Patents

Literature

79results about How to "Consistent mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

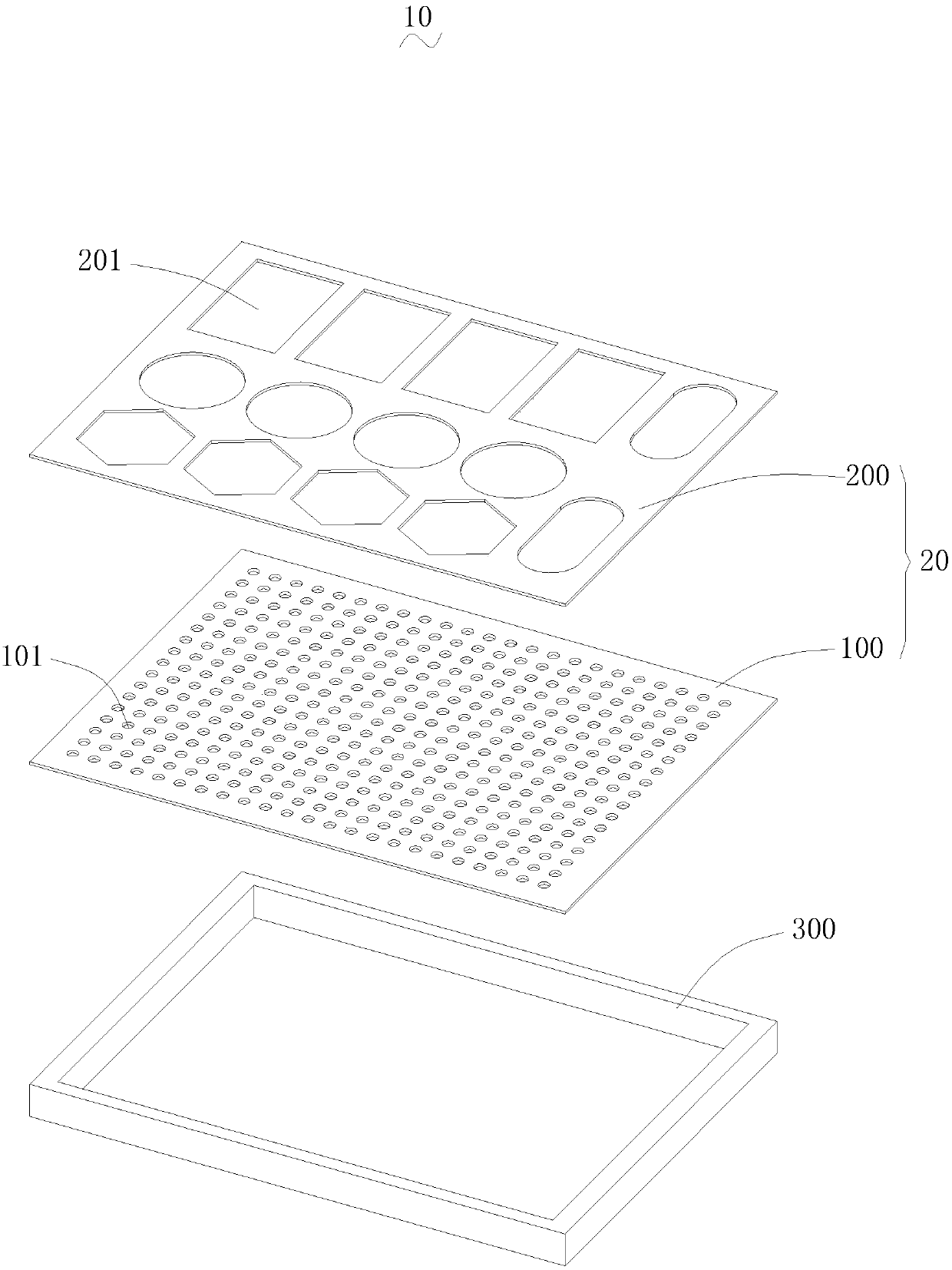

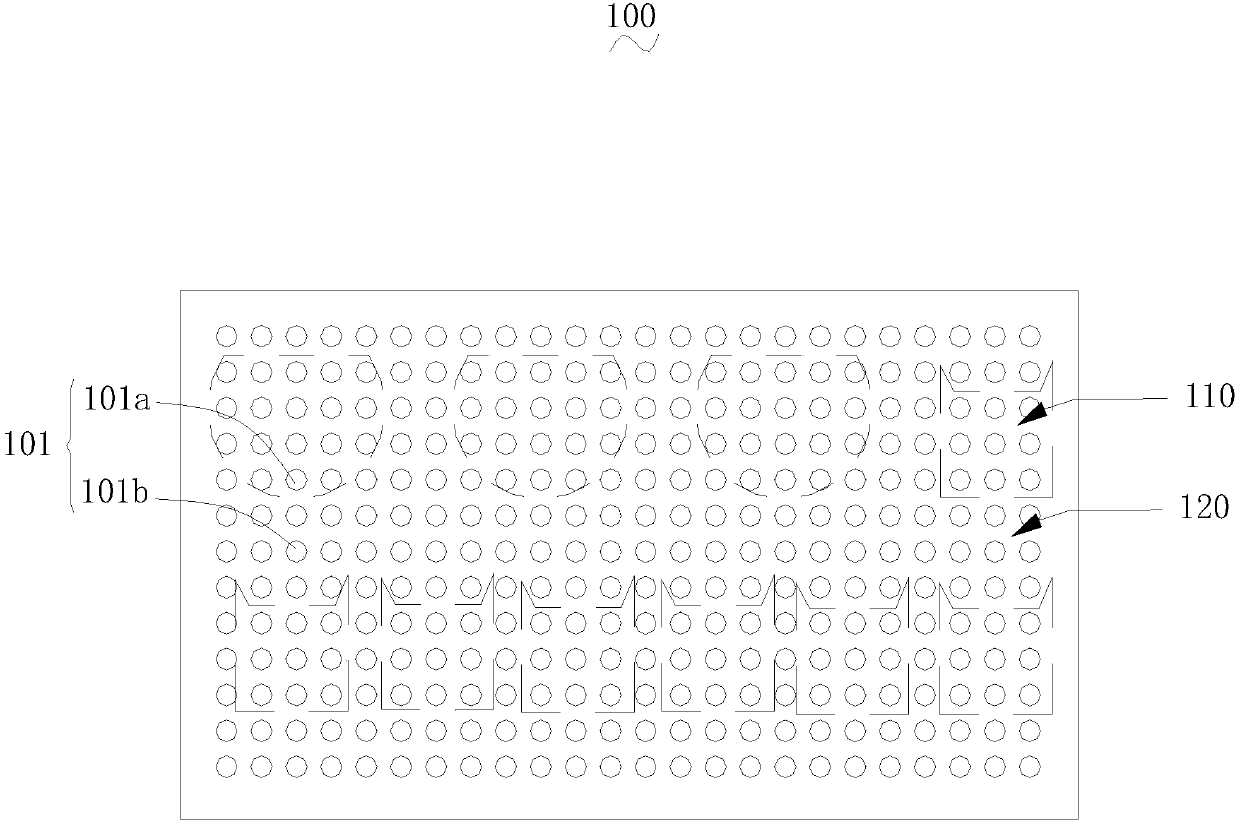

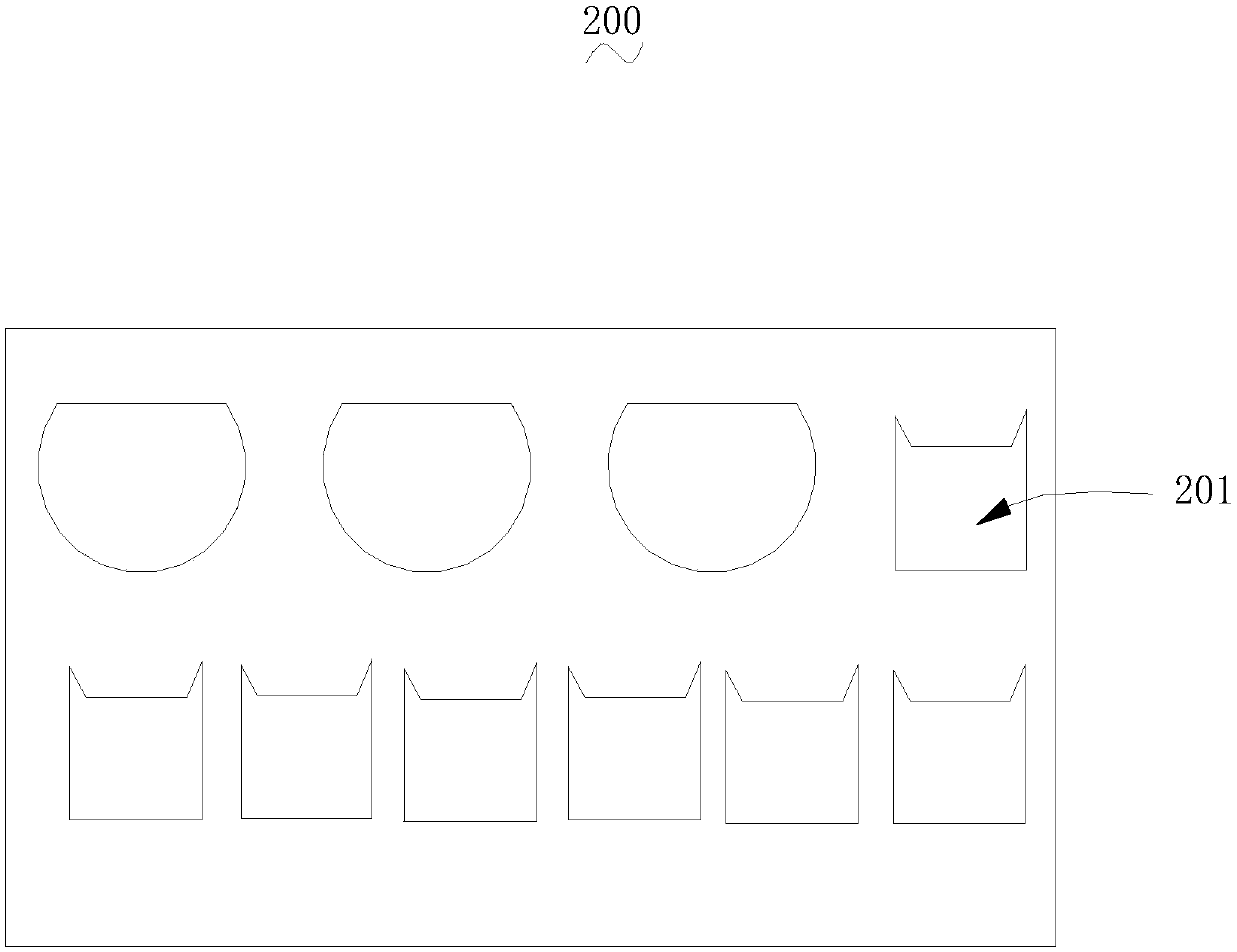

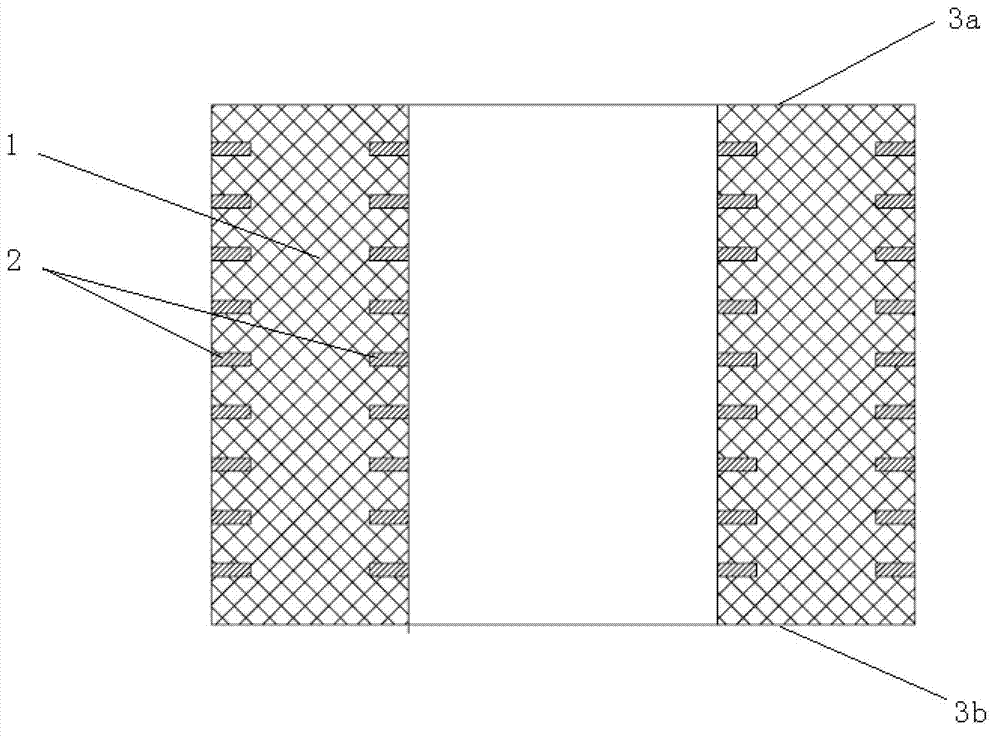

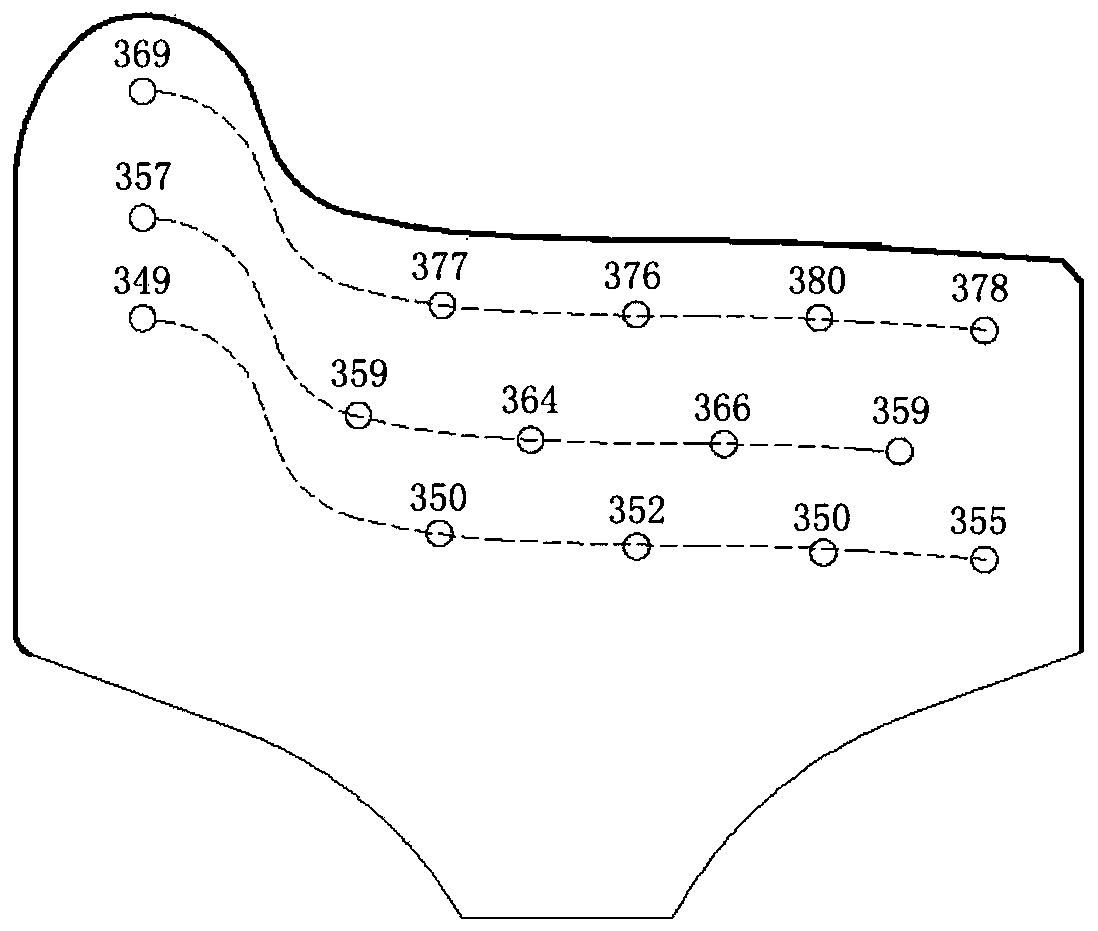

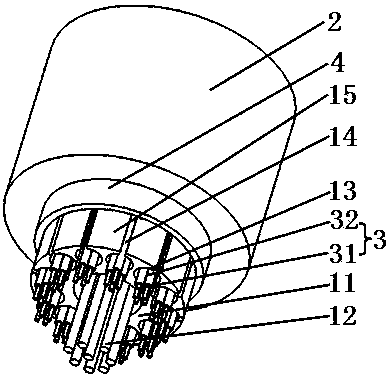

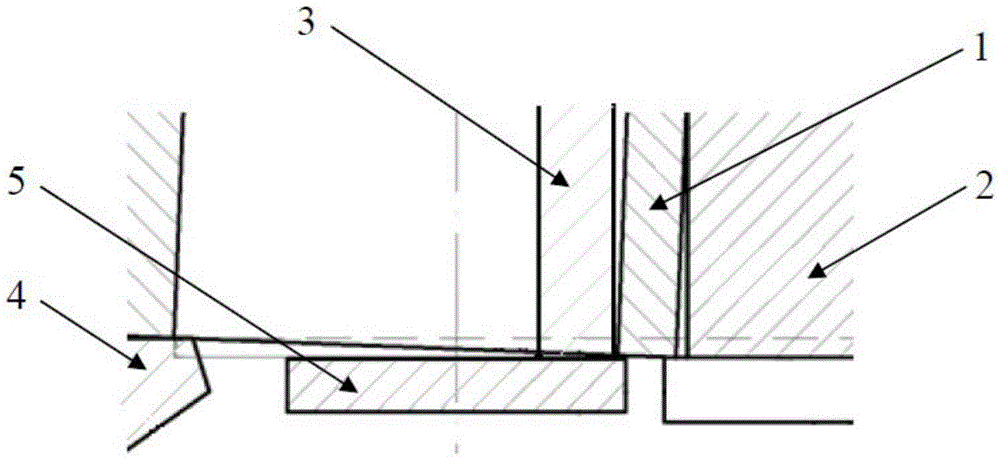

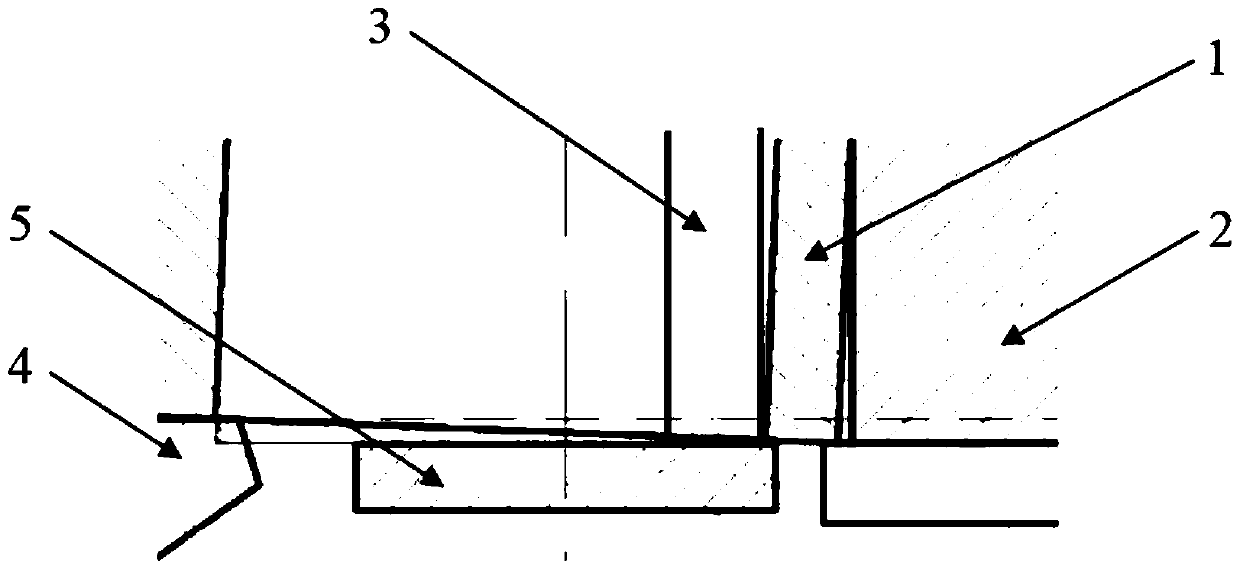

Mask device and mask module and mask plate thereof

InactiveCN107653435AConsistent mechanical propertiesEfficient use ofVacuum evaporation coatingSputtering coatingEtchingEvaporation

The invention relates to a mask device and a mask module and a mask plate thereof. The mask device comprises the mask module and a mask frame; the mask module comprises the mask plate and a shieldingpiece; the edge of the mask plate is connected with the mask frame; multiple through holes are uniformly formed in the mask plate; multiple through ports are formed in the shielding piece; the shielding piece butts against the mask plate; each through port is aligned to part of the through holes in the mask plate; and the shielding piece shields the rest part of the through holes in the mask plate. The mask plate has no need to arrange different reserved areas according to different display areas, and only needs overall etching, so that the etching procedures are reduced, and the process complexity is reduced; the through holes are uniformly formed in the whole mask plate, so that the mechanical performances of all parts of the mask plate tend to be consistent, and the deformation is effectively reduced; and the display areas with different shapes can be evaporated at the same time, so that the utilization rate of a glass substrate is increased, the evaporation efficiency is improved,and the product updating demands can be quickly adapted to.

Owner:TRULY HUIZHOU SMART DISPLAY

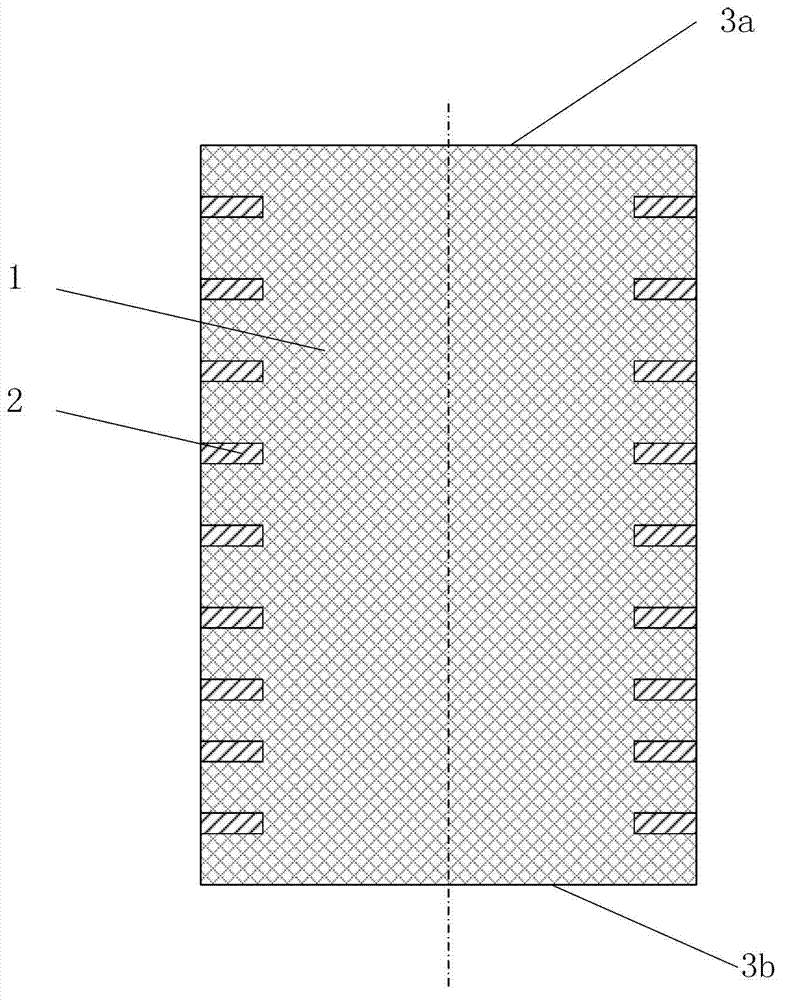

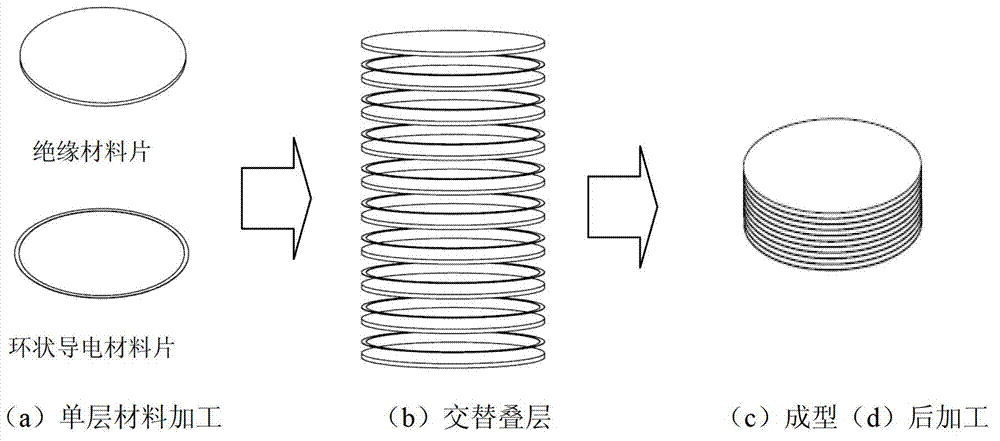

Multi-layer high gradient insulator and manufacturing method thereof

ActiveCN103247395AOvercome mechanical propertiesOvercome difficultySuspension/strain insulatorsSecondary electronsConductive materials

The invention discloses a multi-layer high gradient insulator for a high-voltage pulse power supply and a manufacturing method thereof. The multi-layer high gradient insulator is characterized in that thin conductive layers are regularly embedded in an insulator body made of an insulated material, the side surface of the insulator, which is in a certain depth, is formed by an insulated material layer and a conductive material layer, and the interior of the insulator is formed by a single insulated material. According to the invention, a conductive array is embedded in the side surface of the insulator body, the secondary electron emitting characteristic of the surface of the insulator and the surface load charge accumulation are restrained, the vacuum surface flashover characteristic of the insulator body is improved, the surface impact voltage of the insulator body is improved, the problem that the insulated material layer is not matched with the mechanical and thermal performance of the conductive material layer is solved, and the process difficulty and cost for manufacturing the multi-layer high gradient insulator are remarkably lowered.

