A preparation method of graphene titanium matrix composite material with controllable interface reaction

A titanium-based composite material and interfacial reaction technology, applied in the field of graphene titanium-based composite material preparation, can solve the problems of easy completion of graphene reaction and difficult control of interfacial reaction, and achieve weakening of interfacial reaction, excellent mechanical properties and thermal conductivity, High density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a graphene-titanium-based composite material with controllable interface reaction, comprising the following steps:

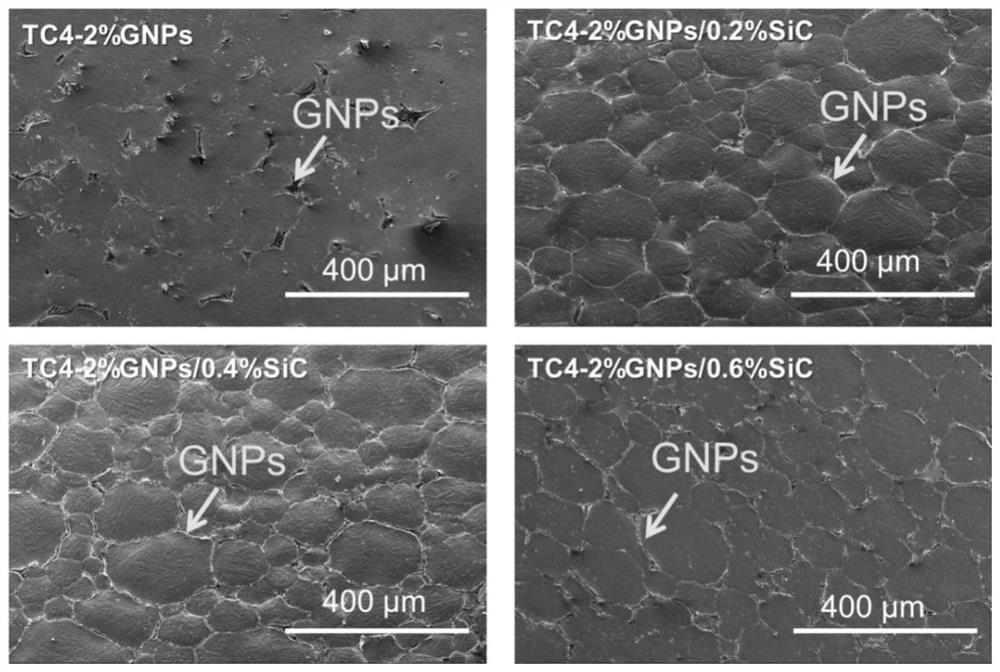

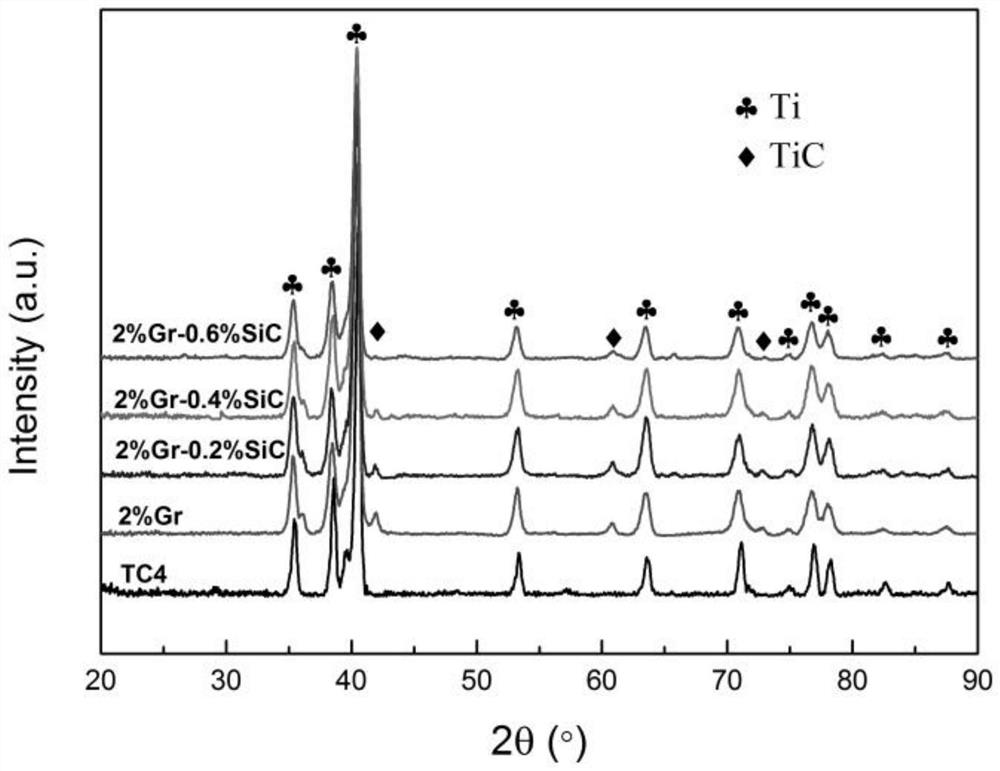

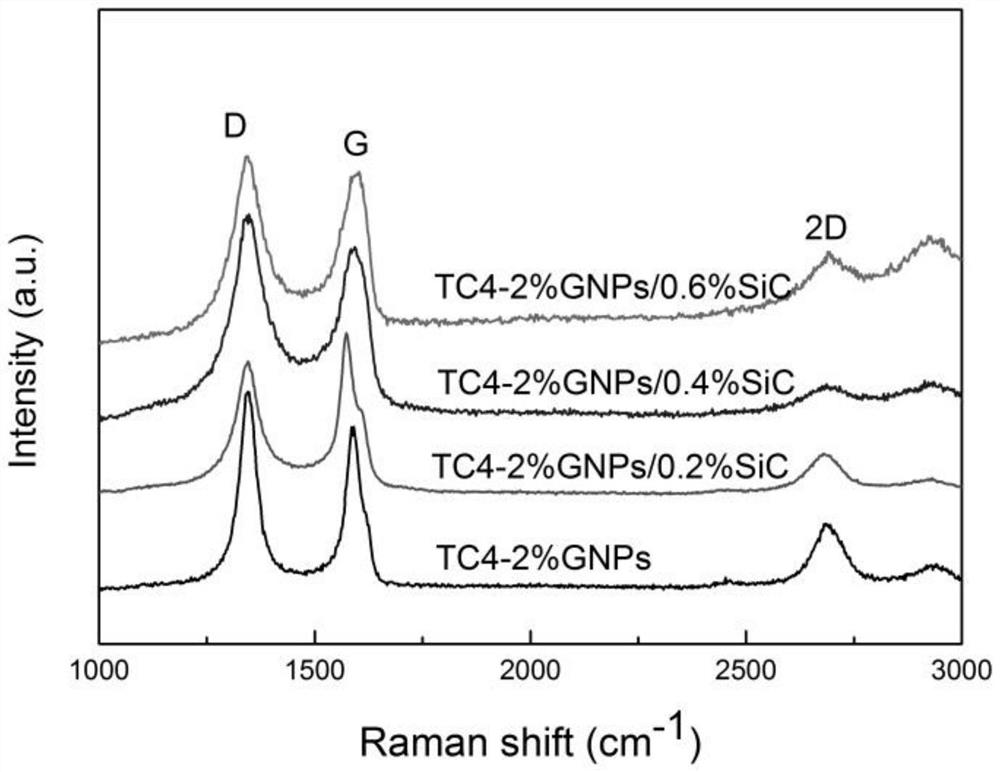

[0038] Step 1, preparing silicon carbide-coated graphene: according to the mass ratio of graphene and silicon carbide nanoparticles of 10:0, the mixed powder of graphene and silicon carbide nanoparticles is added to ethanol, so that the ethanol mixed liquid containing the mixed powder Concentration is 2mg / ml, after ultrasonic vibration for 1h, vacuum oven drying;

[0039] Step 2, prepare silicon carbide modified graphene / TC4 composite powder: add TC4 powder and graphene modified by silicon carbide into a planetary ball mill according to the mass of graphene at 2% (excluding silicon carbide nanoparticles), and use oxidation Zirconium ball milling tank and grinding beads, ball to material ratio 1:1, speed 180rpm, ball milling time 8h, use forward ball milling for 10 minutes and stop for 20 minutes, then reverse ball milling for 10 min...

Embodiment 2

[0043] A method for preparing a graphene-titanium-based composite material with controllable interface reaction, comprising the following steps:

