Diaphragm, preparation method of diaphragm and lithium ion battery

A diaphragm and polymer technology, applied in secondary batteries, battery components, circuits, etc., can solve the problem of increasing lithium ion migration resistance in the electrolyte, reducing the high temperature resistance of battery diaphragms, and the adhesion of sheet-like flexible substrates Poor problems, to achieve the effect of improving lithium ion conductivity, improving electrolyte resistance, and perfect heat-resistant layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a diaphragm, the steps comprising:

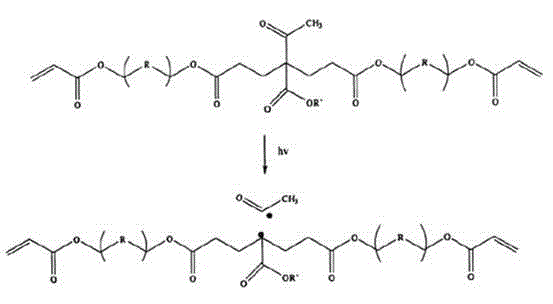

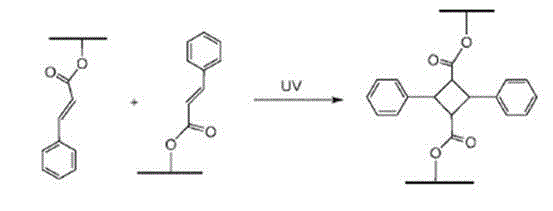

[0031] S1. The polymer matrix containing the self-initiating UV-curable cross-linking resin is prepared by mixing the polymer raw material with the self-initiating UV-curable cross-linking resin. Wherein, the mixing of the polymer raw material and the self-initiating UV-curable cross-linking resin is not limited in the present invention. Preferably, based on the quality of the polymer raw material, the content of the self-initiating UV-curable cross-linking resin is 1-5wt %. The method for preparing a polymer matrix containing a self-initiating UV-curable cross-linking resin from a mixture of a polymer raw material and a self-initiating UV-curable cross-linking resin, such as biaxial stretching, is preferred in the present invention, by A polymer matrix containing a self-initiating UV-curable cross-linked resin was prepared by spinning.

[0032] S2. After the ceramic slurry...

Embodiment 1

[0049] This example is used to illustrate the separator disclosed in the present invention and its preparation method.

[0050] 1. Preparation of polymer matrix

[0051] Polyethylene is mixed with 1wt% unsaturated polyester amide urea (urea 0.04mol%), and a polymer matrix containing self-initiating UV-curable crosslinking resin is prepared by spinning, and the thickness of the prepared polymer matrix is 35 μm , Porosity 50%.

[0052] 2. Preparation of slurry

[0053] The unsaturated polyester amide urea (urea 0.04mol%) of 1 weight part is mixed with the toluene of 39 weight parts, then adds the Al of 10 weight parts wherein 2 o 3 , after fully stirring and mixing evenly, transfer to a ball mill for ball milling until Al 2 o 3 The average particle size is 200nm, and the specific surface area is 10m 2 / g to obtain a ceramic slurry, and then heat the ceramic slurry to 80°C for subsequent use.

[0054] 3. Preparation of slurry layer and curing

[0055] Immerse the polyme...

Embodiment 2

[0057] 1. Preparation of polymer matrix

[0058] Polyethylene was mixed with 4.5wt% vinyl acrylate, and a polymer matrix containing a self-initiating UV-curable crosslinking resin was prepared by spinning. The thickness of the prepared polymer matrix was 35 μm, and the porosity was 63%.

[0059] 2. Preparation of slurry

[0060] The vinyl acrylate of 1 weight part and the carbon tetrachloride of 41 weight parts are mixed uniformly, then add the MgO of 10 weight parts wherein, after fully stirring and mixing, transfer to ball mill and carry out ball milling, to MgO average particle size 60nm, ratio Surface area is 43m 2 / g to obtain ceramic slurry, and then heat the ceramic slurry to 70°C for later use.

[0061] 3. Preparation of slurry layer and curing

[0062] Immerse the polymer matrix obtained in step 1 in the ceramic slurry, take it out after 10 minutes, attach 0.8 μm thick ceramic slurry to both sides of the polymer matrix, and then place it under a 100W high-pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com