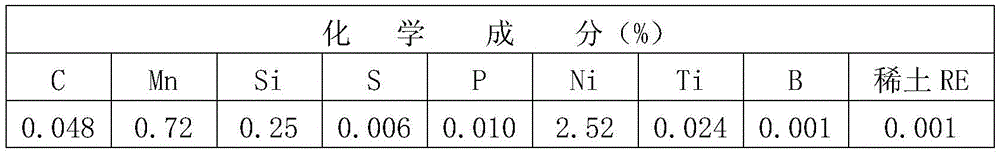

ActiveCN105798481BGuaranteed StrengthGuaranteed weather resistanceWelding/cutting media/materialsSoldering mediaChemical compositionAtmosphere

The invention provides a weather-proof gas protection welding wire for a coating-free weather-proof steel bridge, and belongs to the field of welding materials. According to the technical scheme, in the weather-proof gas protection welding wire for the coating-free weather-proof steel bridge, chemical components comprise the basic component Fe, and the welding wire is further prepared from, by mass percent, 0.03%-0.10% of C, 0.30%-0.50% of Si, 1.20%-1.60% of Mn, not larger than 0.012% of P, not larger than 0.005% of S, 0.30%-0.60% of Cr, 0.20%-0.50% of Ni, 0.20%-0.50% of Cu, 0.005%-0.025% of Ca and 0.005%-0.05% of Re. The welding wire is used for welding of weather-proof bridge steel, the strength of extension of deposited metal is high, the yield strength is high, the elongation is larger than or equal to 24%, and the low temperature impact resisting performance and the atmosphere corrosion resisting performance are excellent; and the welding wire is easy to manufacture and suitable for being popularized on a large scale.

