Low-temperature high-toughness welding wire for X80 pipeline steel and preparation method

A pipeline steel and low-temperature technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of insufficient low-temperature toughness of welds, and achieve the effects of small fluctuations in low-temperature toughness, beautiful weld formation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

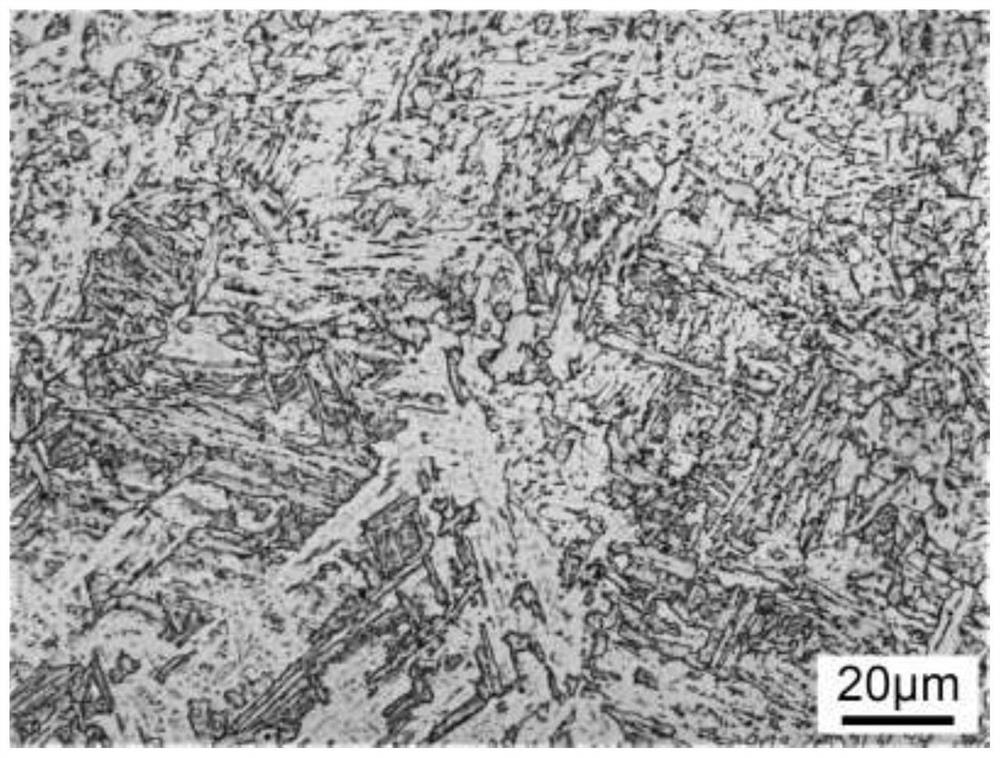

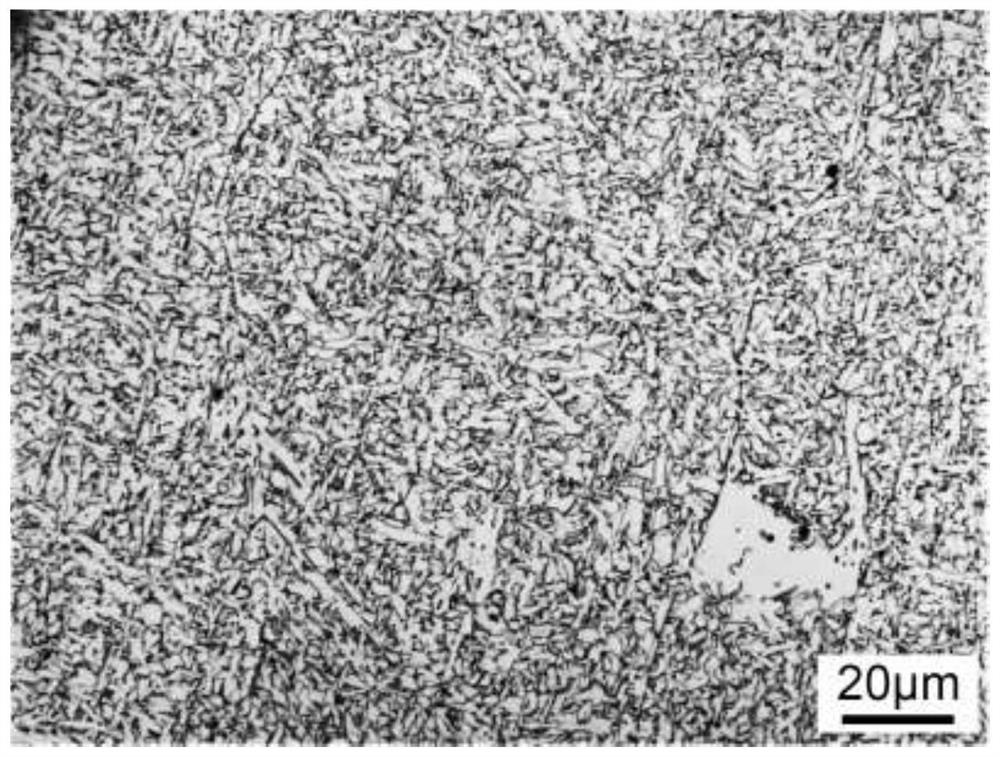

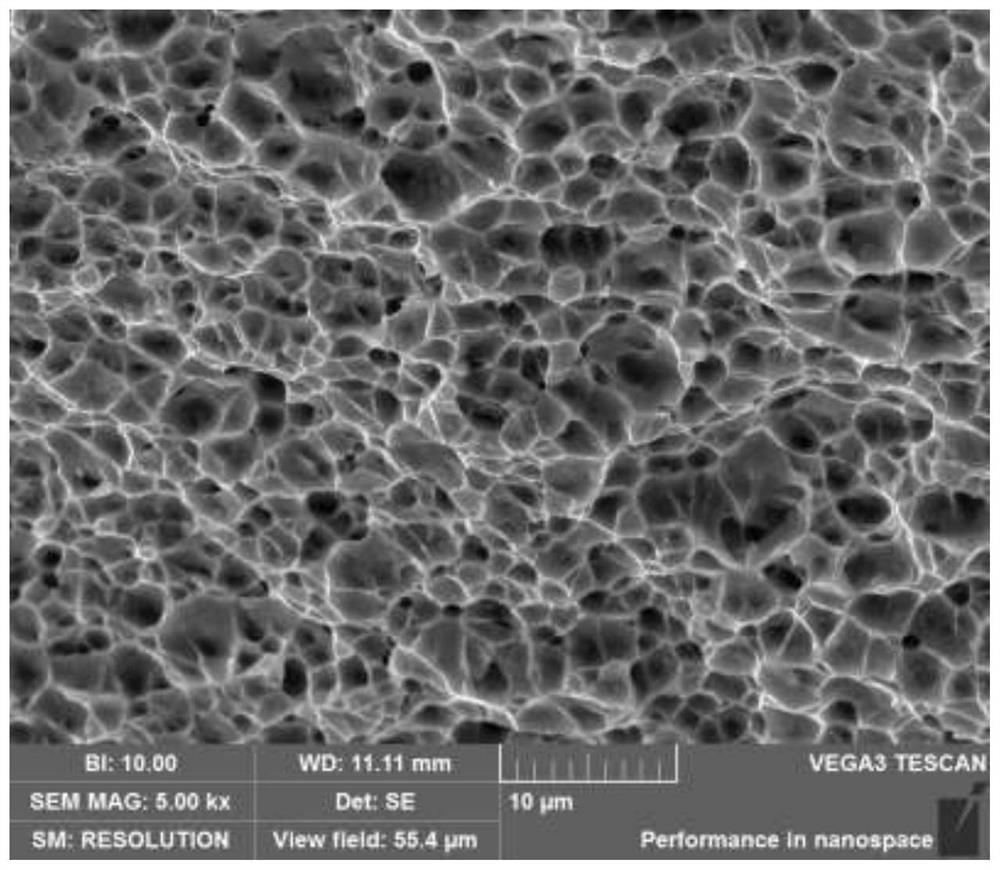

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of low-temperature high-toughness welding wire for X80 pipeline steel, the specific steps are as follows:

[0038] Step 1: Weigh the following raw material powders according to mass percentage: C≤0.06%, Si 0.15~0.27%, Mn1.30~1.50%, P≤0.003%, S≤0.003%, Ni 1.20~2.40%, Cr 0.02~ 0.08%, Cu 0.03~0.05%, Nb 0.02~0.05%, V 0.005~0.010%, Ti 0.06~0.10%, Mo 0.10~0.20%, Al0.01~0.02%, B≤0.005%, N≤0.005%, The balance is Fe, and the sum of the mass percentages of the above-mentioned components is 100%;

[0039] Step 2: Put the raw material powder weighed in step 1 together in a vacuum induction heating furnace for smelting and refining to obtain steel ingot materials;

[0040] In step 2, the temperature of smelting is 1500°C-1800°C, and the time is 1h-3h; the temperature of refining is 1100-1200°C, and the time is 30-60min;

[0041] Step 3: First forge the cast steel ingot into a square billet, and then roll it at a certain temp...

Embodiment 1

[0047] Step 1: Weigh the following raw material powders by mass percentage: C 0.06%, Si 0.15%, Mn 1.30%, P0.003%, S 0.003%, Ni 1.20%, Cr 0.02%, Cu 0.03%, Nb 0.02%, V 0.005%, Ti0.06%, Mo 0.10%, Al 0.01%, B 0.005%, N 0.005%, the balance is Fe, and the sum of the mass percentages of the above components is 100%;