Owner:NORTHWEST INST OF NUCLEAR TECH

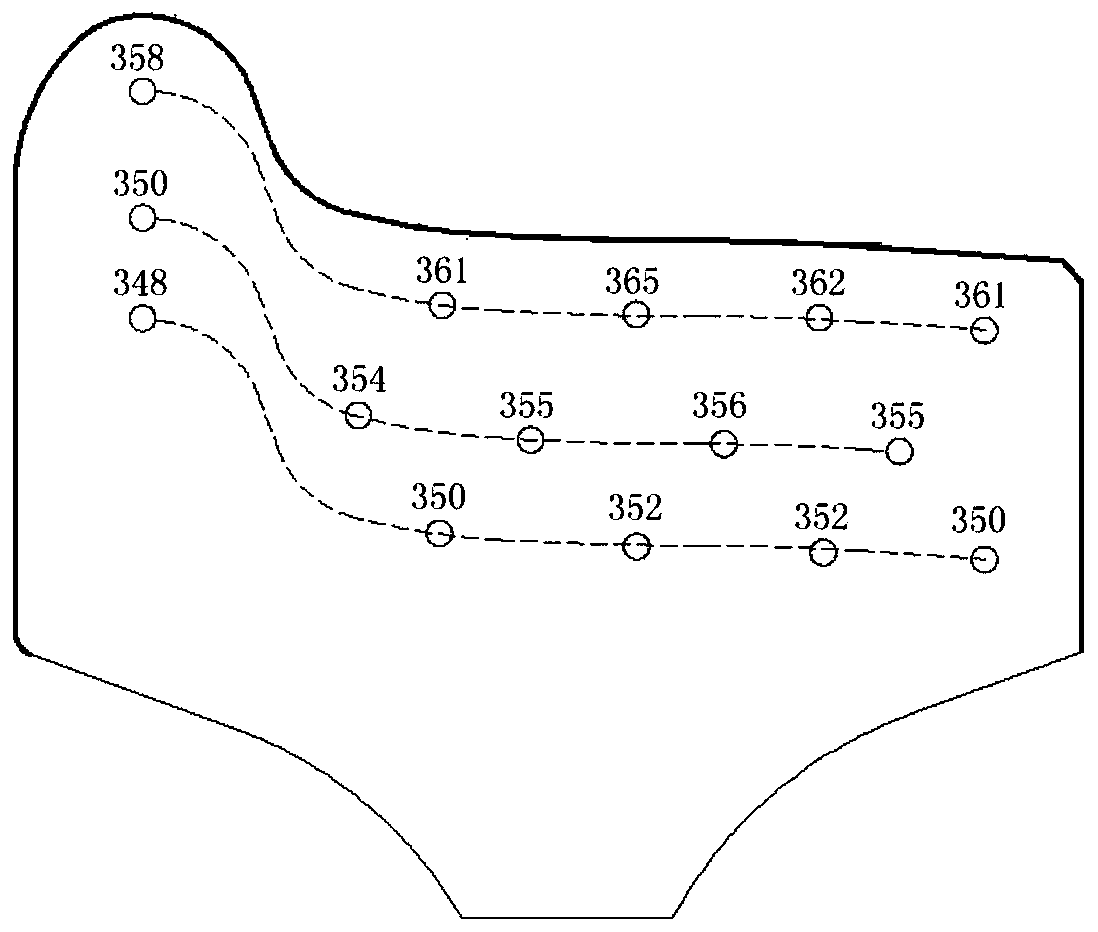

Heat-treatment cooling process for train wheel

ActiveCN110055394AImprove mechanical propertiesEasy to useFurnace typesHeat treatment furnacesThree stageHardness

The invention discloses a heat-treatment cooling process for a train wheel, and belongs to the technical field of heat-treatment cooling for train wheels. The heat-treatment cooling process for the train wheel comprises the steps that first, the whole wheel is heated to be completely austenitized; second, the wheel is transferred onto a quenching table and is made to rotate, a gas-mist two-phase flow with the pressure being increased step by step is sprayed onto a wheel tread; and third, the whole wheel is placed into a tempering furnace for heat preservation and is finally taken out to be air-cooled, wherein the gas-mist two-phase flow with the pressure being increased step by step is sprayed onto the wheel tread sequentially through three stages, the rotation speeds V1, V2 and V3 of thewheel, the water pressures P1, P2 and P3 and the quenching times T1, T2 and T3 in the three stages are controlled, and the numbers of started nozzles which are distributed at equal intervals in the circumferential direction of the wheels in the three stages are respectively M, 2M and 3M. By adoption of the heat-treatment cooling process for the train wheel, the capacity to cool the interior of a rim can be improved, the cooling speed is kept balanced and consistent from the wheel tread to the deep interior of the rim, the structure of the whole cross section of the rim is optimized, and accordingly, the radial hardness gradient of the rim is greatly reduced, and the mechanical property and usability of the wheel are greatly improved.

Owner:MAANSHAN IRON & STEEL CO LTD

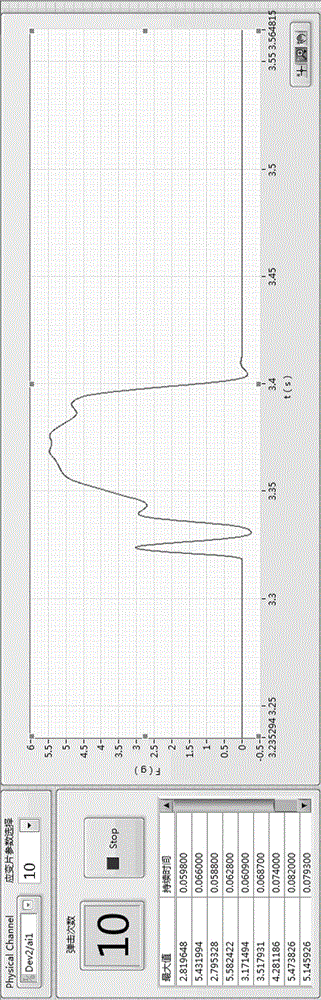

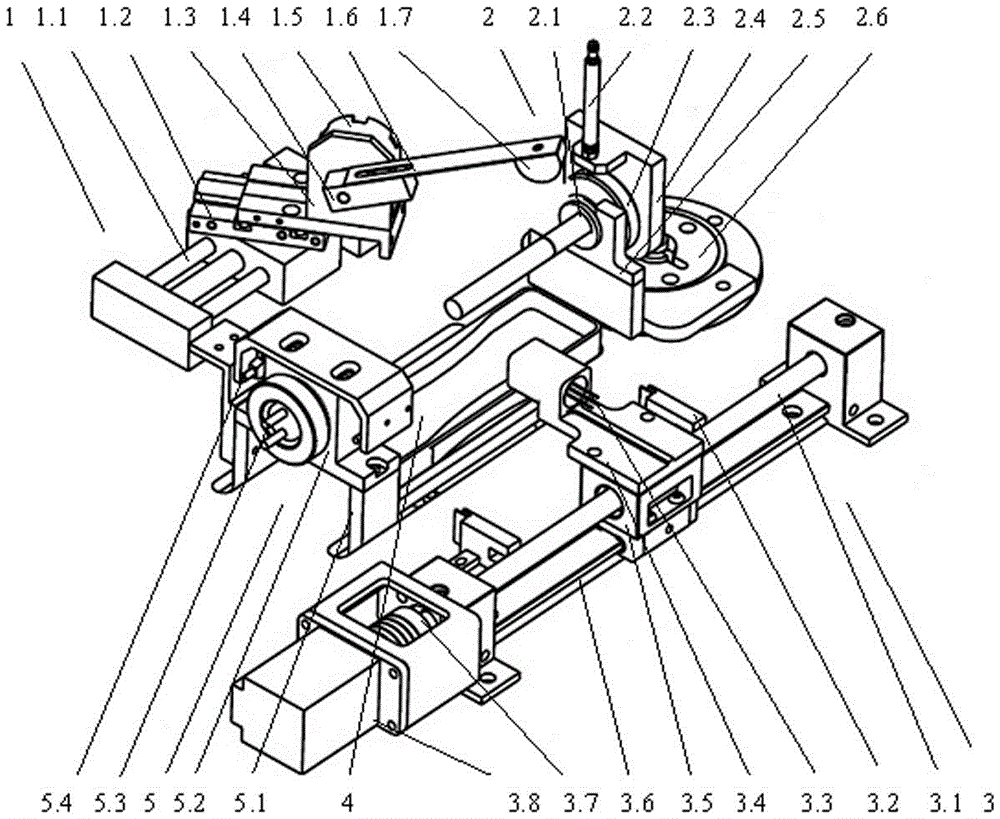

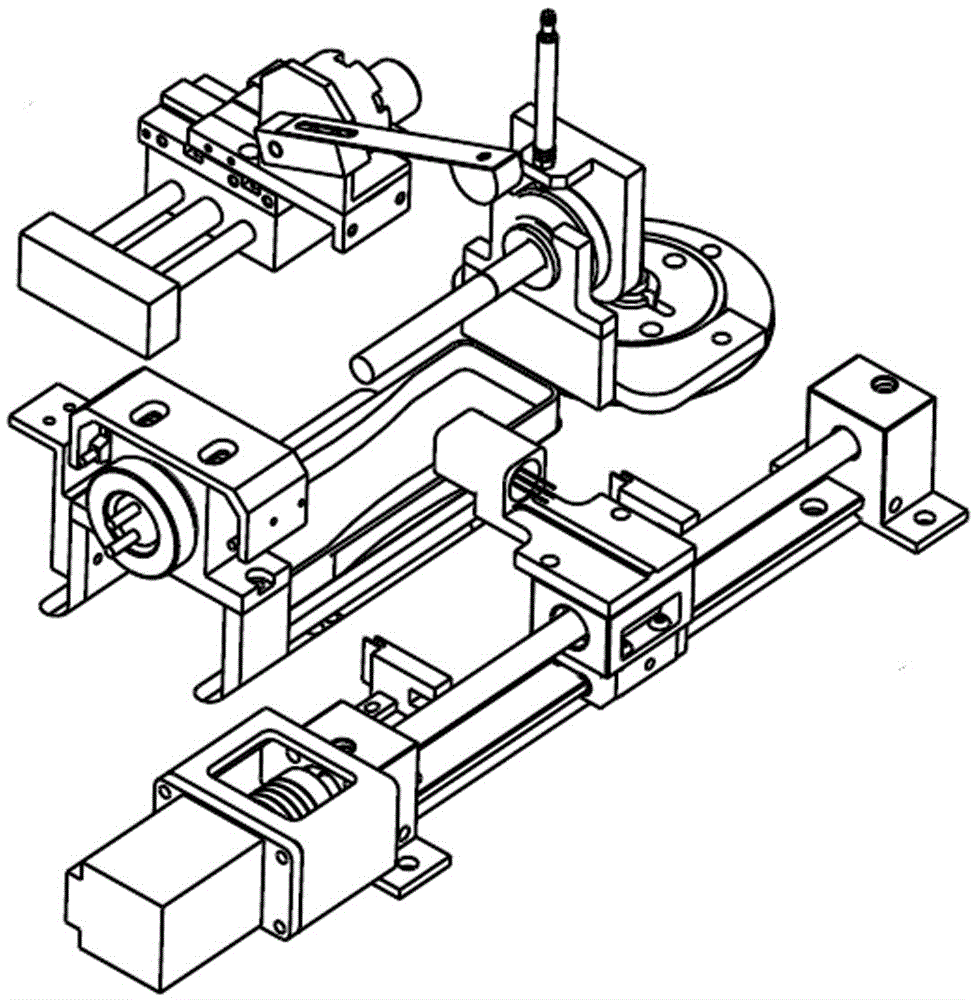

Mechanical behavior device for simulating cigarette ash dropping process by person

ActiveCN105628273AAdjust the elasticityAdjustable positionRadiation pyrometryApparatus for force/torque/work measurementDevice MonitorEngineering

The invention discloses a mechanical behavior device for simulating a cigarette ash dropping process by a person, which is characterized by comprising a cigarette clamping mechanism, a cigarette lighting device located right in front of the cigarette clamping mechanism, a cigarette striking device located at one side of the cigarette clamping mechanism and an optical sensing device located at the other side of the cigarette clamping mechanism. The device of the invention has the advantages that through researching on the mechanical behavior when a person drops the cigarette ash, high consistency between the mechanical behavior when a mechanical device drops the cigarette ash and the actual mechanical behavior can be ensured; and the optical sensing device monitors the surface temperature of a burning cone during a cigarette smoking process, the cigarette end dropping phenomenon is recorded in real time through temperature detection, and automation and intelligence of the striking device are improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

