FRP (fiber reinforced polymer) rebar anchoring clamp piece, manufacturing method thereof and anchoring method thereof

An anchoring method and clip technology, applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problems of lateral shear damage and stress concentration of FRP bars, avoid lateral shear damage and reduce the size of anchors , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

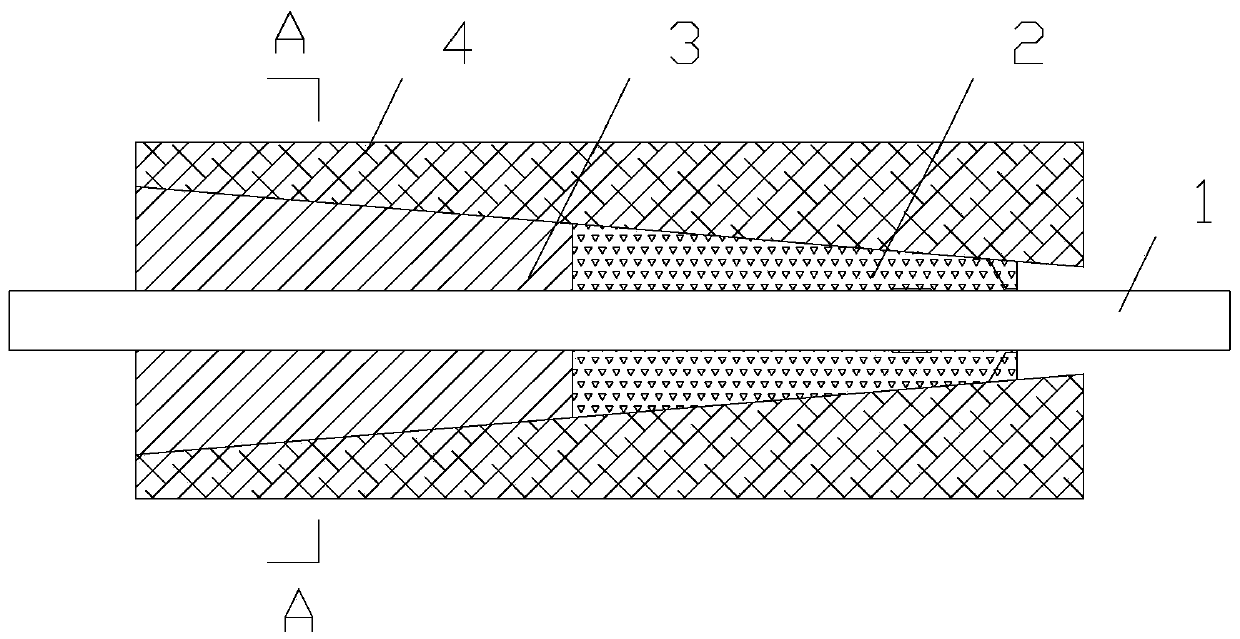

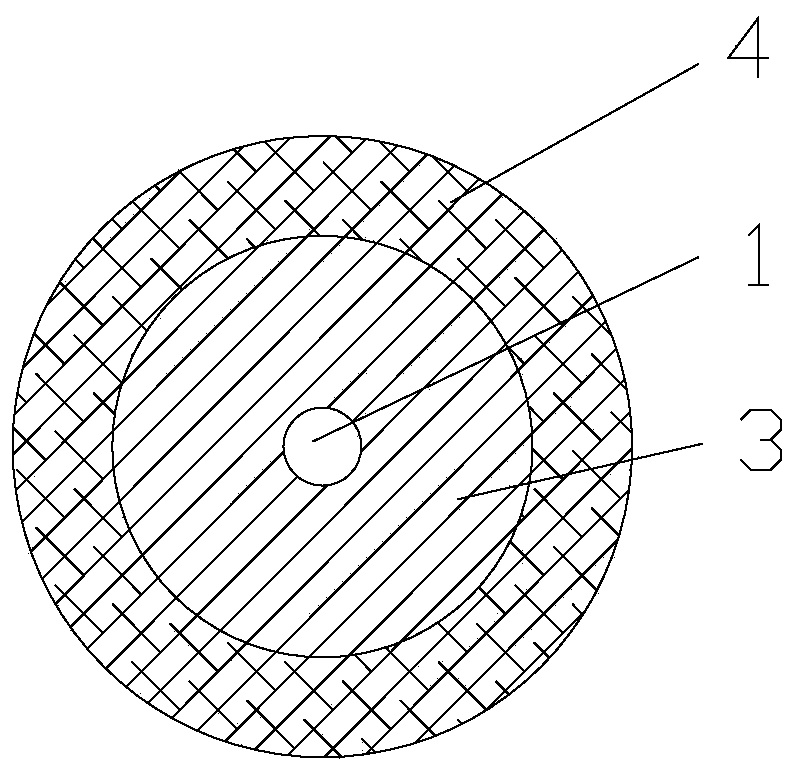

[0041] see figure 1 with figure 2 As shown, the anchorage structure for prestressed FRP tendons of the present invention includes variable stiffness clips and anchor cups 4, wherein the clips are integrally formed, and the stiffness distribution increases sequentially from the loading end to the free end, including variable stiffness loads Transmission of the second medium segment 2 and variable stiffness load transfer of the second medium segment to the first medium segment 3 . The variable stiffness load transfer first medium section 3 is made of resin-impregnated chopped fiber cured; the variable stiffness load transfer second medium section 2 is made of resin-impregnated quartz sand. The stiffness of the first medium section 3 for variable stiffness load transmission is 15GPa to 25GPa; the stiffness of the second medium section for variable stiffness load transmission is 3GPa to 12GPa; the length of the first medium section for variable stiffness load transmission and th...

