Patents

Literature

83results about How to "Avoid thermal influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

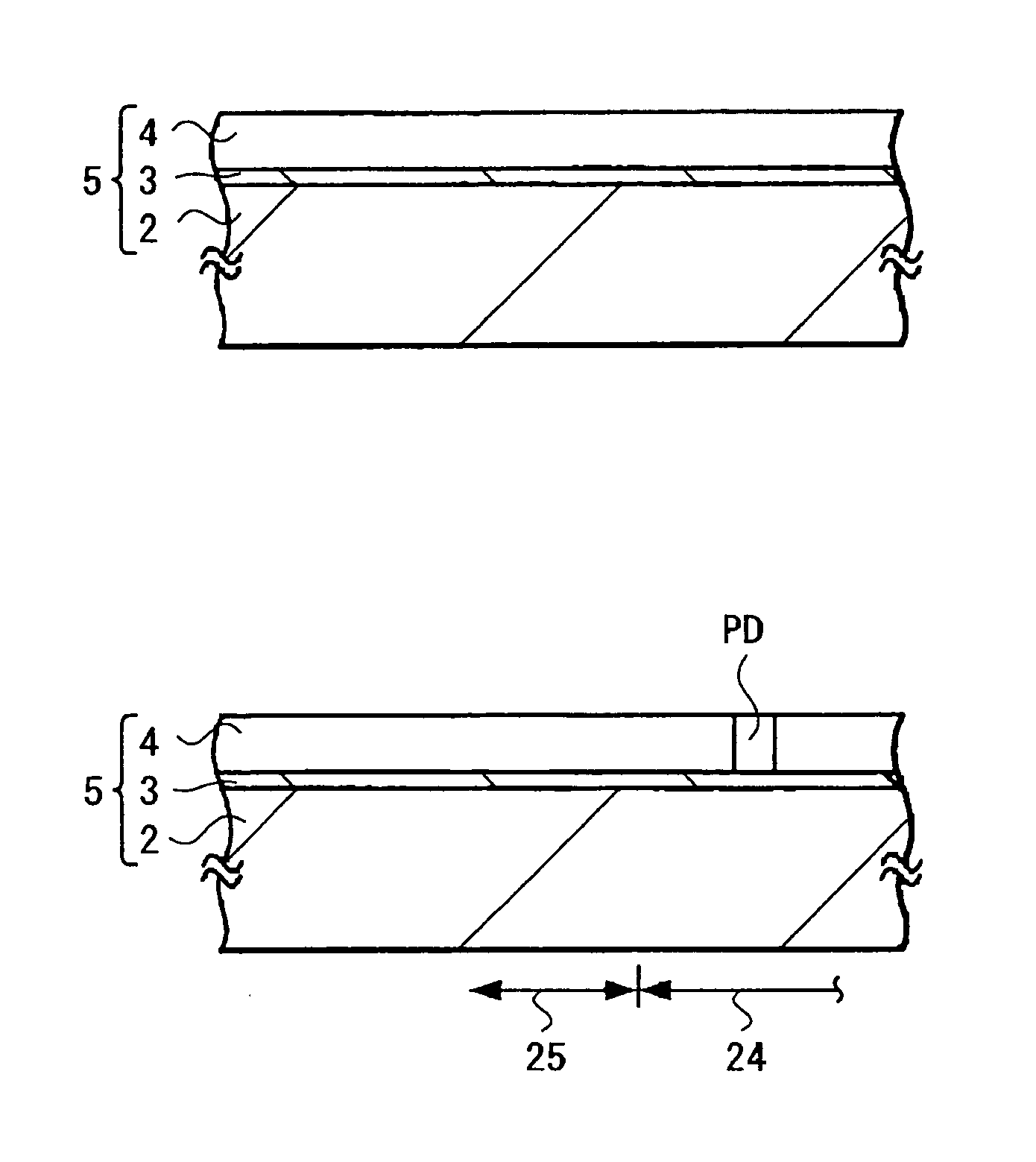

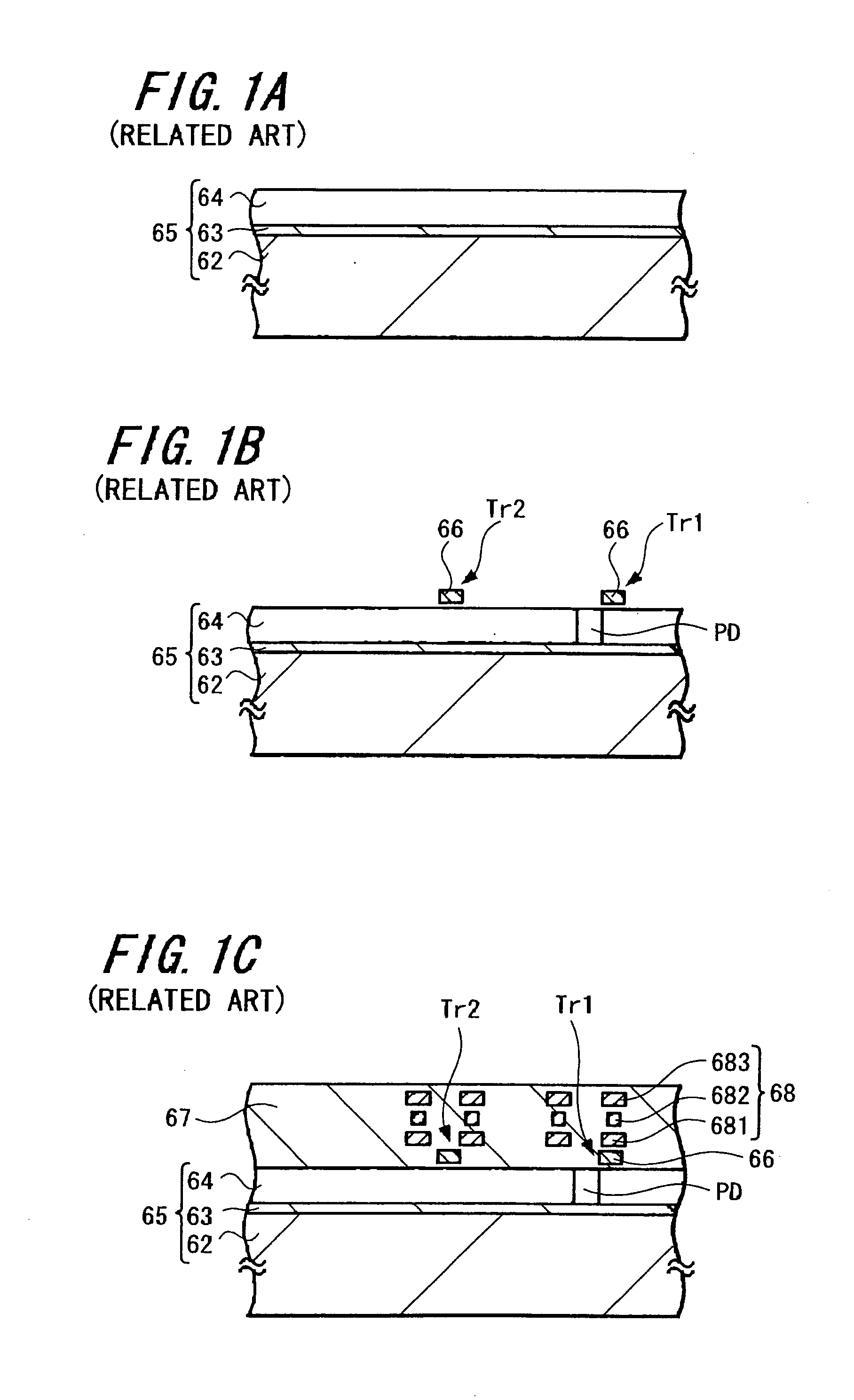

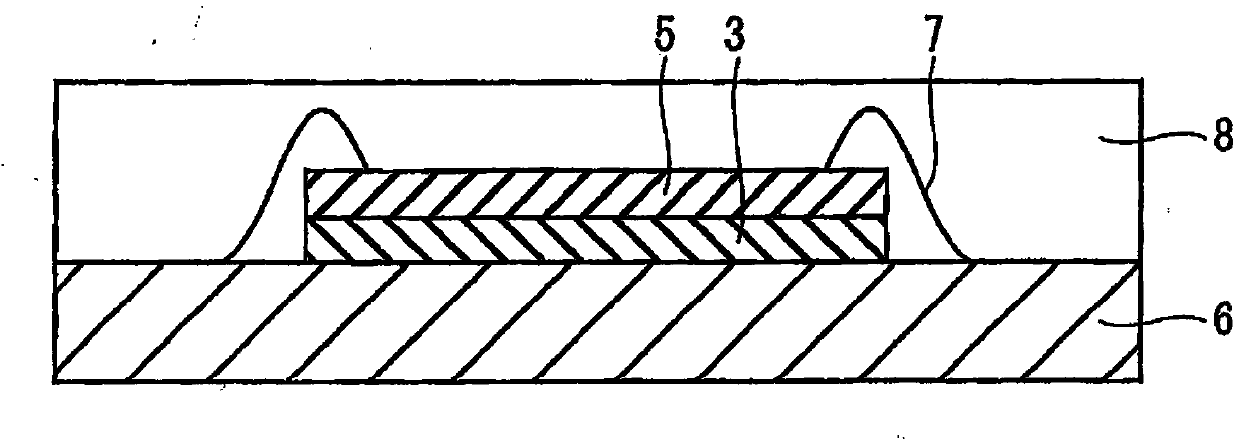

Solid state image pickup device and manufacturing method thereof and semiconductor integrated circuit device and manufacturing method thereof

InactiveUS20050227403A1Reduce the temperatureImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingInterconnectionPhotoelectric conversion