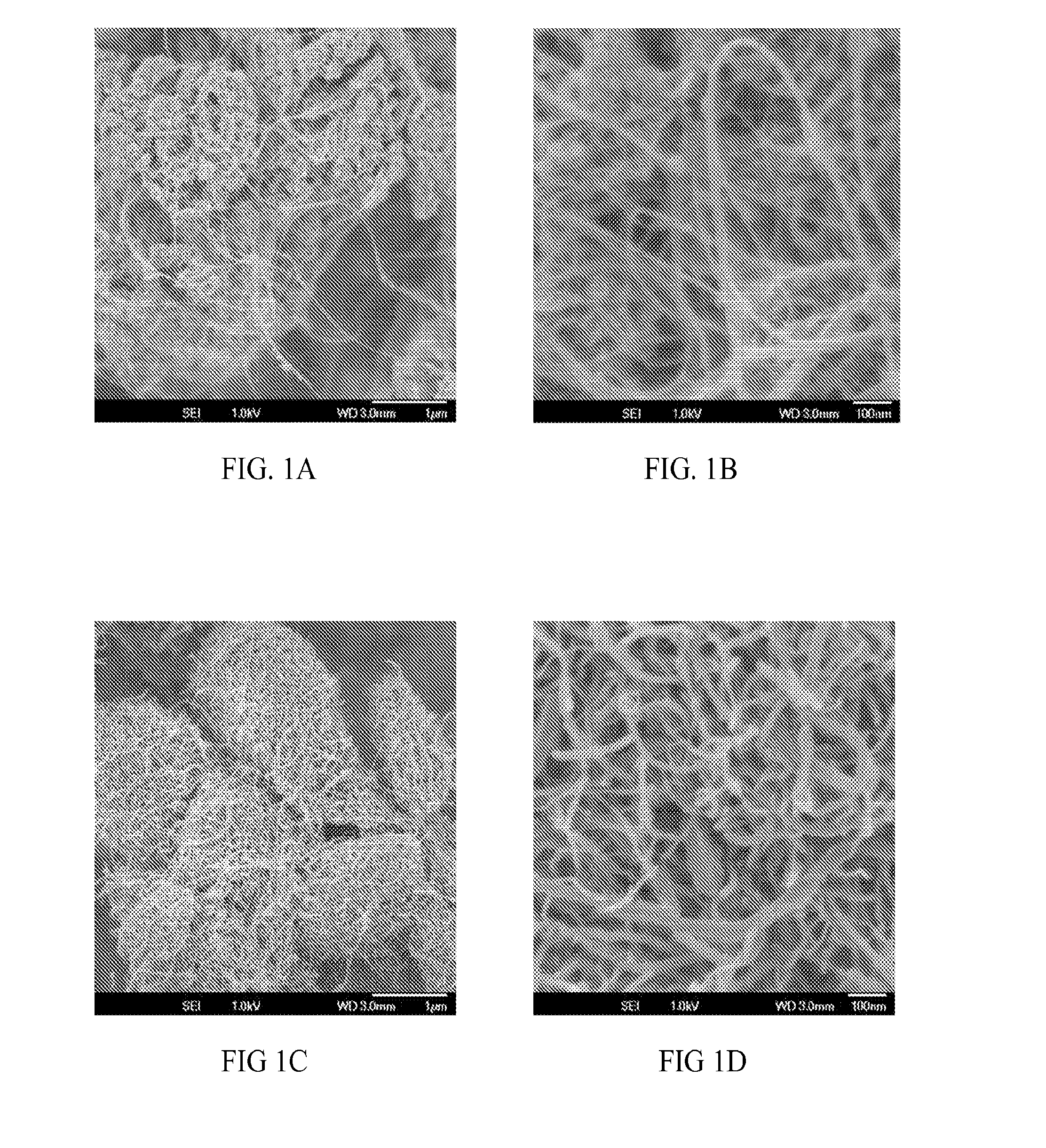

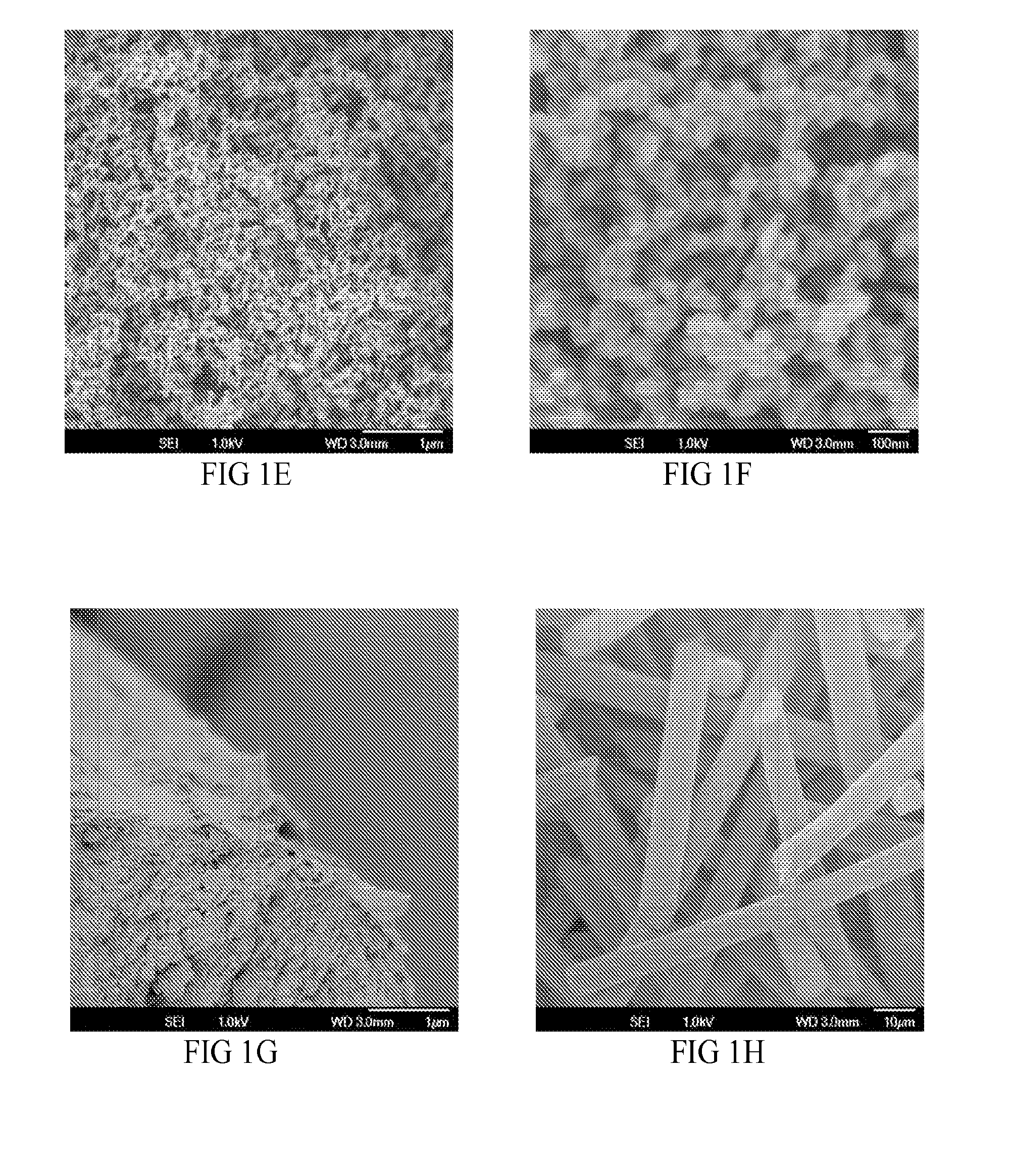

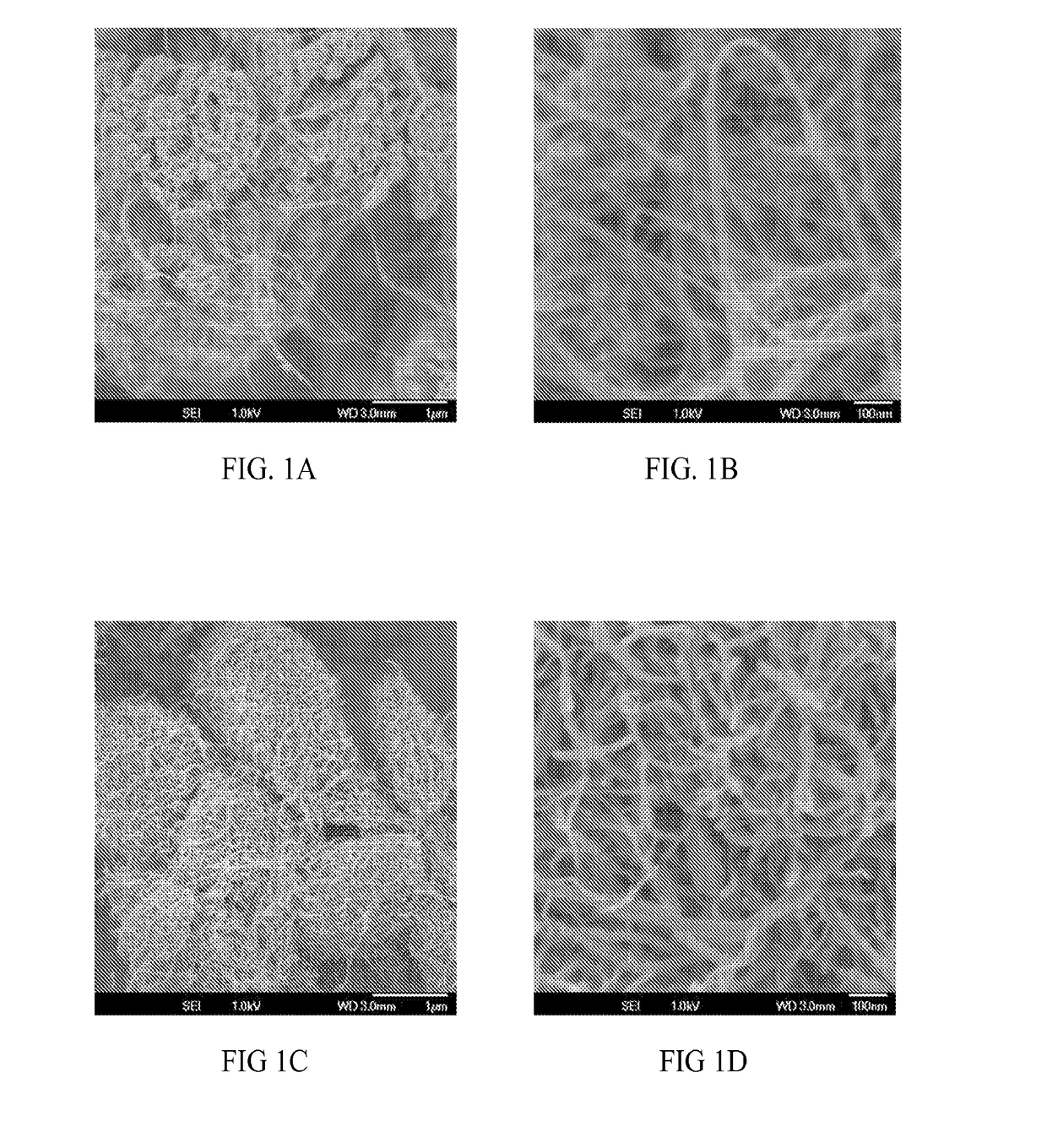

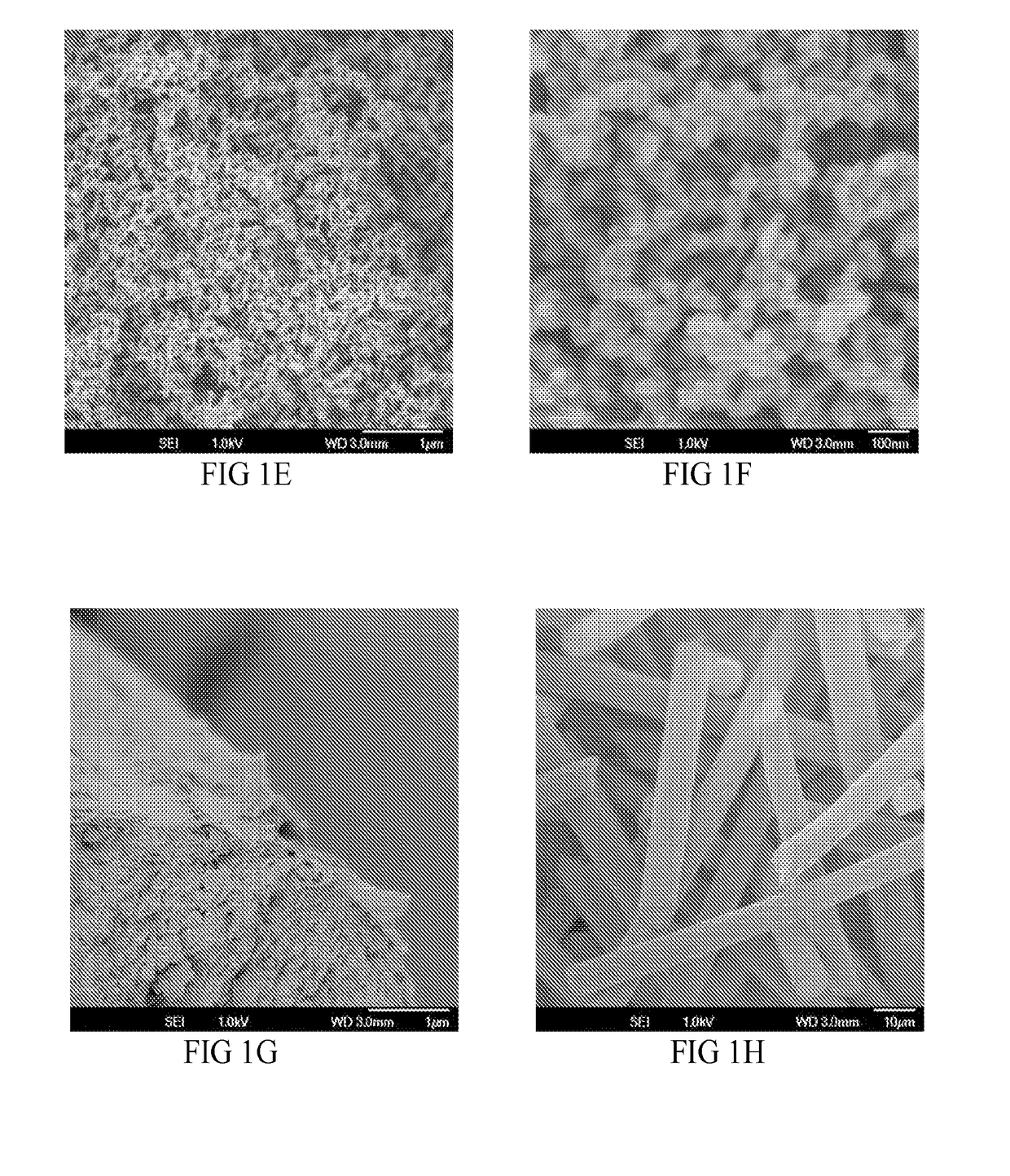

Nanotube and finely milled carbon fiber polymer composite compositions and methods of making

InactiveUS20140287176A1Nanotube loadingHigh carbon loading levelMaterial nanotechnologyPlastic/resin/waxes insulatorsFiberElectrical resistance and conductance

Embodiments of the present invention include composite compositions extrusion compounded together comprising a polymer, an amount of nanotubes, and an amount of finely milled carbon fiber having an aspect ratio greater than 1 and less than about 5. The resulting composite materials allow for high carbon loading levels with improved tribological properties including coefficient of friction and wear rates, provides uniform surface resistance with minimal processing sensitivity, retains rheological properties similar to the base resin, and provides isotropic shrink and a reduced coefficient of thermal expansion leading to minimal warp. In general, various articles can be formed that take advantage of the properties of the composite materials incorporating a polymer, carbon nanotubes and finely milled carbon fiber.

Owner:ENTEGRIS INC

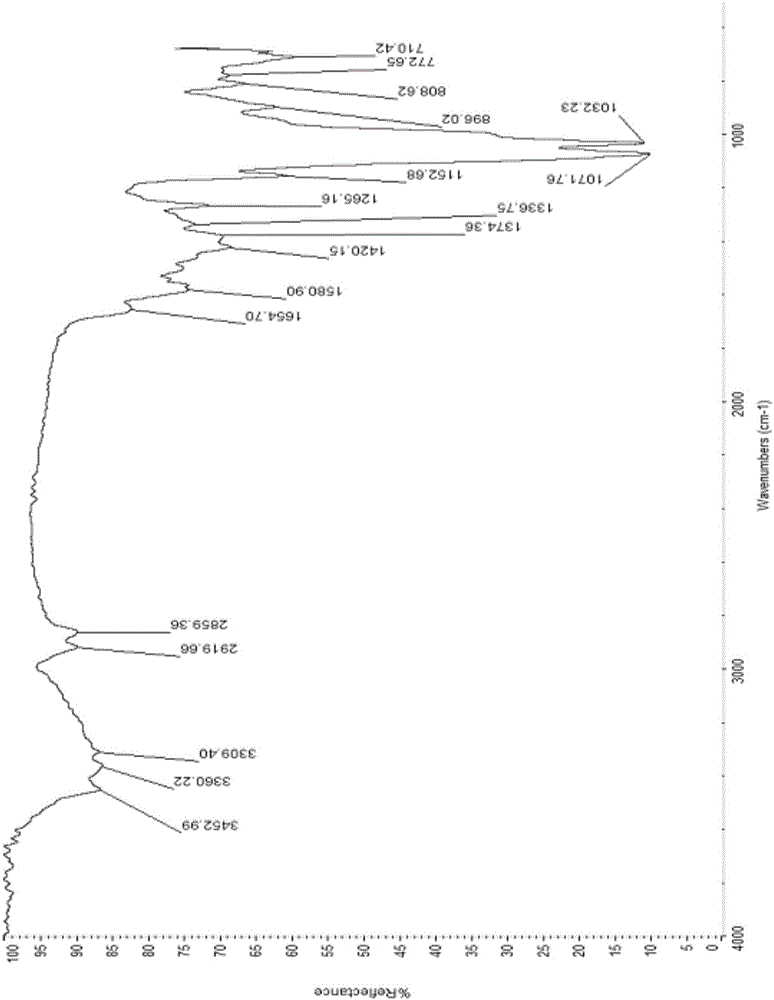

{0><}0{>Low-temperature alkaline fuel cell anion exchange membrane and preparation method thereof

ActiveCN105968398AImprove conductivityImprove mechanical propertiesPolyvinyl alcoholMechanical property

{0><}0{>The invention relates to the field of preparation of cell ion exchange membranes and particularly relates to a low-temperature alkaline fuel cell anion exchange membrane and a preparation method thereof. <0}{0><}0{>The preparation method comprises the following steps: preparing a high molecular polymer into a membrane; immerging the membrane into staining solution containing a quaternary ammonium salt cation reactive dye, thereby obtaining a dyed membrane; and soaping the dyed membrane, washing the membrane with water and drying the membrane; performing aldolization on the dried membrane with multi-aldehyde group, wherein the high molecular polymer is any one of chitosan and polyvinyl alcohol. <0}{0><}0{>According to the method, a dye dyeing technology is introduced into the preparation method of the fuel cell alkaline membrane; the chitosan or polyvinyl alcohol is selected as a substrate, and the cation reactive dye serves as a load body, cation groups are introduced onto a macromolecule main chain under a relatively mild reaction condition, so that OH- conduction is effectively performed; then <0}{0><}0{>aldolization is performed, so that the finally prepared membrane is excellent in conductivity, mechanical property and thermostability.

Owner:河南荣盛包装材料有限公司

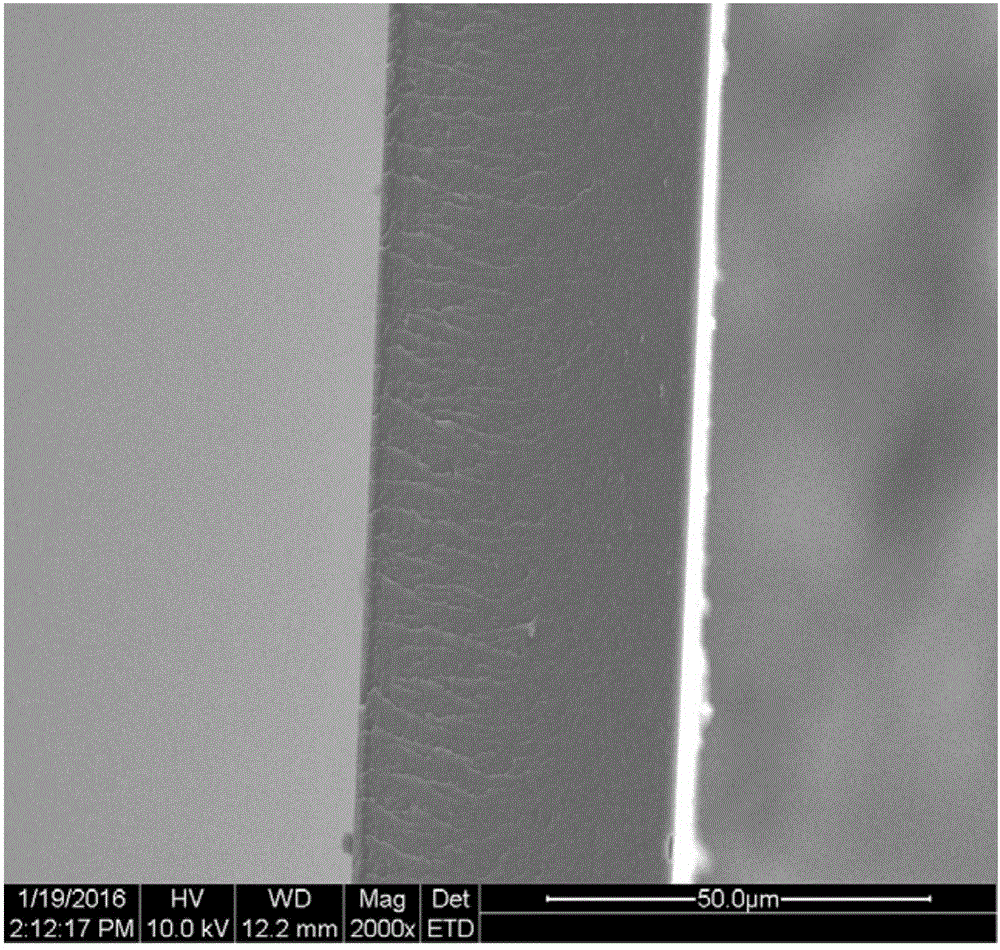

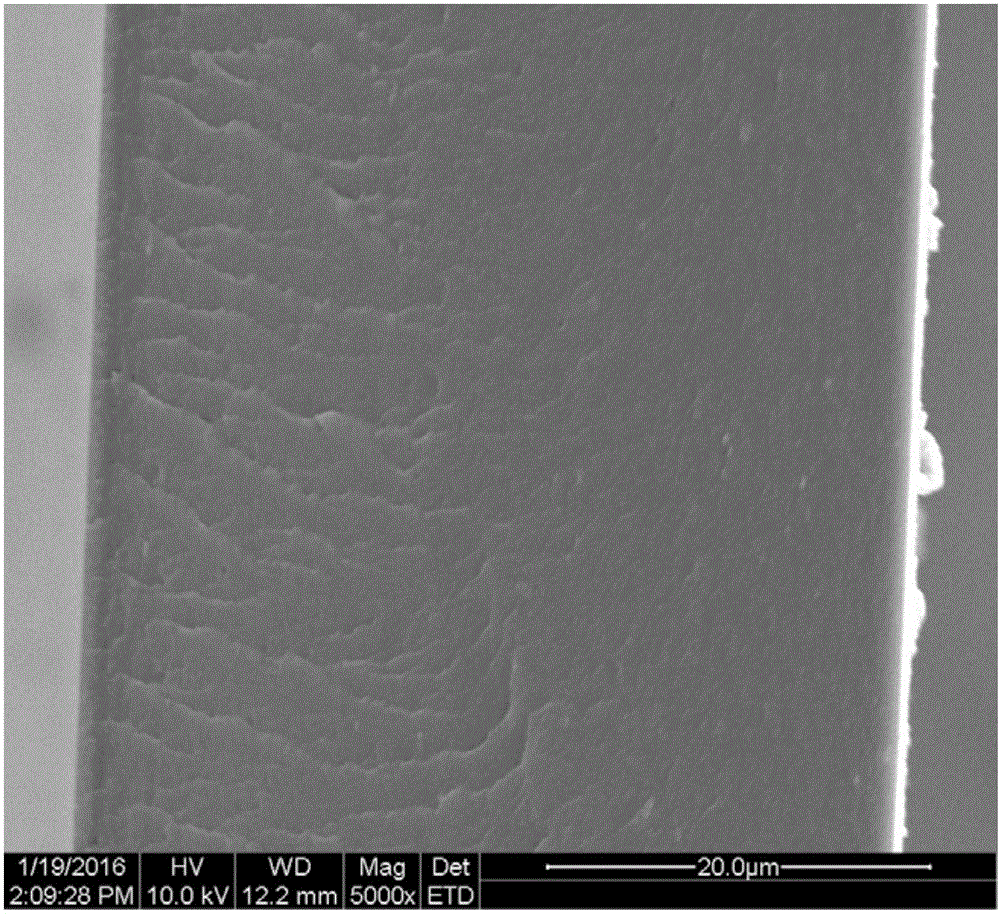

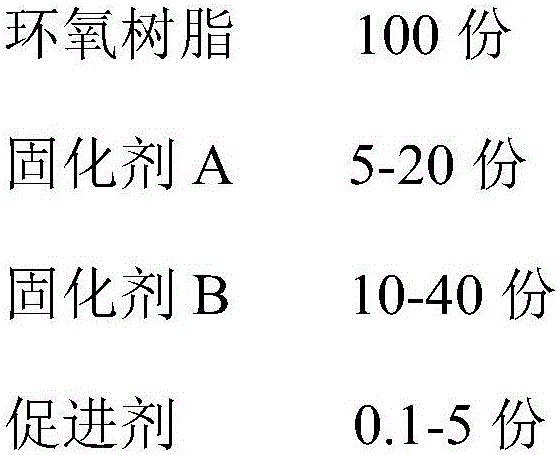

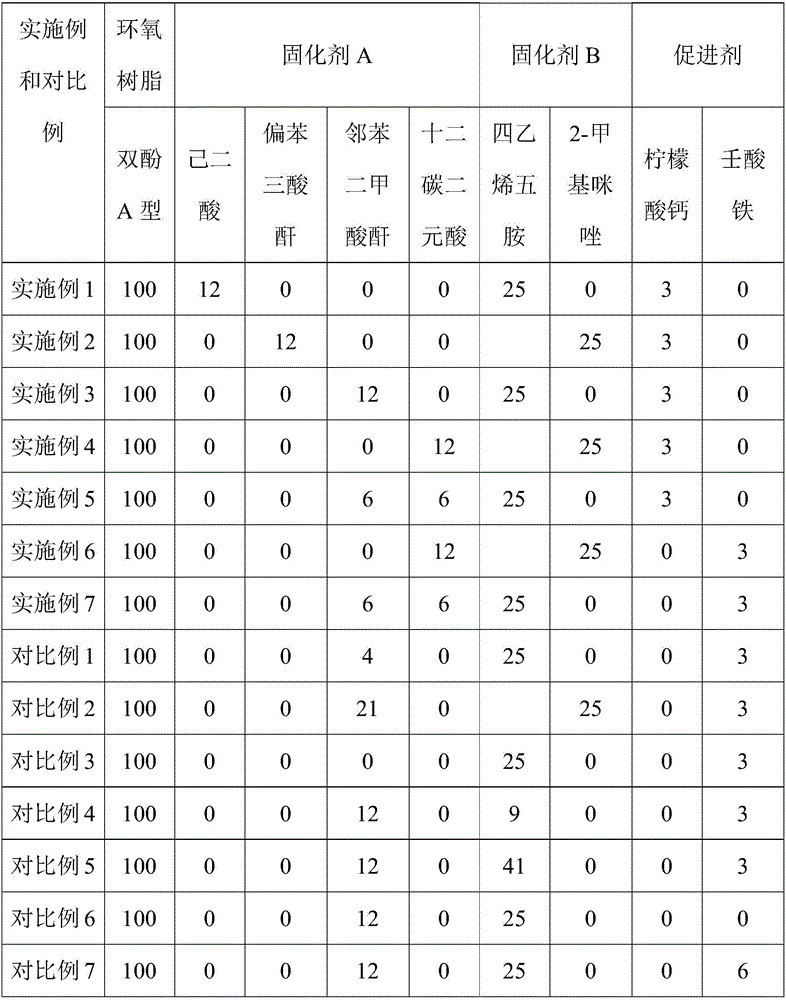

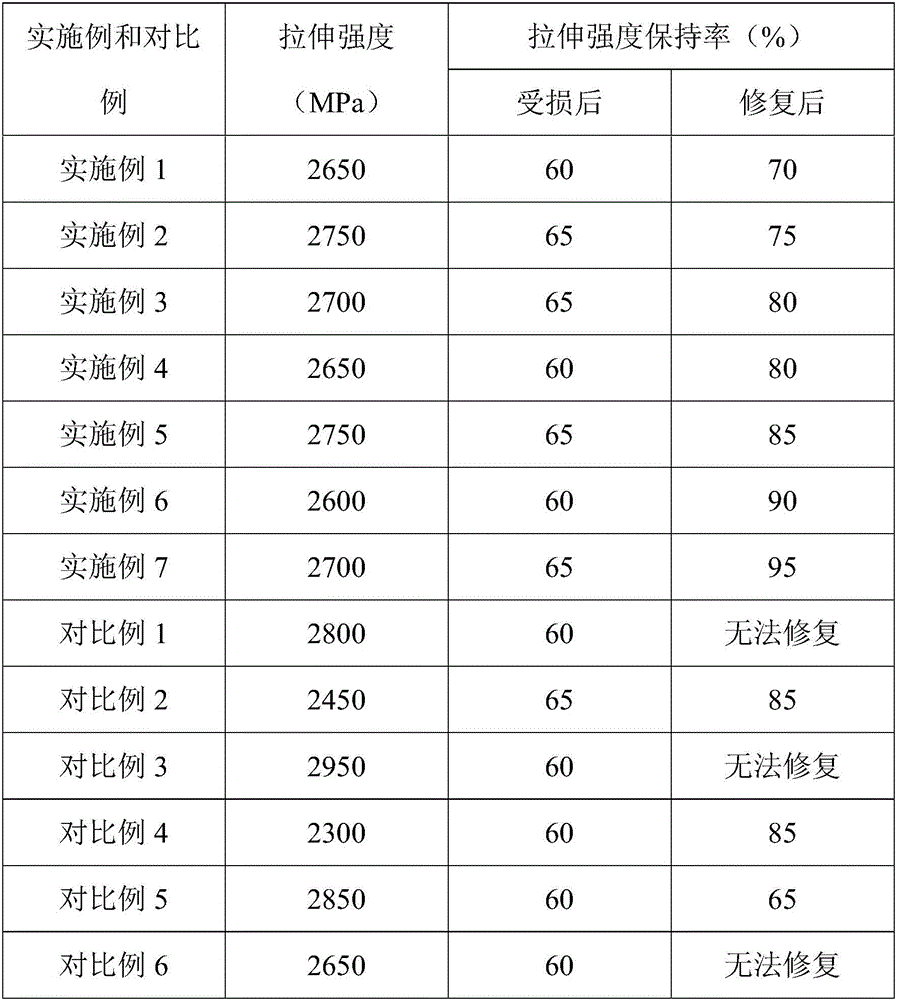

Repairable carbon fiber cloth reinforced epoxy resin plate and preparation and repairing methods thereof

The invention provides a repairable carbon fiber cloth reinforced epoxy resin plate and preparation and repairing methods thereof; the repairable carbon fiber cloth reinforced epoxy resin plate is prepared from, by weight, 100 parts of epoxy resin, 5-20 parts of curing agent A, 10-40 parts of curing agent B, 0.1-5 parts of an accelerant, and at least one layer of carbon fiber cloth; the curing agent A is selected from one or more of acid anhydride and carboxylic acid curing agents, the curing agent B is selected from one or more of curing agents other than acid anhydride and carboxylic acid ones, and the accelerant is selected from one or more of calcium salts, zinc salts and iron salts. The repairable carbon fiber cloth reinforced epoxy resin plate of the invention has the advantages of common carbon fiber cloth reinforced epoxy resin plates, such as high rigidity, high hardness, high tolerance to temperatures, low flammability and good article size stability, is repairable, allows damage in use to be repaired easily, and has post-repairing mechanical properties basically identical with initial mechanical properties of the resin plate, and the repairing process is simple and low in cost.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

