Casting grinding ball gradation modeling method and system based on visual platform

A technology for casting grinding balls and modeling methods, which is applied in design optimization/simulation, special data processing applications, complex mathematical operations, etc. Good quality, consistent performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

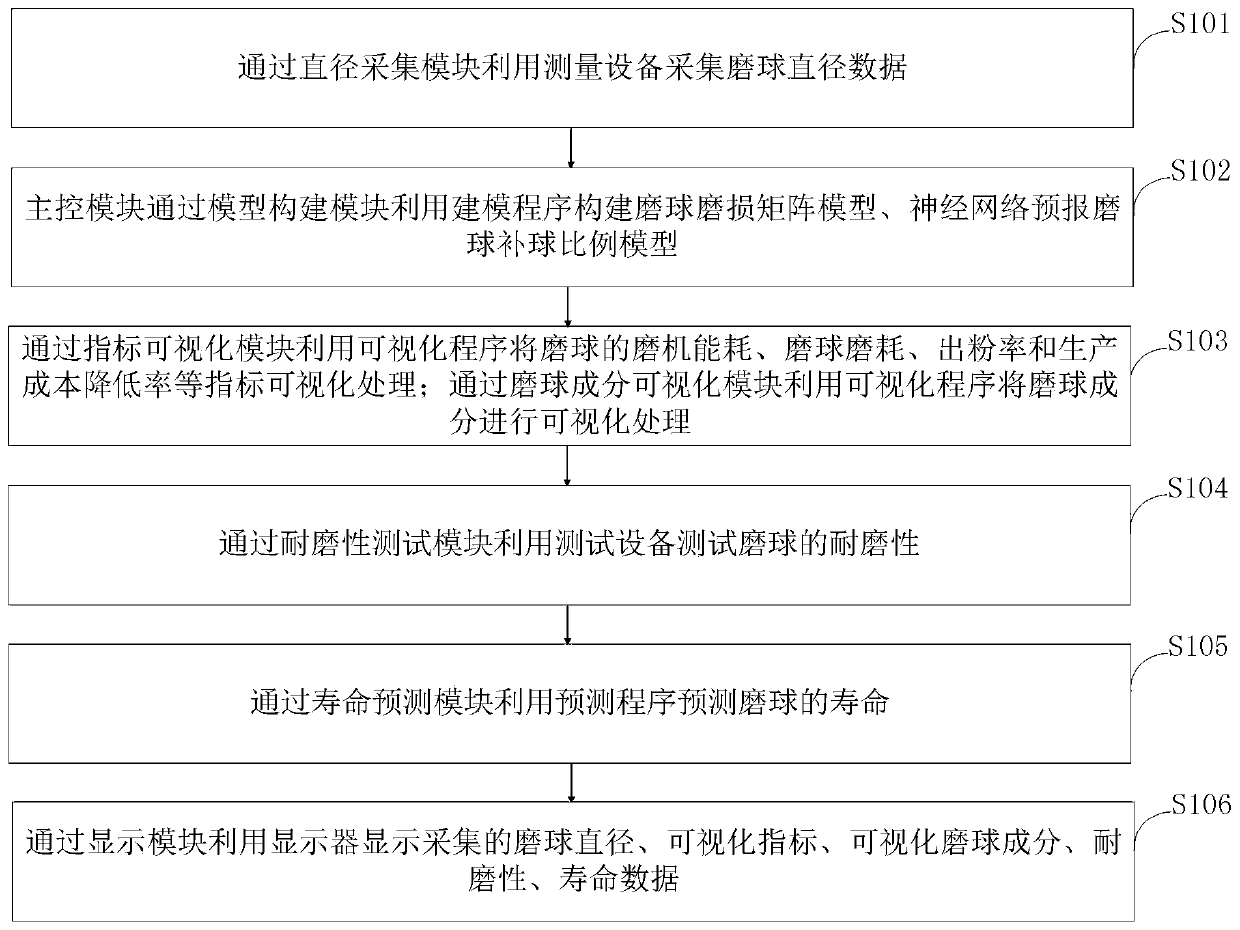

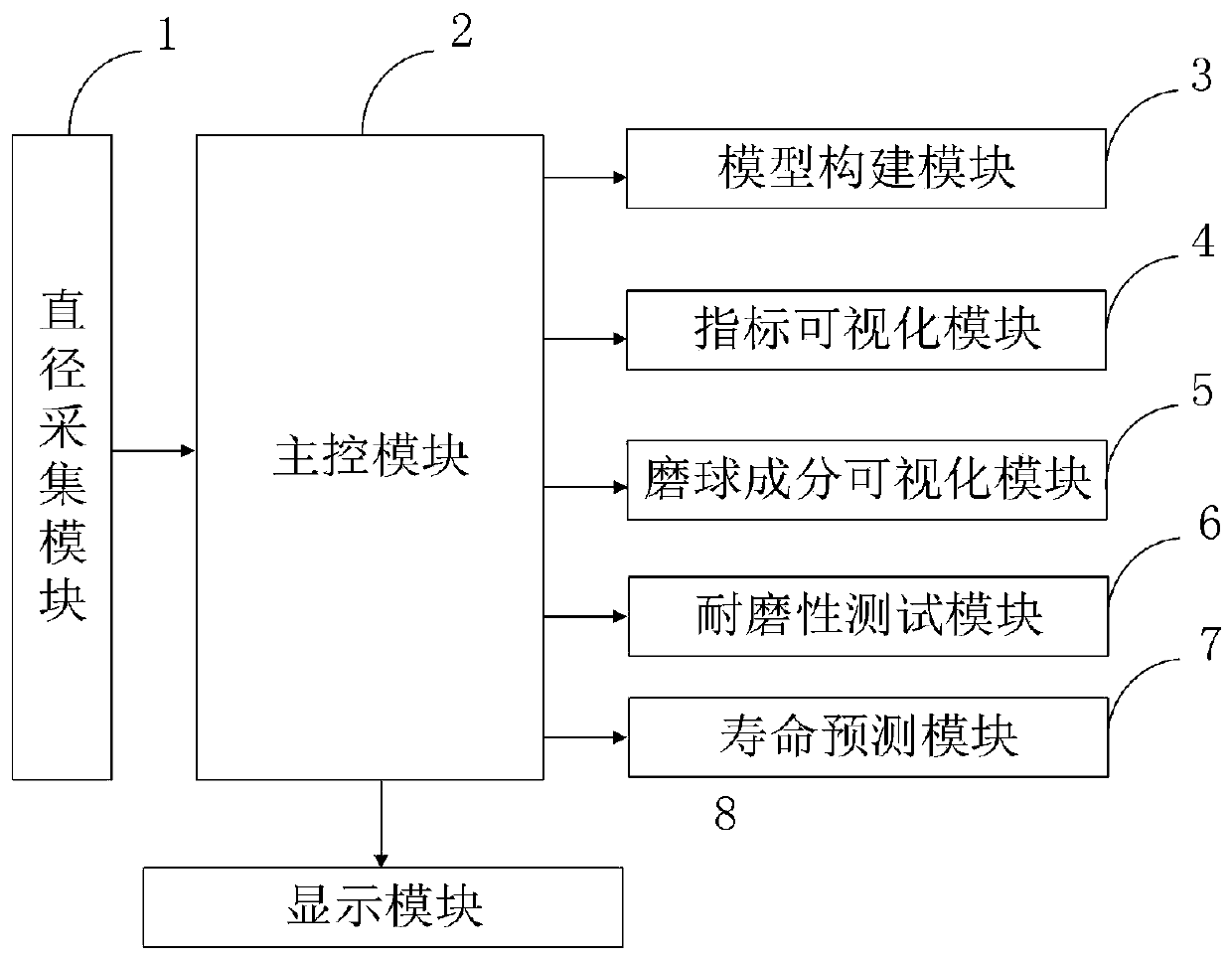

Method used

Image

Examples

Embodiment 1

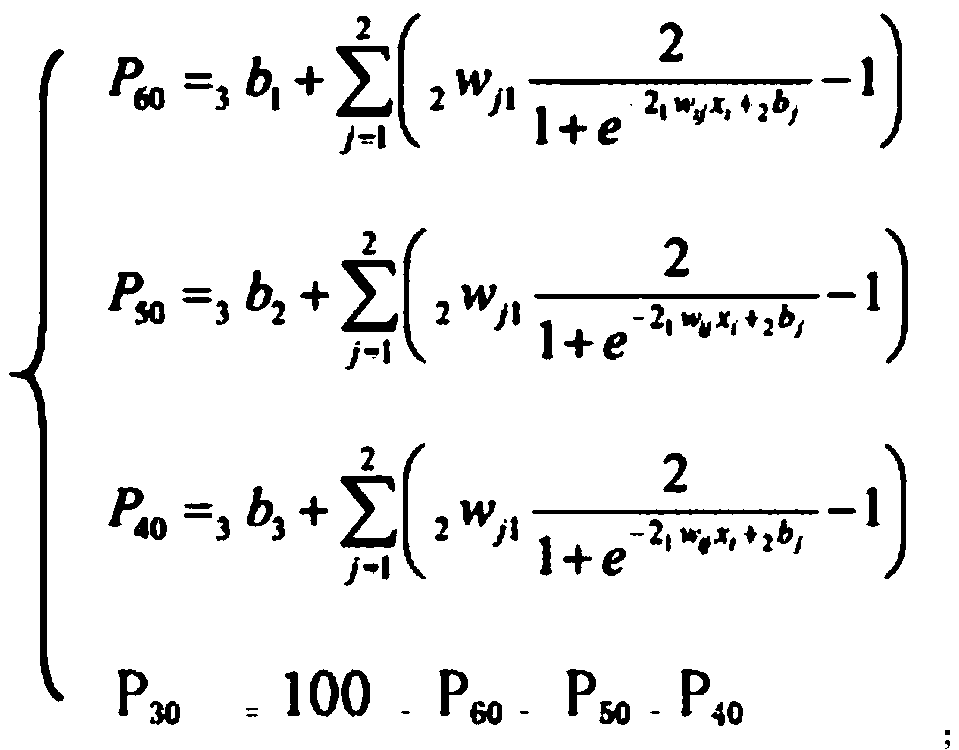

[0084] Model construction module 3 construction methods provided by the present invention are as follows:

[0085] (1) Establishment of grinding ball wear matrix model.

[0086] A1: Determine the steady-state characteristic matrix of grinding ball wear as [p(t)],

[0087]