[0048] Step 2: Put the raw material powder weighed in step 1 together in a vacuum induction heating furnace for smelting and refining to obtain steel ingot materials;

[0049] In step 2, the temperature of smelting is 1500°C, and the time is 3h; the temperature of refining is 1100°C, and the time is 30min;

[0050] Step 3: Forge the cast steel ingot into a 50mm×50mm×50mm square billet, and then roll it at 600°C the wire rod;

[0051] Step 4: Carry out mechanical peeling-pickling-drying-rough drawing-crimping-heat treatment-finishing-finishing-curling-polishing-curling and other processes in turn on the wire rod, and finally obtain a welding wire with a diameter of 1....

Embodiment 2

[0058] Step 1: Weigh the following raw material powders according to mass percentage: C 0.02%, Si 0.20%, Mn 1.40%, P0.003%, S 0.003%, Ni 2.0%, Cr 0.05%, Cu 0.03%, Nb 0.02%, V 0.010%, Ti 0.08%, Mo 0.20%, Al 0.02%, B 0.005%, N 0.002%, the balance is Fe, and the sum of the mass percentages of the above components is 100%;

[0059] Step 2: Put the raw material powder weighed in step 1 together in a vacuum induction heating furnace for smelting and refining to obtain steel ingot materials;

[0060] In step 2, the temperature of smelting is 1600°C, and the time is 2h; the temperature of refining is 1200°C, and the time is 60min;

[0061] Step 3: Forge the cast ingot into a 50mm×50mm×50mm square billet, and then roll it at 700°C the wire rod;

[0062] Step 4: Carry out mechanical peeling-pickling-drying-rough drawing-crimping-heat treatment-finishing-finishing-curling-polishing-curling and other processes in turn on the wire rod, and finally obtain a welding wire with a diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com