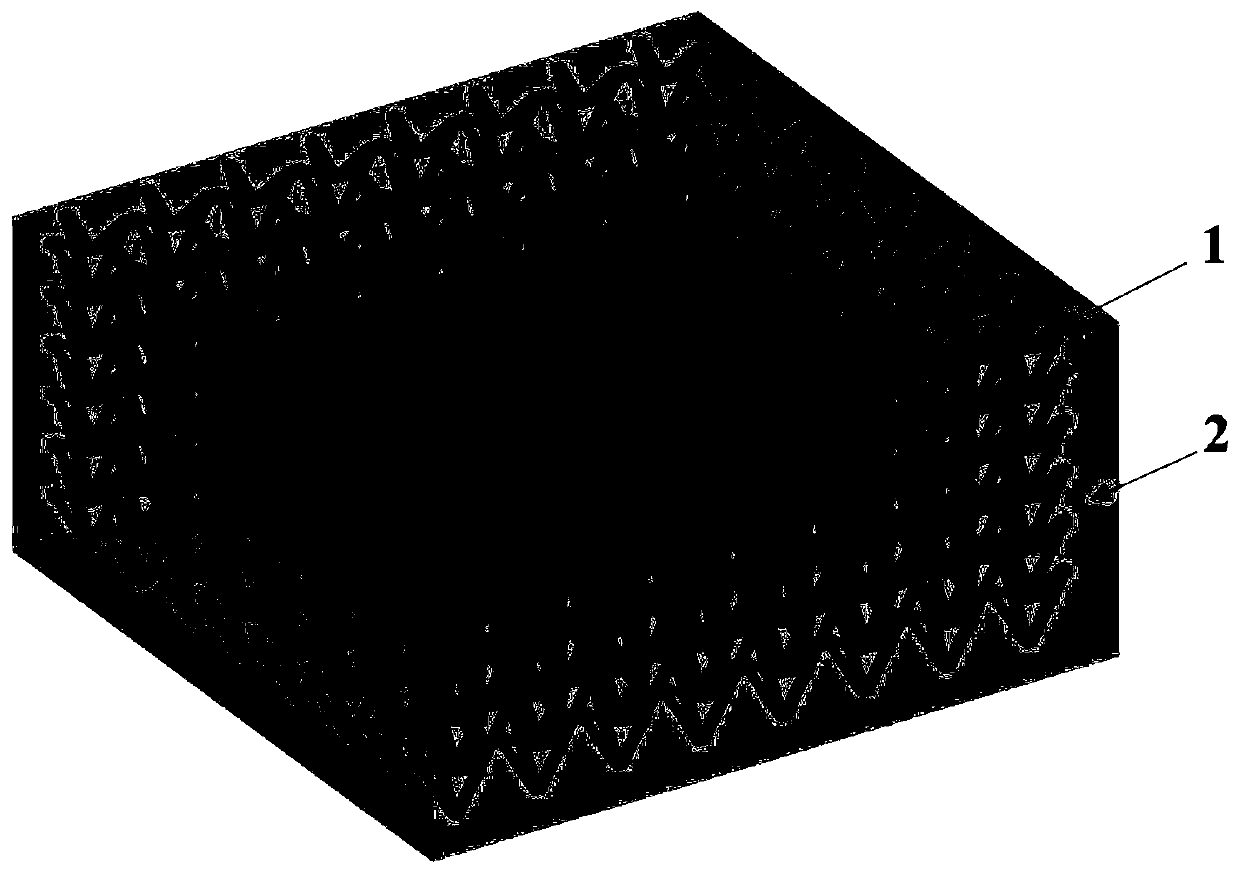

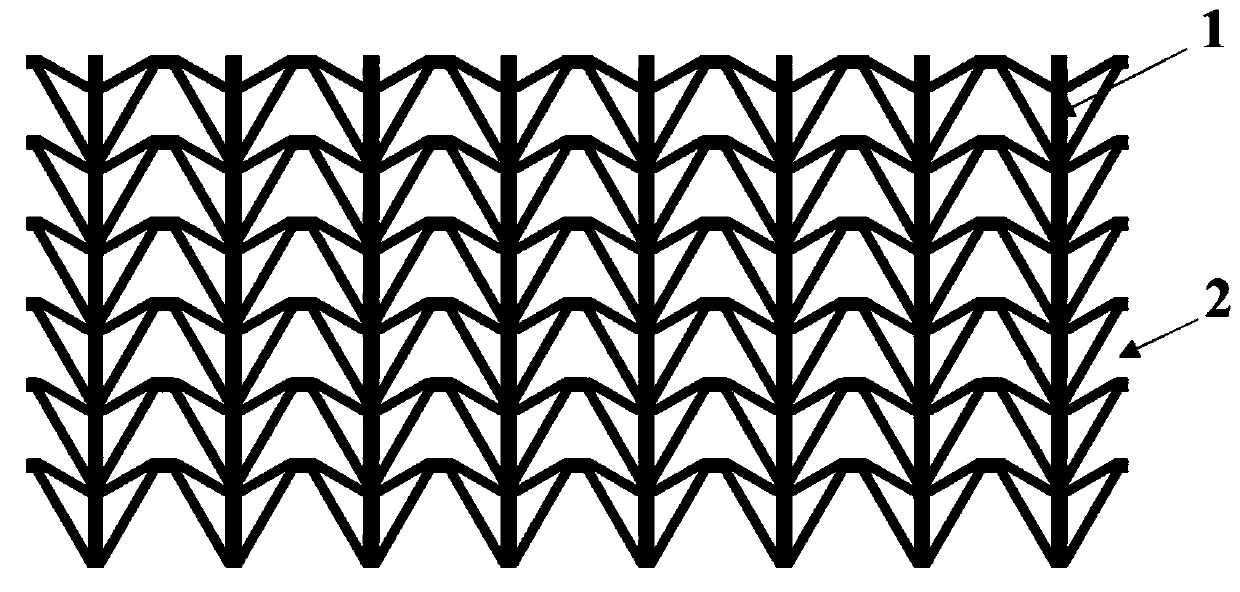

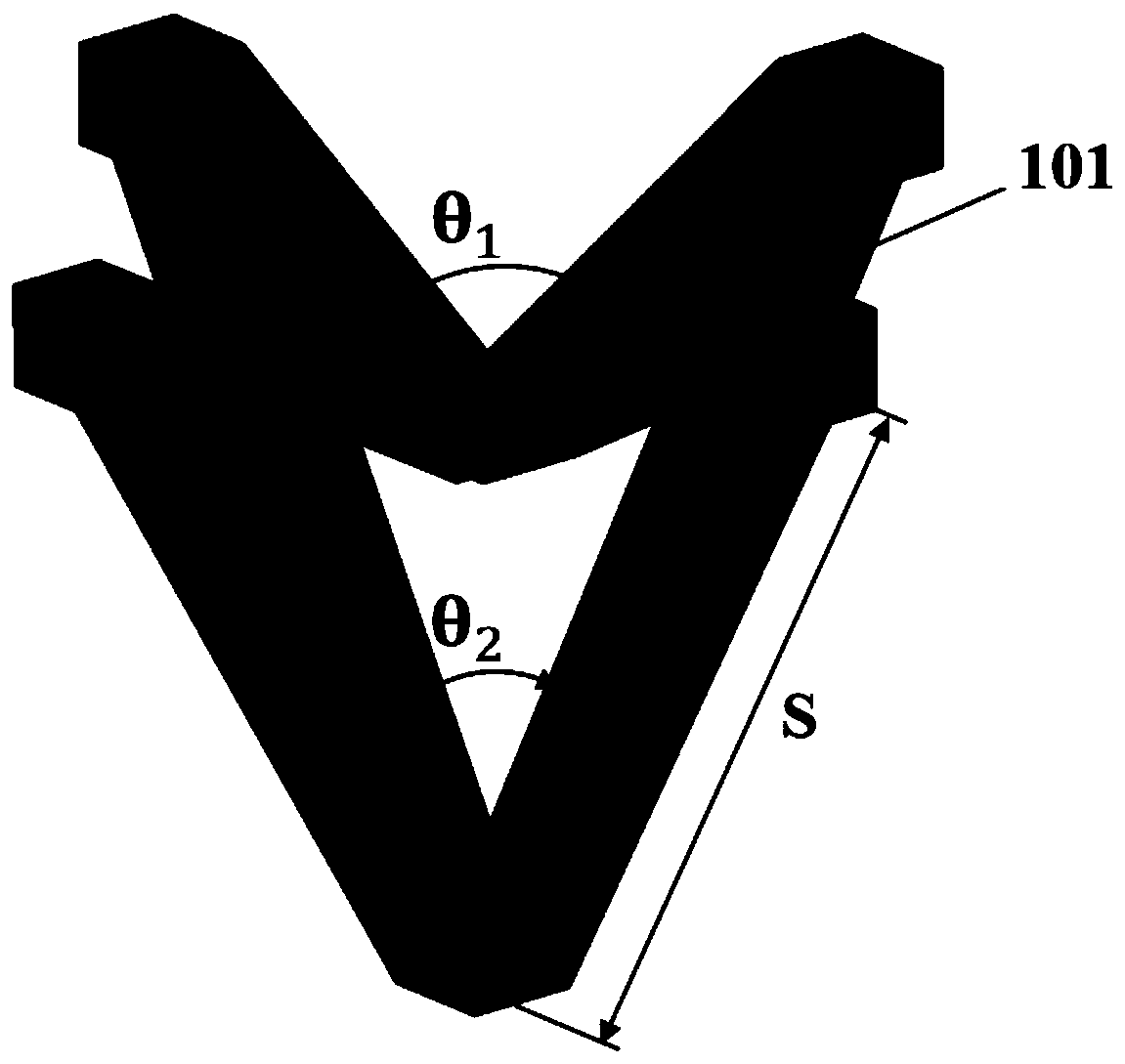

Negative Poisson's ratio cell lattice type ceramic skeleton reinforced composite material and manufacturing method

PendingCN110819843AConsistent mechanical propertiesImprove fracture toughnessMetal matrix compositeCeramic

The invention belongs to the field of armor materials, and particularly relates to a negative Poisson's ratio cell lattice type ceramic skeleton reinforced composite material and a manufacturing method. The composite material comprises a ceramic framework reinforcing phase and a metal matrix phase, wherein the ceramic framework reinforcing phase is formed by arraying negative Poisson's ratio cellsin a three-dimensional space; the negative Poisson's ratio cells are formed by vertically nesting and connecting two double-arrow unit structures at an inner concave end point; a metal matrix infiltrates and completely fills a ceramic framework through a melt infiltration process; and the periodic communication structure composite material with a macroscopic negative Poisson's ratio effect is formed after the metal matrix is solidified. According to the composite material, the problems that granular or fibrous ceramics are unevenly distributed in a traditional ceramic reinforced metal matrixcomposite material, the ceramic reinforced phase is prone to displacement in a projectile penetration process, and the difference of the penetration resistance in all directions is large are overcome,the composite material has stronger macroscopically uniform fracture resistance, and the local density of a target plate loading area is increased under the negative Poisson's ratio effect to furtherimprove the bulletproof performance.

Owner:NANJING UNIV OF SCI & TECH

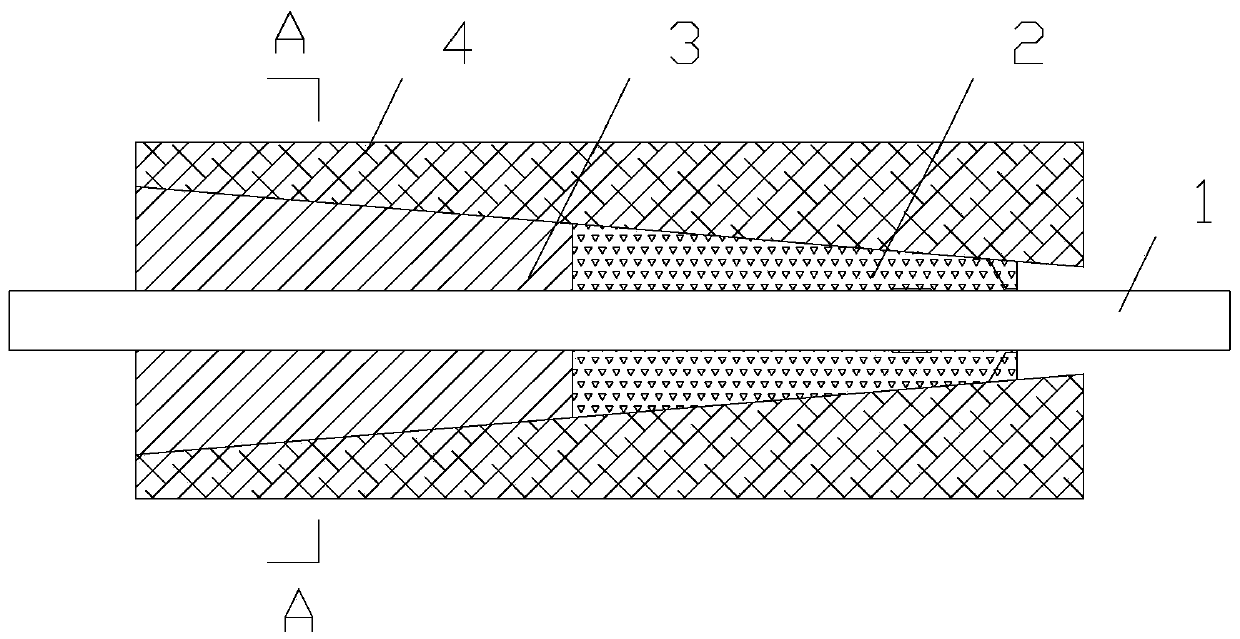

Low-stress copper steel composite welded pipe and production method thereof

InactiveCN103511759AImprove corrosion resistanceConsistent mechanical propertiesRigid pipesTubular elementsCopperUltimate tensile strength

The invention discloses a pipe for a heat exchanger and particularly relates to a low-stress copper steel composite welded pipe and a production method of the low-stress copper steel composite welded pipe. The low-stress copper steel composite welded pipe comprises copper layers (2) and a steel layer (3), wherein the steel layer (3) is arranged between the two copper layers (2), after the copper layers (2) and the steel layer (3) are bended and form the pipe, padding brazing solders (1) are welded to the contact portion between the two sides of each copper layer (2) and the two sides of the steel layer (3). The low-stress copper steel composite welded pipe has the advantages that 80% of the heat conduction effect of copper and 100% of the corrosion resistance effect of the copper are achieved at about 50% of the price of copper; the anti-corrosion effect is good, a low-stress copper welding rod is applied to welding, and the copper layers and the mechanical performance of a welding joint can be identical to those of other parts; the mechanical performance is good, and the tenacity and the strength of steel materials are achieved.

Owner:浙江兆隆合金股份有限公司

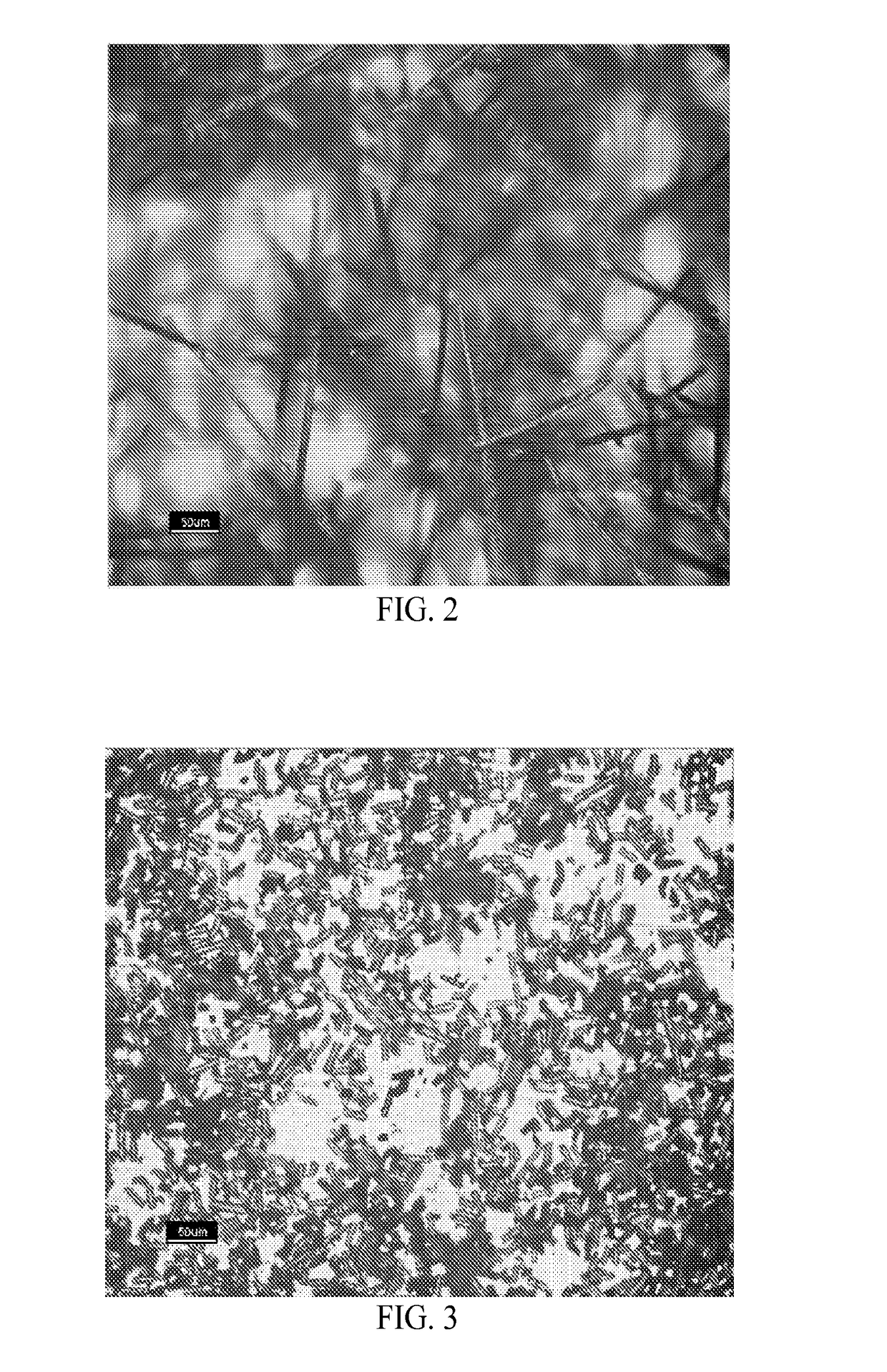

A method of simulating a complex natural crack structure in coal rock

InactiveCN106501091AReduce collectionFit closelyPreparing sample for investigationMaterial strength using tensile/compressive forcesHydraulic fracturingRefrigerated temperature

A method of simulating a complex natural crack structure in coal rock is disclosed. The method is characterized in that the method includes a specimen molding mold, cement, gypsum, coal powder, water, a bucket, a refrigerator and a board, the water is prepared into ice blocks having different shapes through the refrigerator in advance to simulate the natural crack structure in a coal reservoir stratum, then the specimen molding mold is assembled on the ground, the cement, the gypsum, the coal powder and the water are fully stirred in the bucket according to a certain ratio, and poured into the specimen molding mold, the ice blocks play a role of simulating the structure of the natural cracks in the practical coal reservoir stratum through addition of the ice blocks into concrete according to the structure of the natural cracks in the practical coal reservoir stratum in a specimen molding process, the method has characteristics of simple, convenient and easy operation, and capability of saving time and labor, and the method can greatly reduce the working load of raw coal collection on site and provides a raw material for a hydrofracture test.

