Cold-fixed PDC (polycrystalline diamond compact) bit

A technology of polycrystalline diamond and composite disc drill bits, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc., to achieve the effects of improving work indicators, reducing drilling costs, and simple replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

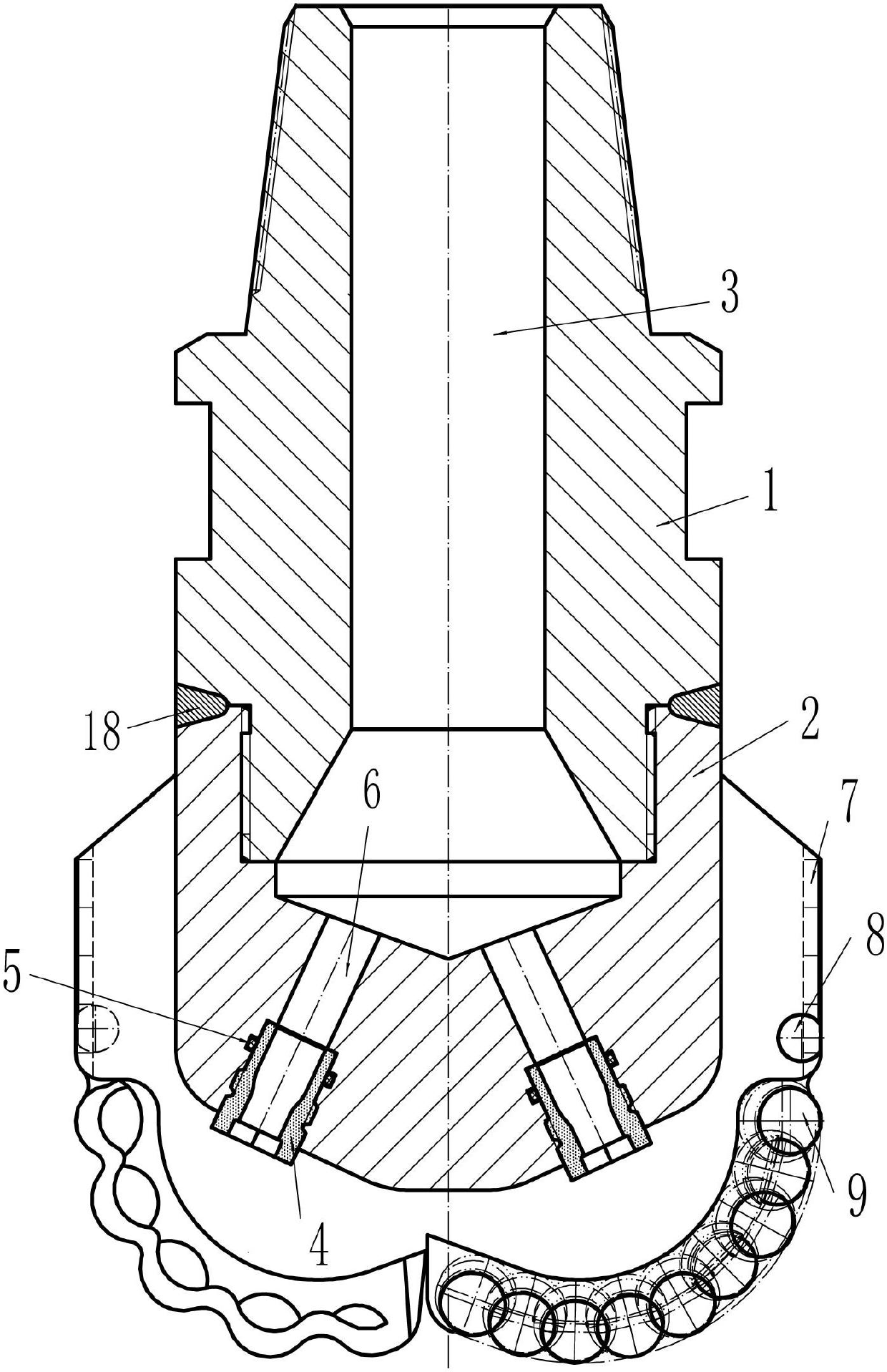

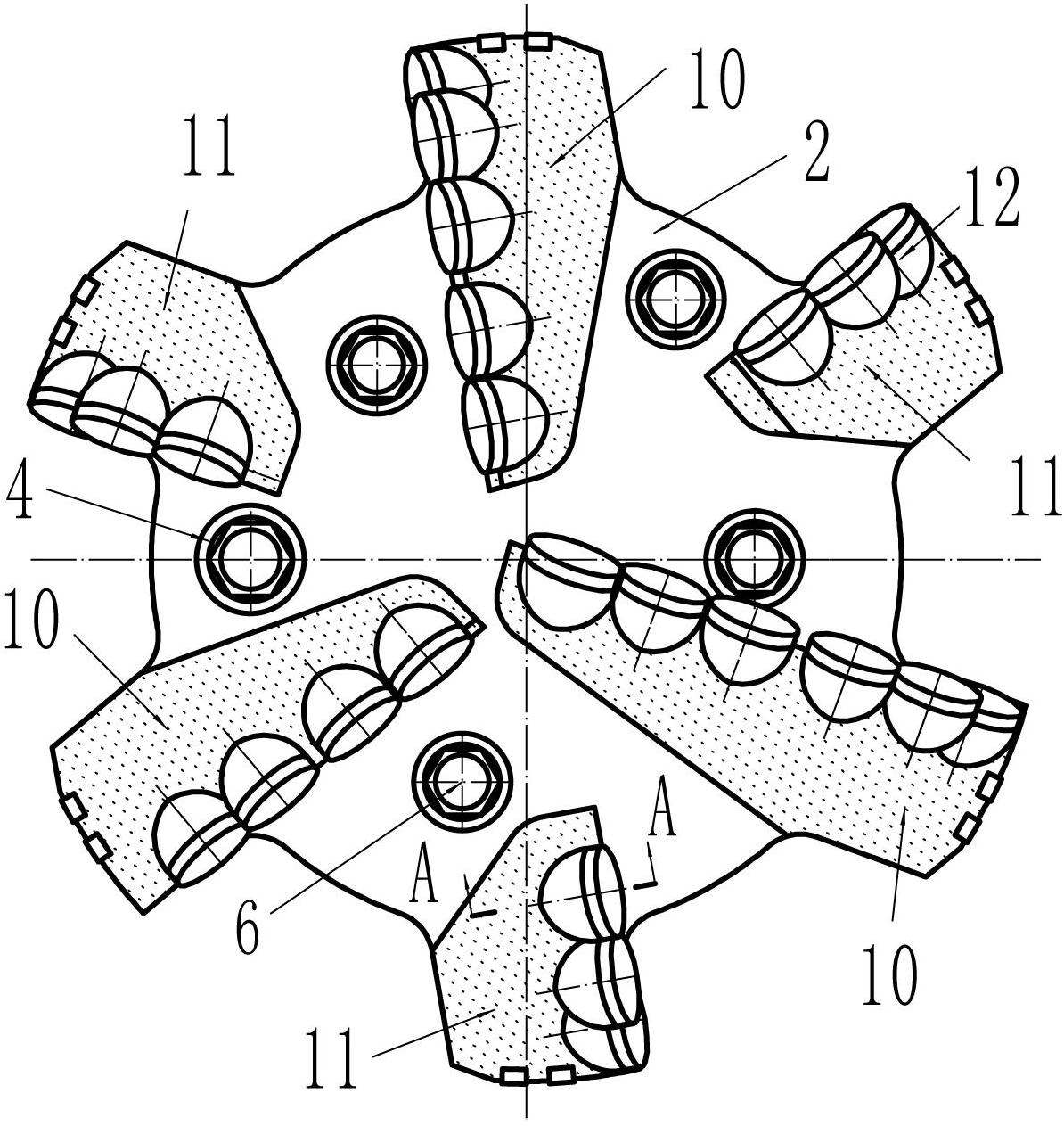

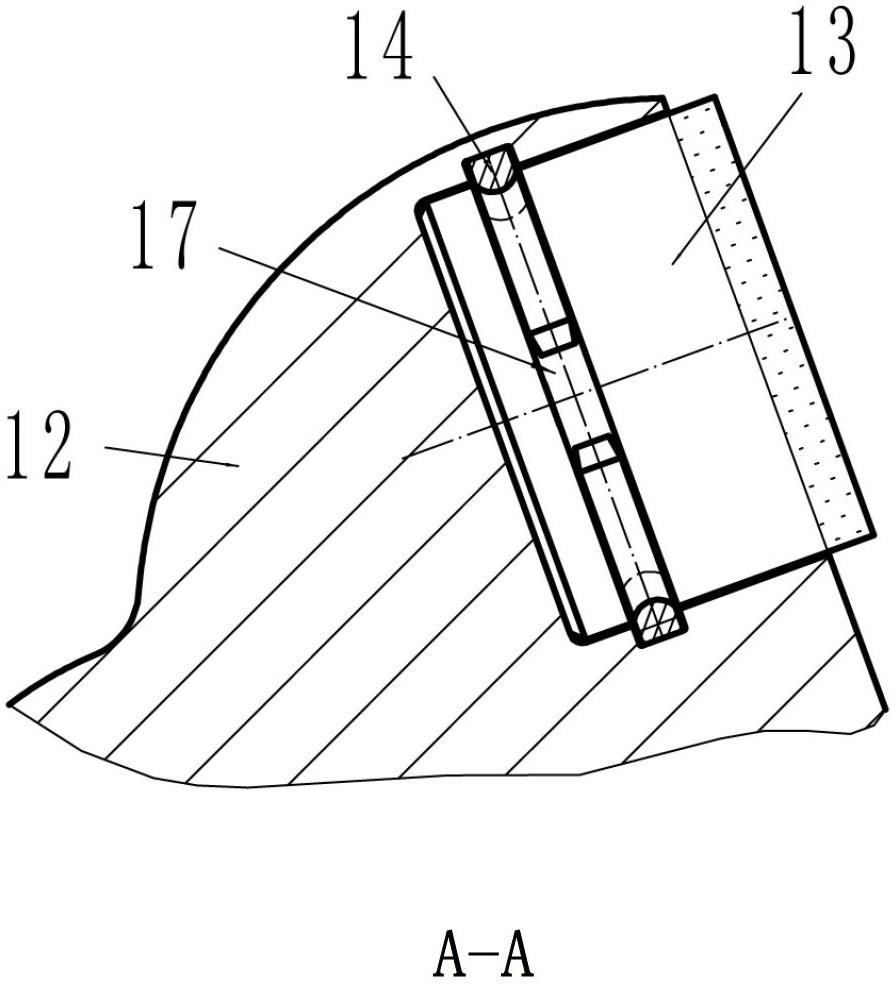

[0015] Embodiment 1: The upper body of the drill bit (1) and the lower body of the drill bit (2) are fixed together by the electric welding layer (18), and the center of the drill bit is longitudinally opened with a main water hole (3), and the lower part of the main water hole (3) is connected to 8 water diversions hole (6), each water diversion hole (6) is equipped with a water nozzle (4) and a nozzle sealing ring (5), and three long blades (10) and three A short blade (11), a cylindrical polycrystalline diamond (7) and a diameter-gauge PDC sheet (8) fixed by interference cold pressing are fixed at the gages of the long