Owner:YANSHAN UNIV

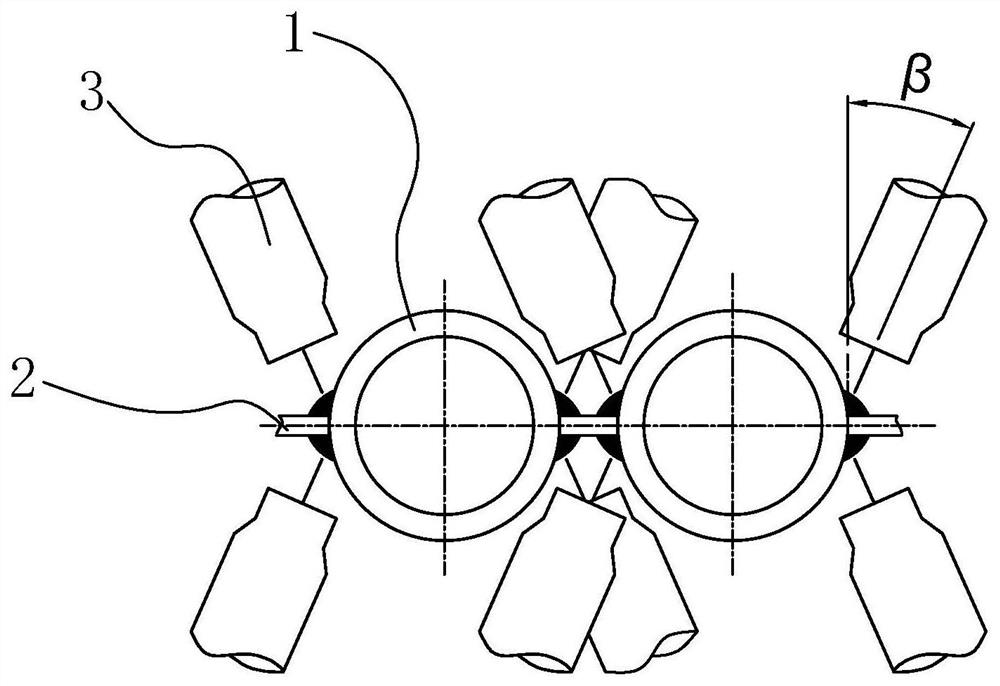

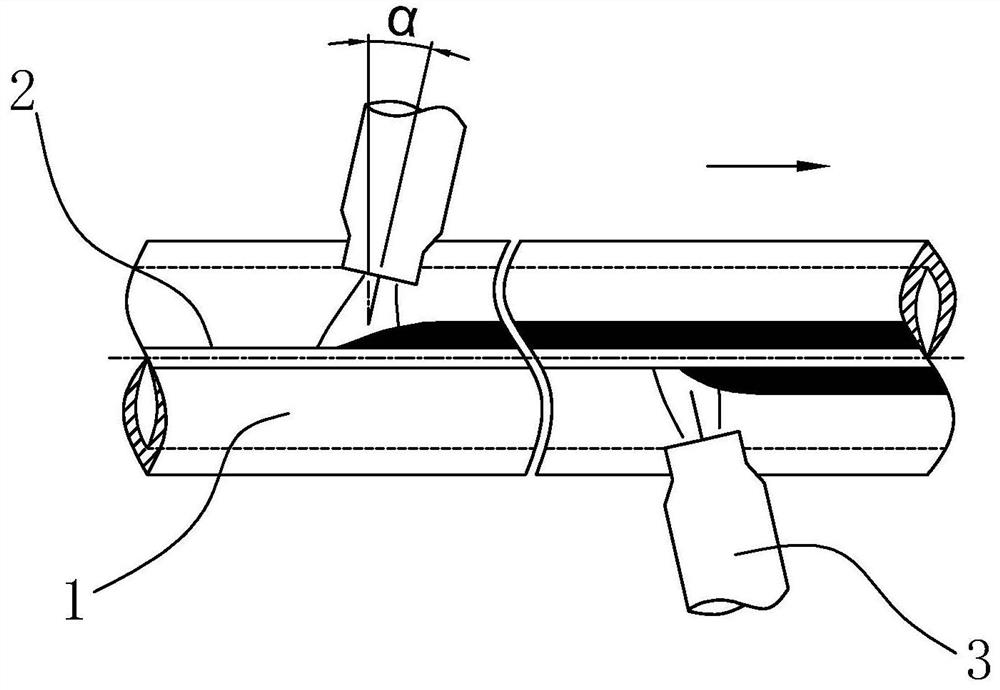

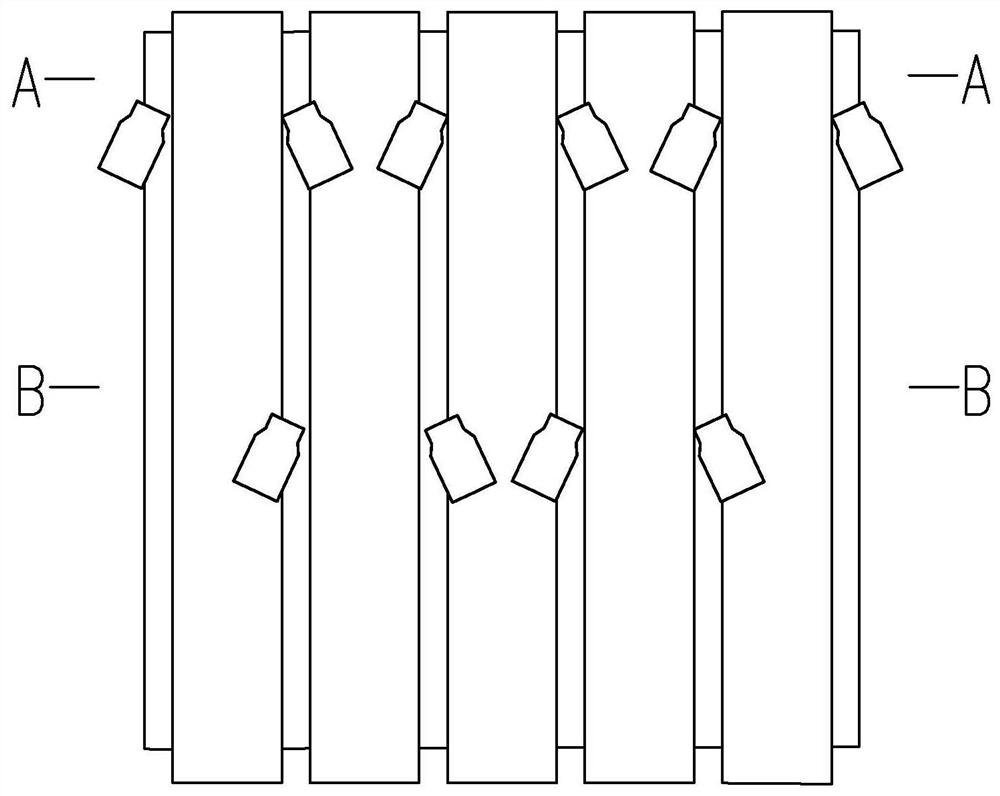

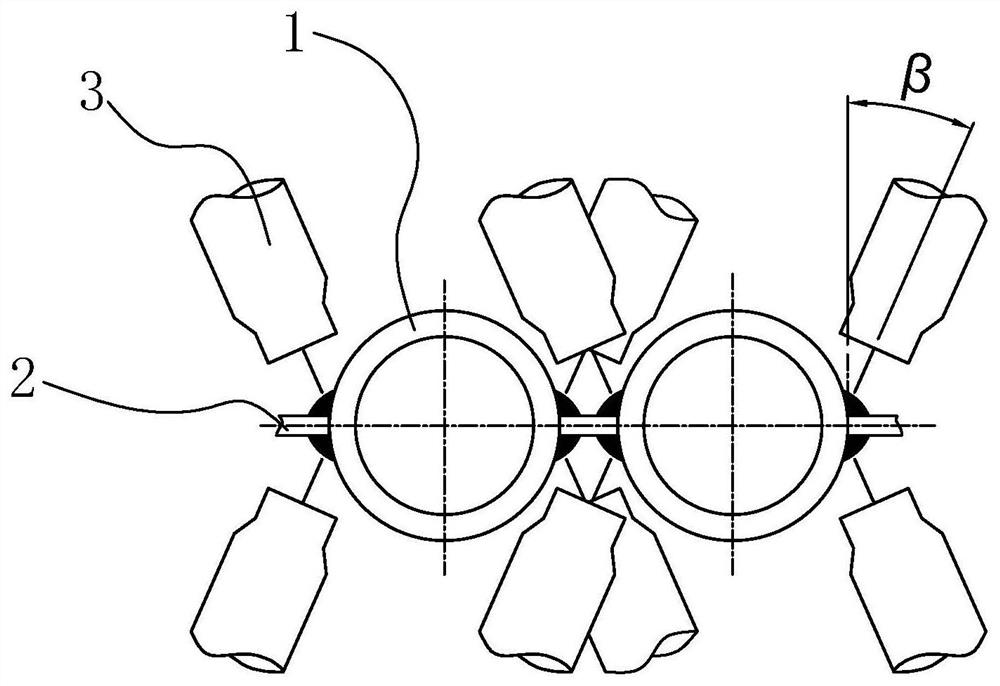

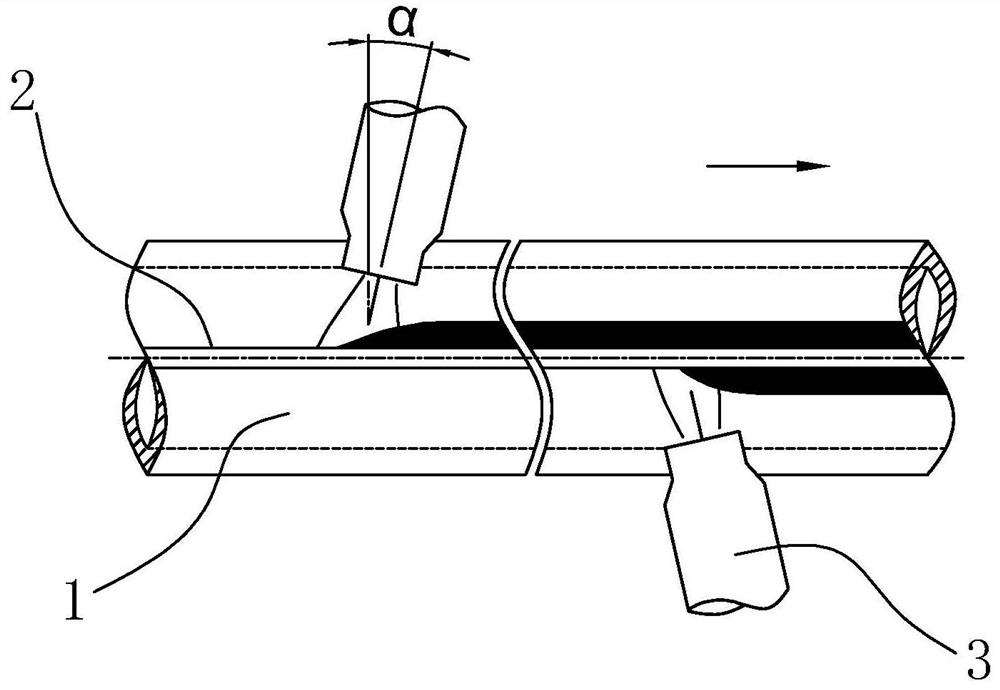

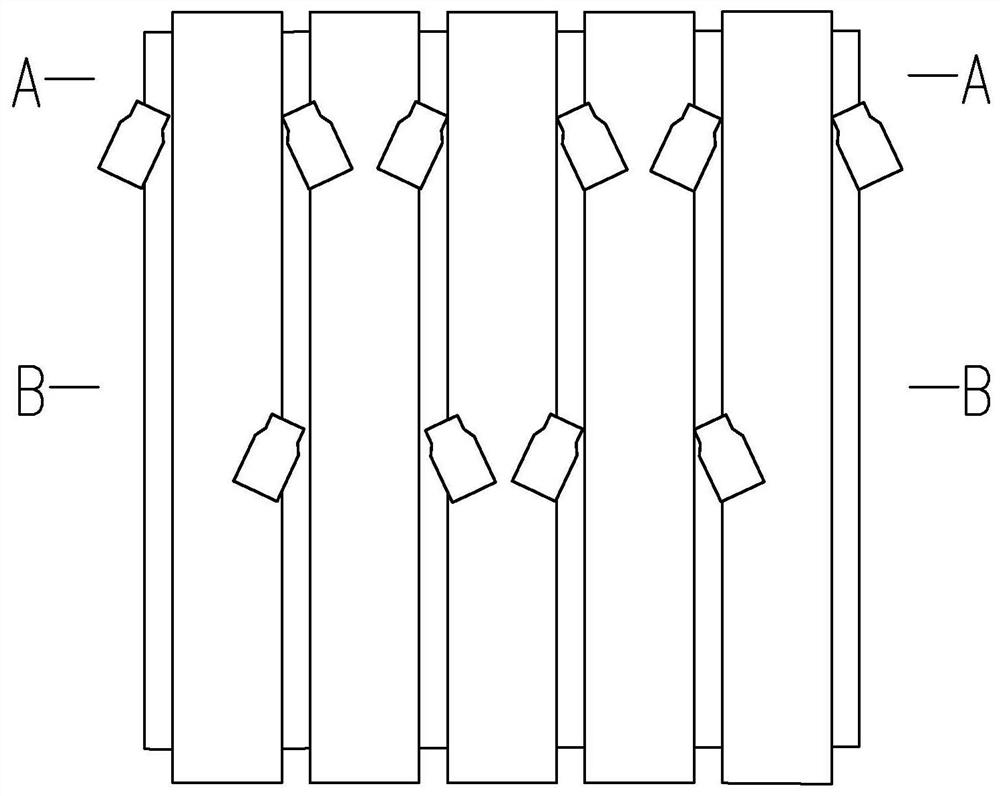

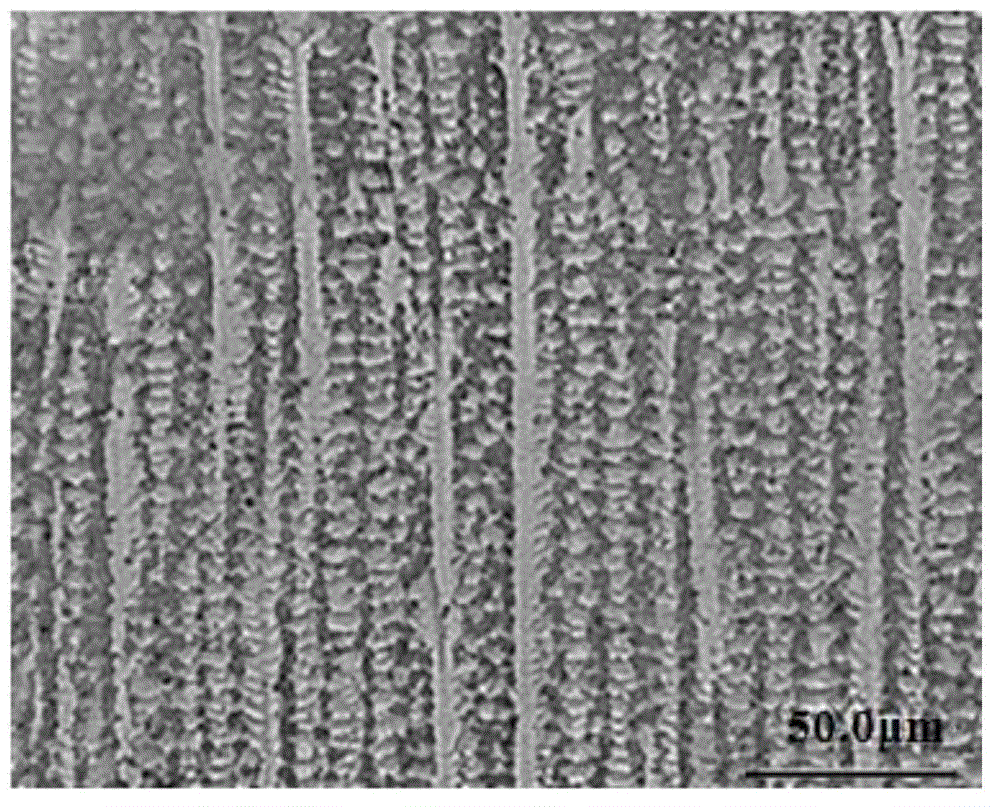

SA-213 S30432 material membrane tube panel welding method

ActiveCN112846463AGuaranteed StrengthUniform and full shapeElectrode supporting devicesWelding accessoriesThermal dilatationStructural engineering

The invention relates to a welding method, in particular to an SA-213S30432 material membrane type tube panel welding method. The problems that an SA-213S30432 material membrane type tube panel is large in welding hot crack trend and large in restraint stress, the risk of welding crack generation is increased, stainless steel is poor in heat conductivity and large in thermal expansion coefficient, and deformation is extremely prone to occurring due to welding are solved. The SA-213S30432 material membrane type tube panel welding method comprises the following steps that S1, after a plurality