System and method for improving biochemistry and deeply treating sewage by utilizing powdered activated carbon

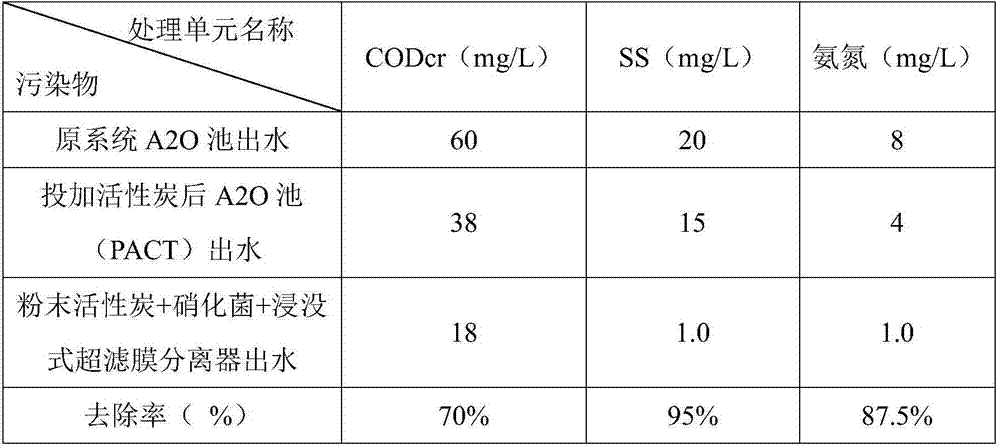

A technology of powder activated carbon and advanced treatment, which is applied to improve biochemical and advanced sewage treatment systems, and improve the field of biochemical and advanced sewage treatment. Achieve the effect of improving sedimentation performance, shortening work cycle and improving effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

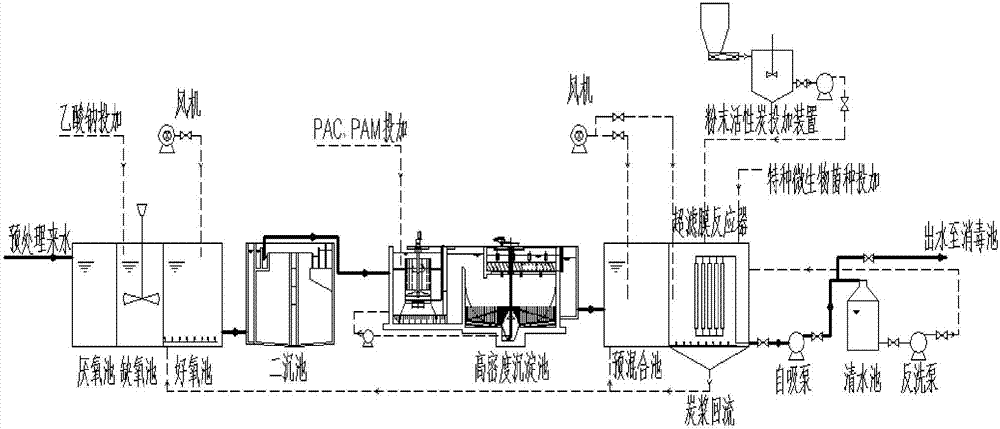

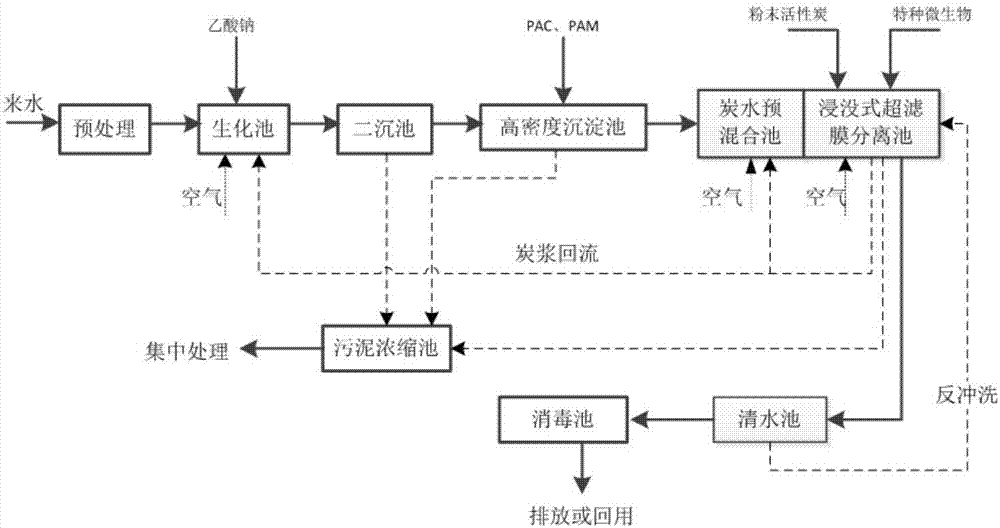

[0032] please see figure 1 , the present invention provides a biochemical and advanced sewage treatment system using powdered activated carbon, including traditional pretreatment equipment, biochemical tanks, secondary sedimentation tanks, high-density sedimentation tanks, submerged ultrafiltration membrane separation subsystems, and dosing rooms;

[0033]The sewage enters the biochemical pool after being treated by traditional pretreatment equipment. The biochemical pool is composed of anaerobic pool, anoxic pool and aerobic pool. Through anaerobic, anoxic,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com