[0088] A2: Determine the ideal ball loading grading vector {x0} and the actual ball loading grading vector {x}, the rated ball loading capacity of a ball mill is W, and its grinding ball wear steady-state characteristic matrix is [p(t )], the ideal ball distribution vector {x0} and the actual ball distribution vector {x} are respectively:

[0089] {x 0}=(x 10 , x 20 ,...,x h0 ,...,x n0 T .

[0090] {x}={x 1 , x 2 ,...,x k ,...x n} T .

[0091] A3: After t days of continuous coal grinding, the difference between the residence amount of kth grade grinding balls in the drum and the ideal ball distribution is ΔWk:

[0092]

[0093] A4: The total amount to be added is ΔW:

[0094] A5: The...

Embodiment 2

[0123] The visualization method of the grinding ball component visualization module 5 provided by the present invention is as follows:

[0124] 1) Configure the initial data of the grinding ball equipment.

[0125] 2) Select materials according to the needs of working conditions and service life.

[0126]3) Adopt visualization method one after determining the N grading assessment indicators, list the influencing factors affecting the N grading assessment indicators and list the level ranges of the influencing factors affecting the N grading assessment indicators according to work experience, the N is an integer.

[0127] 4) Determine the symmetrical horizontal experimental point that can most effectively reflect the variation range of the assessment index within the horizontal range drawn up in step 3) according to visualization method one.

[0128] 5) Design a certain grinding ball with a variety of ball diameters in a certain proportion with a non-integer multiple, and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com