Heat-treatment cooling process for train wheel

A heat treatment cooling and wheel technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as abnormal structure of the wheel tread near the surface layer, affecting wheel performance, etc. The effect of faster cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

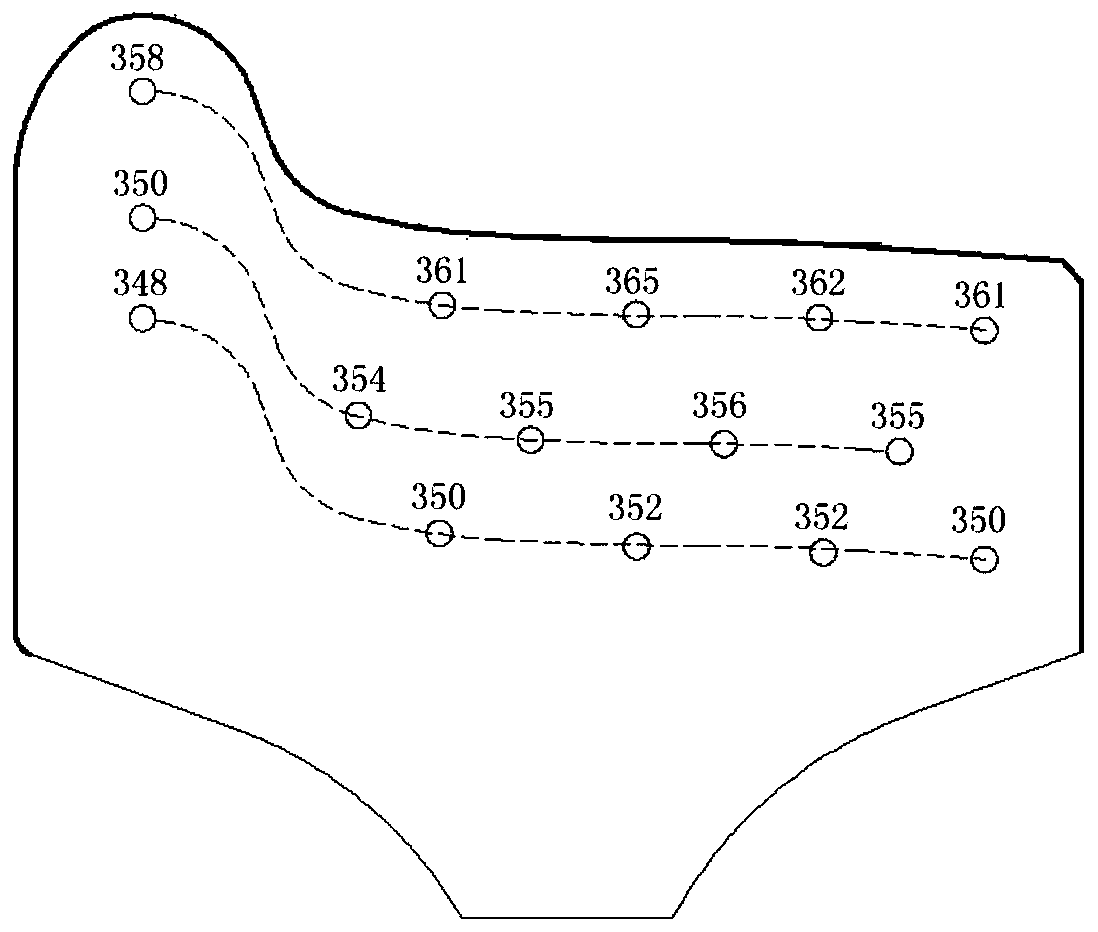

Embodiment 1

[0068] The railway wheel in this embodiment is a mining truck wheel, with a nominal diameter of 950-1000 mm and a weight of about 500 kg. Its main chemical components and mass percentages (wt%) are as shown in Table 1. The process steps are as follows:

[0069] S1. Heating: heating the rolled and slow-cooled wheel as a whole until it is fully austenitized;

[0070] S2. Quenching and cooling: After the heating is completed, take the railway wheels out of the heating furnace, transfer them to the horizontal quenching platform, turn on the frequency conversion servo motor in the horizontal quenching platform to keep the railway wheels in a rotating state, and keep the inner side of the railway wheels facing up; then open The quenching electronic control unit in the horizontal quenching table controls the start-up of the valves of the water and gas ring pipelines, and uses three-stage pressure step-increasing aerosol two-phase flow to spray the wheel tread;

[0071] In the first ...