Embodiment 2

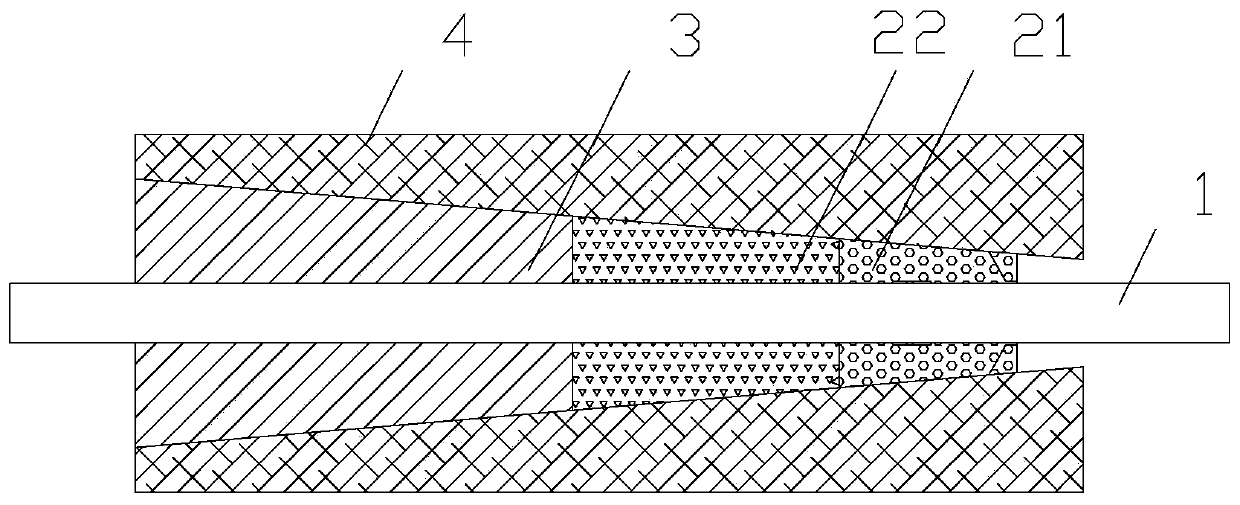

[0044] Such as Figure 3-Figure 5 shown. The variable stiffness load transfer second medium segment 2 is divided into two segments, namely: the first segment 21 of the variable stiffness load transfer second medium segment and the second segment 22 of the variable stiffness load transfer second medium segment. In this embodiment, when the stiffness distribution along the loading end to the free end is 4GPa-10GPa-20GPa, the length ratio of the stiffness distribution is 2:3:5. The resin containing quartz sand is model WSR618 (E-51) Phoenix brand epoxy resin, the size of quartz sand is 100 mesh to 300 mesh, the length of basalt fiber chopped yarn is 6mm to 10mm; the mass ratio of 4GPa is quartz sand / Phoenix brand epoxy Resin=30%, the mass ratio of 10GPa is quartz sand / Phoenix brand epoxy resin=100%, the mass ratio of 20GPa is basalt fiber chopped yarn / vinyl resin=100%. Refer to the figure for the number of segments of the variable stiffness load transfer medium clip Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com