Torsion bar shaft machining method

A processing method and torsion bar technology, applied in the field of shaft processing, can solve the problems of poor mechanical properties of torsion bar shafts, achieve consistent mechanical properties, and improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

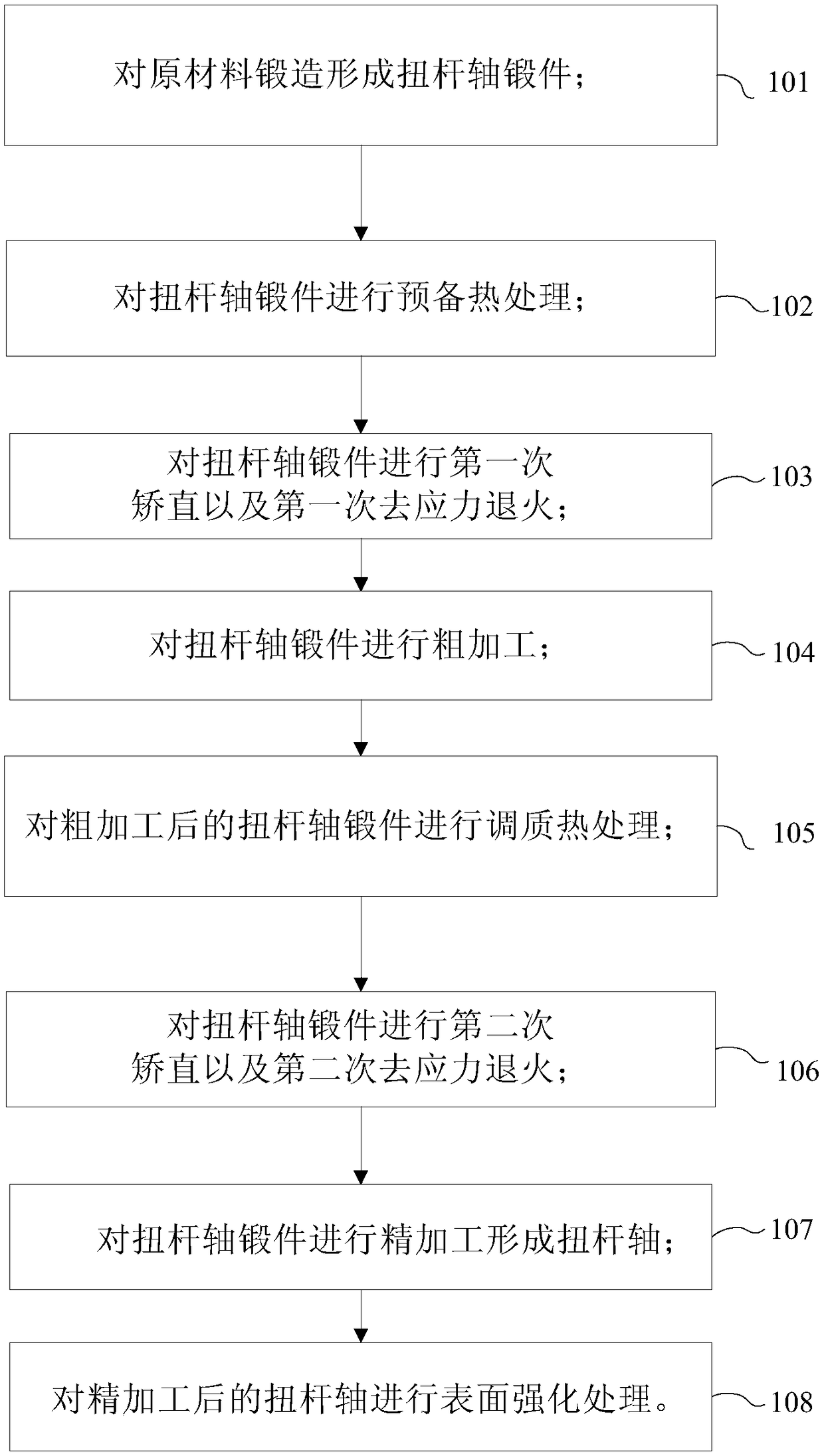

[0036] figure 1 It is a flow chart of Embodiment 1 of the method for machining a torsion bar shaft according to the present invention.

[0037] Please combine figure 1 , the present embodiment provides a method for machining a torsion bar shaft, comprising the following steps:

[0038] Step 101: Forging the raw material to form a torsion bar shaft forging.

[0039] The torsion bar shaft is a slender shaft component, which is generally used in the anti-rolling system of the EMU. In order to make the mechanical properties of the torsion bar shaft consistent at each position, the raw material can be processed by forging process.

