Magnesium alloy plate grain refining controlled edge crack rolling method

A fine-grained, magnesium alloy technology, applied in the direction of metal rolling, contour control, etc., can solve the problems of ineffective control of edge cracks, improved plate yield, and ineffective grain refinement of magnesium alloy plates. Achieve the effect of taking into account cost and processing efficiency, increasing the overall yield of the plate, and achieving a remarkable effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

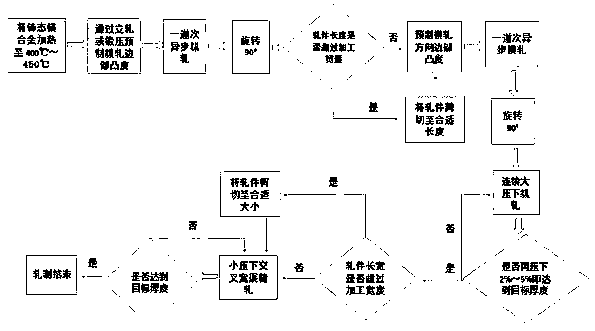

Method used

Image

Examples

Embodiment Construction

[0020] The billet is AZ31 magnesium alloy ingot, the specifications are: thickness╳width╳length=50mm╳200mm╳200mm, product thickness 5mm, roll length 350mm.

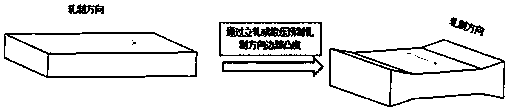

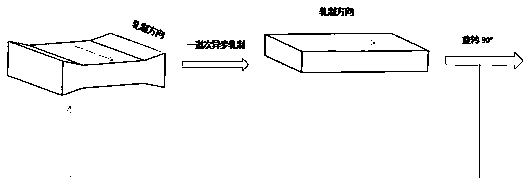

[0021] According to the method of the present invention: first, the edge of the plate along the rolling direction is prefabricated by vertical rolling or forging, etc., and the rolling reduction of the next pass is set to 20mm, and the wide deformation width is 20mm, then the edge of the plate is prefabricated The reduction amount of the crown side can be obtained from formula (1) △h2 = 8.8 ~ 9.6mm, and then carry out asynchronous longitudinal rolling with a reduction amount of 20mm along the direction of the prefabricated crown, and select the speed ratio of the upper and lower rolls in the asynchronous rolling stage The range is between 1.01 and 1.05. At this time, the plate thickness is 30mm. After the completion, the rolled piece is rotated 90° clockwise. At this time, the length of the rolled piece is about 280mm, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com