of pipes and flat steel made of SA-213S30432 are horizontally placed according to the pipe panel layout, a plurality of pulse gas metal shield welding power sources are arranged; S2, a plurality of welding guns are arranged, each welding gun is connected with the corresponding pulse gas metal arc welding power source, the welding guns are arranged on the upper side and the lower side of each pipe and the flat steel correspondingly, and the welding guns point to the joints of the pipes and the flat steel; and S3, an ER308LSi solid gas shielded welding wire is adopted for conducting uniform-speed welding on the pipes and the flat steel. Welding seams are formed uniformly and fully, smooth transition with base metal is achieved, defects are avoided, upper and lower welding guns are adopted for simultaneous welding, and deformation after welding is small.

Owner:HARBIN BOILER

Coating-free weather-resistant steel bridge with a tensile strength of 650mpa submerged arc automatic welding wire and wire rod

ActiveCN111975245BGood atmospheric corrosion resistanceReasonable ratioWelding/cutting media/materialsSoldering mediaWire rodEngineering

The invention discloses a wire rod for a submerged arc automatic welding wire with a tensile strength of 650 MPa for a coating-free weathering steel bridge, which belongs to the field of weathering steel welding materials. : 0.12~0.32, Mn: 1.60~2.20, P: ≤0.015, S: ≤0.005, Cr: 0.25~0.55, Ni: 0.6~1.10, Cu: 0.20~0.35, Mo: 0.10~0.40, Ti: 0.02~0.15 , Nb: 0.010~0.025, Ca: 0.005~0.030, Zr: ≤ 0.030, Ce: ≤ 0.025, B ≤ 0.0010, the balance is Fe and other inevitable impurities. Based on the above-mentioned wire rod for submerged arc automatic welding wire, the present invention also provides a submerged arc automatic welding wire with a tensile strength of 650 MPa for a coating-free weathering steel bridge. The welding wire and wire rod of the invention are suitable for the welding of non-painted bridge steel bridges with a tensile strength of 650MPa, wherein the tensile strength of the deposited metal is greater than or equal to 650MPa; the yield strength is greater than or equal to 500MPa; the elongation is greater than or equal to 22%; Low temperature impact energy KV2≥80J.