[0040] The raw material can be purchased square steel or round steel and other materials, which are not specifically limited here. Preferably, the material of the torsion bar shaft is 52CrMo4.

[0041] Forging is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with cer...

Embodiment 2

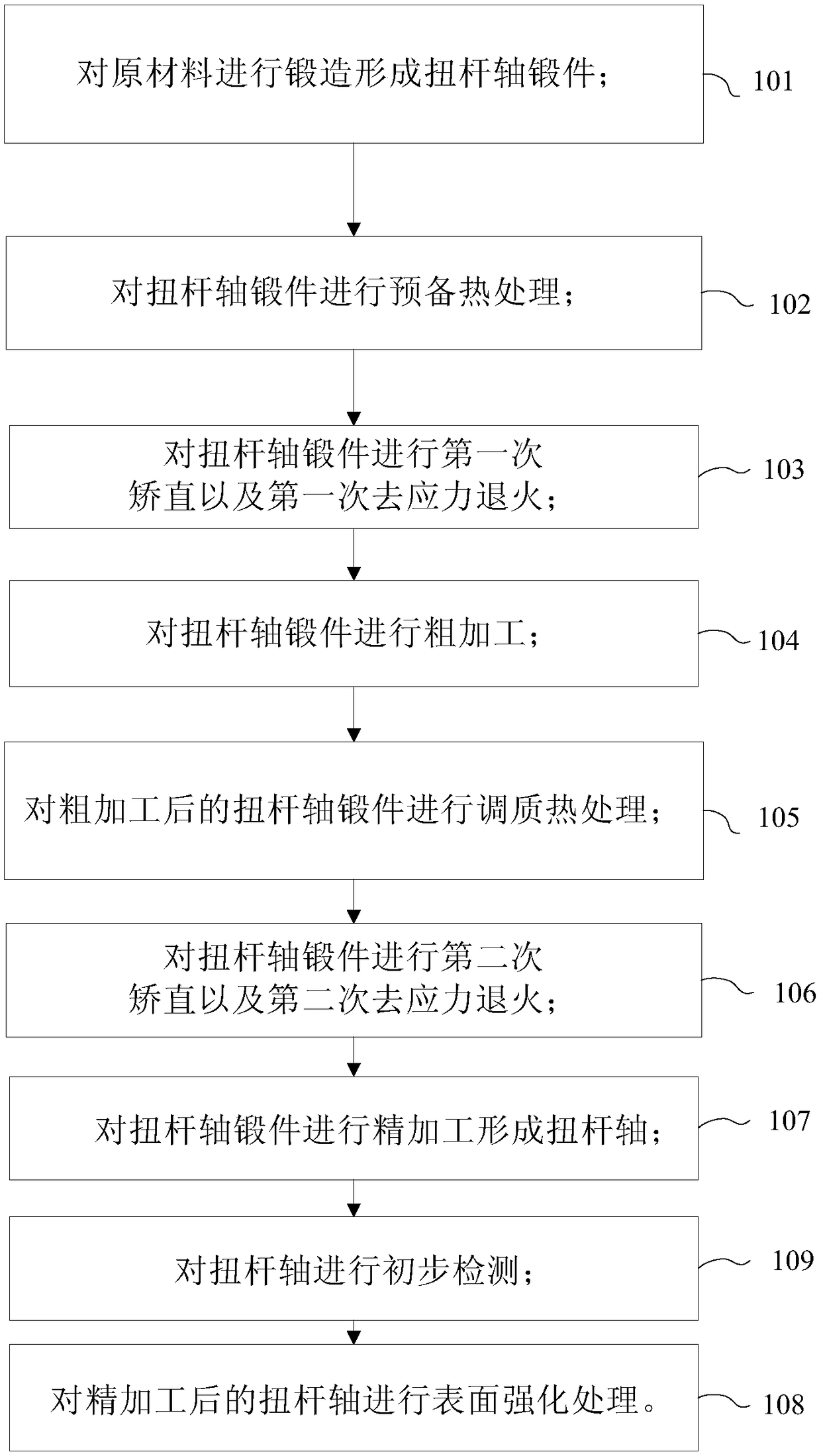

[0085] figure 2 It is a flow chart of Embodiment 2 of the torsion bar shaft processing method of the present invention.

[0086] Please combine figure 2 , in this embodiment, before performing surface strengthening treatment on the finished torsion bar shaft, step 109 is also included: performing a preliminary inspection on the torsion bar shaft.

[0087] Preliminary inspection can find out whether there are defects in the torsion bar shaft in time, thereby improving the pass rate of the torsion bar shaft. There are many methods for preliminary inspection, such as visual inspection, electromagnetic flaw detection, ultrasonic flaw detection, etc.

