Ceramic fiber-reinforced polyimide electric insulation composite material

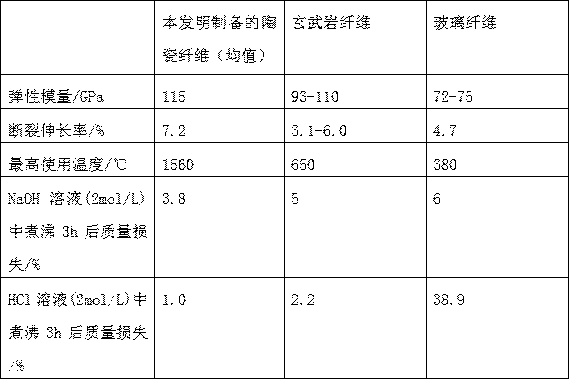

A polyimide electrical and ceramic fiber technology, applied in the field of ceramic fiber reinforced polyimide electrical insulating composite materials, can solve the problem of low elongation, little improvement in electrical insulation performance, poor acid and alkali resistance, etc. problems, to achieve the effect of improving elongation, excellent mechanical properties, and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

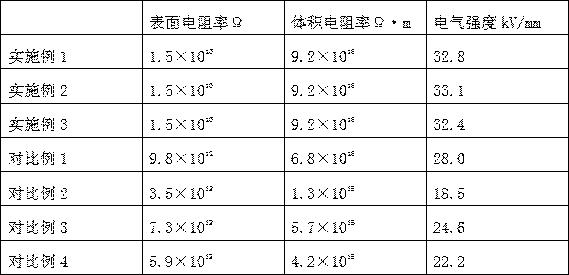

Embodiment 1

[0029] A ceramic fiber reinforced polyimide electrical insulation composite material, comprising the following steps:

[0030] (1) adopt polyacrylamide to modify nano sericite, obtain polyacrylamide modified nano sericite;

[0031] (2) Disperse polyacrylamide modified nano-sericite in absolute ethanol, then disperse polyimide powder in absolute ethanol, then add 0.12% silane coupling agent of polyimide quality, heat To 80°C, stir at 1800r / min for 2 hours to obtain a mixed dispersion;

[0032] (3) Stir the polyimide and the mixed dispersion liquid at a ratio of 150g: 300mL under an ultrasonic field at high speed, then grind them, and then dry them at high temperature under an inert gas atmosphere to obtain a mixed material;

[0033] (4) Mix the mixed material and the ceramic fiber at a mass ratio of 12:1, and obtain a ceramic fiber-reinforced polyimide electrically insulating composite material by compression molding.

[0034] Further, the preparation method of polyacrylamide...

Embodiment 2

[0048] A ceramic fiber reinforced polyimide electrical insulation composite material, comprising the following steps:

[0049] (1) adopt polyacrylamide to modify nano sericite, obtain polyacrylamide modified nano sericite;

[0050] (2) Disperse polyacrylamide modified nano-sericite in absolute ethanol, then disperse polyimide powder in absolute ethanol, then add 0.12% silane coupling agent of polyimide quality, heat To 80°C, stir at 1800r / min for 2 hours to obtain a mixed dispersion;

[0051] (3) Stir the polyimide and the mixed dispersion at a ratio of 200g: 300mL under an ultrasonic field at high speed, then grind them, and then dry them at a high temperature under an inert gas atmosphere to obtain a mixed material;

[0052] (4) Mix the mixed material and the ceramic fiber at a mass ratio of 12:2, and obtain a ceramic fiber-reinforced polyimide electrically insulating composite material by compression molding.

[0053] Further, the preparation method of polyacrylamide-modi...

Embodiment 3

[0067] A ceramic fiber reinforced polyimide electrical insulation composite material, comprising the following steps:

[0068] (1) adopt polyacrylamide to modify nano sericite, obtain polyacrylamide modified nano sericite;

[0069] (2) Disperse polyacrylamide modified nano-sericite in absolute ethanol, then disperse polyimide powder in absolute ethanol, then add 0.12% silane coupling agent of polyimide quality, heat To 80°C, stir at 1800r / min for 2 hours to obtain a mixed dispersion;

[0070] (3) Stir the polyimide and the mixed dispersion at a ratio of 180g: 300mL under an ultrasonic field at high speed, then grind them, and then dry them at high temperature under an inert gas atmosphere to obtain a mixed material;

[0071] (4) Mix the mixed material and the ceramic fiber at a mass ratio of 12:1.5, and obtain a ceramic fiber-reinforced polyimide electrically insulating composite material by compression molding.

[0072] Further, the preparation method of polyacrylamide-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com