blade (10) and the short blade (11), the long The cutter wing (10) and the cutting teeth (9) on the short cutter wing (11) use the retaining ring (14) to fix the PDC piece (8) with the PDC piece groove (17) to the drill bit column (12) inside the hole.

Embodiment 2

[0016] Embodiment 2: The upper body of the drill bit (1) and the lower body of the drill bit (2) are fixed together by the electric welding layer (18), and the center of the drill bit is longitudinally opened with a main water hole (3), and the lower part of the main water hole (3) is connected to 10 water diversions hole (6), each water diversion hole (6) is equipped with a water nozzle (4) and a nozzle sealing ring (5), and four long blades (10) and The four short blades (11), the long blades (10) and the short blades (11) are fixed with a rectangular polycrystalline diamond (7) and a gauge PDC sheet (8) fixed by interference cold pressing. The cutting teeth (9) on the blade (10) and the short blade (11) use the stopper pin (15) to fix the PDC sheet (13) with the PDC sheet groove (17) in the hole of the tooth post (12) Inside.

Embodiment 3

[0017] Embodiment 3: The upper body of the drill bit (1) and the lower body of the drill bit (2) are fixed together by an electric welding layer (18), and the center of the drill bit is longitudinally opened with a main water hole (3), and the lower part of the main water hole (3) is connected to 6 water diversions hole (6), each water diversion hole (6) is equipped with a nozzle (4) and a nozzle sealing ring (5), and three long blades (10) and two short blades are distributed on the lower end surface of the lower body of the drill bit (2). Wing (11), long blade (10) and short blade (11) have polycrystalline diamond (7) and a gauge PDC sheet (8) fixed by interference cold pressure, long blade (10) With the cutting teeth (9) on the short knife wing (11), the PDC sheet (13) is fitted in the hole of the tooth post (12) with clearance, and the baffle plate (16) is spot-welded and fixed on the end face of the tooth post (12).

[0018] The foregoing embodiments are applicable to all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com