Owner:HENAN POLYTECHNIC UNIV

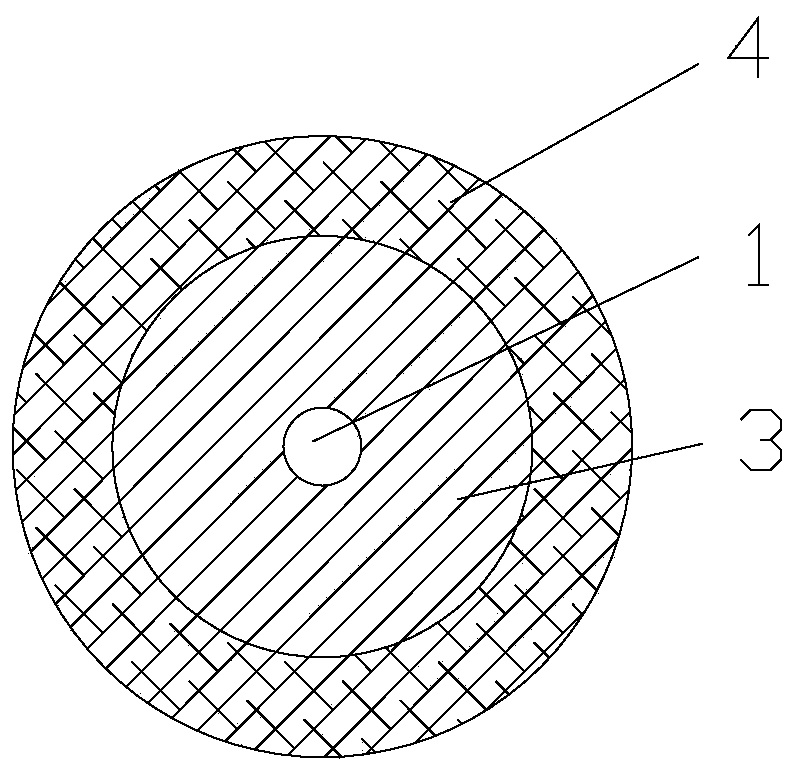

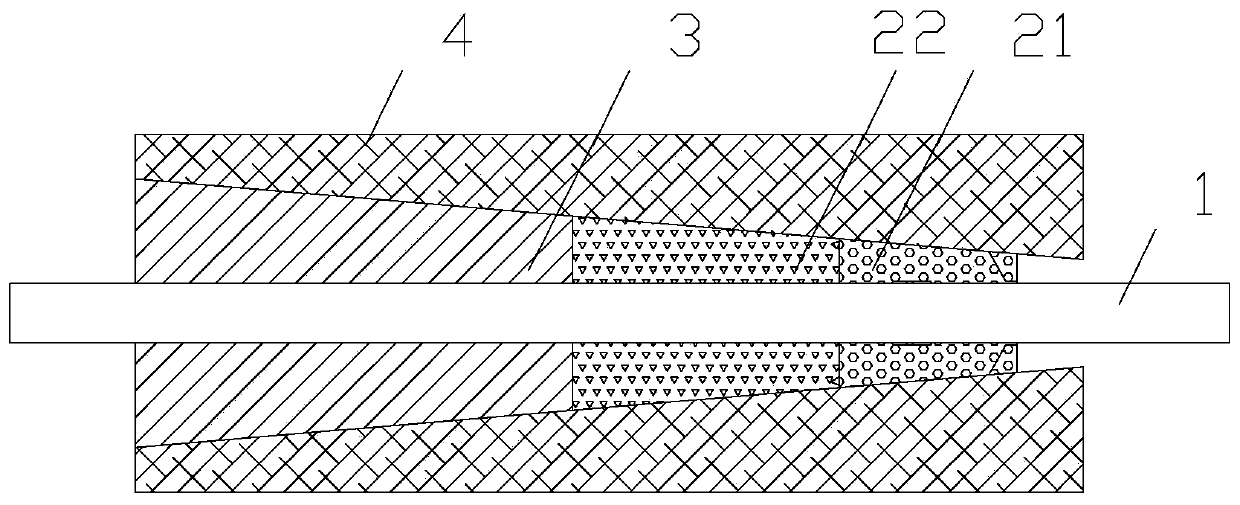

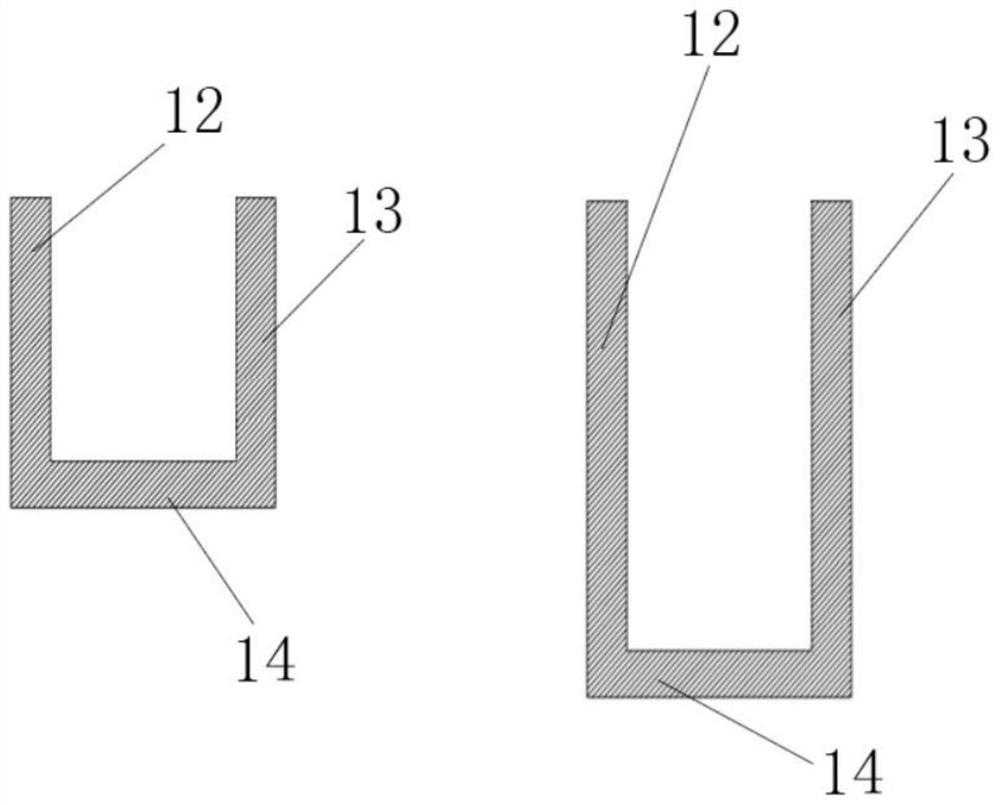

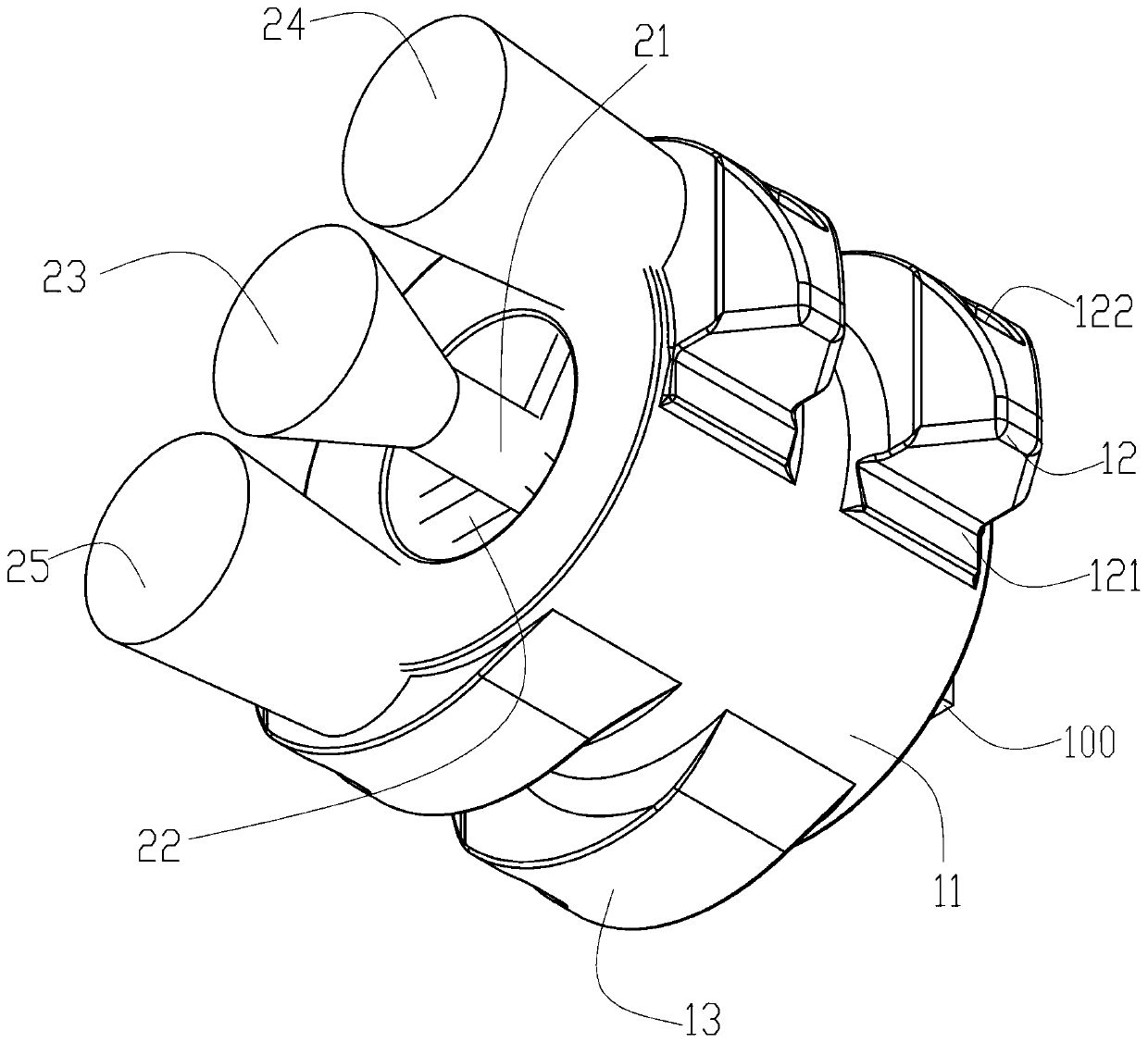

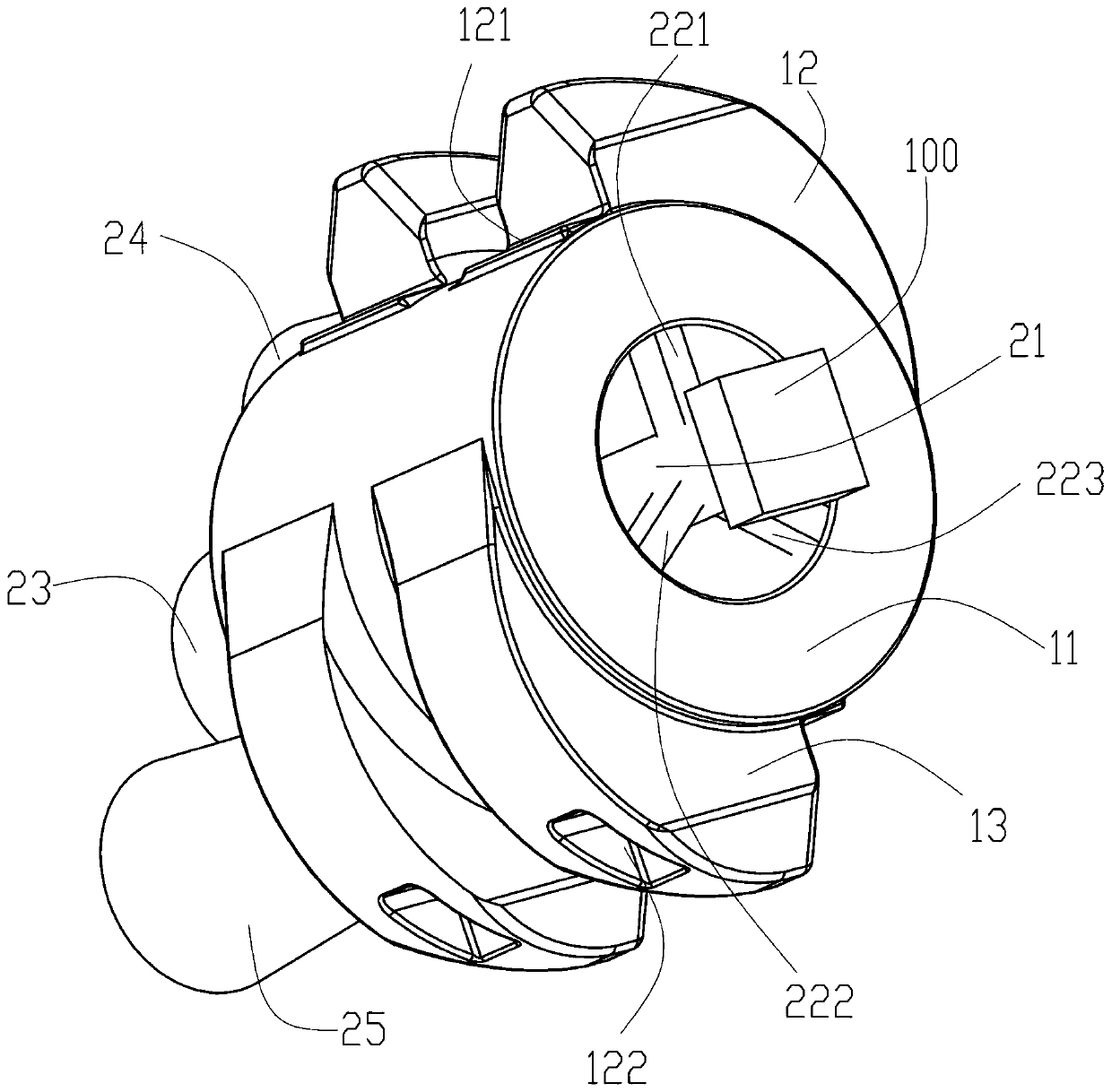

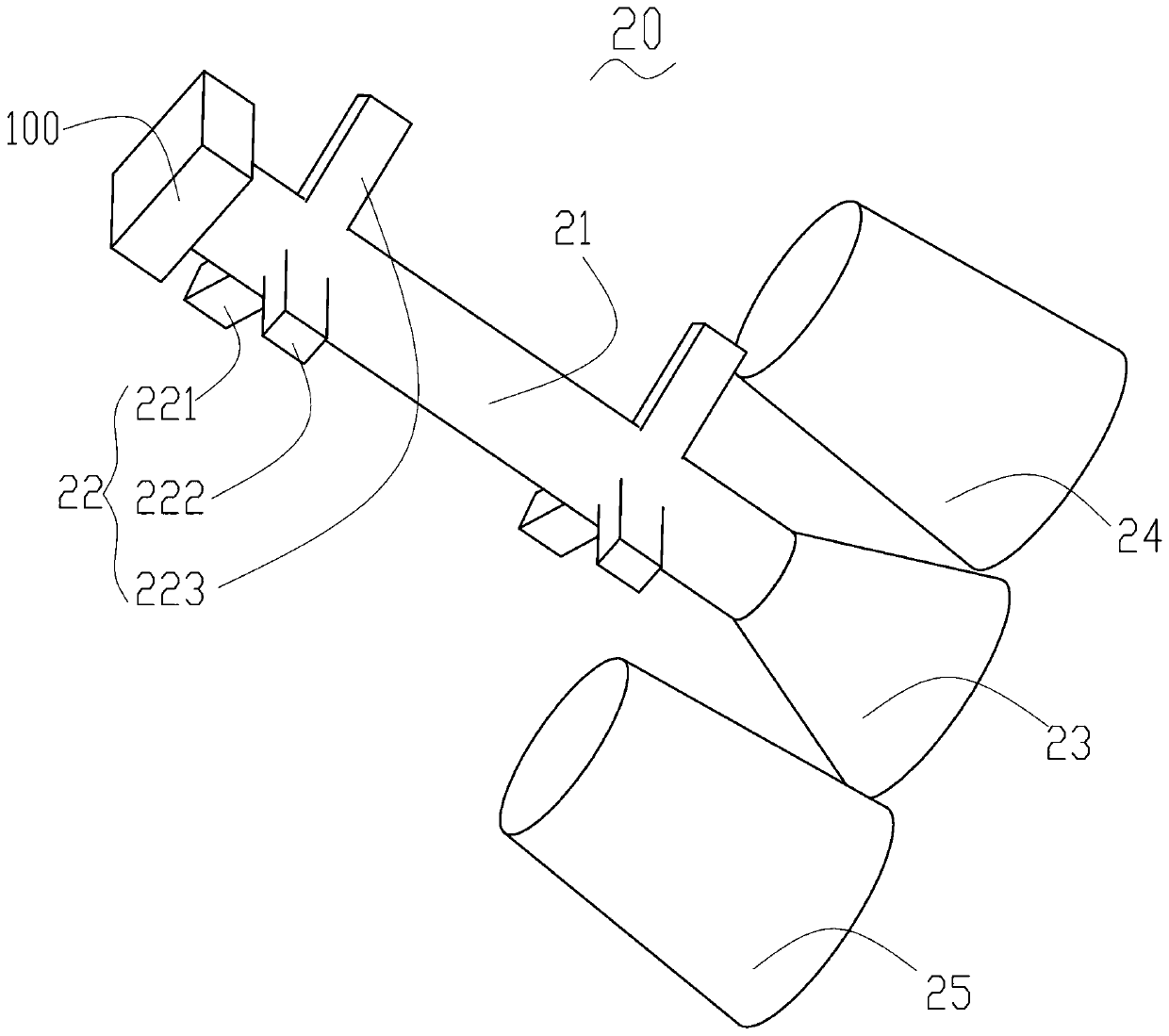

FRP (fiber reinforced polymer) rebar anchoring clamp piece, manufacturing method thereof and anchoring method thereof

ActiveCN109797910AReliable anchoringEasy constructionBuilding reinforcementsStress concentrationFiber

The invention discloses an FRP (fiber reinforced polymer) rebar anchoring clamp piece, a manufacturing method thereof and an anchoring method thereof. A circular arc groove for holding FRP rebars is formed in the sector-shaped FRP rebar anchoring clamp piece, the outer surface of the FRP rebar anchoring clamp piece is a circular conical surface, the FRP rebar anchoring clamp piece comprises a first medium segment for variable-stiffness load transfer and a second medium segment for variable-stiffness load transfer along the length direction, the stiffness of the FRP rebar anchoring clamp piecegradually increases from the loading end to the free end, and the first medium segment for variable-stiffness load transfer is formed by curing of resin-infiltrated fiber chopped yarn while the secondmedium segment for variable-stiffness load transfer is formed by curing of resin-infiltrated quartz sand. The FRP rebar anchoring clamp piece has the advantages that the content of fibers and the content of the quartz sand in the variable-stiffness load transfer media as well as lateral stiffness gradually increase from the loading end to the free end, so that the 'notch effect' at the loading ends of the FRP rebars can be relieved or eliminated, and the problem that lateral shear failure of the FRP rebars due to stress concentration is prior to tensile fracture is avoided.

Owner:SOUTHEAST UNIV

Ratproof and termiteproof material

The invention discloses a ratproof and termiteproof material, which comprises the following components in percentage by weight: 80 to 85 percent of polypropylene, 8 to 20 percent of glass fiber, 0.6 to 2 percent of capsaicine, 0.8 to 2 percent of dihydrocapsaicine and 1 to 2.5 percent of cypermethrin. Because the capsaicine, the dihydrocapsaicine and the cypermethrin can generate strong odor irritating both olfactory sensation and taste sensation of mice and insects, the ratproof and termiteproof material can effectively prevent the bite and encroachment of mice and termites and is particularly suitable to manufacture civil engineering members used outdoors for a long period of time such as filling sacks and fixing buckles used in barrier building; a built barrier has less potential threat and high safety factor and passes experimental verification; and the mechanical property of the ratproof and termiteproof material is identical to that of ordinary polypropylene materials and does not influence the quality of products manufactured by the material.

Owner:CHONGQING DANHAI IND

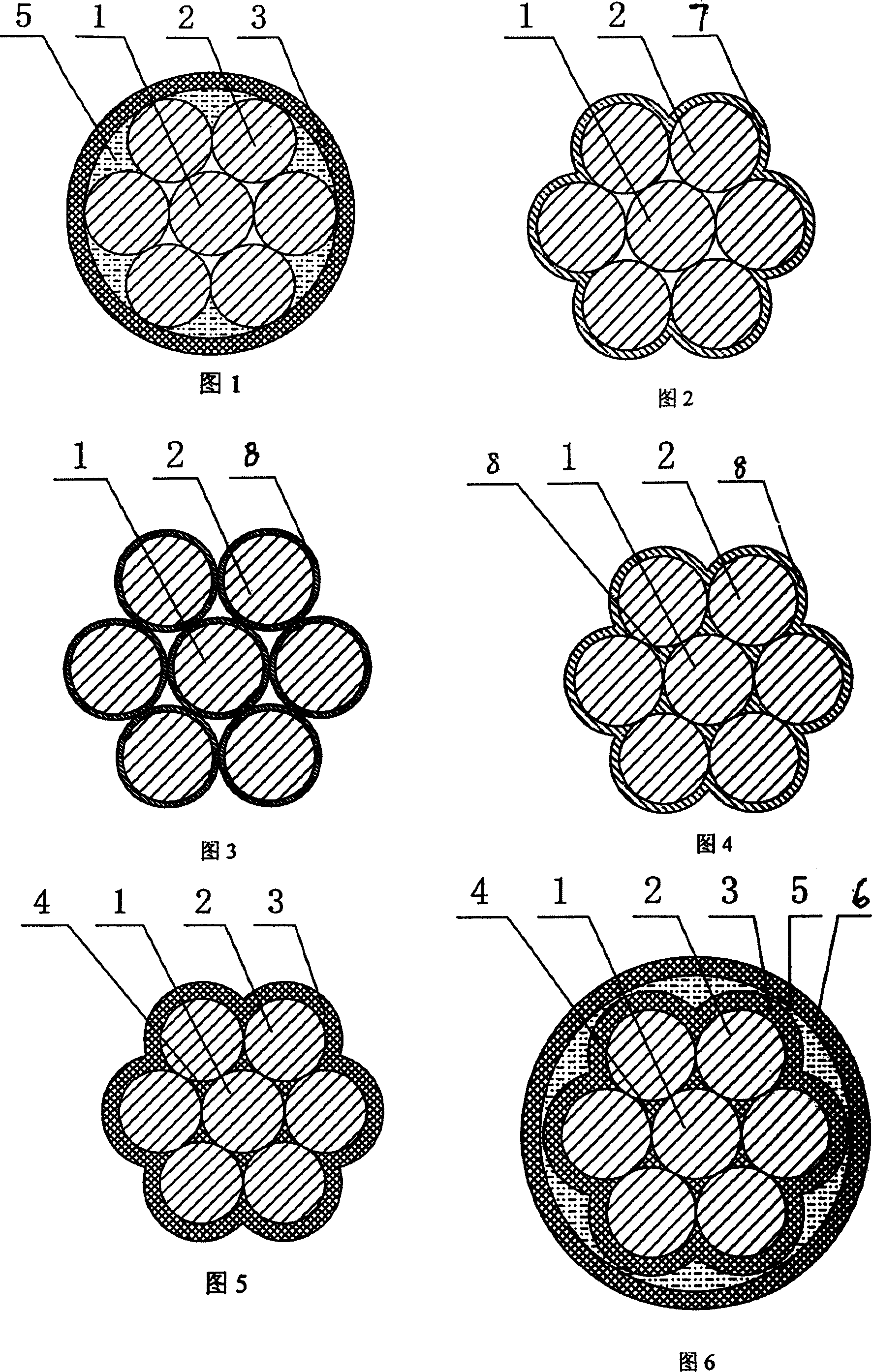

Integral-filled type plastic-coated steel twisted line

InactiveCN1936229AImprove corrosion resistanceGood chemical resistanceBuilding reinforcementsEngineeringMechanical property

The invention relates to an entire filling plastic coating steel strand that includes a core thread and plural side track. The feature is that it is coated a HDPE plastic anticorrosion insulation, and HDPE plastic anticorrosion layer is also filled in the clearance between core thread and side track. It has good anticorrosion capability, and has the same mechanical properties and utilization property as normal PC steel strand.

Owner:FAERSHENG ZHUDIAN NEW MATERIAL

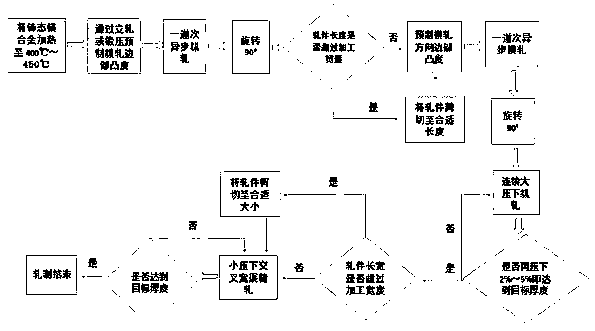

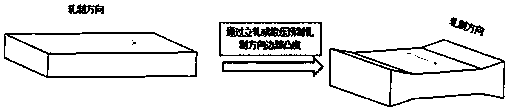

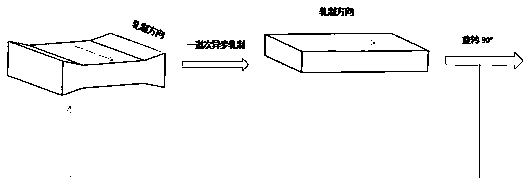

Magnesium alloy plate grain refining controlled edge crack rolling method

ActiveCN110216145ASimple processImprove yieldMetal rolling arrangementsProfile control deviceTechnical supportCrystallite

The invention particularly relates to a magnesium alloy plate grain refining controlled edge crack rolling method, and belongs to the technical field of metal material processing. The method aims to solve the problems that in existing magnesium alloy plate rolling, the yield is low caused by edge cracks; the production cost is greatly increased due to the fact that the damage of a rolling mill anda lining plate is large; and the grain refining effect in a plate is not obvious. The rolling method comprises the steps of prefabricating rolling direction edge convexity, asymmetrical cross rollingprefabricating a convexity plate, large-pressure lower continuous axial rolling, cross broad siding finish rolling and the like. The invention discloses a rolling method for effectively weakening cracks at the edge of a magnesium alloy plate and refining grains. The magnesium alloy plate grain refining controlled edge crack rolling method carries out composite optimization on broadside rolling, asymmetrical rolling, prefabricating convexity rolling and cross rolling methods which are applied to a magnesium alloy rolling forming process widely. The method provides technical support for improving the yield, refining grains and promoting magnesium alloy plate large-scale application, and has wide application prospects.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

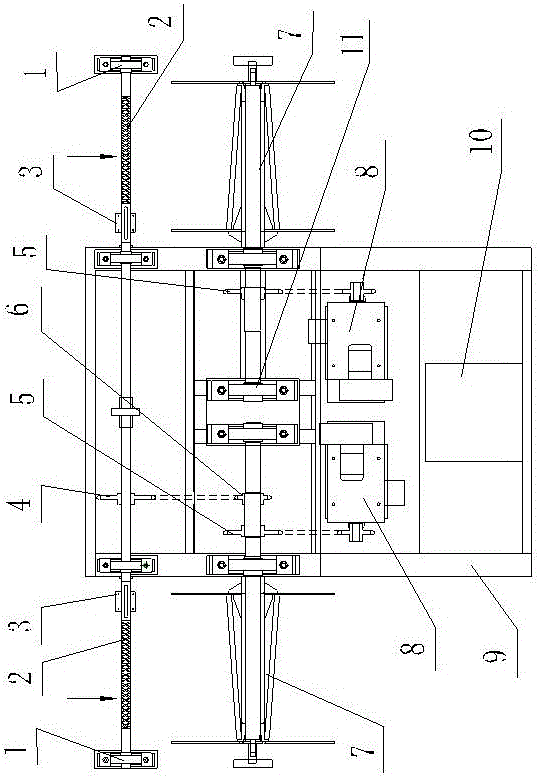

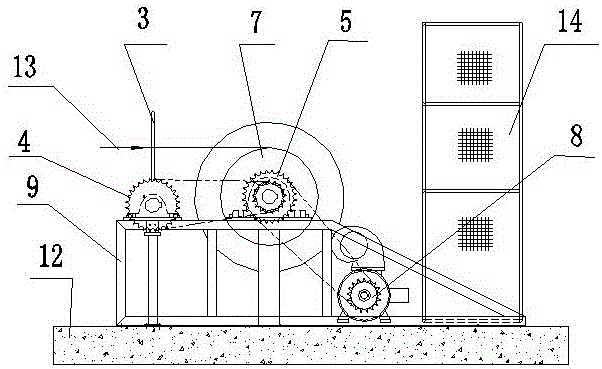

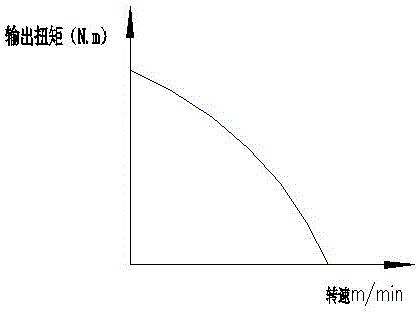

On-line winding device for waste edge for aluminum processing equipment

ActiveCN106315301AEnsure edge cutting qualityConstant tensionFilament handlingMaintainance and safety accessoriesTorque motorSprocket

The invention discloses an on-line winding device for the waste edge for aluminum processing equipment. A mandrel of a winding shaft is hinged to a rack. A bidirectional circulating lead screw is characterized in that two thread lines of the same specification and opposite in screwing directions are correspondingly arranged in the middle of a guide shaft. A sliding block is fixed to a bottom face of a frame type guide frame, and a hole with the diameter matched with the maximum outer diameter of the bidirectional circulating lead screw is formed in the sliding block. A circular-arc guide block is fixedly arranged on the upper end wall of the hole. When the bidirectional circulating lead screw is sleeved with the sliding block, the circular-arc guide block is embedded into a threaded groove in the bidirectional circulating lead screw. An output chain wheel of a torque motor is connected with a drive chain wheel A of the winding shaft through a chain. A middle chain wheel is arranged on the winding shaft. The middle chain wheel is arranged on a drive chain wheel B on the bidirectional circulating lead screw through the chain in a connected manner. By means of the on-line winding device for the waste edge for the aluminum processing equipment, the waste edge is evenly wound around the winding shaft, it is guaranteed that the tension in the waste edge winding process is constant, the edge shearing quality of finished product strips is guaranteed, the yield is increased, the waste edge is wound on line, and the production efficiency is improved.

Owner:涿神有色金属加工专用设备有限公司

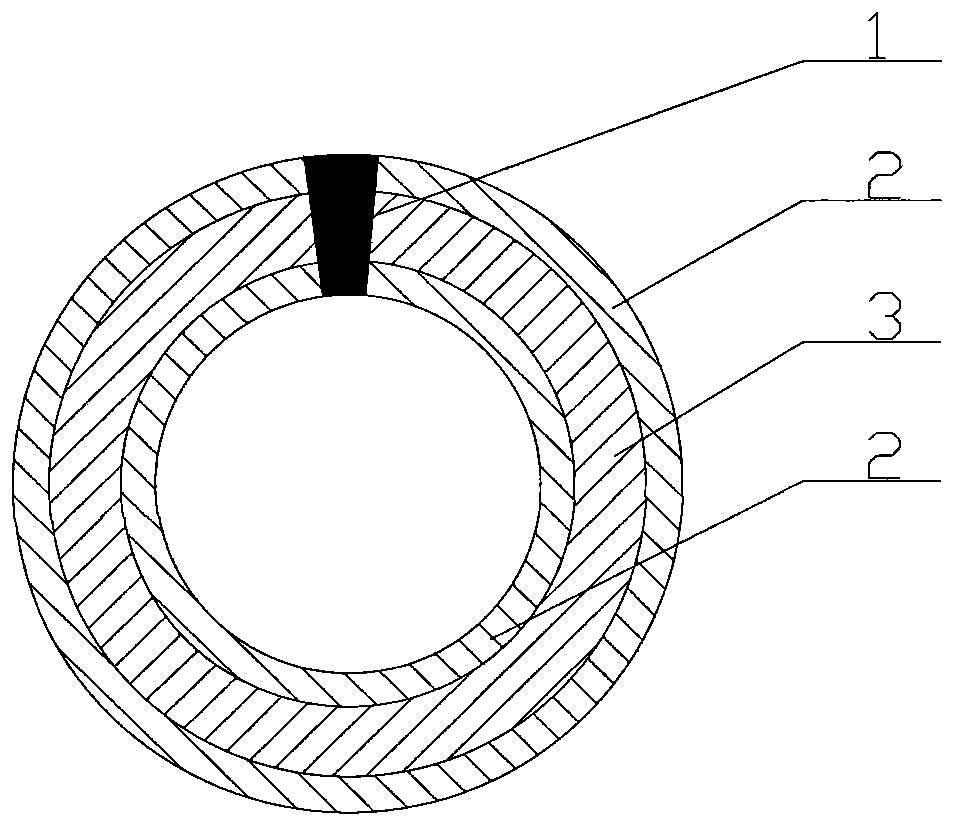

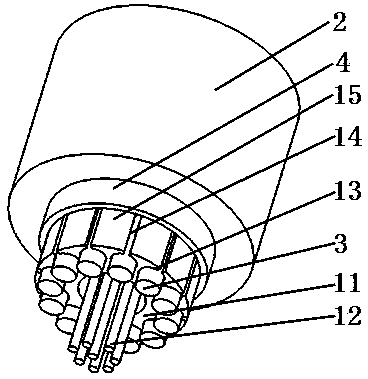

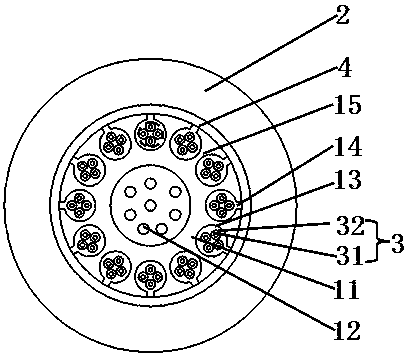

Photovoltaic composite cable for power system

InactiveCN103971840AEasy to insertConsistent mechanical propertiesInsulated cablesPower cables including optical transmission elementsElectric power systemProtection layer

The invention belongs to the technical field of the electric power and cables, and particularly relates to a photovoltaic composite cable for a power system. The photovoltaic composite cable comprises a bushing body, a protection layer and a jacket layer, and the photovoltaic composite cable is characterized in that a light transmission element is arranged in the bushing body, and the outer circumference of the bushing body is provided with an opening and a protection bar; a symmetric axis of the opening passes through the center of the bushing body, a storage chamber which is communicated with the opening is arranged below the opening, the storage chamber is not communicated with a cavity for storing the light transmission element, two adjacent storage chambers are not communicated with each other, the storage chambers are distributed in the bushing body, each storage chamber is provided with an opening inner side and an opening outer side, and the width of each storage chamber is gradually increased from any opening inner side to the center of the storage chamber along the symmetric axis of the opening; a power transmission unit is arranged in each storage chamber. The photovoltaic composite cable has the main beneficial effects that branches are convenient to introduce, no electric transmission unit twisting device is needed, few production procedures are needed, the outer diameter of the composite cable is small, and the cost is low.

