Method for stabilizing rare earth elements in nickel-based single crystal superalloy

A technology of nickel-based single crystal and rare earth elements, which is applied in the field of stable rare earth element components in nickel-based single crystal alloys, can solve the problems of lower blade yield, weakened performance, surface inclusions, etc., and achieve improved oxidation resistance and high temperature creep resistance Effects of denaturation, stable content of rare earth elements, and reduction of interfacial reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

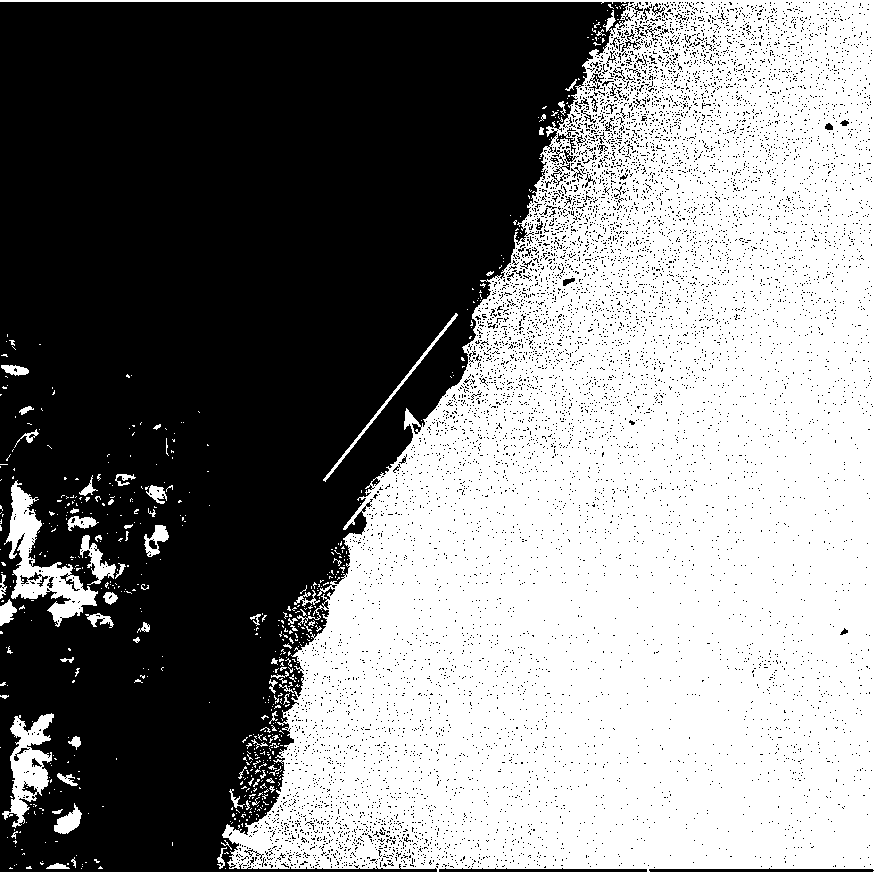

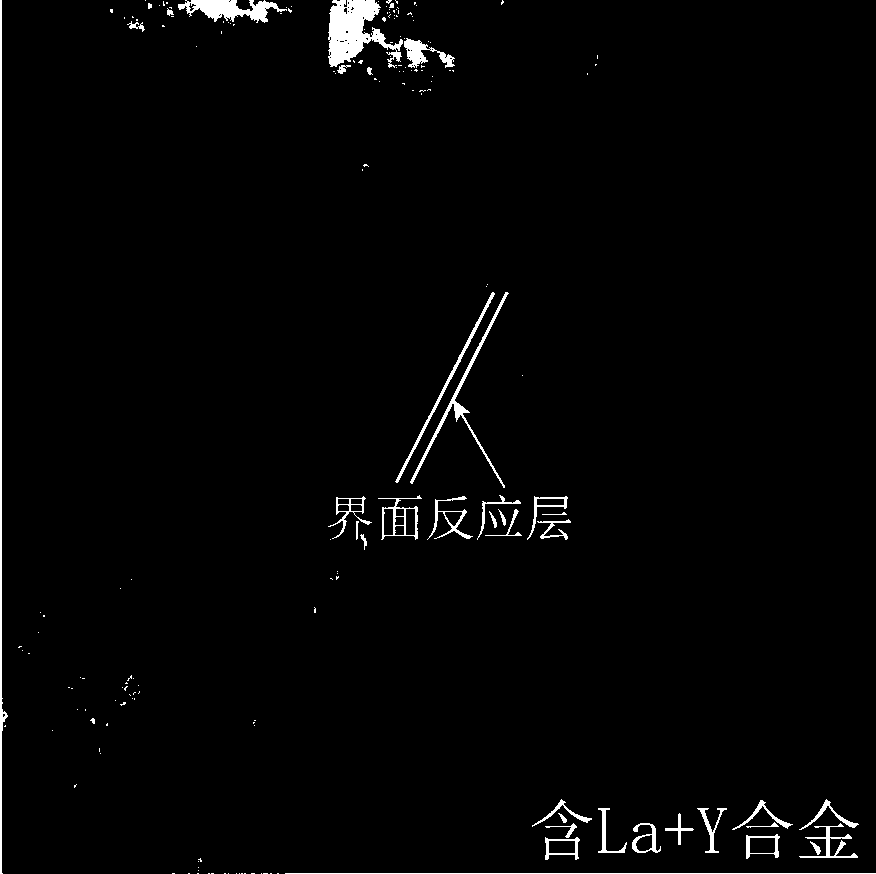

[0014] Prepare a nickel alloy master alloy ingot with the corresponding composition (regardless of the composition of the nickel alloy), and add a certain amount of La and Y elements to it according to the addition amount in Table 1. The content of the rare earth La element is 50ppm, and the content of the rare earth Y element is 100ppm, the content ratio of rare earth La element and rare earth Y element is 1:2, and the casting is prepared by directional solidification process. The contents of rare earth elements in the castings are shown in Table 1. By scanning electron microscope observation, it can be obtained as figure 2 As shown in the image, it can be seen that, compared with the image of adding rare earth Y alone, after the compound addition of rare earth La and Y elements, the degree of interface reaction is higher than that of the single addition of Y element in the prior art figure 1 Lower, the final composition of rare earth elements in nickel alloy castings is mo...

Embodiment 2

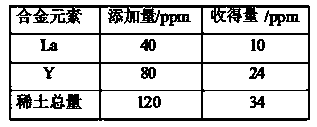

[0018] Prepare a master alloy ingot of nickel alloy with corresponding composition, and add a certain amount of La and Y elements in it according to the addition amount in Table 2, the content of rare earth La element is 40ppm, the content of rare earth Y element is 80ppm, and the content of rare earth La element and rare earth Y The element content ratio is 1:2, and the casting is prepared by directional solidification process. The contents of rare earth elements in the castings are shown in Table 2.

[0019] Table 2 Addition and yield of rare earth elements in nickel alloys

[0020]

Embodiment 3

[0022] Prepare a master alloy ingot of a nickel alloy with the corresponding composition, and add a certain amount of La and Y elements in it according to the addition amount in Table 3, the rare earth La element content is 60ppm, the rare earth Y element content is 120ppm, the rare earth La element and the rare earth Y element The element content ratio is 1:2, and the casting is prepared by directional solidification process. The contents of rare earth elements in the castings are shown in Table 3.

[0023] Table 3 Addition and yield of rare earth elements in nickel alloys

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com