Lithium battery pack

A technology for lithium battery packs and battery modules, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as difficult replacement and maintenance, small conductive contact area, and single point failure, so as to avoid the risk of single point failure , Convenient replacement and maintenance, and the effect of reducing the risk of assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

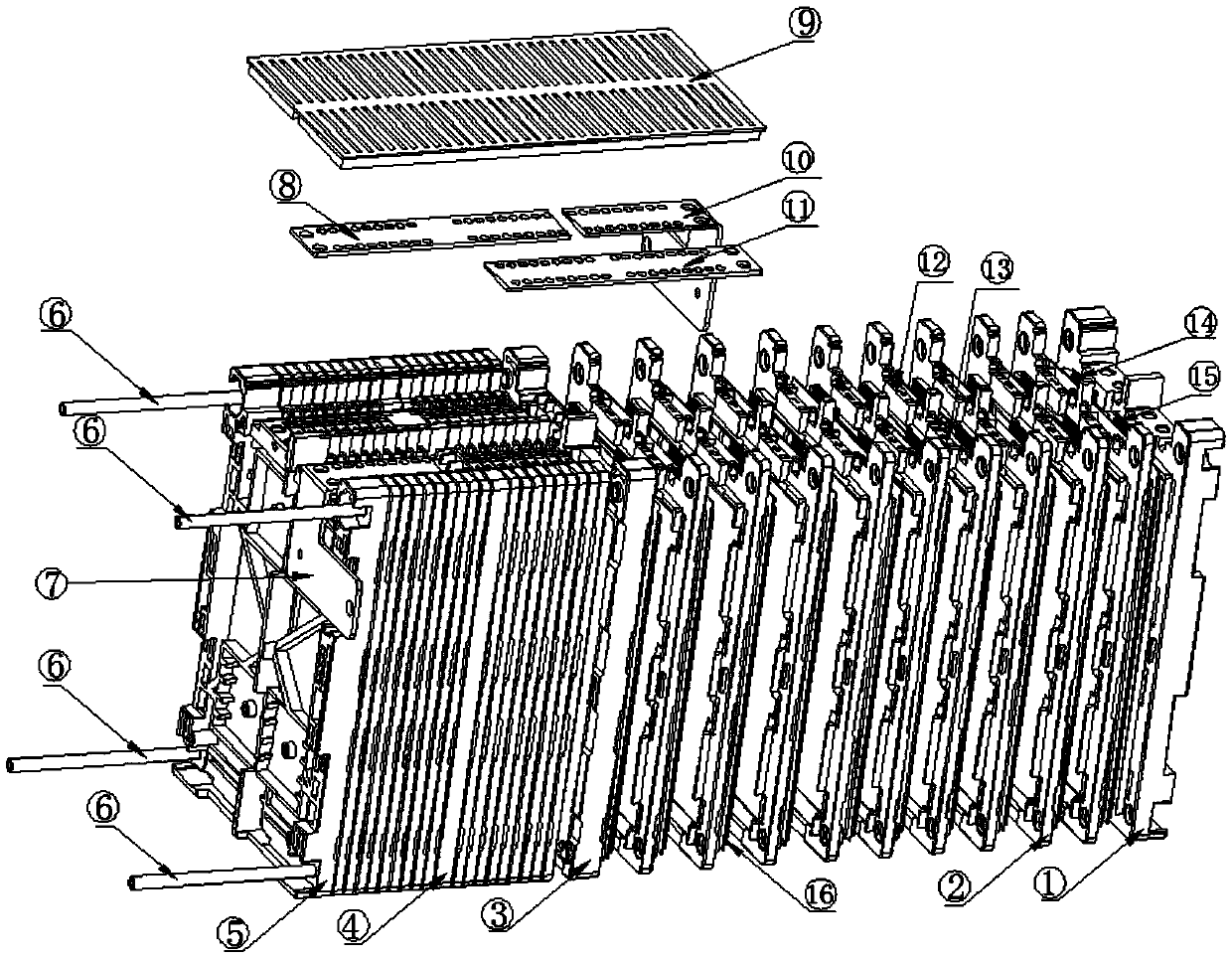

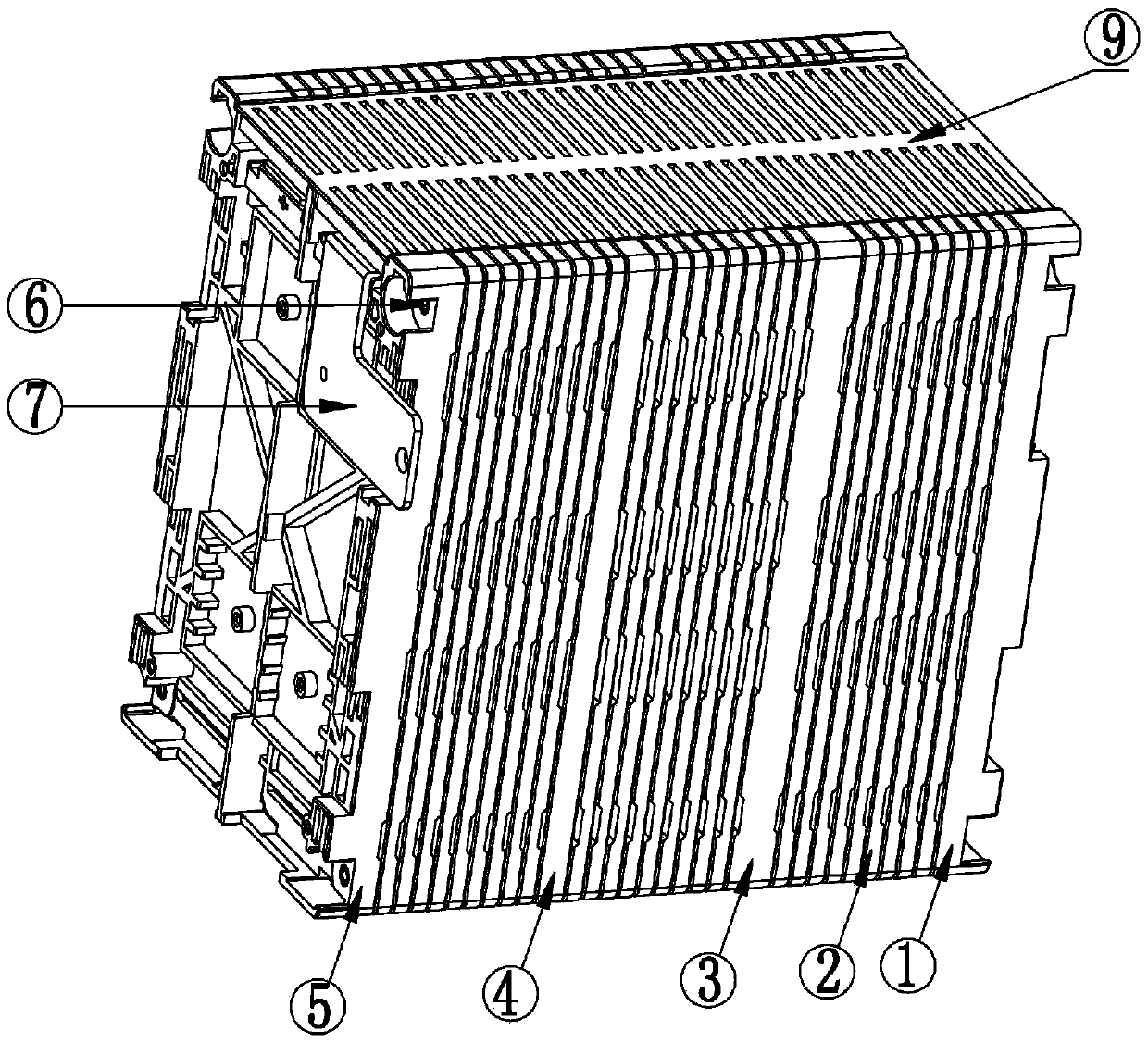