Owner:YANSHAN UNIV

Low-hydrogen alkaline electrode for online welding of X80 pipeline steel

InactiveCN102873473BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberSlag

The invention discloses a low-hydrogen alkaline electrode for online welding of X80 pipeline steel. The low-hydrogen alkaline electrode comprises a core wire and a coating. The coating comprises, by weight, from 40% to 45% of marble, from 15% to 20% of fluorite, from 2% to 4% of titanium dioxide, from 6% to 10% of rutile, from 7% to 10% of ferrotitanium, from 4% to 7% of low-carbon ferromanganese, from 2% to 5% of ferrosilicon, from 6% to 10% of iron powder, from 2.5% to 3% of synthetic mica, from 1.8% to 2.2% of rare earth and from 2% to 2.4% of microcrystal fibers, and the sum of the weight percents of the components is 100%. The electrode made from the coating is good in arc stabilization performance, a molten pool is good in flowability, splashing particles are tiny, post-welding slag detachability is good, slag coverage is uniform, and formed weld joints are delicate and attractive. Besides, the content of diffusible hydrogen in deposited metal of the manufactured electrode is effectively controlled.

Owner:XIAN UNIV OF TECH

Titanium-calcium welding rod

InactiveCN103084758BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a titanium-calcium welding rod which comprises a welding core and a coating. The coating comprises, by weight, 6%-25% of dolomite, 2%-8% of fluorite, 30%-45% of rutile, 1%-8% of titanium dioxide, 2%-8% of ferrotitanium, 2%-10% of ferromanganese, 5%-20% of feldspar, 2%-10% of white mud, 2%-7% of chalk, 1%-2% of mica, wherein sum of the weight percentages of all the components is 100%. The welding core comprises, by weight, 0.02%-0.03% of carbon, 1.25%-1.6% of manganese, 0.2%-0.3% of silicon, 20%-23% of chromium, 8.5%-9.5% of nickel, 2.5%-4.0% of molybdenum, 0.15%-0.20% of nitrogen, less than 0.01% of sulfur, less than 0.02% of phosphorus and the rest of ferrum, wherein the sum of the weight percentages of all the components is 100%. After the titanium-calcium welding rod is welded, slag is easy to remove and cover of the slag is uniform.

Owner:XIAN UNIV OF TECH

A kind of sa-213 S30432 material membrane tube screen welding method

ActiveCN112846463BGuaranteed StrengthUniform and full shapeElectrode supporting devicesWelding accessoriesThermal dilatationEngineering

A welding method for SA‑213S30432 material membrane tube panel, relating to a welding method to solve the problem that SA‑213S30432 membrane tube panel welding tends to have thermal cracks, the restraint stress is large, the risk of welding cracks is increased, and the thermal conductivity of stainless steel is poor Moreover, the coefficient of thermal expansion is large, and welding is extremely prone to deformation problems. The present invention comprises the following steps: S1, after a plurality of pipes and flat steels made of SA-213S30432 are placed horizontally according to the layout of the tube panel, a plurality of pulse melting electrode gas shielded welding power sources are equipped; S2, a plurality of welding torches are arranged, each The welding torch is connected to the pulse melting pole gas shielded welding power supply, and the welding torches are arranged on the upper and lower sides of the pipe and the flat steel, and each welding torch points to the joint between the pipe and the flat steel; Uniform welding. The welding seam of the invention is uniform and full in shape, smoothly transitions with the base material, has no defects, adopts upper and lower welding torches to perform welding simultaneously, and has small deformation after welding.

Owner:HARBIN BOILER

Low-hydrogen basic welding rod for welding 1Ni9 steel and preparation method thereof

InactiveCN103008923BLow diffusible hydrogen contentReduce toughnessWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

Owner:XIAN UNIV OF TECH

Flux-cored welding wire for x90 pipeline steel welding and preparation method thereof

InactiveCN104741834BImprove self-protection performanceGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention discloses a flux-cored wire for welding X90 pipeline steel. The flux-cored wire for welding the X90 pipeline steel comprises a flux core and skin. The flux core comprises, by mass, 30%-55% of fluoride, 10%-20% of oxide, 2%-5% of carbonate, 7%-10% of Al-Mg, 8%-15% of nickel powder, 0.5%-2.5% of chromium powder, 3%-6% of molybdenum powder, 1%-3% of copper powder, 10%-15% of electrolytic manganese metal, 1%-4% of ferrocolumbium, 0.5-1.5% of ferrotitanium, and 2%-4% of ferrosilicon. According to the flux-cored wire for welding the X90 pipeline steel, through control over the addition of the denitrfying agent and the oxygen agent and the slag making function and the gas making function of the fluoride, a good slag-gas-metal triune self-protection function is achieved; the arcing performance and the arc stabilizing performance are good, the fluidity of a molten bath is high, splashed particles are fine and small, slag is evenly covered after welding, slag removal is easy, and formed weld joints are delicate and attractive.

Owner:XIAN UNIV OF TECH

Martensitic stainless steel flux-cored wire

InactiveCN105945445AGood arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaMartensitic stainless steelTitanium nitride

The invention discloses a martensitic stainless steel flux-cored wire. The martensitic stainless steel flux-cored wire comprises the following components in percentage by weight: 15-20% of calcium carbonate, 15-20% of sodium carbonate, 15-40% of chromium powder, 10-25% of nickel powder, 10-15% of ferrovanadium, 2-5% of molybdenum nitride, 5-8% of titanium nitride, and 4-7% of niobium nitride; and the sum of all the components in percentage by mass is 100%. The flux-cored wire is excellent in arc starting and arc stabilizing performance, excellent in fluidity of a molten pool, fine in splashing particles, uniform in covering of after-welded molten slag, easy to remove slag and meticulous and beautiful in welding line formation.

