Hot press molding method for spherical head made of 10CrNi3MoV steel

A technology of spherical head and hot press forming, which is applied in the direction of furnace type, heat treatment furnace, heat treatment equipment, etc., and can solve the problems of high cost and difficult processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, comprises the following steps:

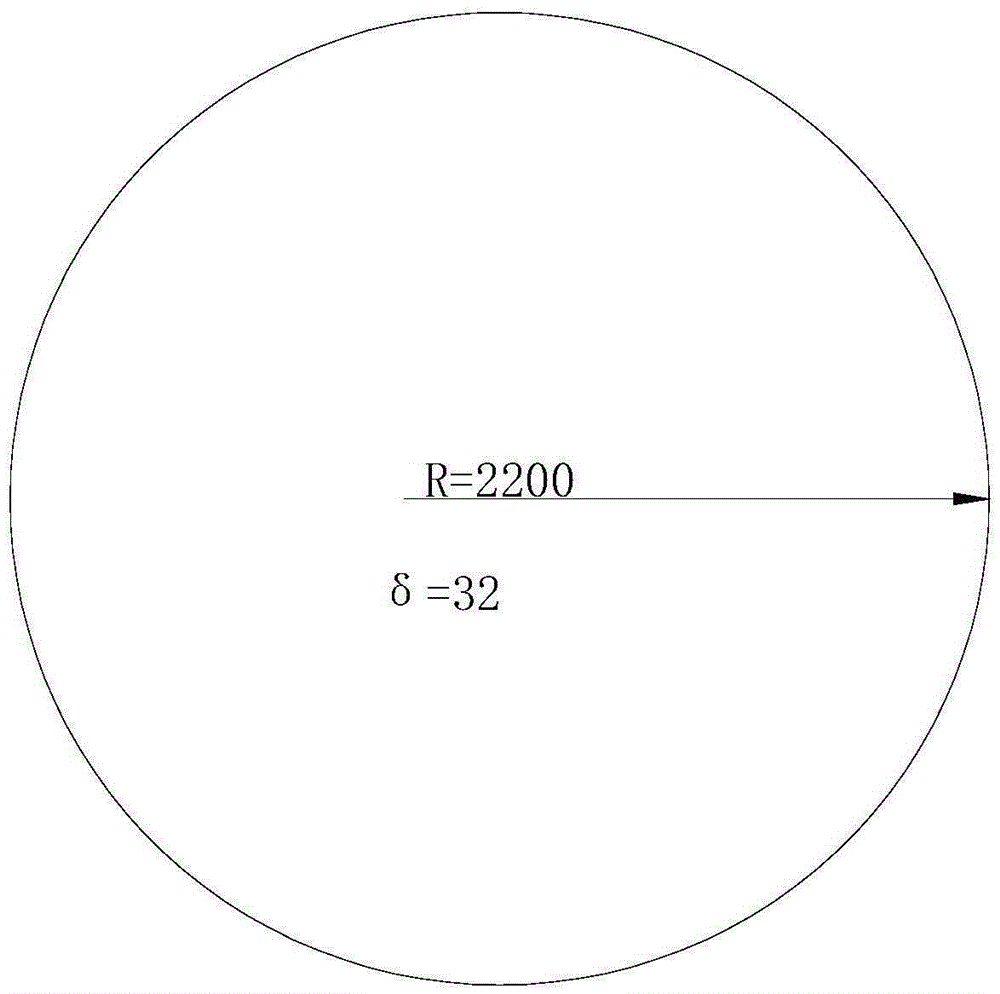

[0016] (1) disc heating step: put figure 1 The 10CrNi3MoV steel disc shown is put into the heating furnace. The temperature of the furnace is 750°C when the furnace is installed. The steel circular plate is heated evenly to avoid over-burning of the material or insufficient holding time; the radius R of the 10CrNi3MoV steel circular plate is 2200mm, and the thickness δ 1 32mm;

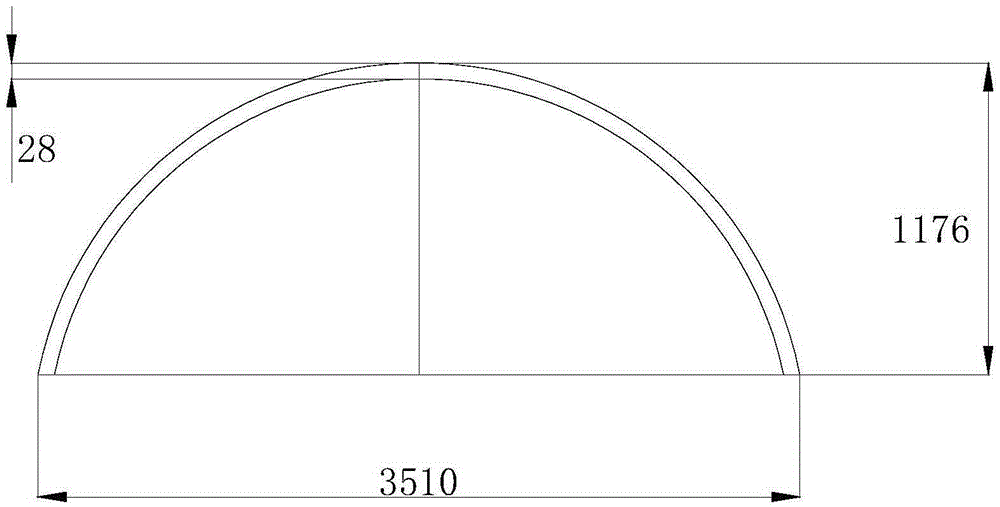

[0017] (2) Compression molding step: transfer the heated 10CrNi3MoV steel circular plate to the platform of the punching machine, and align the mold on the punching machine with the center of the 10CrNi3MoV steel circular plate for stamping. The stamping start temperature is 860°C, and the final pressing temperature is 750°C. formed as figure 2 The 10CrNi3MoV steel spherical head shown in the figure; then demoulding at a temperature of 720°C, the demoulded 10CrNi3MoV steel spherical head is cooled to 480°C and lifted off the workbench, and coole...

Embodiment 2

[0020] Embodiment 2, comprises the following steps:

[0021] (1) Disc heating step: Put the 10CrNi3MoV steel disc into the heating furnace. The furnace temperature is 780°C when the furnace is installed, and the temperature is raised at a rate of 135°C / hour after the furnace is installed. When the temperature reaches 940°C±20°C, keep it for 45 minutes ; When heating, it should be ensured that the 10CrNi3MoV steel disc is heated evenly to avoid overburning of the material or insufficient holding time; the radius R of the 10CrNi3MoV steel disc is 1800mm, and the thickness δ 1 34mm;

[0022] (2) Compression molding step: transfer the heated 10CrNi3MoV steel circular plate to the platform of the punching machine, and align the mold on the punching machine with the center of the 10CrNi3MoV steel circular plate for stamping. The starting temperature of stamping is 940°C, and the final pressing temperature is 800°C. Form a 10CrNi3MoV steel spherical head; then demould at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com