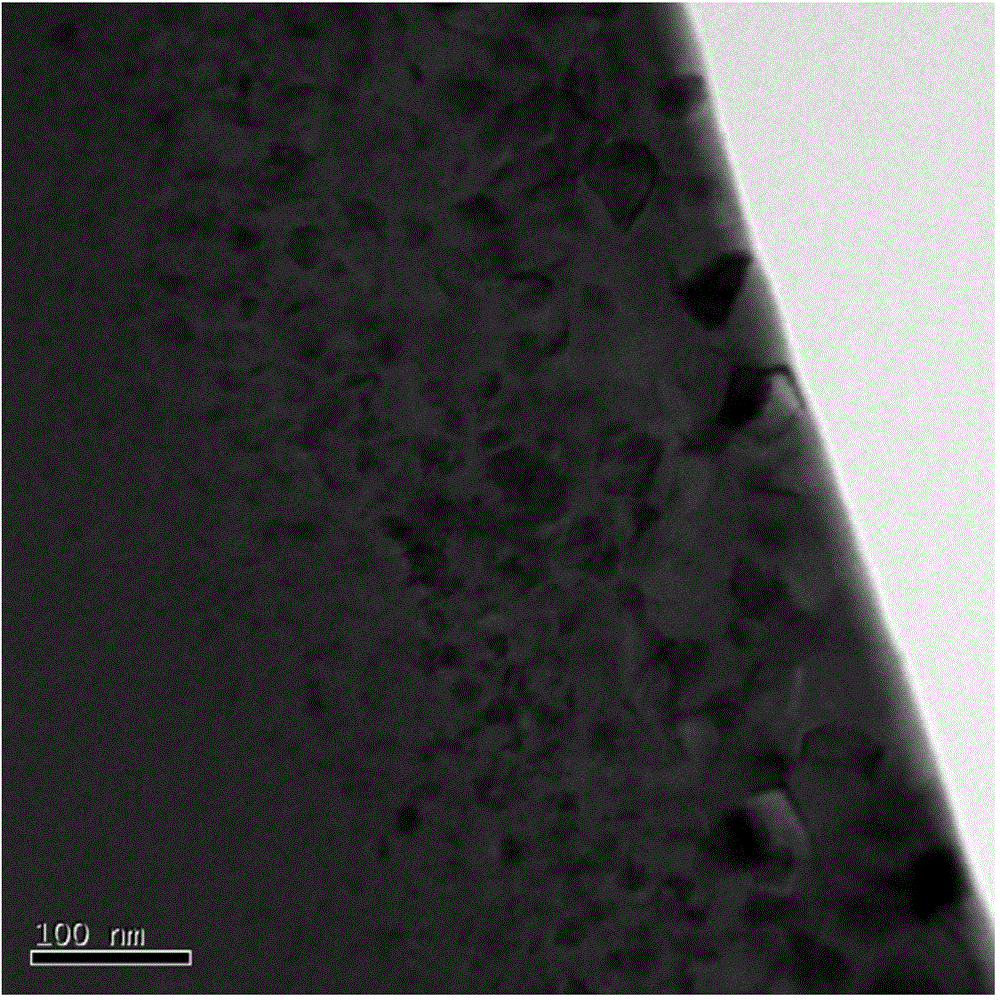

Transmission electron microscope-based Sample preparation method for observing section grain characteristics of laser-induced crystallized nano-film

An electron microscope, laser-induced technology, applied in the preparation of test samples, material analysis using radiation, etc., can solve the problems of cumbersome operation, easy contamination of samples, long time consumption, etc., to shorten the process time, avoid pollution and heat. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

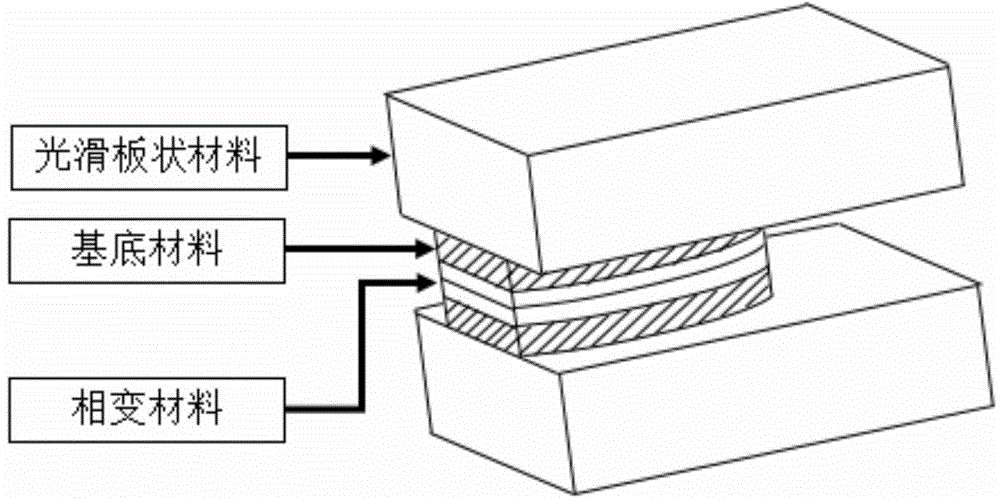

[0026] (1) Take two copper grids with a diameter of 3 mm and attach a layer of carbon support film (the standard transmission electron microscope sample preparation substrate), and use magnetron sputtering to prepare Ge with a thickness of 70 nanometers on the two substrates. 2 Sb 2 Te 5 Ternary alloy phase change material film material;

[0027] (2) Relatively attach the 2 disc film phase change material layers prepared in (1), and fix the appearance with adhesive tape;

[0028] (3) Cut the two discs of film materials that have been bonded well in (2) at one-third of the diameter, so that the fracture is in the gap between the edges of the interlayer of two flat and smooth plate materials, and make the fracture The section is placed outward along the interlayer;

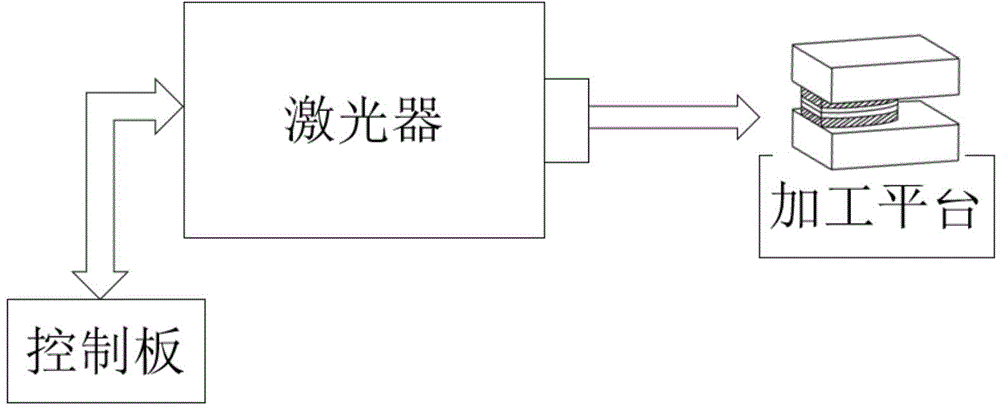

[0029] (4) Turn on the excimer laser with a pulse width of 30 nanoseconds and a wavelength of 248 nanometers, adjust the platform, use photosensitive paper to locate the spot position, and place the cross section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com