Owner:HAIMEN WEILING WELDING MATERIAL MFG

Argon-enriched gas shielded welding wire and wire rod with tensile strength 650mpa grade for coating-free weather-resistant steel bridge

ActiveCN111975246BGood atmospheric corrosion resistanceReasonable ratioWelding/cutting media/materialsSoldering mediaWire rodUltimate tensile strength

The invention discloses a wire rod for a coating-free weather-resistant steel bridge with a tensile strength of 650MPa grade argon-enriched gas shielded welding wire. The chemical composition includes: C: 0.05-0.09, Si: 0.27-0.50, Mn: 1.65~2.00, P≤0.015, S≤0.005, Cr: 0.35~0.65, Ni: 0.65~0.90, Cu: 0.15~0.30, Mo: 0.08~0.20, Ti: 0.04~0.09, Ca: 0.010~0.030, V: ≤0.030, Nb: ≤0.020, Zr: ≤0.030, Ce: ≤0.020, O: ≤0.005, N: ≤0.007, the balance is Fe and unavoidable impurities. The invention also discloses an argon-enriched gas-shielded welding wire with a tensile strength of 650MPa for a coating-free weather-resistant steel bridge. The welding wire of the present invention is suitable for argon-rich shielded welding of coating-free bridge steel with a tensile strength of 650MPa, wherein the tensile strength of the deposited metal is ≥650MPa; the yield strength is ≥500MPa; the elongation is ≥23%; the deposited metal-40 ℃ low temperature impact energy KV2≥80J.

Owner:YANSHAN UNIV

Low-hydrogen basic electrode for welding FV520 (B) stainless steel

ActiveCN101905395BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a low-hydrogen basic electrode for welding FV520 (B) stainless steel, comprising a core wire and an electrod covering, wherein the electrode covering comprises the following materials in weight percentage: 35%-45% of marble, 18%-26% of fluorite, 6%-9% of quartz, 3%-6% of zircon sand, 6%-12% of rutile, 1%-3% of ferrosilicon, 6%-10% of ferrotitanium, 5%-11% of low-carbon ferromanganese, 1%-3% of rare-earth ferrosilicon and 0.5%-1.5% of sodium carbonate, and the sum of the weight percentages of the components is 100%. Compared with the traditional special imported electrode for the FV520 (B) stainless steel, the electrode made of the electrode covering has the advantages of favorable arc stabilization performance, good fluidity of a molten bath, less splash and dust, easier slag removal after welding, uniform slag coverage, and delicate and attractive welding joint formation. The content of diffusible hydrogen generated by using the developed electrode for depositing metal is effectively controlled and meets the requirements of low-carbon contents.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

600-MPa-grade fire-resistant weather-resistant steel welding rod

ActiveCN112975195ADiffusion hydrogen content controlReduce splashWelding/cutting media/materialsProcess efficiency improvementPhysical chemistryEngineering

The invention provides a 600-MPa-grade fire-resistant weather-resistant steel welding rod. Deposited metal of the 600-MPa-grade fire-resistant weather-resistant steel welding rod comprises the following chemical components in percentages by mass: 0.6-1.5wt% of Ni, 0.10-0.6wt% of Cr, 0.1-0.4wt% of Cu, 0.03-0.12wt% of V, 0.05-0.17wt% of W, 0.25-0.9wt% of Mo, 0.5-1.4wt% of Mn, 0.1-0.7wt% of Si, 0.04-0.11wt% of C, 0.005-0.009wt% of S, 0.01-0.02wt% of P and the balance of Fe and inevitable impurities, and the sum of the mass percentages of all the components is 100%. The yield strength of the fire-resistant weather-resistant steel welding rod at the high temperature of 600 DEG C is still 307 MPa or above, and the low-temperature (-40 DEG C) impact performance is good.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

A -70℃ low temperature steel welding rod

ActiveCN104551455BReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

Low temperature and high toughness welding wire for X80 pipeline steel and preparation method thereof

ActiveCN112705880BSmall diameterSolve the problem of insufficient low temperature toughness of weldsIncreasing energy efficiencyWelding/cutting media/materialsToughnessWeld bead

Owner:XIAN UNIV OF TECH

Low-temperature high-toughness welding wire for X80 pipeline steel and preparation method

ActiveCN112705880ASmall diameterSolve the problem of insufficient low temperature toughness of weldsIncreasing energy efficiencyWelding/cutting media/materialsLine tubingWeld seam

The invention discloses a low-temperature high-toughness welding wire for X80 pipeline steel. The welding wire comprises the following components of, in percentage by mass, less than or equal to 0.06% of C, 0.15-0.27% of Si, 1.30-1.50% of Mn, less than or equal to 0.003% of P, less than or equal to 0.003% of S, 1.20-2.40% of Ni, 0.02-0.08% of Cr, 0.03-0.05% of Cu, 0.02%-0.005% of Nb, 0.005 -0.010% of V, 0.06 -0.10% of Ti, 0.10 -0.20% of Mo, 0.01 -0.02% of Al, less than or equal to 0.005% of B, less than or equal to 0.005% of N, and the balance of Fe, and the sum of the percentage by mass of the components is 100%. The welding wire solves the problem of insufficient low-temperature toughness of a welding seam. The invention further discloses a preparation method of the low-temperature high-toughness welding wire for the X80 pipeline steel.