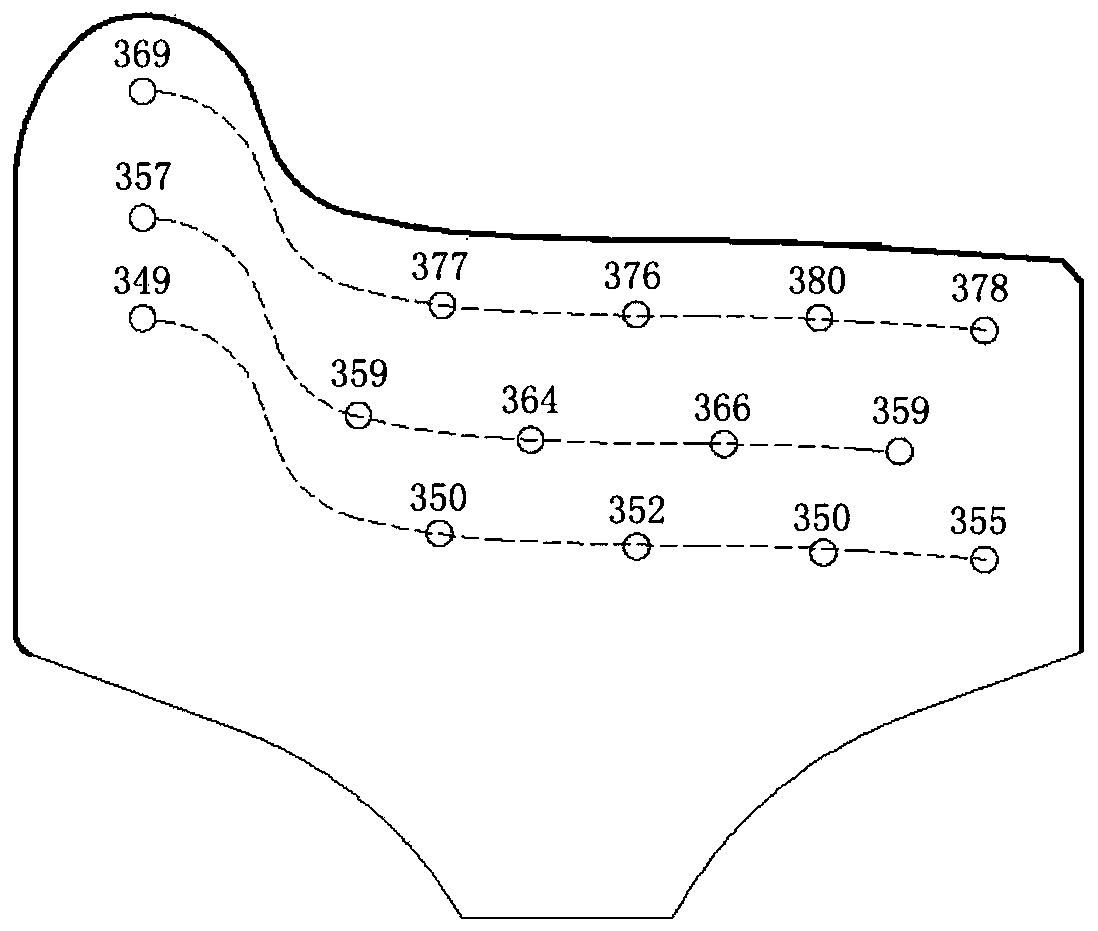

Embodiment 2

[0087] The railway wheel in this embodiment is a mining truck wheel, with a nominal diameter of 950-1000 mm and a weight of about 500 kg. Its main chemical components and mass percentages (wt%) are as shown in Table 1. The process steps are as follows:

[0088] S1. Heating: heating the rolled and slow-cooled wheel as a whole until it is fully austenitized;

[0089] S2. Quenching and cooling: After the heating is completed, take the railway wheels out of the heating furnace, transfer them to the horizontal quenching platform, turn on the frequency conversion servo motor in the horizontal quenching platform to keep the railway wheels in a rotating state, and keep the inner side of the railway wheels facing up; then open The quenching electronic control unit in the horizontal quenching table controls the start-up of the valves of the water and gas ring pipelines, and uses three-stage pressure step-increasing aerosol two-phase flow to spray the wheel tread;

[0090] In the first ...

Embodiment 3

[0101] The railway wheel in this embodiment is a mining truck wheel, with a nominal diameter of 950-1000 mm and a weight of about 500 kg. Its main chemical components and mass percentages (wt%) are as shown in Table 1. The process steps are as follows:

[0102] S1. Heating: heating the rolled and slow-cooled wheel as a whole until it is fully austenitized;

[0103] S2. Quenching and cooling: After the heating is completed, take the railway wheels out of the heating furnace, transfer them to the horizontal quenching platform, turn on the frequency conversion servo motor in the horizontal quenching platform to keep the railway wheels in a rotating state, and keep the inner side of the railway wheels facing up; then open The quenching electronic control unit in the horizontal quenching table controls the start-up of the valves of the water and gas ring pipelines, and uses three-stage pressure step-increasing aerosol two-phase flow to spray the wheel tread;

[0104] In the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com