Constructional column chiseling-free construction method beneficial to controlling top sealing quality of constructional column

A construction method and a technology of structural columns, which are applied in the direction of building structure, building components, and building materials, can solve problems such as difficulty in ensuring the compactness of concrete pouring, affecting the construction of structural columns, and rough surfaces of structural columns, so as to avoid mechanical damage. Performance and safety performance, simplified construction, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

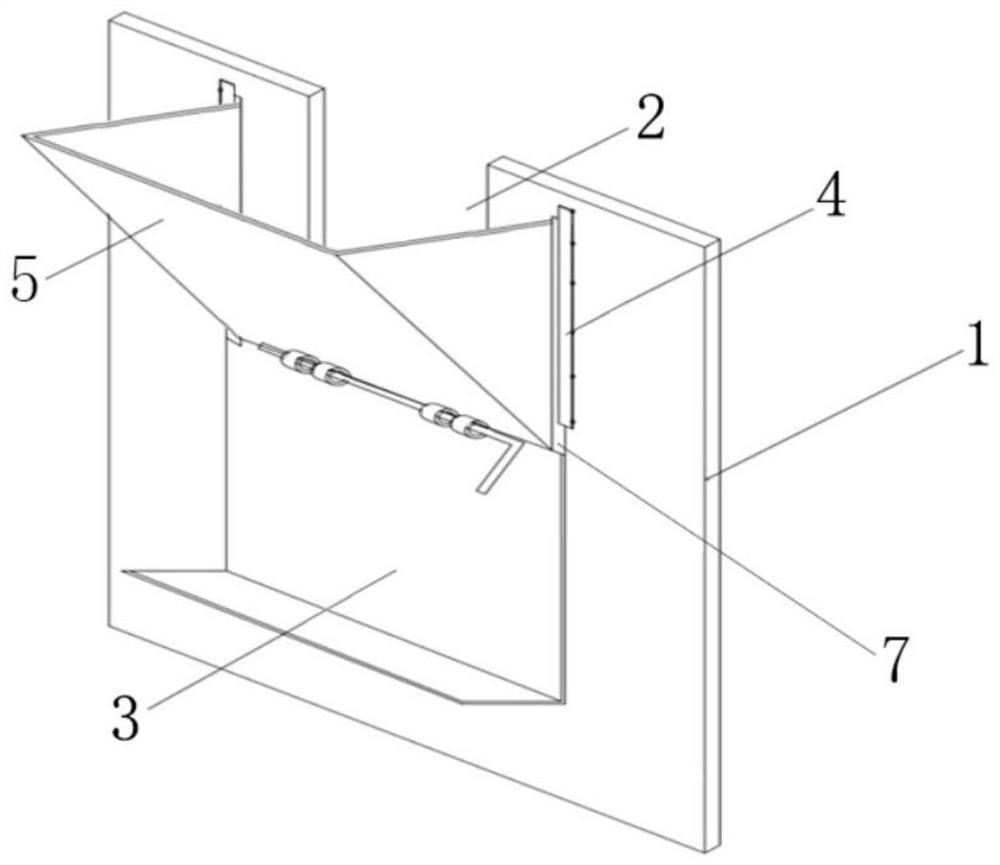

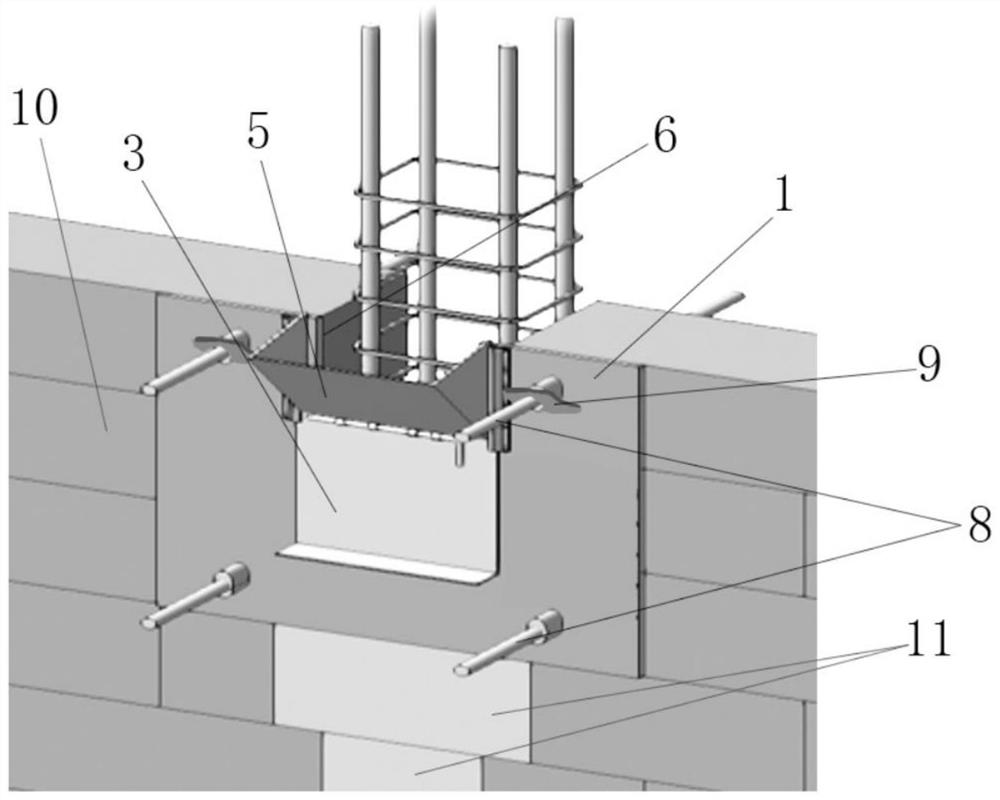

[0063] Specific implementation: as Figure 1-3 shown,

[0064] A construction method for a structural column without chiseling, which is conducive to controlling the sealing quality of the top of the structural column, comprises the following steps:

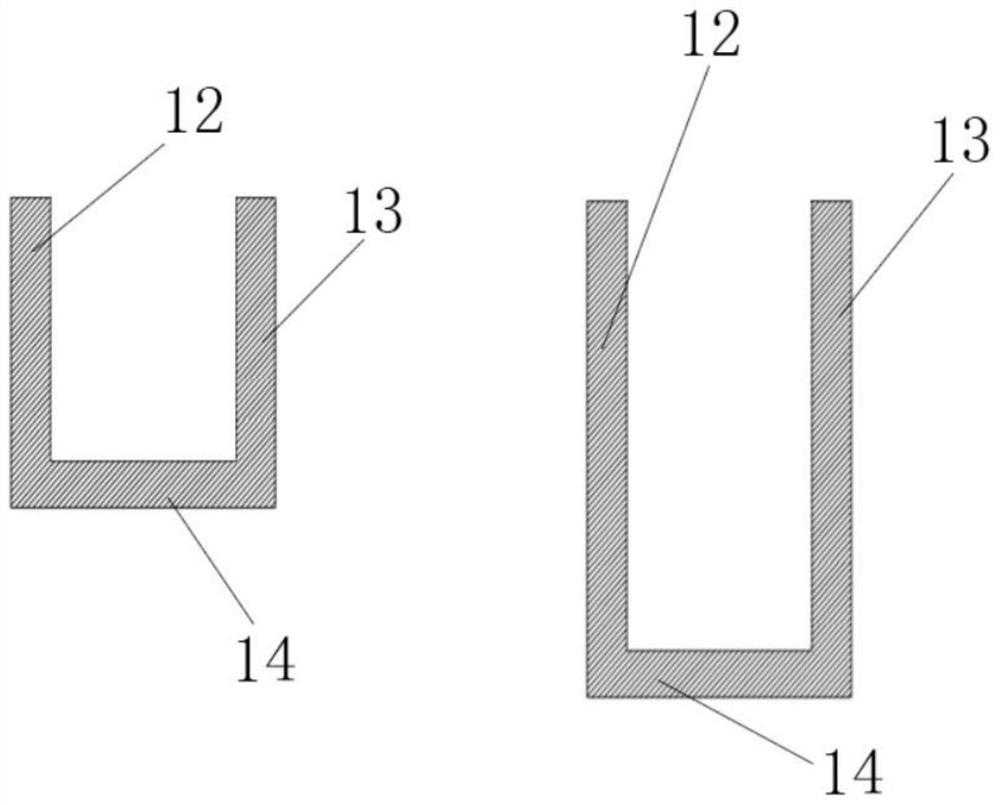

[0065] 1. Masonry of the wall body 10: When the wall body 10 is built, the mold brick 11 is used to build the wall body 10 together at the design position of the structural column. The mold brick 11 includes a first side plate 12 and a second side. plate 13, the outer wall of the first side plate 12 is flush with one side wall of the wall body 10, the outer wall of the second side plate 13 is flush with the other side wall of the wall body 10, the The first side plate 12 and the second side plate 13 are spaced apart, and a structural column casting cavity is formed between the first side plate 12 and the second side plate 13;

[0066] 2. Installation of pouring components: When the wall body 10 in step 1 is built to the top, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com