Owner:国网山东省电力公司临邑县供电公司 +1

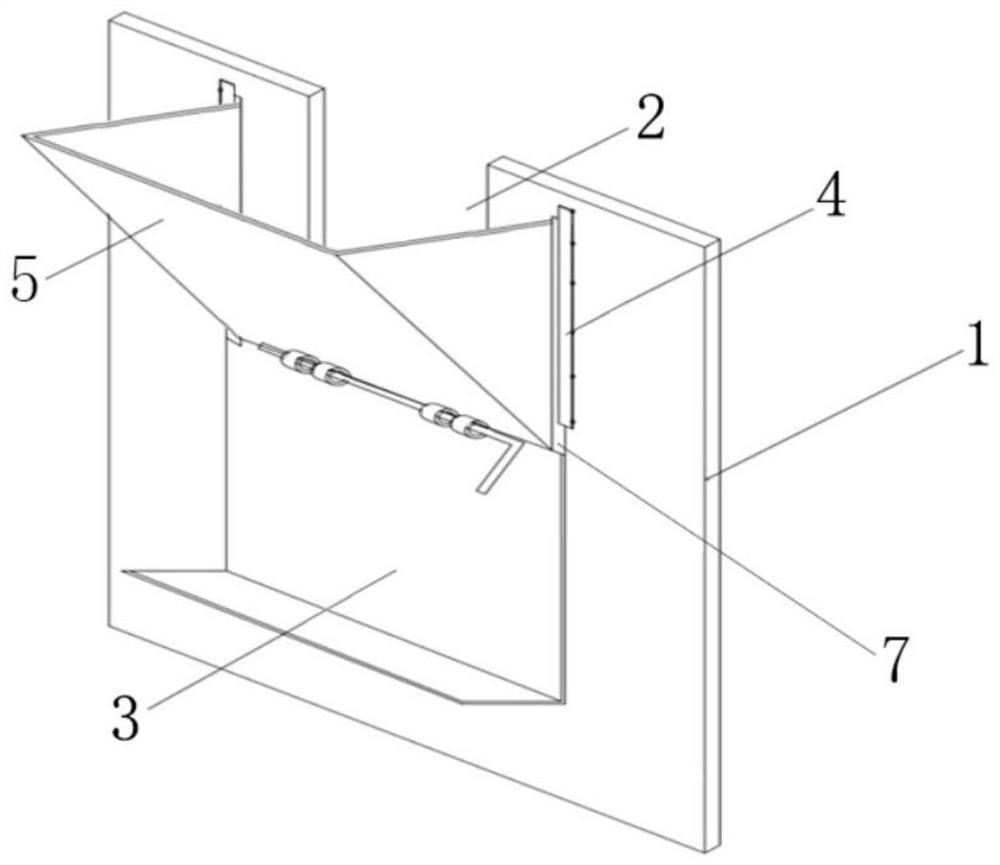

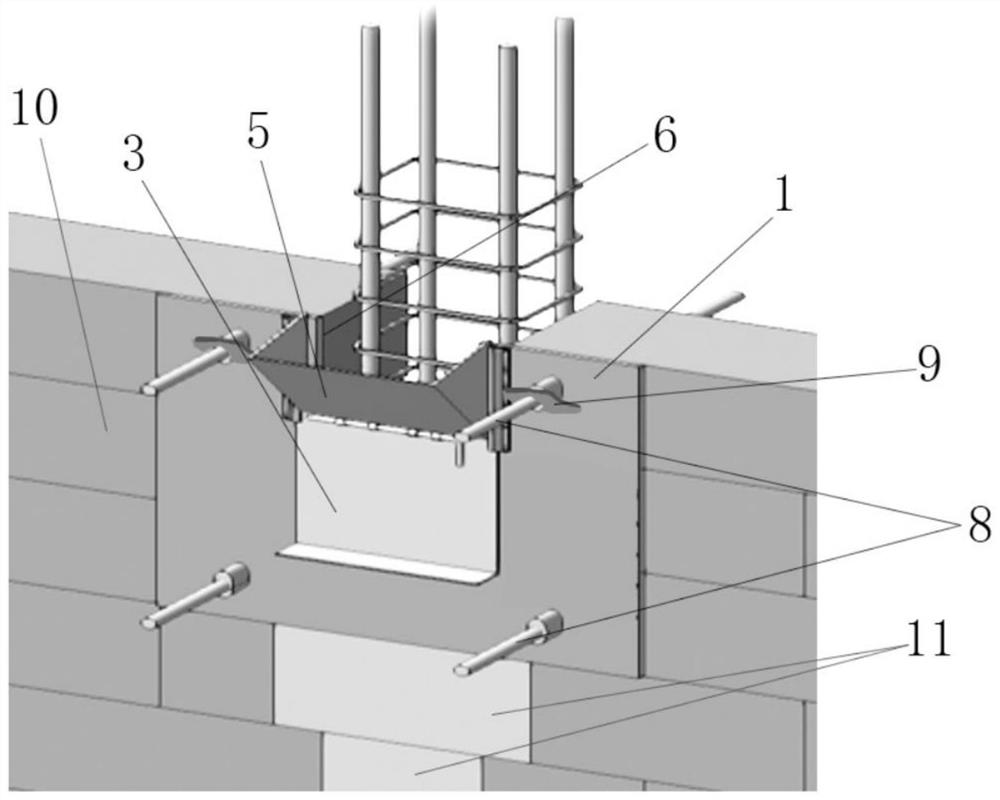

Constructional column chiseling-free construction method beneficial to controlling top sealing quality of constructional column

InactiveCN111622505AAct as a reinforcementImprove mechanical propertiesWallsForms/shuttering/falseworksBrickArchitectural engineering

The invention relates to the field of building construction, in particular to a constructional column chiseling-free construction method beneficial to controlling the top sealing quality of a constructional column. The method includes the following steps: firstly, wall building, wherein during wall building, mould bricks are built together with a wall body at a constructional column design position; secondly, pouring assembly installation, wherein when the wall body in the first step is built to the top, a gap for pouring constructional column concrete is reserved at the top of the constructional column design position, and a pouring assembly for pouring the concrete is arranged at the gap position of the wall body; thirdly, constructional column pouring, wherein the concrete is poured into a construction column pouring cavity through the pouring assembly, after concrete pouring is completed, the gap at the top of the constructional column is sealed through a sealing plate, a pouring bucket of the pouring assembly is detached, and concrete in the pouring bucket is recycled; and fourthly, maintenance. The constructional column chiseling-free construction method firstly simplifies the construction, greatly shortens the construction period and greatly improves the surface flatness of the constructional column.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

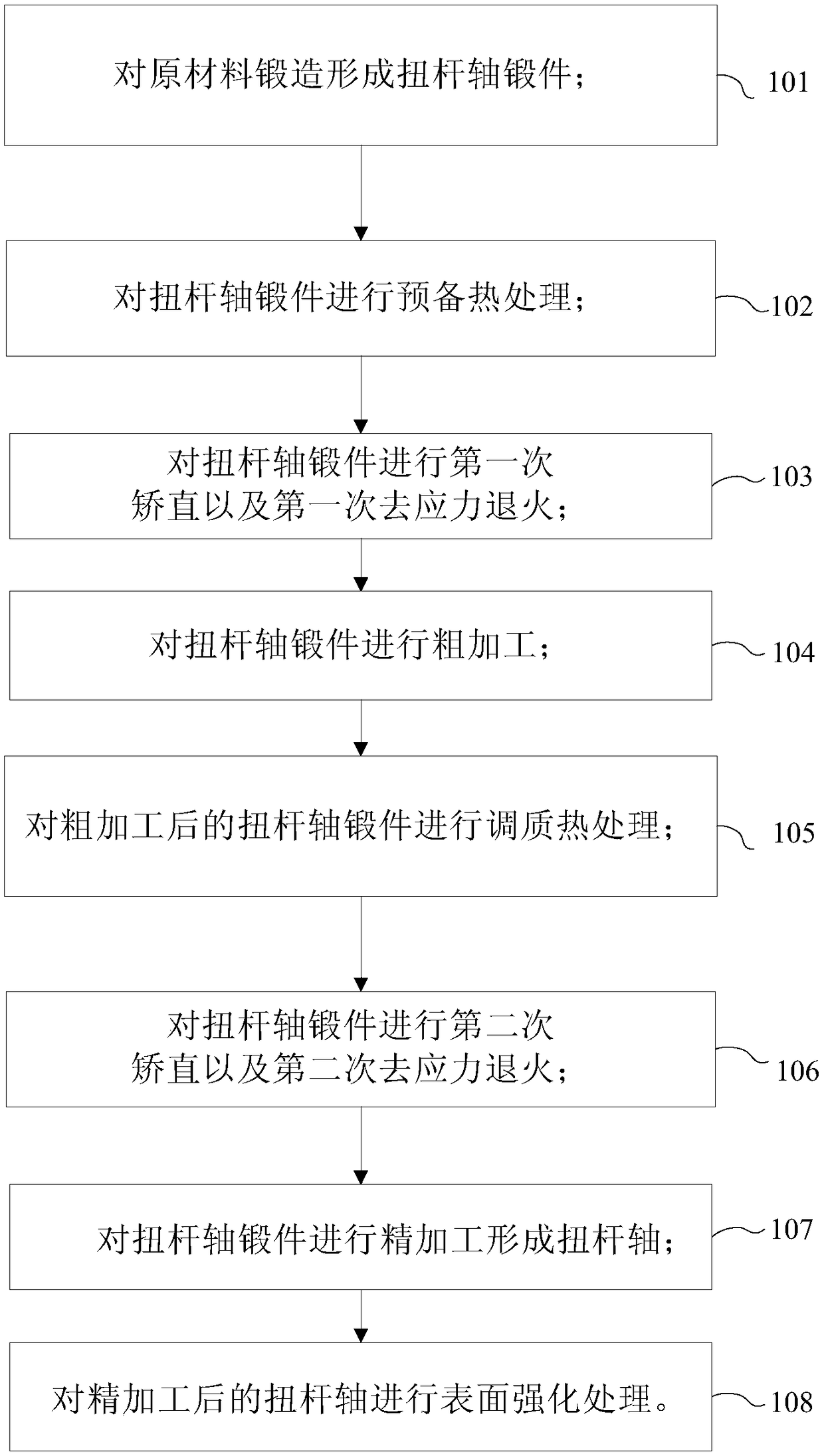

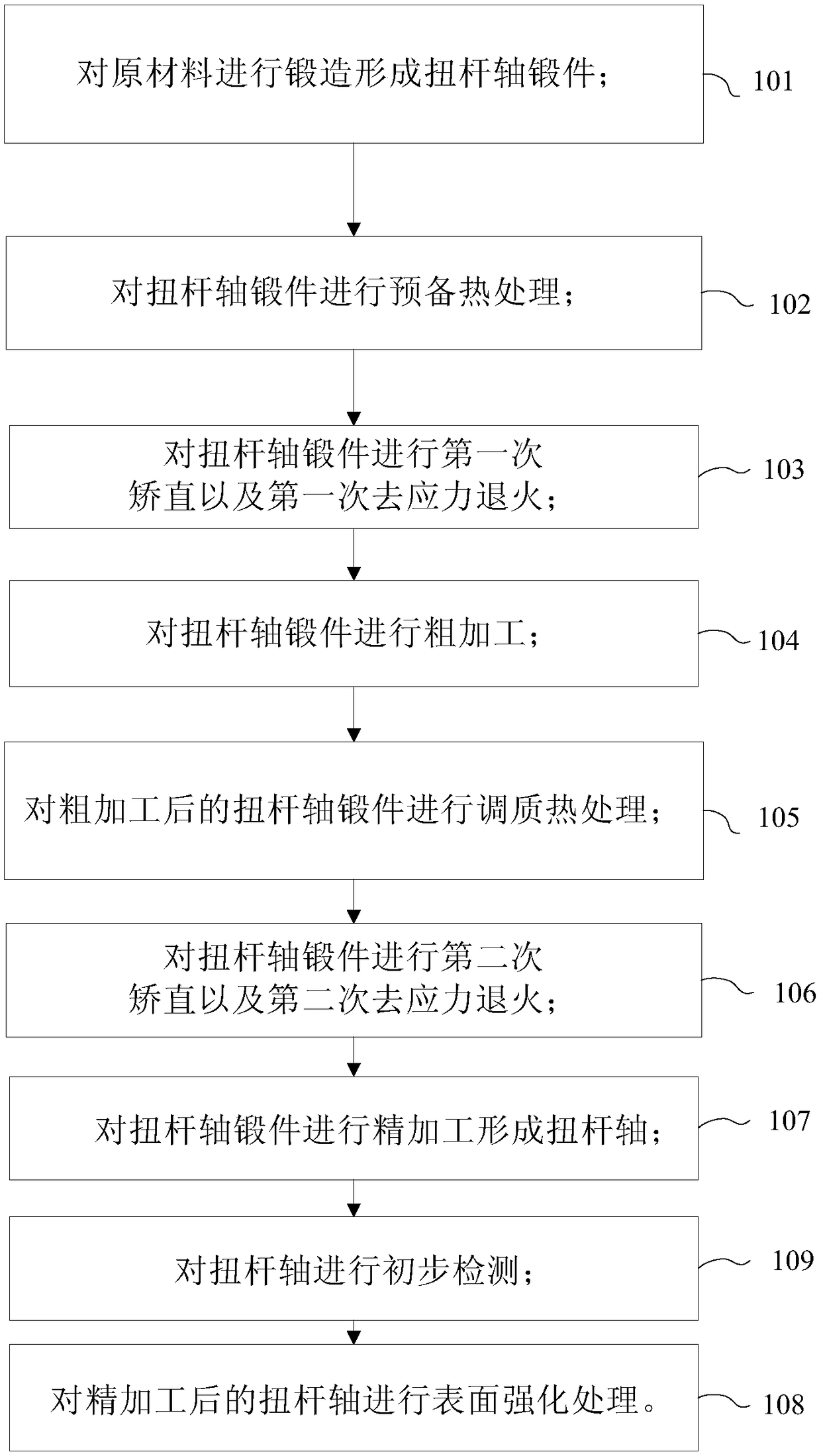

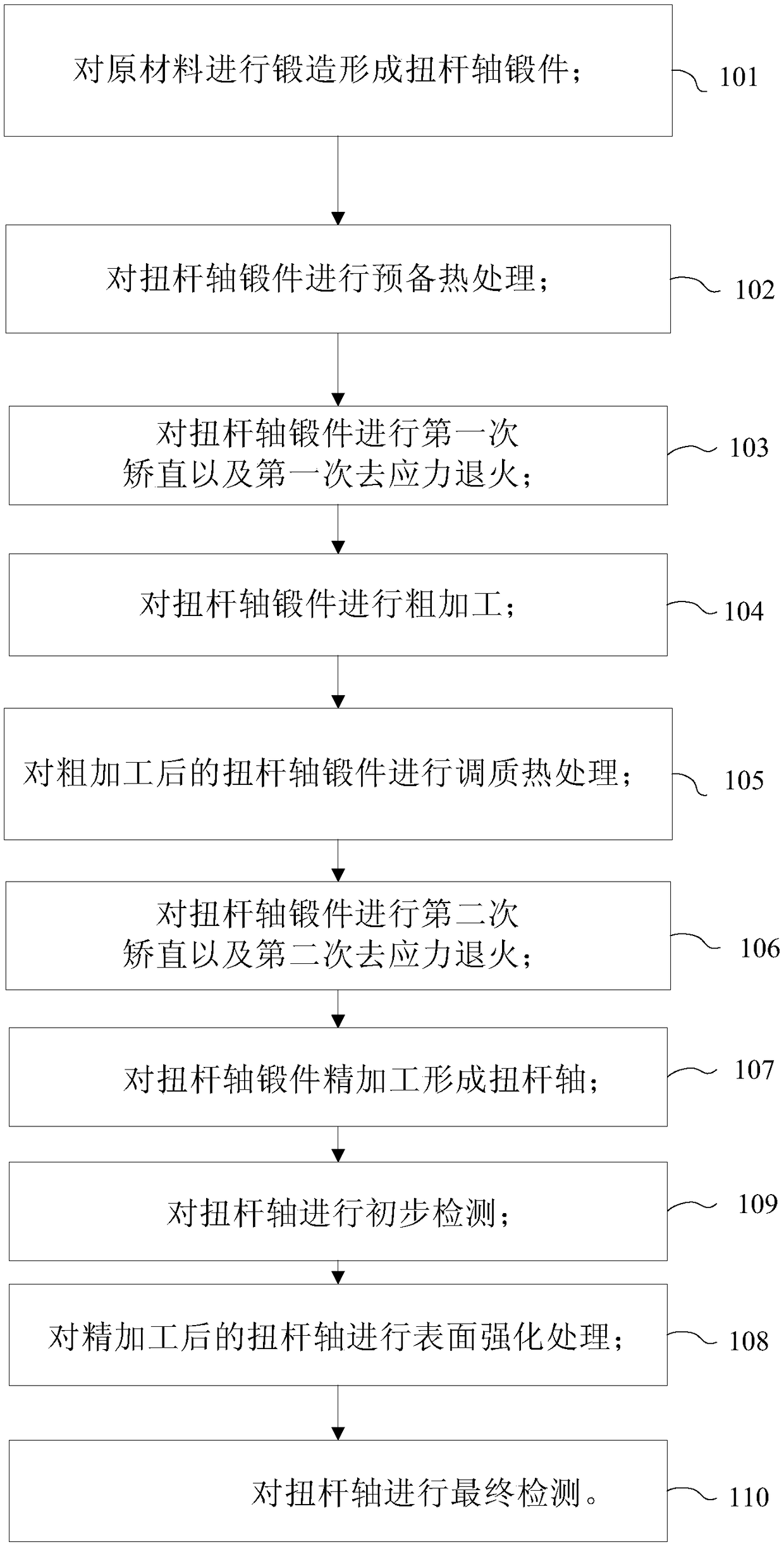

Torsion bar shaft machining method

The invention provides a torsion bar shaft machining method. The torsion bar shaft machining method comprises the following steps that a raw material is forged to form a torsion bar shaft forge piece;preliminary heat treatment of the torsion bar shaft forge piece is conducted; first-time straightening and first-time stress relief annealing of the torsion bar shaft forge piece are conducted; roughmachining of the torsion bar shaft forge piece is conducted; quenched-tempered heat treatment of the after-rough-machining torsion bar shaft forge piece is conducted; second-time straightening and second-time stress relief annealing of the torsion bar shaft forge piece are conducted; finish machining of the torsion bar shaft forge piece is conducted to form a torsion bar shaft; and surface strengthening treatment of the after-finish-machining torsion bar shaft is conducted. According to the torsion bar shaft machining method, crystal grains of the torsion bar can be refined, forging fiber coherence is guaranteed, so that the mechanical property of each position of the torsion bar shaft is consistent, and the comprehensive mechanical property of the torsion bar shaft is improved.