[0044] Step 1, preparing silicon carbide-coated graphene: according to the mass ratio of graphene and silicon carbide nanoparticles of 9:1, the mixed powder of graphene and silicon carbide nanoparticles is added to ethanol, so that the ethanol mixed liquid containing the mixed powder The concentration was 2 mg / ml, and dried in a vacuum oven after ultrasonic vibration for 1 h.

[0045] Step 2, prepare silicon carbide modified graphene / TC4 composite powder: add TC4 powder and graphene modified by silicon carbide into a planetary ball mill according to the mass of graphene at 2% (excluding silicon carbide nanoparticles), and use oxidation Zirconium ball milling tank and grinding beads, ball to material ratio 1:1, speed 180rpm, ball milling time 8h, use forward ball milling for 10 minutes and stop for 20 minutes, then reverse ball milli...

Embodiment 3

[0049] A method for preparing a graphene-titanium-based composite material with controllable interface reaction, comprising the following steps:

[0050]Step 1, preparing silicon carbide-coated graphene: according to the mass ratio of graphene and silicon carbide nanoparticles of 8:2, the mixed powder of graphene and silicon carbide nanoparticles is added to ethanol, so that the ethanol mixed liquid containing the mixed powder The concentration was 2 mg / ml, and dried in a vacuum oven after ultrasonic vibration for 1 h.

[0051] Step 2, prepare silicon carbide modified graphene / TC4 composite powder: add TC4 powder and graphene modified by silicon carbide into a planetary ball mill according to the mass of graphene at 2% (excluding silicon carbide nanoparticles), and use oxidation Zirconium ball milling tank and grinding beads, ball to material ratio 1:1, speed 180rpm, ball milling time 8h, use forward ball milling for 10 minutes and stop for 20 minutes, then reverse ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com