A casting process of solid lost foam for bed castings of large horizontal machining centers

A technology of machining center and casting process, which is applied in manufacturing tools, casting and forming equipment, metal processing equipment, etc., and can solve the problems of large outline size, single weight, difficulty in process production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

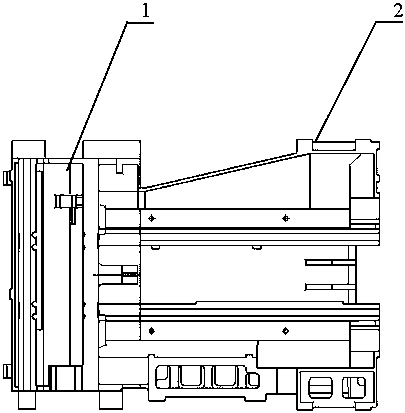

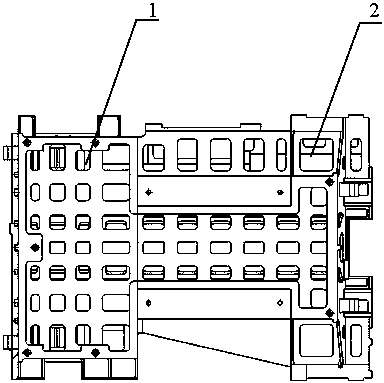

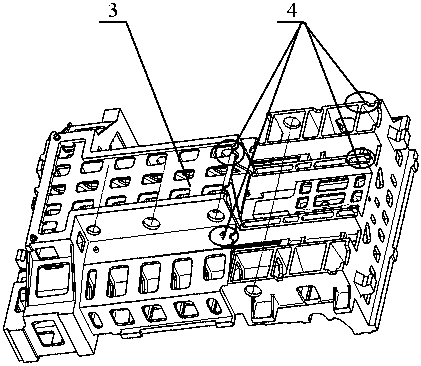

[0017] A casting process of solid lost foam castings for bed castings of large horizontal machining centers, such as Figure 1-7 As shown, the process includes: 1. The bed casting is composed of the large end part 1 of the bed and the small end part 2 of the bed, and the EPS density material of 18 kg / m3 is used to make the lost foam matrix 3 and the bed The lost foam live material 5 of the bed is equivalent to a part cut out from the large end part 1 of the bed casting, and the remaining bed casting after cutting out the lost foam live material 5 of the bed is equivalent to The bed lost foam matrix 3, and the bed lost foam matrix 3 and the bed lost foam material 5 are fixed together through the concave-convex positioning groove 4 to form the bed lost foam, and at the same time, it is made of EPS density material of 30 kg / m3 The padding used to suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com