Molten titanium and titanium alloy crucible and preparation method thereof

A titanium alloy and crucible technology, which is applied in the field of titanium and titanium alloy smelting devices, can solve the problems of unsuitable industrial production, uneconomical economic cost, and easy to grow cracks, etc., and achieves easy replacement and maintenance, flexible assembly and disassembly, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

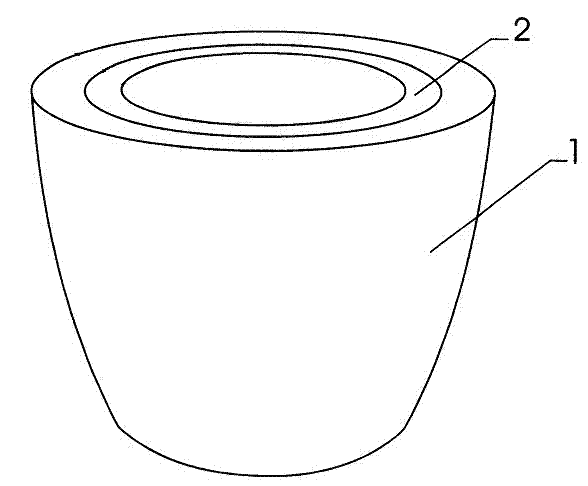

[0033] In this example, see figure 1 , a crucible for smelting titanium and titanium alloys, which is composed of a crucible shell 1 and a crucible lining 2, the crucible lining 2 is integrally sintered from a composite material, and the crucible lining 2 has the ability to hold titanium melt and titanium alloy The open structure of the melt, the crucible lining 2 is made of composite material, the crucible shell 1 is made of high melting point high temperature resistant material, the crucible lining 2 has a structure that matches the shape of the crucible shell 1, so that the crucible shell 1 The inner surface of the crucible fits the outer surface of the crucible lining 2, and makes the crucible shell 1 directly contact the supporting crucible lining 2, so that the crucible shell 1 can withstand the pressure generated by the titanium melt and titanium alloy melt. The main components of the crucible lining 2 Part 1 is a sintered composite material prepared by mixing the above...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

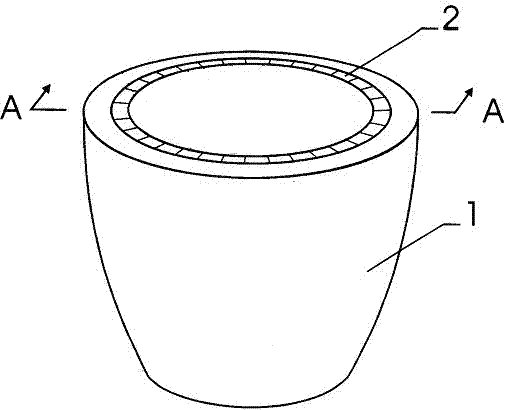

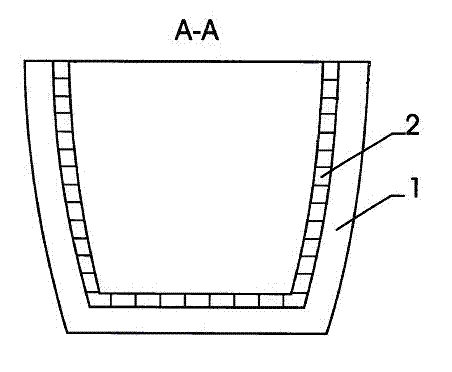

[0042] In this example, see Figure 2 to Figure 5 , the crucible lining 2 is a cup-shaped structural liner, the cup-shaped structural liner is composed of a single-layer cup-shaped structural layer, and the single-layer cup-shaped structural layer is formed by stacking a layer of composite material sintered bricks, located inside the same cup-shaped structural layer Any adjacent composite material sintered bricks are installed and connected through the combination of their concave and convex parts to form a positioning structure of concave-convex cooperation between composite material sintered bricks, so that the same cup-shaped structure layer that forms the cup-shaped structural bushing The composite material sintered bricks are integrated into one.

[0043] The preparation method of the crucible for smelting titanium and titanium alloy in this embodiment comprises the following steps:

[0...

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 2, and the special features are:

[0051] In this example, see Image 6 , The cup-shaped structural bushing is composed of two cup-shaped structural layers, that is, it is made of double-layer composite sintered bricks. In this embodiment, the crucible lining 2 is stacked with double-layer composite material sintered bricks, and the composite material sintered bricks are clamped and connected, so that the crucible lining 2 forms a two-layer bushing assembly, which can more effectively absorb the heat of the molten metal. Vibration, and effectively block the infiltration of molten metal from the gap between the composite sintered bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com