Owner:XIAN UNIV OF TECH

Welding wire for all-position welding of x100 pipeline steel and its preparation method

InactiveCN103962743BImprove self-protection performanceGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaArc stabilitySlag

A welding stick for the all-position welding of X100 pipeline steel comprises a flux core and a covering. The flux core comprises, by mass, 40-60% of fluoride, 10-20% of oxide, 2-6% of carbonates, 12-16% of Al-Mg alloy powder, 2-10% of nickel powder, 2-5% of chromium powder, 3-8% of molybdenum powder, 5-10% of electrolytic manganese metal and 0-3% of ferroniobium, and the sum of the mass percents of the components is 100%. According to the welding stick for the all-position welding of the X100 pipeline steel, adding of a denitrification agent and a deoxidizing agent (namely the Al-Mg alloy powder and ferromanganese) is controlled, the slagging and gas making functions of the fluoride and the carbonates are matched, and the good slag-gas-metal triune self-protection effect is achieved. The arcing and arc stability properties are good, the fluidity of a weld pool is good, splashing particles are small, postwelding slag coverage is even, slag removal is easy, and the appearance of weld seams is delicate and attractive.

Owner:XIAN UNIV OF TECH

High-toughness low-hydrogen basic welding rod and preparation method thereof

InactiveCN103084757BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberMisch metal

Owner:XIAN UNIV OF TECH

Low-hydrogen basic electrode for 1Ni9 low-temperature steel welding and preparation method of low-hydrogen basic electrode

InactiveCN103433642BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention provides a low-hydrogen basic welding electrode for 1Ni9 low-temperature steel welding. The low-hydrogen basic welding electrode comprises a welding core and a coating, wherein the welding core consists of the following components in percentage by mass: 0.01 to 0.03 percent of carbon, 0.5 to 0.9 percent of manganese, 0.2 to 0.4 percent of silicon, 21 to 24 percent of chromium, 2.5 to 3.5 percent of iron, 8.5 to 9.5 percent of molybdenum, 0.02 to 0.04 percent of titanium, 4 to 4.5 percent of niobium, 0.15 to 0.20 percent of nitrogen, at most 0.01 percent of sulfur, at most 0.01 percent of phosphorus and the balance of nickel; the coating comprises the following components in percentage by mass: 34 to 48 percent of marble, 17 to 24 percent of fluorite, 2 to 6 percent of zircon sand, 1 to 4 percent of ferrosilicon, 5 to 12 percent of ferrotitanium, 3 to 5 percent of mid-carbon ferromanganese, 2 to 5 percent of titanium dioxide, 2 to 5 percent of rutile, 2 to 6 percent of mica, 0.7 to 1 percent of alkali and 1 to 3 percent of mixed rare earth, and the sum of the mass percentage of the components is 100 percent. The low-hydrogen basic electrode provided by the invention solves the problems of poorer performance and high import price of existing welding electrodes.

