Low-hydrogen basic welding rod for welding 1Ni9 steel and preparation method thereof

A basic electrode and welding core technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of high nickel content in the electrode and poor process performance, and achieve good arc stability and meet engineering requirements. Requirements, beautiful effect of welding seam forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of above-mentioned low-hydrogen alkaline electrode, concrete steps are as follows:

[0017] Step 1, weigh 34-48% of marble, 20-27% of fluorite, 2-8% of quartz, 4-5% of zircon sand, 3-10% of rutile, 1-3% of titanium dioxide, ferrosilicon 2 to 5%, rare earth ferrosilicon 1 to 3%, ferrosilicon 4 to 11%, medium carbon ferromanganese 2 to 8%, synthetic mica 1 to 3%, soda ash 1 to 2%, the sum of the weight percentages of each component is 100%; put the above powder materials and binder together into the mixer and mix for 10-20 minutes, then press the mixed powder into a cylindrical powder in the compactor; the binder is the modulus m= 3 sodium water glass, the weight ratio of drug skin to sodium water glass is 2.8~3.8:1;

[0018] Step 2, select UPT7013Mo or OK92.55 welding core, and place it on the wire feeding table of the press-coating machine, put the cylindrical powder ball prepared in step 1 into the press-coating machine, run the press-coating ma...

Embodiment 1

[0032] Step 1, weigh 350g marble, 230g fluorite, 55g quartz, 40g rutile, 12g titanium dioxide, 40g zircon sand, 45g ferrosilicon, 26g rare earth ferrosilicon, 104g ferrotitanium, 78g medium carbon ferromanganese, 10g synthesis Mica, 10g soda ash, put the above-mentioned medicinal powder material and 350g sodium water glass together in a mixer and mix for 15min, then put the mixed medicinal powder into a compactor and press into a cylindrical powder group;

[0033] Step 2, select UPT7013Mo welding core, and place it on the wire feeder of the press-coating machine, put the cylindrical powder ball prepared in step 1 into the press-coating machine, run the press-coating machine to make welding rod, and put the prepared After grinding the head and tail of the welding rod, put it into the box dryer, and dry it according to 60℃×8h+120℃×1h+180℃×1h+250℃×1h+350℃×1.5h, and then it will be used for welding Low hydrogen alkaline electrode for 1Ni9 steel.