Owner:齐齐哈尔北盛机械制造有限公司

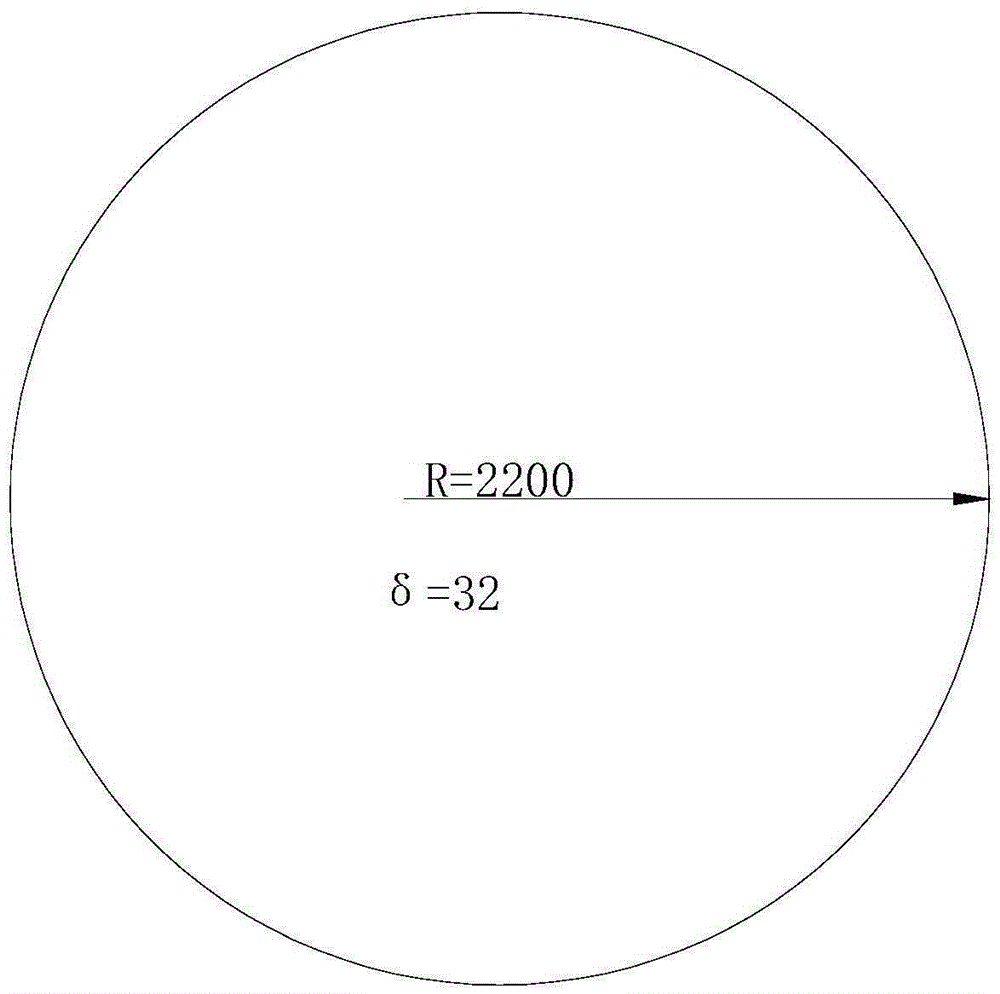

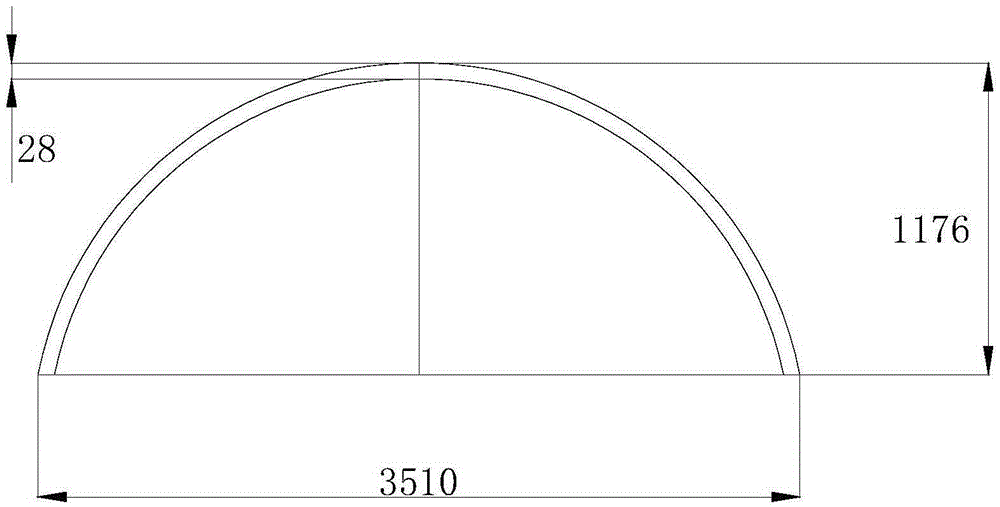

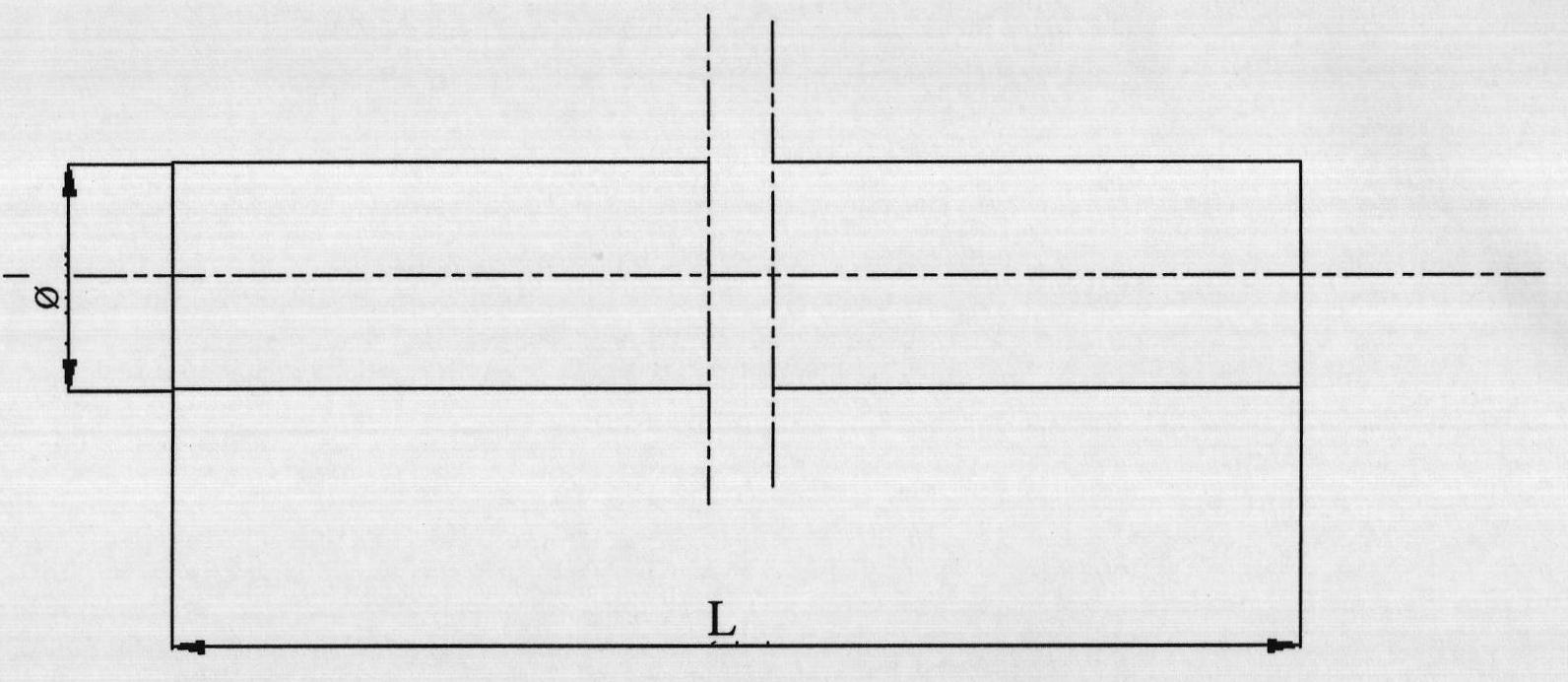

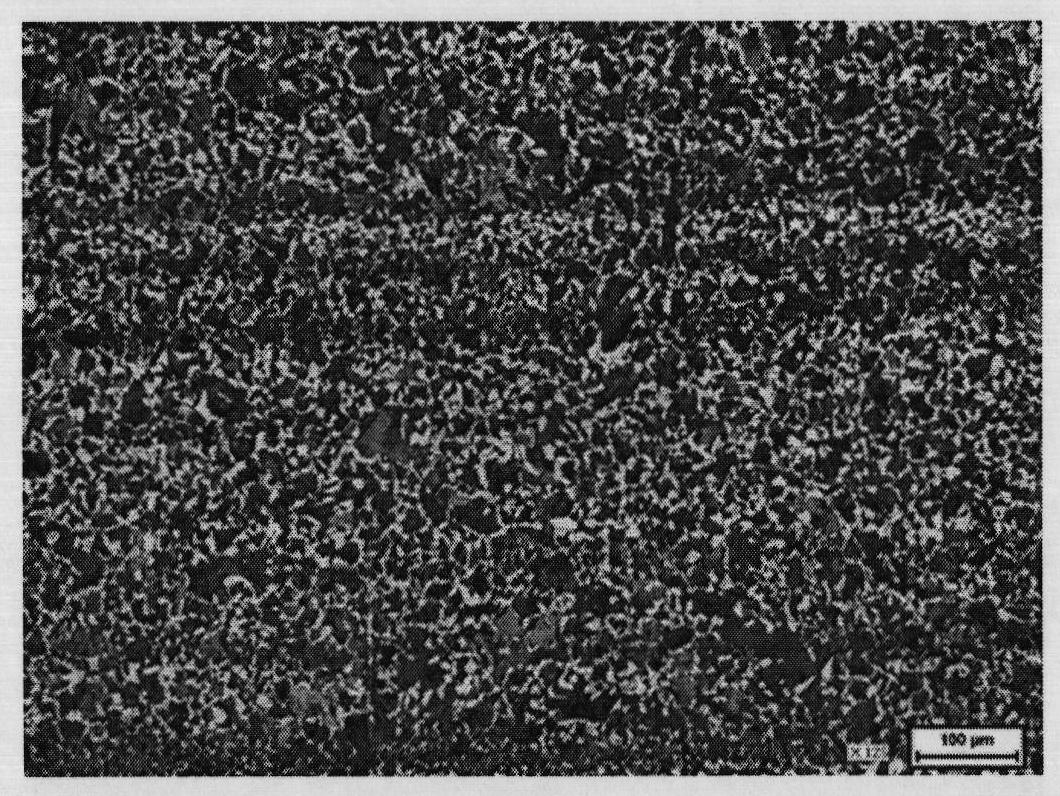

Hot press molding method for spherical head made of 10CrNi3MoV steel

InactiveCN105256116ASmall mechanical propertiesConsistent mechanical propertiesFurnace typesHeat treatment furnacesThermal compressionEngineering

The invention provides a hot press molding method for a spherical head made of 10CrNi3MoV steel and belongs to the field of machining and manufacturing methods of end sockets of sealing pressure structures of ship bathyscaphs. The problems that an existing spherical head cold machining and forming process is high in cost and machining stress is difficult to eliminate are solved, so that cost is reduced, and the service life of the spherical head made of the 10CrNi3MoV steel is prolonged. The method includes the round plate heating step, the die forming step, the quenching treatment step and the tempering treatment step. By the adoption of the method, the requirements for pressing die and stamping equipment are lowered, stamping forming is easy to control, quality is better, machining stress does not exist, it can be guaranteed that the mechanical performance of the spherical head made of the 10CrNi3MoV steel is identical to that of the 10CrNi3MoV steel plate, and therefore it is guaranteed that the service life of the spherical head made of the 10CrNi3MoV steel is identical to that of a ship.

Owner:WUCHANG SHIPBUILDING IND

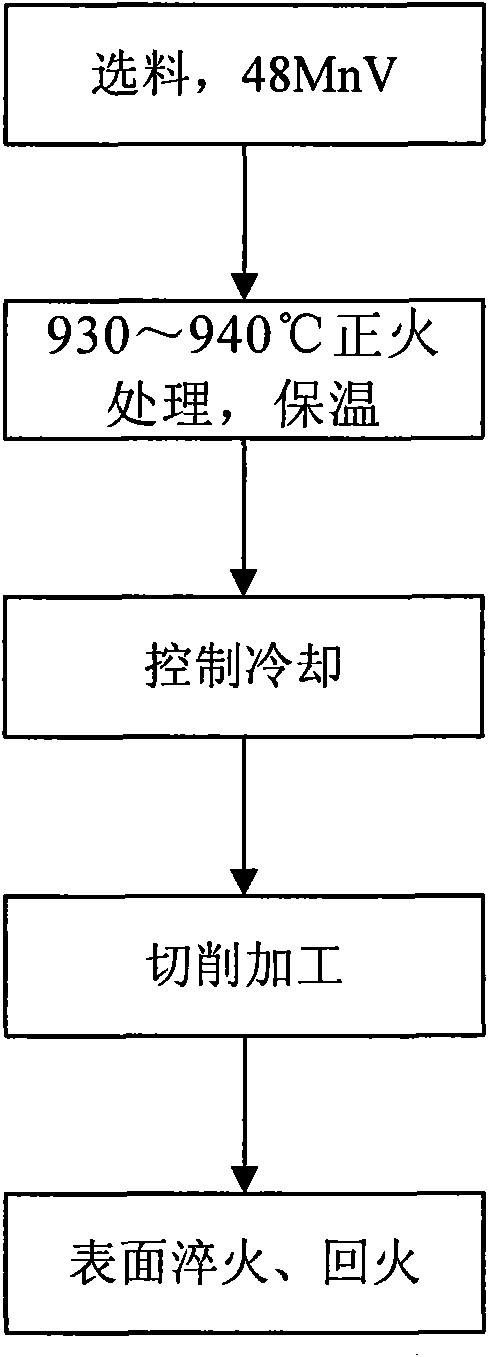

Method for manufacturing hammer shaft of single-stage hammer crusher

InactiveCN101885135AEconomical manufacturing methodThe preparation method is reasonableGrain treatmentsSingle stageRoom temperature

The invention discloses a method for manufacturing a hammer shaft of a single-stage hammer crusher. The method comprises the following steps of: a, selecting hot-rolled 48MnV round steel; b, performing normalizing treatment on the round steel at the temperature of between 930 and 940 DEG C, wherein the soaking time is 70 to 75 minutes; c, cooling the round steel by adopting wind cooling, controlling the cooling speed which is controlled to be between 30 and 40 DEG C per minute at the temperature of over 500 DEG C, and reducing the round steel to the room temperature through air cooling when the temperature is below 500 DEG C; d, performing cutting machine-shaping; and e, performing surface induction hardening and tempering. A great number of material tests summarize that the 48MnV is used as a raw material, and by implementing a great number of tests for summarization and a unique manufacturing process, the method, which is more economical and reasonable, for manufacturing the hammer shaft of the single-stage hammer crusher is obtained, and the method ensures that the mechanical properties of core parts and surfaces of components are more accordant, and the overall comprehensive performance of the components is better.

Owner:上海市机械制造工艺研究所有限公司

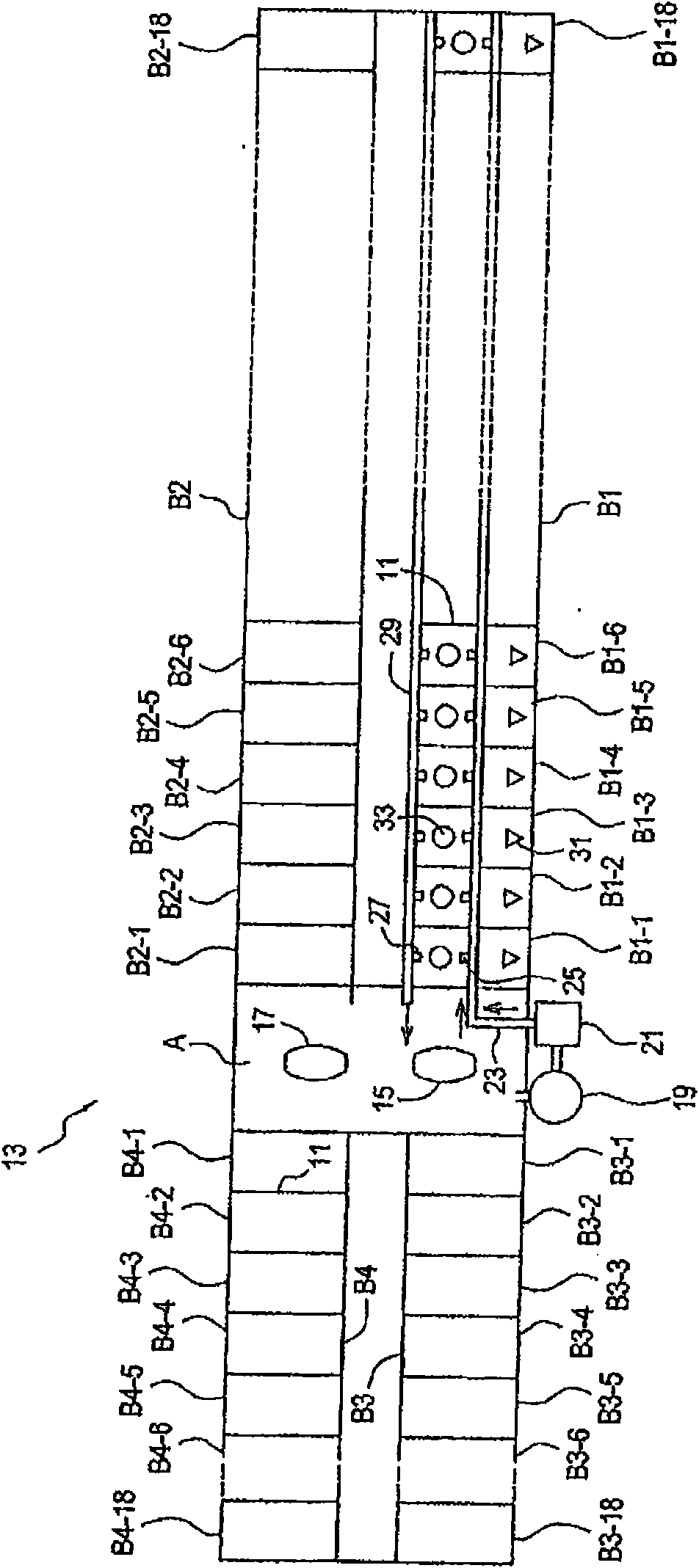

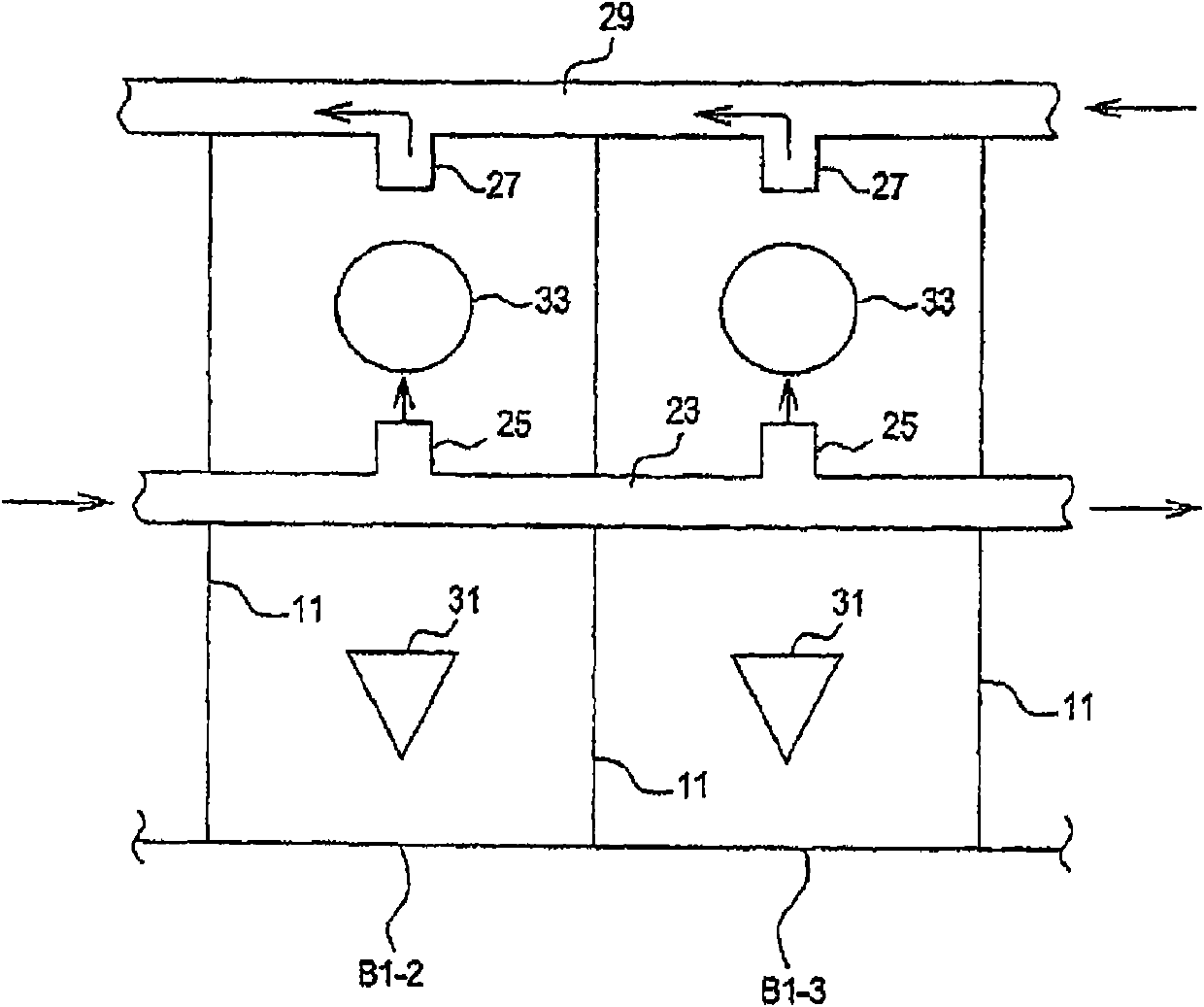

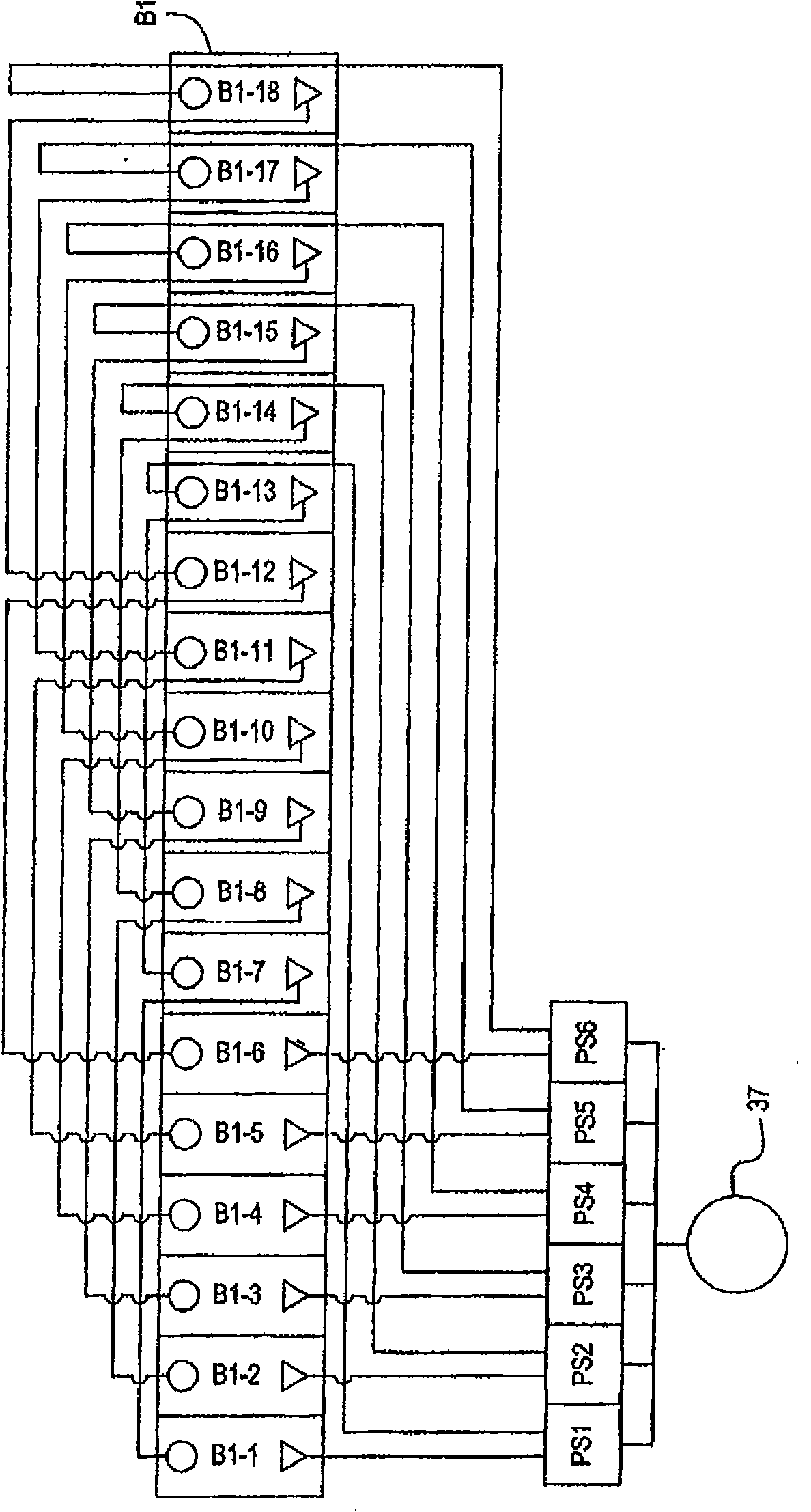

Electroplating method and apparatus

InactiveCN102007232AConsistent mechanical propertiesCellsCurrent conducting devicesElectricityEngineering

An apparatus and method is disclosed for simultaneously electroplating at least two parts in a series electrical configuration in an electroplating system using a shared electrolyte with excellent consistency in thickness profiles, coating weights and coating microstructure. Parts in high volume and at low capital and operating cost are produced as coatings or in free-standing form.

Owner:INTEGRAN TECH

Nanotube and finely milled carbon fiber polymer composite compositions and methods of making

InactiveUS20180002512A9Removal costEliminate timeMaterial nanotechnologyCarbon nanotubesFiberElectrical resistance and conductance

Embodiments of the present invention include composite compositions extrusion compounded together comprising a polymer, an amount of nanotubes, and an amount of finely milled carbon fiber having an aspect ratio greater than 1 and less than about 5. The resulting composite materials allow for high carbon loading levels with improved tribological properties including coefficient of friction and wear rates, provides uniform surface resistance with minimal processing sensitivity, retains rheological properties similar to the base resin, and provides isotropic shrink and a reduced coefficient of thermal expansion leading to minimal warp. In general, various articles can be formed that take advantage of the properties of the composite materials incorporating a polymer, carbon nanotubes and finely milled carbon fiber.

Owner:ENTEGRIS INC

Isotropous rolling method for ion-based high-temperature alloy rectangular ring part

The invention discloses an isotropous rolling method for an ion-based high-temperature alloy rectangular ring part. The isotropous rolling method comprises the following steps: firstly, heating an iron-based high temperature alloy rod to a forging temperature, and carrying out upsetting, punching and pre-rolling on the iron-based high temperature alloy rod to prepare rectangular ring blank; filling the rectangular ring blank into ring rolling machine, lifting a tapered roller by a height h being 5mm-10mm for tilting the rectangular ring blank; then, rolling and shaping the rectangular ring blank to obtain the ion-based high-temperature alloy rectangular ring part. According to the method, by changing the flow direction of materials during rolling, isotropous mechanical properties of the rectangular ring part are kept consistent, so that the comprehensive mechanical properties of the rectangular ring part are improved. The method is used for producing the isotropous ion-based high-temperature alloy rectangular ring part.

Owner:GUIZHOU ANDA AVIATION FORGING

Cutter tooth holder lost foam casting mold and casting method

PendingCN111468675ADischarge in timeExtended service lifeFoundry mouldsFoundry coresCasting moldMechanical engineering

The invention discloses a lost foam casting mold for a cutter tooth holder. The lost foam casting mold for the cutter tooth holder comprises a cutter tooth holder white mold and a casting system whitemold, sand box casting is changed into lost foam casting, and a sprue and a plurality of groups of ingates are arranged in a roller, so that molten metal is cast in the cutter tooth holder white moldfrom bottom to top; the first ingate, the second ingate and the third ingate in the ingates convey the molten metal to the roller and promote the molten metal to form local entrainment scouring in the roller at the same time, so that impurities such as bubbles and dross remaining in the roller, a first inverted teeth and a second inverted teeth are washed away, the pouring quality is greatly improved, the production cost is reduced, a first riser and a second riser are correspondingly arranged at the joints of the end part of the roller and the end parts of the first inverted tooth and the second inverted tooth, so that molten metal with impurities is timely discharged, the pouring quality of a cutter tooth holder is greatly improved, the internal structure distribution is uniform, the compactness is good, the mechanical properties of the two sides are consistent, and the service life of the cutter tooth holder is remarkably prolonged.

