Repairable carbon fiber cloth reinforced epoxy resin plate and preparation and repairing methods thereof

A carbon fiber cloth and epoxy resin technology, applied in the field of high-resolution materials, can solve the problems that the mechanical properties cannot reach the initial performance of the composite material, affect the appearance of the composite material, and have low mechanical properties, and achieve high rigidity, good dimensional stability of products, The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

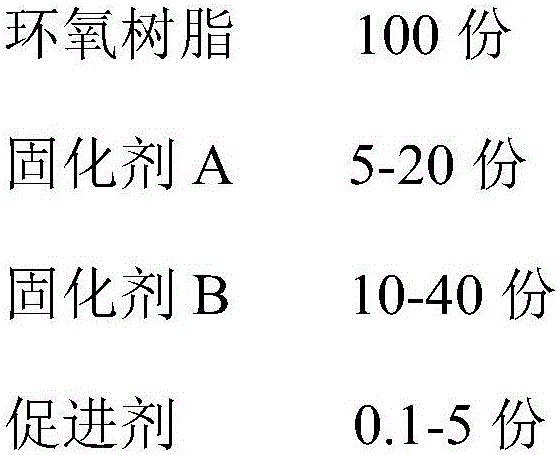

Method used

Image

Examples

Embodiment 8-13

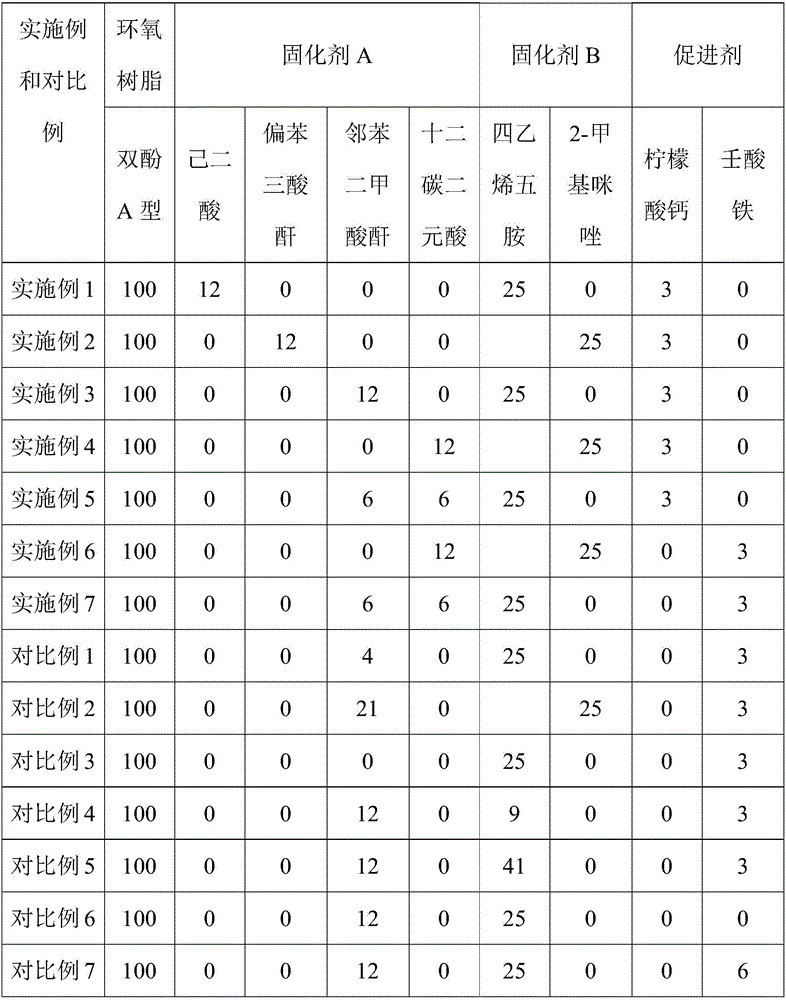

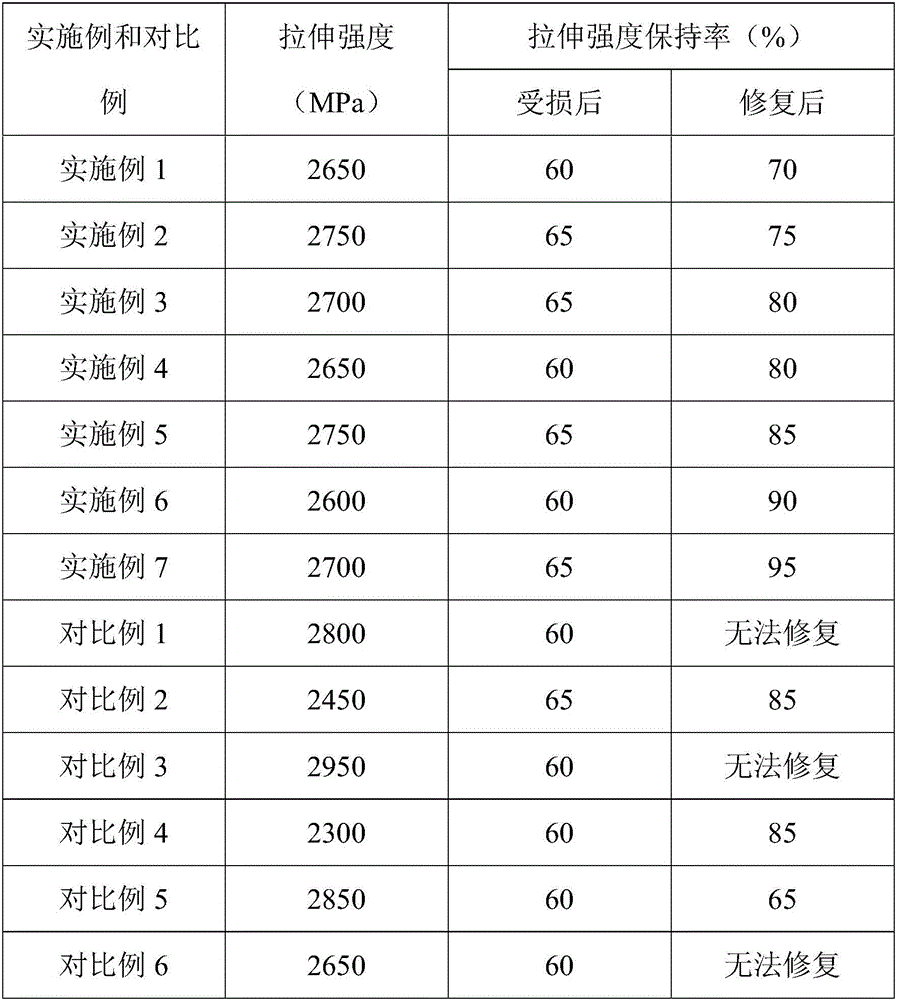

[0054] According to the preparation method of Example 7, the pre-curing temperature is 50 ° C, and the time is 48 hours. According to the ratio of Table 3, a repairable carbon fiber cloth reinforced epoxy resin board is prepared, and the tensile strength and repairability are evaluated. The performance is listed in table 3. The repair method is carried out according to the repair method in Example 7.

[0055] Raw material formula (weight part) and performance of table 3 embodiment 8-13

[0056]

Embodiment 14

[0058] Prepare a repairable carbon fiber cloth reinforced epoxy resin board according to the formula and preparation method of Example 7, the pre-curing temperature is 180 ° C, and the pre-curing is 1 hour, but the preparation method step d) is changed to: make the mixed solution II impregnate 2 layers Carbon fiber cloth, and after laminating two layers of carbon fiber, dry to remove solvent. The tensile strength and repairability were evaluated, and the properties are listed in Table 4. The repair method is carried out according to the repair method in Example 7.

Embodiment 15

[0060] According to the formula and preparation method of Example 7, a repairable carbon fiber cloth reinforced epoxy resin board was prepared, and the tensile strength and repairability were evaluated. The properties are listed in Table 4. The fix is:

[0061] a) Preparation of repair solution, 90 parts by weight of 1,6-hexanediol (boiling point 243°C), 10 parts by weight of epoxy resin and curing agent A, the type and content of the epoxy resin and curing agent used are the same Embodiment 7 raw material formula.

[0062] b) Apply the repair solution to the damaged area and heat it to 200°C; (the boiling point of 1,6-hexanediol is about 243°C)

[0063] c) Maintain for a certain period of time until the surface of the resin plate dissolves;

[0064] d) Continue heating to 250°C to volatilize the restoration solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com