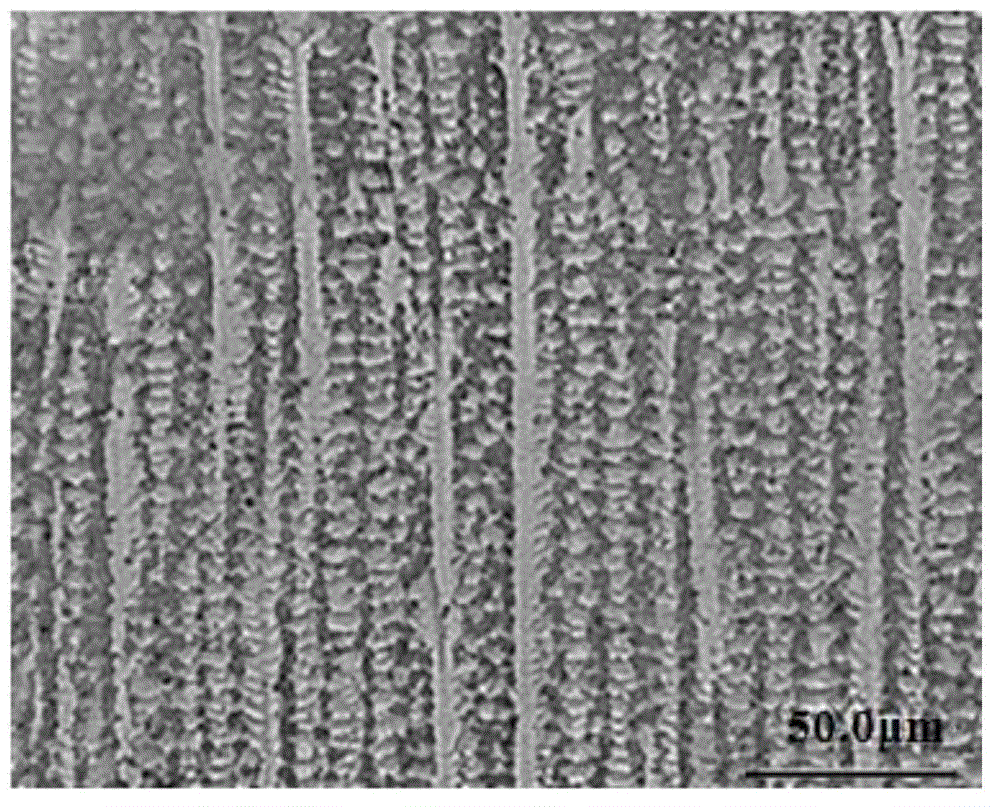

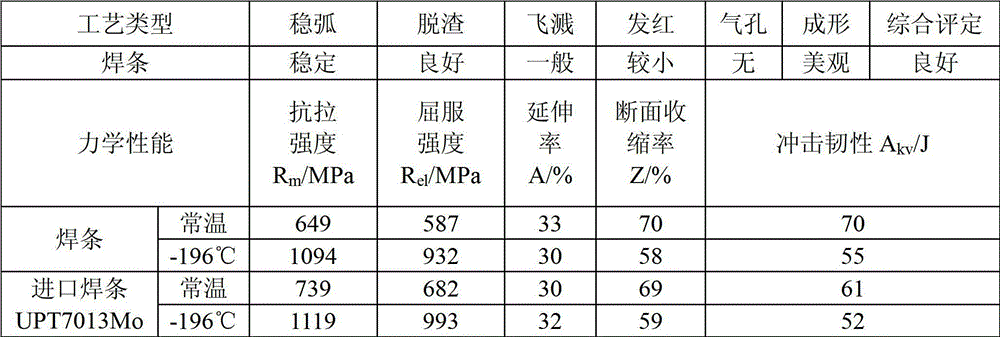

[0034] Use the low-hydrogen basi...

Embodiment 2

[0040] Step 1, weigh 380g marble, 200g fluorite, 50g quartz, 55g rutile, 19g titanium dioxide, 50g zircon sand, 41g ferrosilicon, 21g rare earth ferrosilicon, 84g ferrotitanium, 60g medium carbon ferromanganese, 20g synthetic mica , 20g soda ash, the above-mentioned medicinal powder material and 350g sodium water glass are put into the mixing machine and mix 10min together, then the medicinal powder after mixing is put into a compactor and pressed into a cylindrical powder group;

[0041] Step 2, select the OK92.55 welding core, and place it on the wire feeder of the press-coating machine, put the cylindrical powder ball prepared in step 1 into the press-coating machine, run the press-coating machine to make welding rods, and put the Put the good welding rod into the box dryer after grinding the head and tail, and dry it according to 60℃×8h+120℃×1h+180℃×1h+250℃×1h+350℃×1.5h, and then you can get the used Low-hydrogen basic electrode for welding 1Ni9 steel.

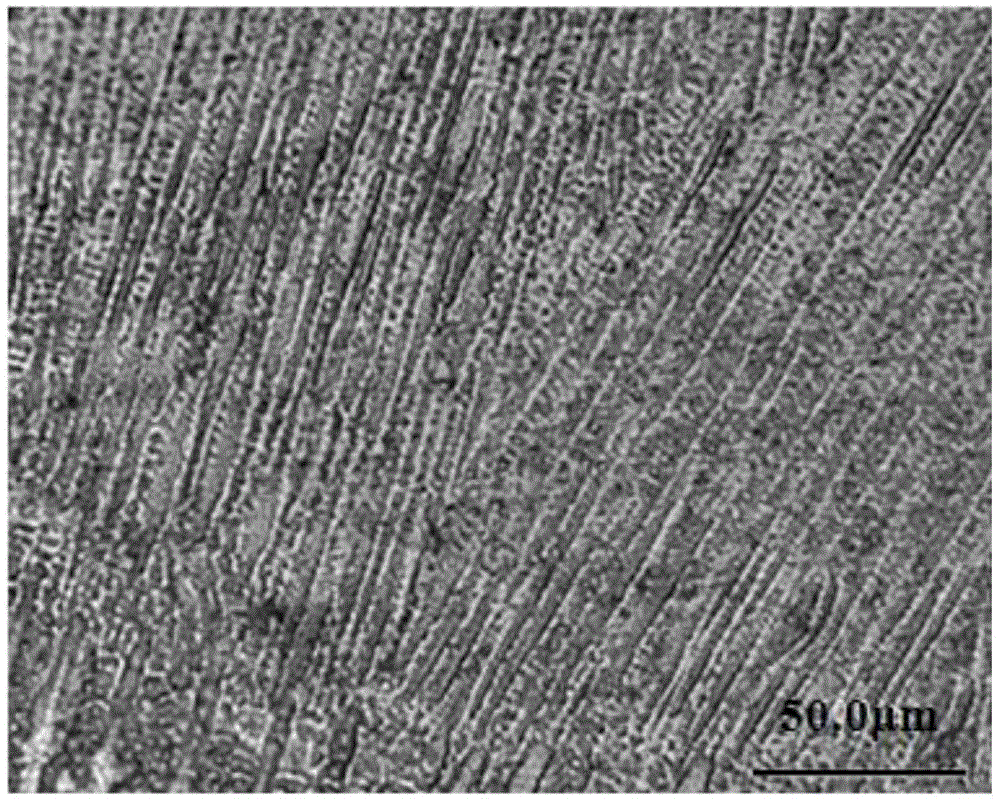

[0042] The 1Ni9 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com