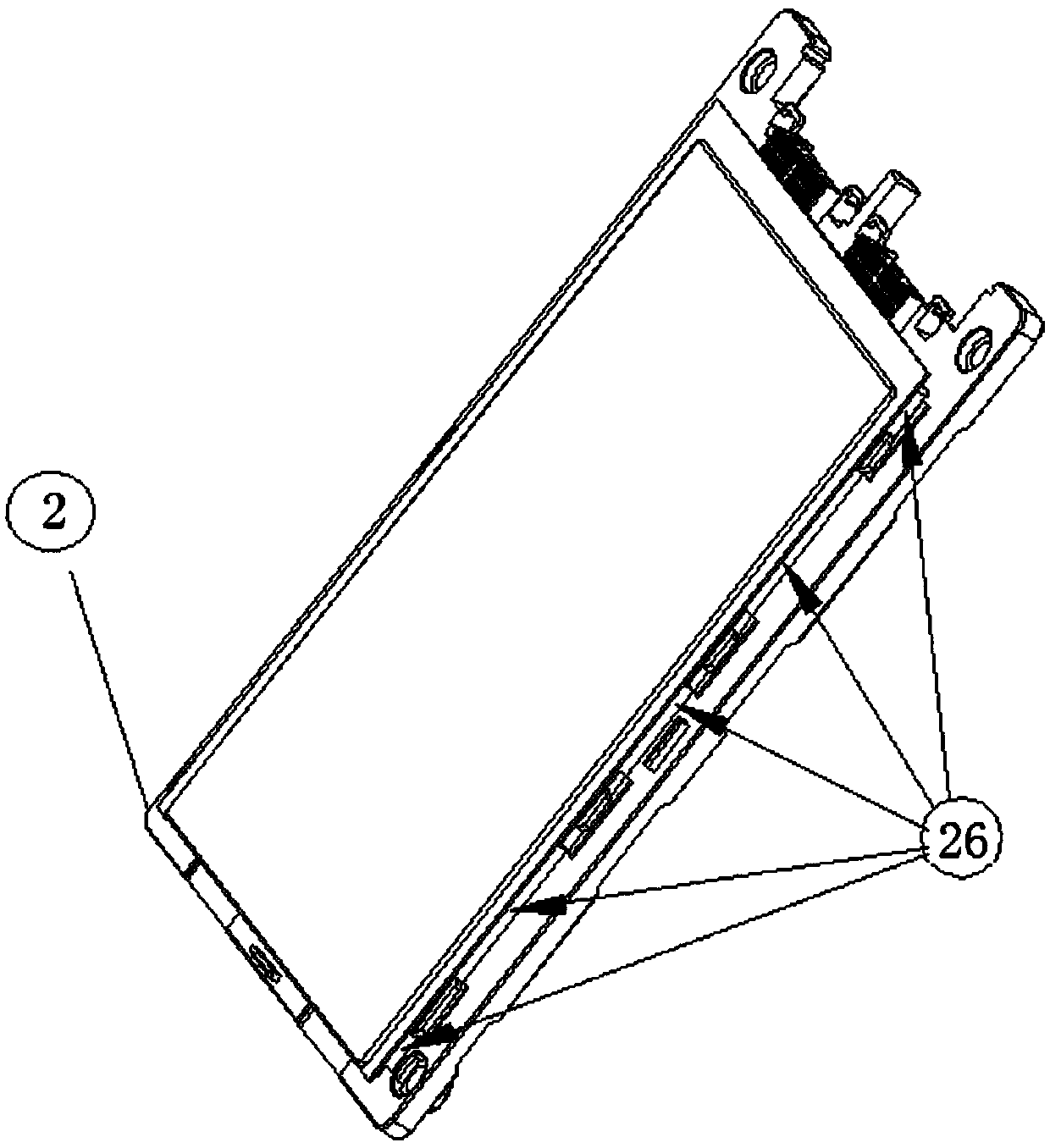

[0024] Figure 1 to Figure 8 The reference numerals in are: right fixing plate 1; battery tray bracket 2; transfer fixing plate 3; transfer fixing plate 4; left fixing plate 5; bolt 6; Plate 8; Dark hole ventilation screen frame 9; Negative output current collecting conductive plate 10; Series and parallel current collecting conductive plate 11; Negative electrode conductive part 12; Positive electrode conductive part 13; 15; single battery cell 16; vertical through-type ventilation hole 21; cable slot 22; insulation protection and connection fool-proof structure 23; insulation protection structure 24; positive and negative outlet grooves 25; convex intermittent bone battery Fixing structure 26 ; circumferential concave battery fixing structure 27 ; wire rod fixing clamping structure 28 ; bottom through-type ventilation hole 29 ; bottom heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com