Coating-free weather-resistant steel bridge with a tensile strength of 650mpa submerged arc automatic welding wire and wire rod

A tensile strength and weathering steel technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of increased phase transition temperature, coarsening of weld structure, reduced welding manufacturability, and metallurgical quality. , to achieve the effect of easy smelting, stable arc and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

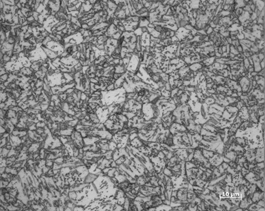

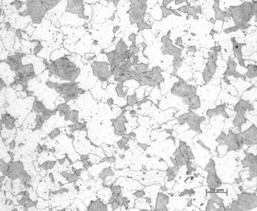

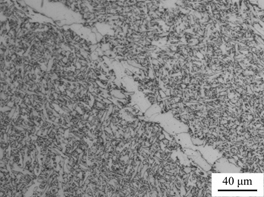

[0041] The invention provides a coating-free weather-resistant steel bridge with a tensile strength of 650MPa class submerged arc automatic welding wire rod, the chemical composition of which includes: C: 0.04~0.09, Si: 0.12~0.32, Mn: 1.60~2.20, P: ≤0.015, S: ≤0.005, Cr: 0.25~0.55, Ni: 0.6~1.10, Cu: 0.20~0.35, Mo: 0.10~0.40, Ti: 0.02~0.15, Nb: 0.010~0.025, Ca: 0.005~0.030, Zr: ≤0.030, Ce: ≤0.025, B≤0.0010, and the balance is Fe and other unavoidable impurities.

[0042] Among them, the chemical composition ratios of C, Si, Mn, Cr, Ni, Cu, Mo and Ca meet: 0.50≤δ≤0.63, 580≤η≤625.

[0043] δ=(1.3Cu+Cr+Ni+Mo) / (1.5Si+Mn+60Ca);

[0044] η=843-401[C]-76.3[Mn]+41.6[Si]-51.4[Ni]-29.9[Cr]-32.2[Cu]-69.8[Mo].

[0045] The above-mentioned wire rod for automatic submerged arc welding contains one or more of Zr, Ce, and B.

[0046] Based on the above-mentioned wire rod for automatic submerged arc welding, the present invention also provides a kind of wire rod for automatic submerged arc w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com