Owner:NINGXIA SUNING NEW ENERGY EQUIP

Isotropic rolling method for cobalt-based high-temperature alloy rectangular ring part

The invention discloses an isotropic rolling method for a cobalt-based high-temperature alloy rectangular ring part. The isotropic rolling method comprises the following steps: firstly, heating a cobalt-based high-temperature alloy bar to a forging temperature, and carrying out upsetting, punching and pre-rolling, thereby forming a rectangular ring blank; secondly, mounting the rectangular ring blank on a ring rolling mill, lifting a conical roller by h=5 to 10 mm such that the rectangular ring blank tilts, and then performing rolling forming to obtain the cobalt-based high-temperature alloy rectangular ring part. According to the method, the mechanical properties of the rectangular ring part in various directions are kept consistent by changing a material flowing direction during rolling, and therefore, the comprehensive mechanical properties of the rectangular ring part are improved. The method is used for producing the cobalt-based high-temperature alloy isotropic rectangular ring parts.

Owner:GUIZHOU ANDA AVIATION FORGING

Butt joint method for long powder metallurgy compressed billets

The invention discloses a butt joint method for long powder metallurgy compressed billets. Materials are prefabricated into at least two compressed billets, and the compression coefficient of the compressed billets ranges from 1.25 to 1.35; butt joint faces of the compressed billets are subjected to roughening; and the butt joint faces of the compressed billets are evenly coated with powder with the same brand number with the compressed billets, then a soft film is used for wrapping every two adjacent compressed billets for locating, afterwards, the compressed billets are put in a cold isostatic press to be subjected to pressurizing and pressure maintaining, and the compression coefficient is lowered to be smaller than 1.21, so that the compressed billets are tightly combined. The butt joint method has the advantages that an original long compressed billet is divided into several small compressed billets which are compressed through molds, but the compression coefficient is not directly settled in one step, then the powder with the same brand number with the compressed billets is laid between every two adjacent compressed billets for cold isostatic pressing, and therefore the two compressed billets are bonded together to form a long compressed billet, and the design requirements are met; according to the method, existing short molds can be fully utilized, the compressed billet obtained through the butt joint method is consistent with a one-time formed compressed billet in mechanical property, and the consistent density of the whole compressed billet also can be guaranteed.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

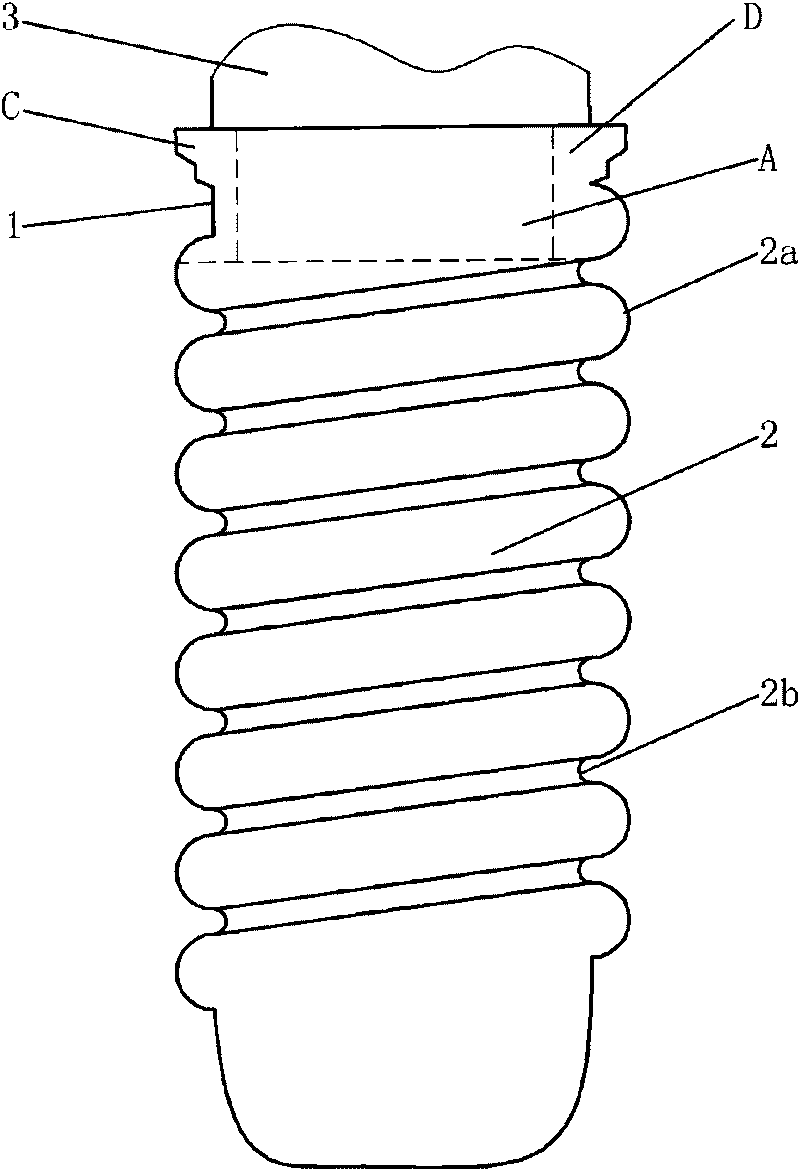

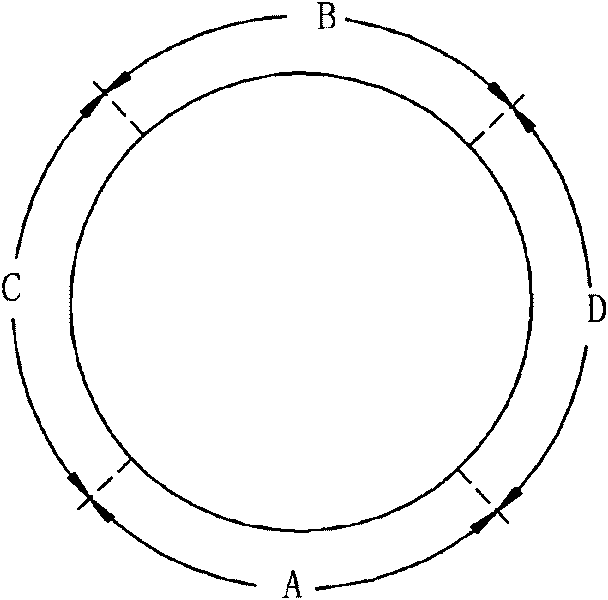

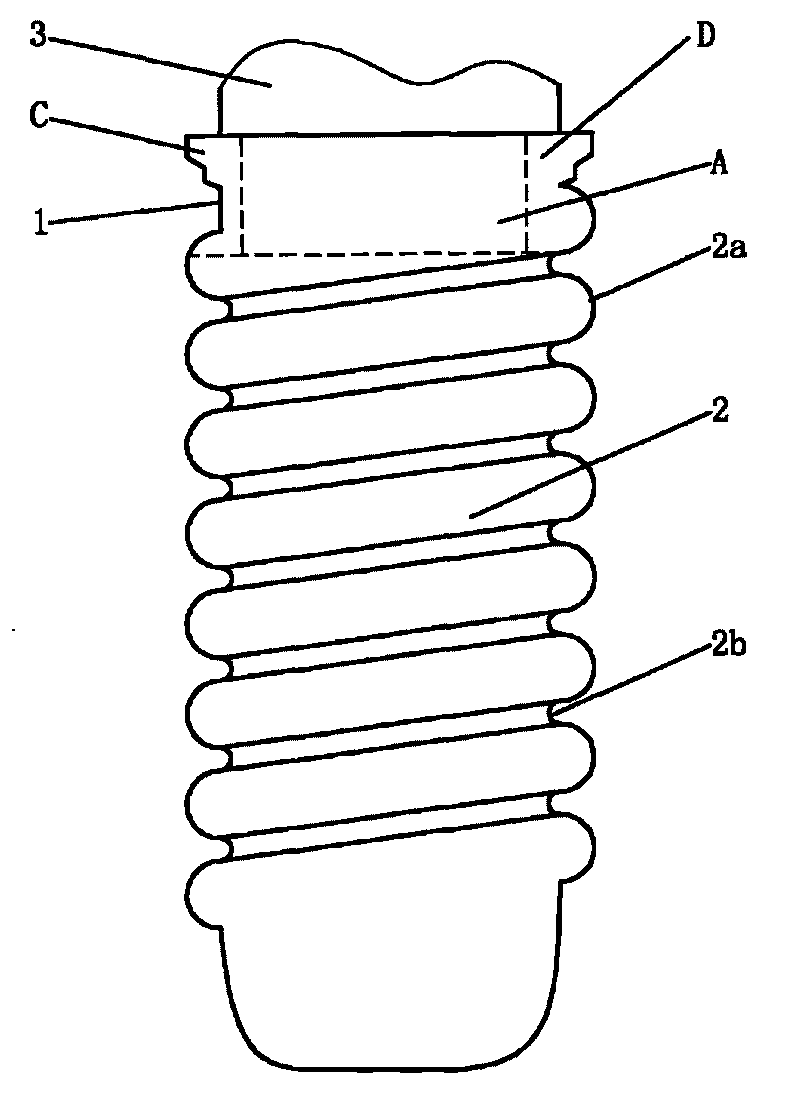

Fretting damage resistant endosseous dental implant

ActiveCN101732098AConsistent mechanical propertiesImplement partition designDental implantsCeramic coatingHydroxyapatite coating

The invention discloses a fretting damage resistant endosseous dental implant, which comprises a foundation pile (3), a neck part (1) and a body part (2) with external thread, wherein the periphery surface of the neck part (1) of an implant is provided with four areas of a tongue side area (A), a cheek side area (B), a near center area (C) and a far center area (D); the surfaces of the near center area (C) and the far center area (D) are coated with a hydroxyapatite / tetragonal zirconia compound ceramic coating, and the tongue side area (A) and the cheek side area (B) are coated with hydroxyapatite coatings; the thread top (2a) and the thread bottom (2b) of the external thread of the body part (2) are both arc-shaped; the two arcs are smoothly connected; and the curvature radius of the arc of the thread top (2a) is 1 / 4-1 / 6 of the radium of the body part (2), and the radium of the arc of the thread bottom (2b) is 1 / 3-1 / 4 of the radius of the arc of the thread top (2a). The implant in the invention has the advantages of good fretting damage resistance, high success rate of dental implant and long service life.

Owner:SICHUAN UNIV

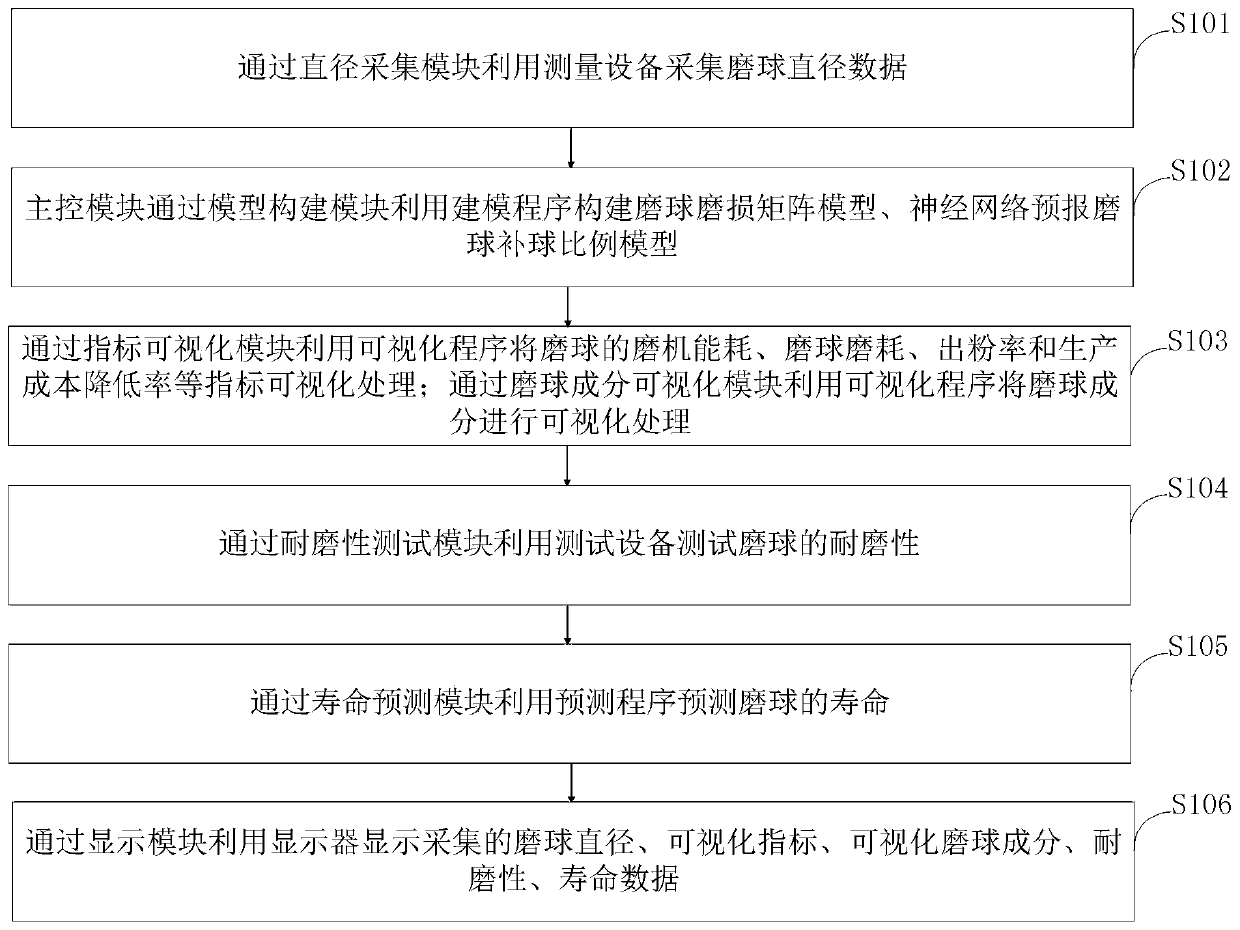

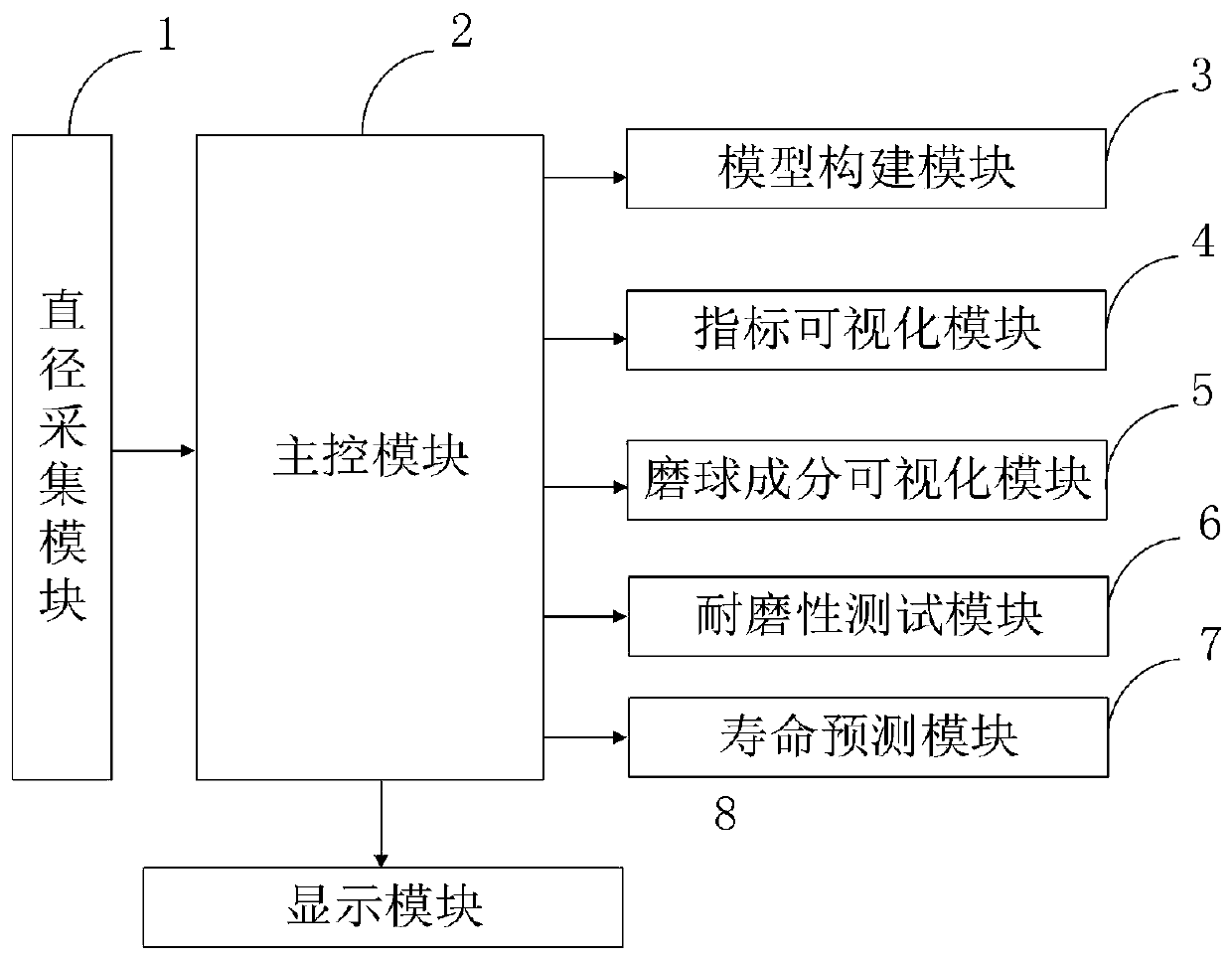

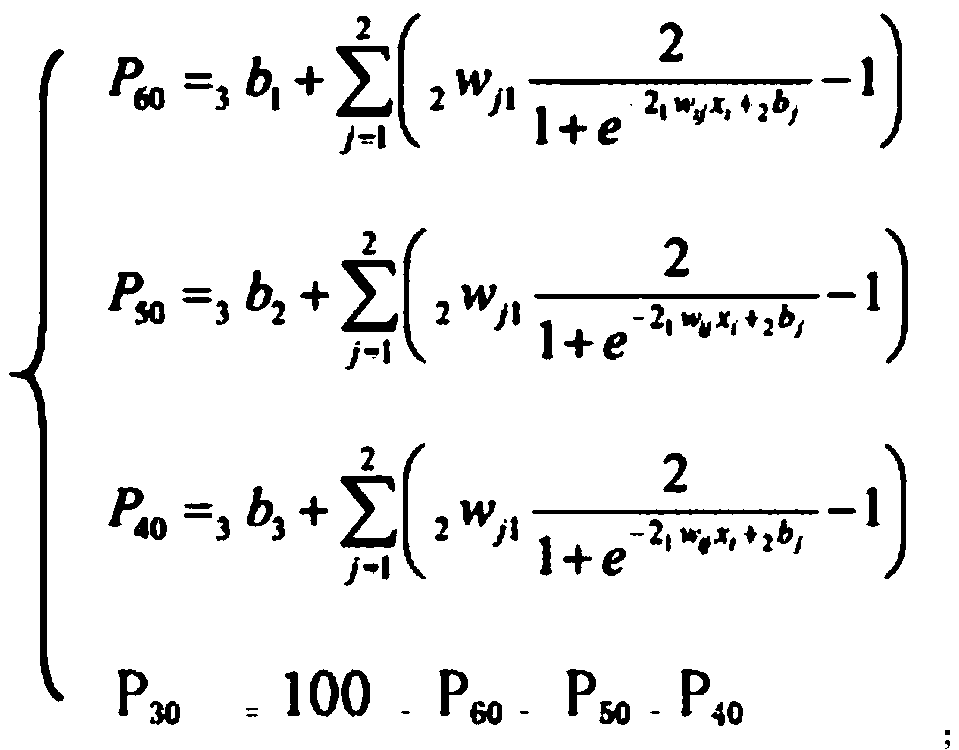

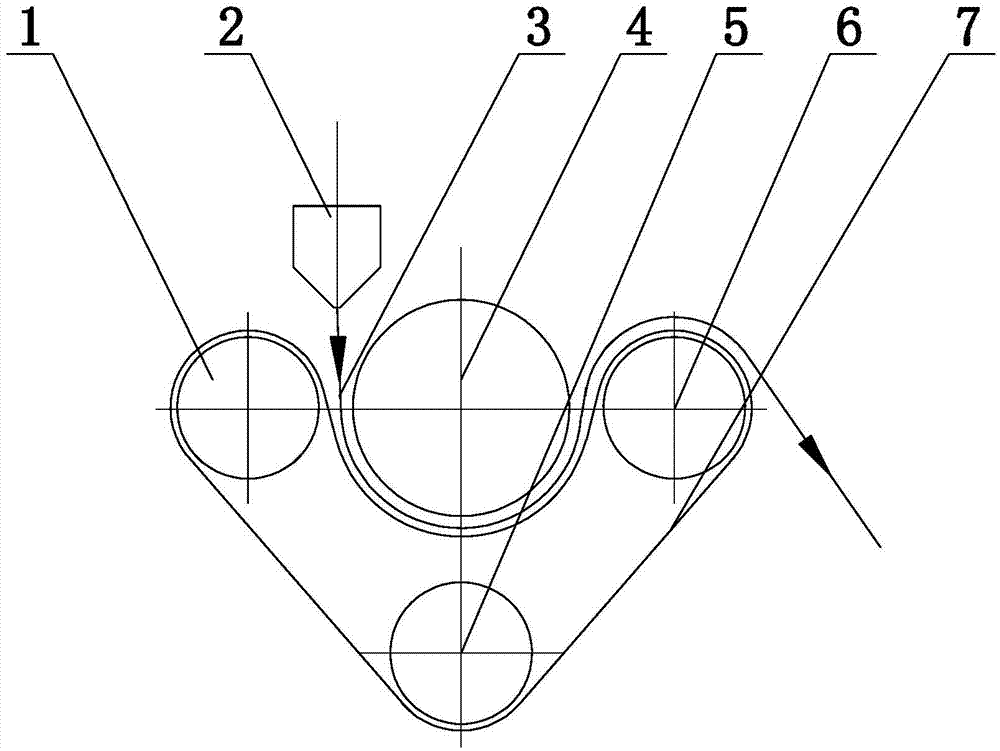

Casting grinding ball gradation modeling method and system based on visual platform

PendingCN110287606ACasting precisionExtended service lifeGeometric CADDesign optimisation/simulationReduction rateEngineering

The invention belongs to the technical field of grinding ball gradation mathematical modeling, and discloses a casting grinding ball gradation modeling method and system based on a visual platform. A grinding ball wear matrix model and a neural network forecasting grinding ball supplement proportion model are constructed through a model construction module by utilizing a modeling program; indexes such as mill energy consumption, mill ball abrasion, powder yield and production cost reduction rate of the mill balls are visualized by utilizing a visualization program; and the like. By constructing the grinding ball wear matrix model and the neural network prediction grinding ball supplement proportion model, grinding ball casting can be more accurate, and the quality is higher; by applying the visualization method, the visualization method is obtained with extremely few experiment times, and a material formula range and a heat treatment process condition range of which three technical indexes of hardness, toughness and hardness uniformity meet the requirements can be obtained by designing and optimizing the experiment; the service life of the grinding ball is prolonged; therefore, energy is saved, consumption is reduced and production cost is reduced.

Owner:HUAIYIN TEACHERS COLLEGE

Device and process for producing and forming OV type high-gloss films

The invention discloses a device and a process for producing and forming OV type high-gloss films. The device comprises a rack, wherein an elastic roller, a flat die head, a mirror roller, a deviation correcting roller and a cooling roller are arranged on the rack; the elastic roller is mounted on one side of the mirror roller; the cooling roller is mounted on the other side of the mirror surface; the elastic roller and the mirror roller are mounted in a manner of infinitely close to each other; the flat die head is mounted on the upper part of the joint of the elastic roller and the mirror surface; the deviation correcting roller is mounted on the rack under the mirror roller; a stainless steel strip is mounted among the elastic roller, the mirror roller, the cooling roller and the deviation correcting roller; the mirror roller is connected with a servo motor. By virtue of the device and the process for producing and forming OV type high-gloss films, the problems of transparency and thickness uniformity of the films are solved; and the problem of the gloss of the surfaces of the films is solved.

Owner:绍兴博瑞挤出设备有限公司

Triaxial test method for measuring shear strength index of rammed earth wall

PendingCN111579391AEfficient determinationAccurate measurementPreparing sample for investigationMaterial strength using tensile/compressive forcesSoil scienceEngineering

The invention discloses a triaxial test method for measuring the shear strength index of a rammed earth wall, which comprises the following steps: 1) preparing a soil sample in combination with the manufacturing process of the rammed earth wall in engineering practice, preparing materials required by the soil sample and the proportion of the materials, and ensuring that the moisture content requirement of the soil sample obtained after stirring is consistent with the manufacturing process of the rammed earth wall in engineering practice; 2) tamping a soil sample in the sample striking cylinderaccording to the construction process requirement of the rammed earth wall to obtain a cylindrical sample; 3) applying confining pressure to the cylindrical sample; shearing the cylindrical sample atan axial strain of which the shearing rate is 0.5-1% per minute until the cylindrical sample is subjected to shear failure, and recording and storing data; and 4) drawing an envelope curve of the damage stress circle under different confining pressures so as to obtain the shear strength parameter cohesive force C and the internal friction angle of the cylindrical sample. The method can effectively and accurately determine the shear strength index of the rammed earth test piece.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com