Carbon steel electrode for welding SA516 Gr.70 carbon steel plate, and preparation method thereof

A sa516gr.70, welding rod technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of welding rod spatter, large slag removal, etc., and achieve excellent strength and toughness matching, uniform coverage, and good weld resistance. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

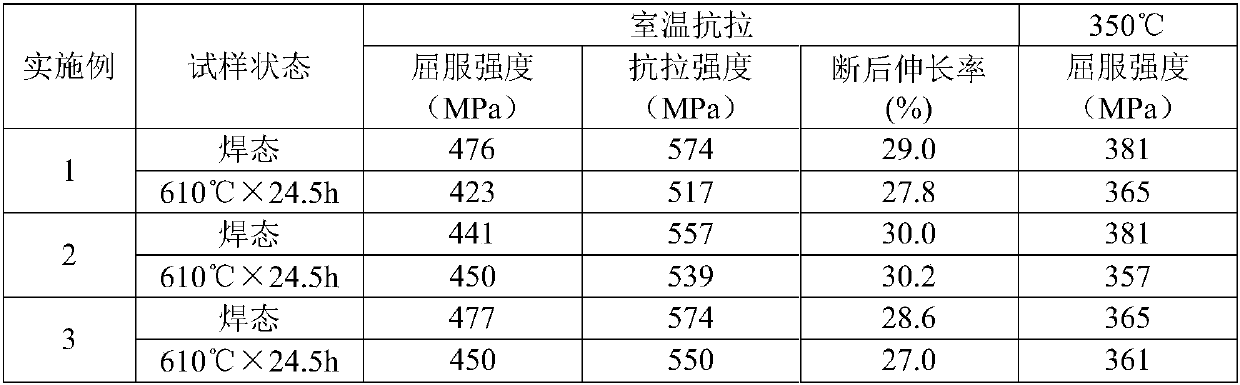

Examples

Embodiment 1~3

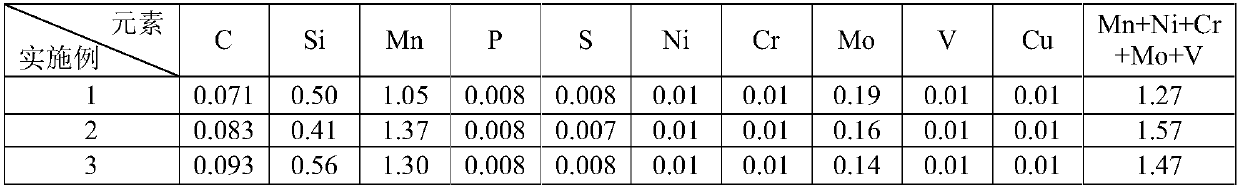

[0019] The present invention provides a carbon steel welding rod for welding SA516 Gr.70 carbon steel plates. The high-quality H08A carbon steel welding core with a diameter of Φ4.0mm is selected, and its specific chemical composition is shown in Table 1;

[0020] The concrete chemical composition of the welding core of table 1 present embodiment electrode compares (weight %)

[0021] C

S

mn

Si

P

Cr

Ni

Cu

As

0.055

0.008

0.46

0.01

0.005

0.01

0.01

0.01

0.01

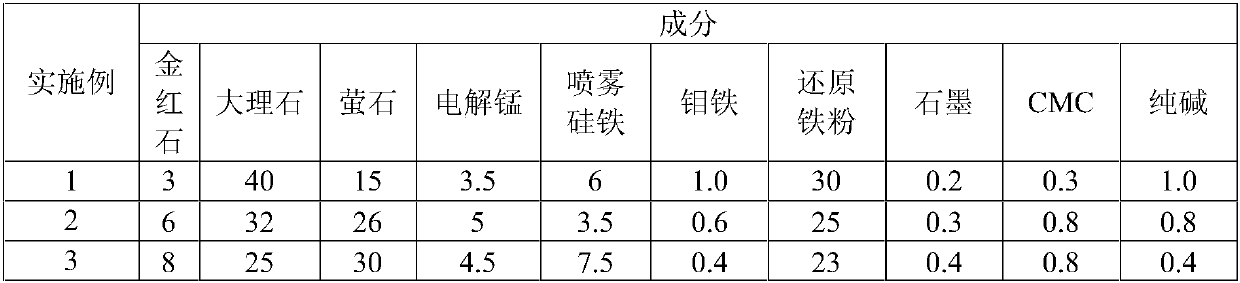

[0022] (1) get various ingredients and mix homogeneously by the components and percentages shown in Table 2;

[0023] (2) Use potassium sodium mixed water glass with Baume concentration of 43° as the binder, the weight ratio of powder to binder is 100:20, stir and mix evenly; send the mixed material and H08A carbon steel welding core into the plodder Inside, wrap it on the H08A carbon steel welding core according to the conventional method;

[0024] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com