[0088] Preferably, the preliminary detection can be electromagnetic flaw detection. The principle of electromagnetic flaw detection is to use electromagnetic principles to find metal defects. This method magnetizes metal parts, the magnetic resistance at the defect will increase, and the magnetic force lines here will change accor...

Embodiment 3

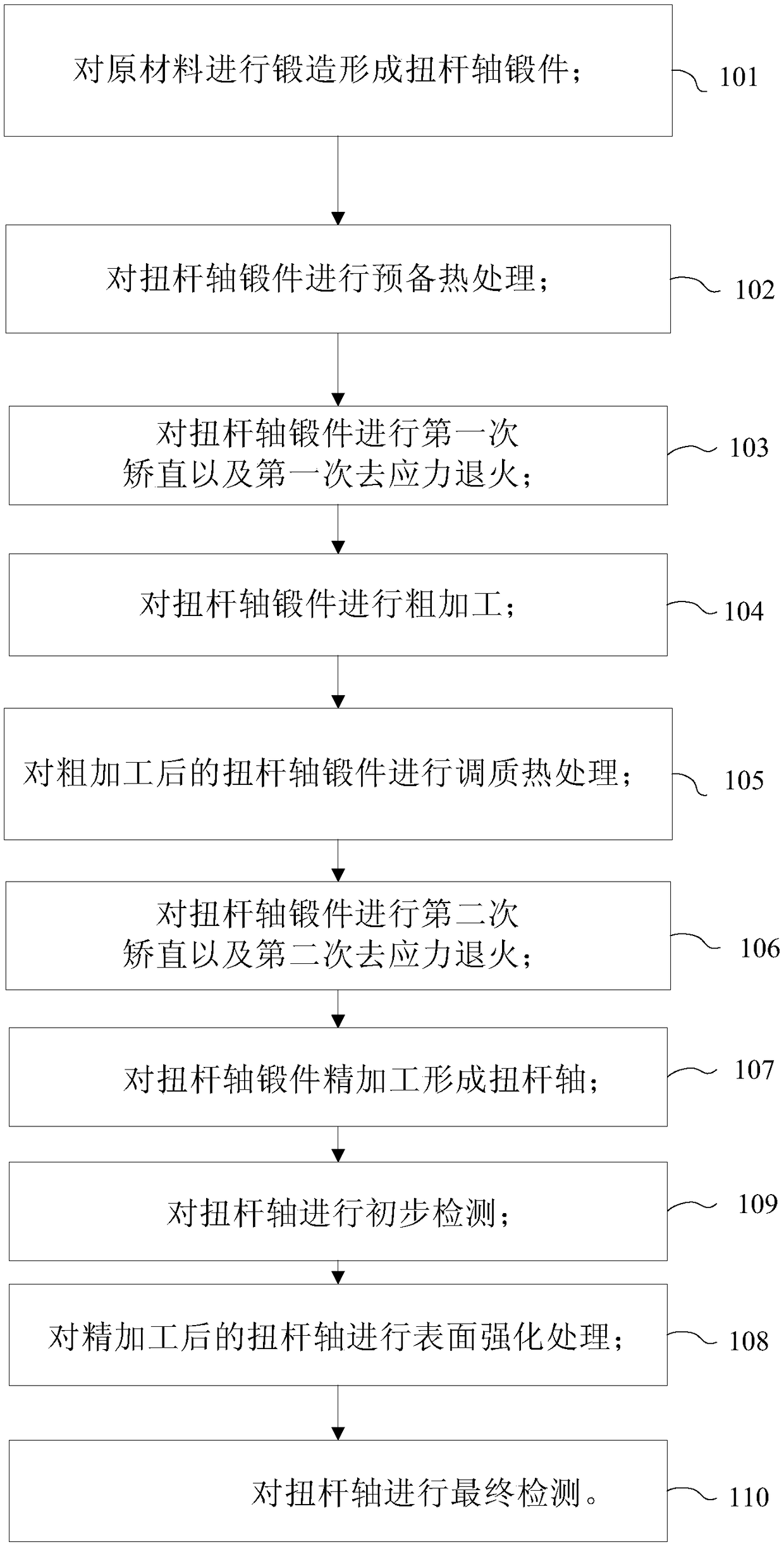

[0093] image 3 It is a flow chart of Embodiment 3 of the torsion bar shaft processing method of the present invention.

[0094] Please combine image 3 , in this embodiment, after performing surface strengthening treatment on the finished torsion bar shaft, step 110 is further included: performing final inspection on the torsion bar shaft.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com