A fiber-reinforced wood-plastic composite foam sound-absorbing board

A wood-plastic composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced wood-plastic composite foam sound-absorbing panels and sound-absorbing panels, can solve the problems of limited application fields, ordinary sound insulation effects, and difficulty in construction and maintenance, so as to increase the overall Excellent strength, sound insulation effect, light weight and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

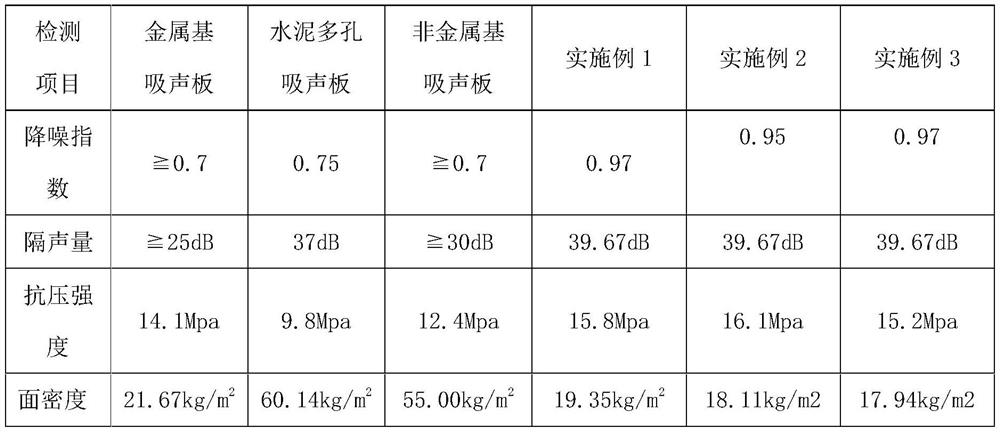

Examples

Embodiment 1

[0022] This embodiment provides a fiber-reinforced wood-plastic composite material foamed sound-absorbing board, which includes two skin layers and a foam layer located between the two skin layers. Among them, the epidermis is compact and smooth, with high hardness and a thickness of 15-35mm. The foam layer has hollow micropores, which can play the role of sound absorption and sound insulation. In this embodiment, the thickness of the epidermis is 20mm, and the thickness of the foam layer 100mm.

[0023] The skin layer is made of the following raw materials in parts by weight: wood powder 40, polyethylene resin particles 25, skin layer coupling agent 2, anti-aging additive 2, flame retardant 2, lubricant 2 and light calcium carbonate 3. The preparation method of the skin layer is: step 1, mixing wood powder, polyethylene resin particles, skin layer coupling agent, anti-aging additive, flame retardant, lubricant and light calcium carbonate at 80 ° C, and then cooling, Form a p...

Embodiment 2

[0031] This embodiment provides a fiber-reinforced wood-plastic composite material foamed sound-absorbing board, which includes two skin layers and a foam layer located between the two skin layers.

[0032]The skin layer is made of the following raw materials in parts by weight: wood powder 50, polyethylene resin particles 30, skin layer coupling agent 3, anti-aging additive 3, flame retardant 2, lubricant 2 and light calcium carbonate 3. The preparation method of the skin layer is as follows: step 1, mixing wood powder, polyethylene resin particles, skin layer coupling agent, anti-aging additive, flame retardant, lubricant and light calcium carbonate at 90 ° C, and then cooling, Form a protective layer on the surface of the wood powder to prevent carbonization, and the protective layer can be solidified by cooling; step 2, heat the mixture obtained in step 1 to 160°C to melt; step 3, the mold is pre-cooled with 8°C water, and then step 2 The resulting melt is extruded into a ...

Embodiment 3

[0040] This embodiment provides a fiber-reinforced wood-plastic composite material foamed sound-absorbing board, which includes two skin layers and a foam layer located between the two skin layers.

[0041] The skin layer is made of the following raw materials in parts by weight: wood powder 45, polyethylene resin particles 20, skin layer coupling agent 3, anti-aging additive 3, flame retardant 3, lubricant 1 and light calcium carbonate 2. The preparation method of the skin layer is as follows: step 1, mixing wood powder, polyethylene resin particles, skin layer coupling agent, anti-aging additive, flame retardant, lubricant and light calcium carbonate at 90 ° C, and then cooling, Form a protective layer on the surface of the wood powder to prevent carbonization, and the protective layer can be solidified by cooling; step 2, heat the mixture obtained in step 1 to 145°C to melt; step 3, the mold is pre-cooled with 3°C water, and then step 2 The resulting melt is extruded into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com