SA-213 S30432 material membrane tube panel welding method

A SA-213S30432, welding method technology, applied in welding equipment, welding accessories, welding rod characteristics and other directions, can solve the problems of poor thermal conductivity of stainless steel, easy deformation of welding, large thermal expansion coefficient, etc., to achieve beautiful molding, uniform and full, moisturizing Wet strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

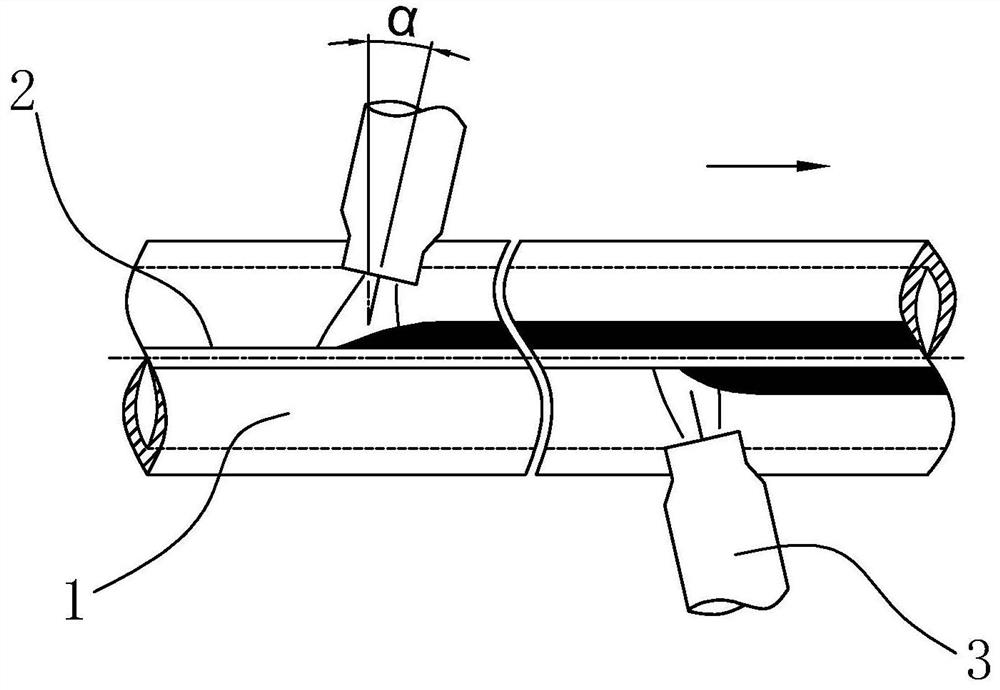

[0025] Embodiment 1: the following combination Figure 1-Figure 5 To illustrate this embodiment, this embodiment relates to a welding method of SA-213 S30432 material membrane tube panel, including the following steps:

[0026] S1. After placing multiple pipes (1) and flat steel (2) horizontally according to the tube panel layout, equip multiple pulse melting electrode gas shielded welding power sources;