Owner:XIAN UNIV OF TECH

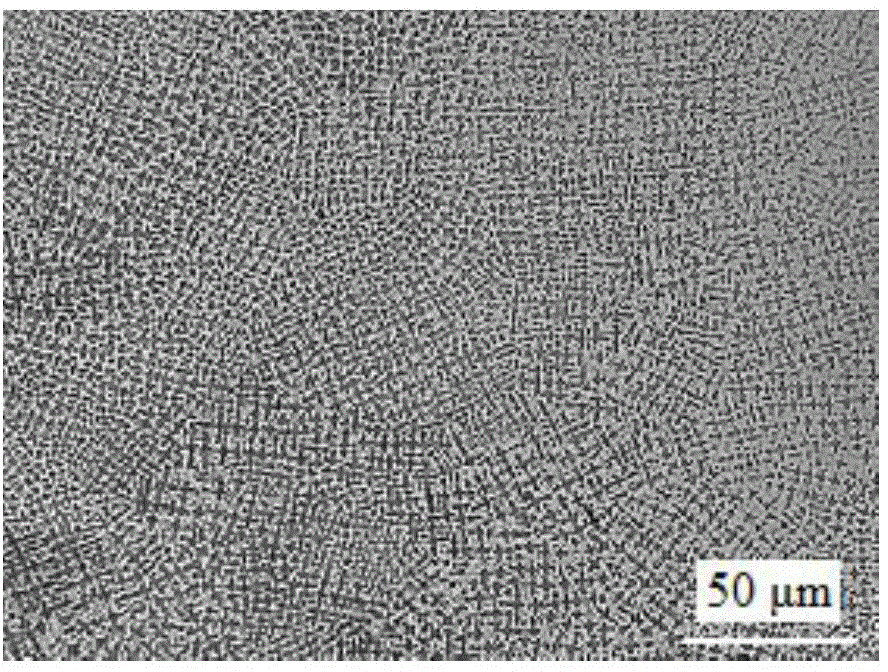

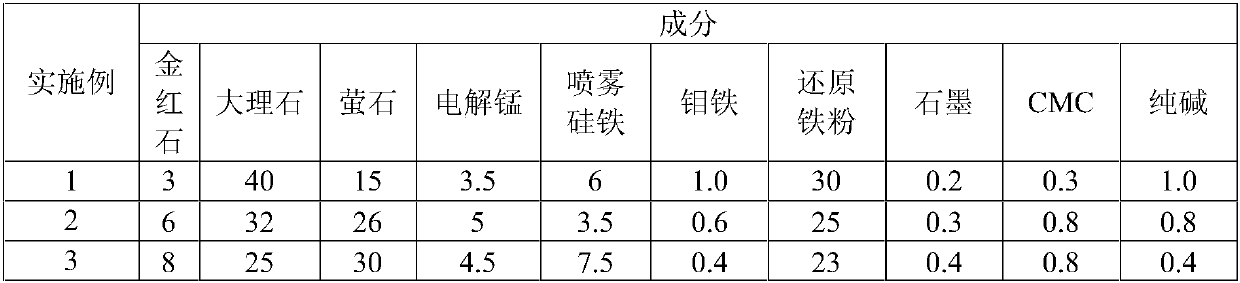

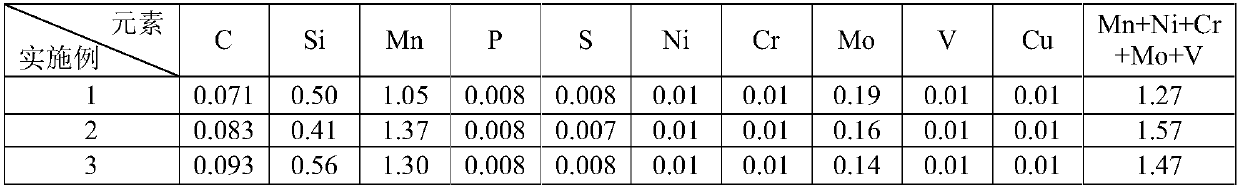

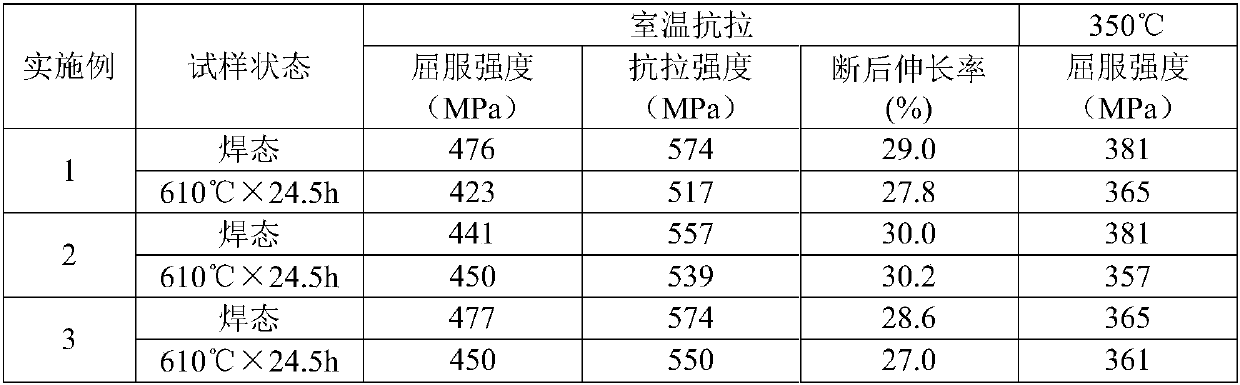

Carbon steel electrode for welding SA516 Gr.70 carbon steel plate, and preparation method thereof

PendingCN109093280AUniform coverageHigh purity of chemical compositionWelding/cutting media/materialsSoldering mediaArc stabilityMolten bath

The invention relates to the technical field of electrodes and preparation methods thereof, in particular to a carbon steel electrode for welding an SA516Gr.70 carbon steel plate, and a preparation method thereof. The carbon steel electrode comprises a core wire, an electrode coating and a binder. The material component of the electrode coating is powder, wherein the weight ratio of the powder tothe electrode is (35-45):100, the weight ratio of the powder to the binder is 100:(20-30), and the rest is the core wire. The components in the electrode coating comprise, by weight, 3-8% of rutile powder, 25-40% of marble powder, 15-30% of fluorite powder, 3-5% of electrolytic manganese, 2-8% of spray silicon iron, 0.2-1.0% of ferromolybdenum, 20-30% of reduced iron powder, 0.1-0.4% of graphite,0.2-0.8% of CMC and 0.3-1.0% of sodium carbonate. The carbon steel electrode has the advantages that electrical arc stability and molten bath liquidity are good, and molten slag shells evenly cover; deslagging is easy; and weld joints are formed flatly.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding

InactiveCN101890594BImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention discloses a low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding, which comprises a core wire and a coating, wherein the coating is prepared from the following materials in percentage by weight: 40-47% of marble, 16-24% of fluorite, 3-6% of quartz, 3-6% of zircon sand, 4-12% of rutile, 6-11% of ferrotitanium, 4-8% of low-carbon ferromanganese, 2-5% of ferrosilicon, 1-3% of rare earth ferrosilicon, 2.8-3.2% of synthetic mica and 0.5-1.5% of soda ash, and the sum of the weight percentage of all the components is 100%.The electrode prepared from the coating has the advantages of high arc stabilizing performance, good molten pool fluidity, fine splashing particles, easier deslagging after welding, uniform slag covering and delicate and attractive molded weld. Besides, the diffusible hydrogen content of the deposited metal of the prepared electrode is effectively limited.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com