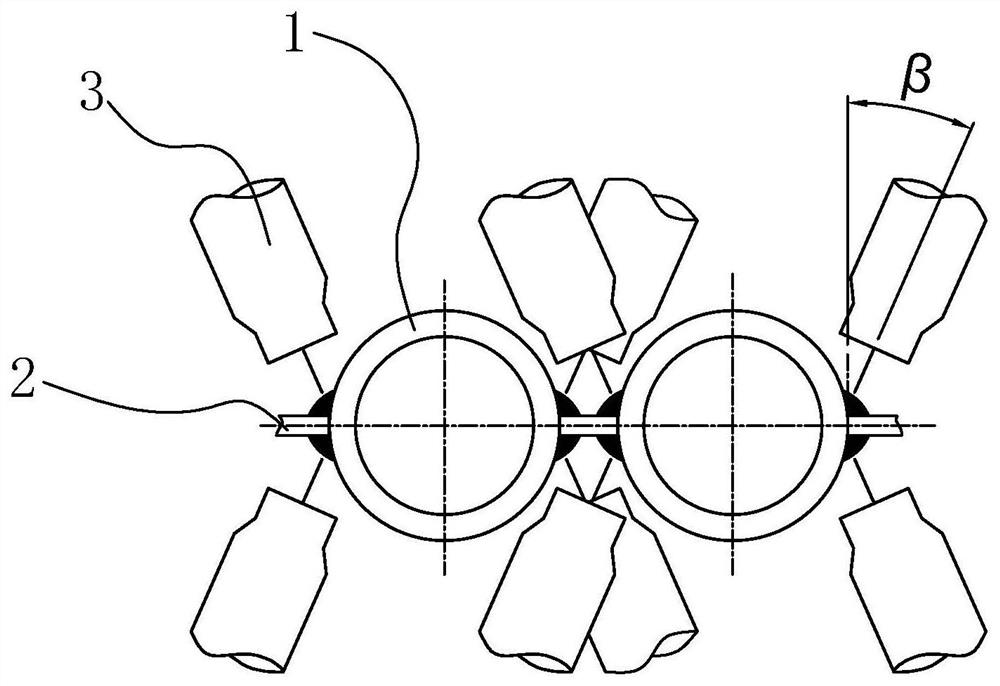

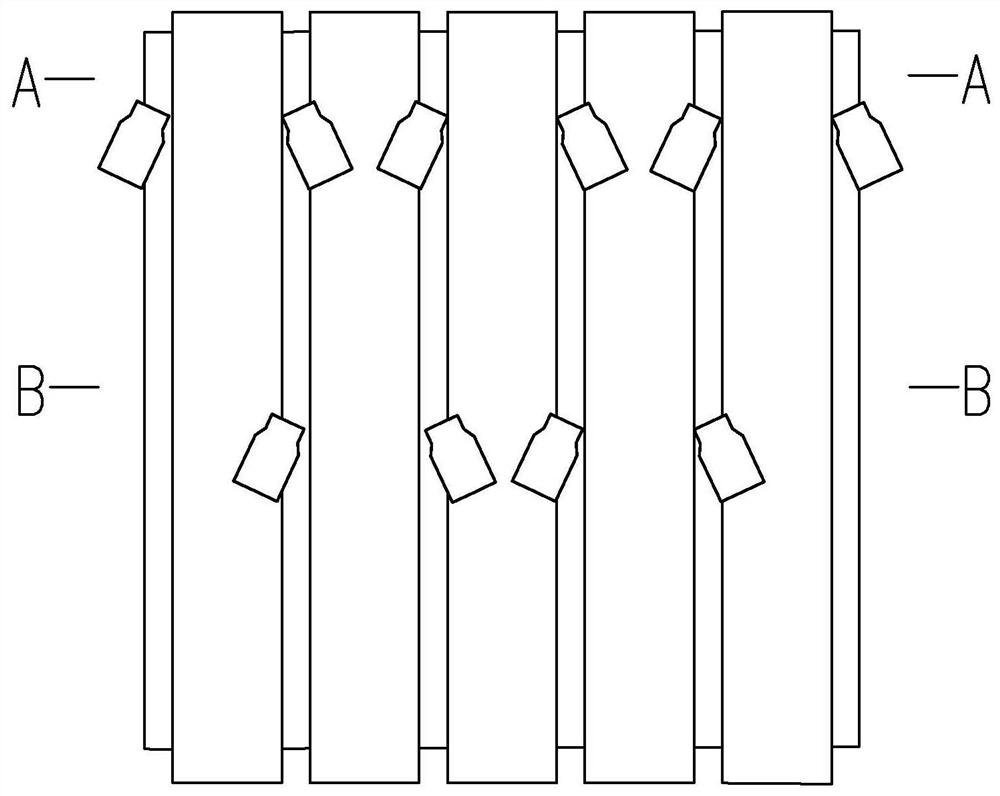

[0027] S2, arranging a plurality of welding torches (3), each welding torch (3) is connected with the pulse melting gas shielded welding power supply, and the welding torches (3) are arranged on the upper and lower sides of the pipe (1) and the flat steel (2), each welding torch All point to the junction of the pipe (1) and the flat steel (2), the welding torches are arranged in two rows on the upper and lower sides of the tube panel and welded at the same time to avoid welding deformation caused by uneven heating of the tube panel;

[0028] S3. Use ER308LSi solid gas-shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com