A method of manufacturing a solid-state image pickup device comprises a process for forming a plurality of photoelectric conversion elements PD within a semiconductor substrate 4, a process for forming an interconnection portion, having an interconnection layer 8 in an insulating layer 7, on the surface side of the semiconductor substrate 4, a process for forming an adhesive layer, made of a material cured at a temperature lower than a deterioration starting temperature of the interconnection layer 8, on the surface of the interconnection portion and bonding a supporting substrate 30 to the surface side of the interconnection portion through the adhesive layer 9 by heat treatment at a temperature lower than the deterioration starting temperature of the interconnection layer 8 and a process for decreasing a thickness of the semiconductor substrate 4 from the back side. A solid-state image pickup device manufacturing method can bond the supporting substrate 30 to the surface side of the interconnection portion through the adhesive layer 9 without exerting a thermal influence upon the interconnection layer 8 that was previously formed on the surface side of the semiconductor substrate 4.

Owner:SONY CORP

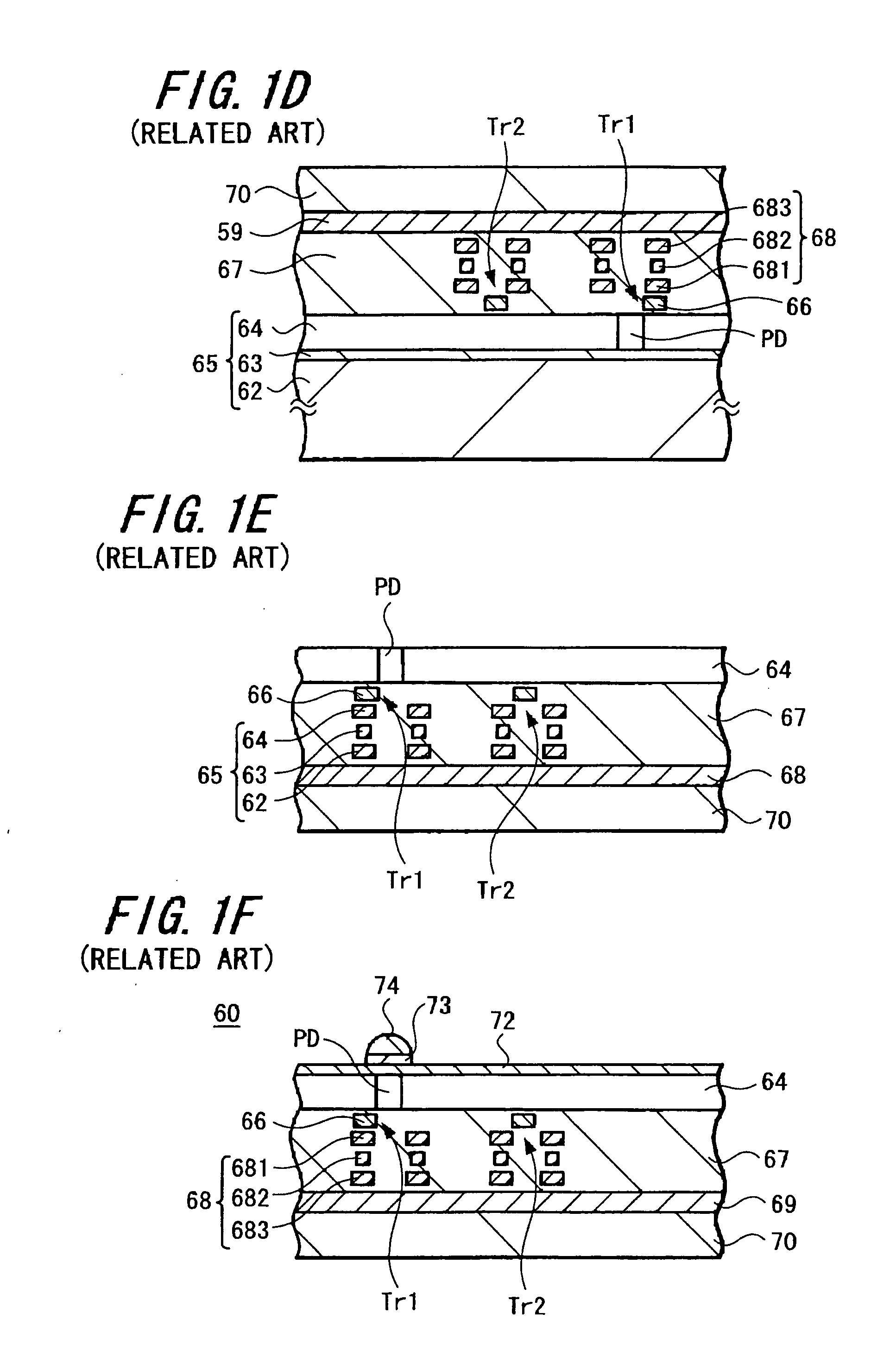

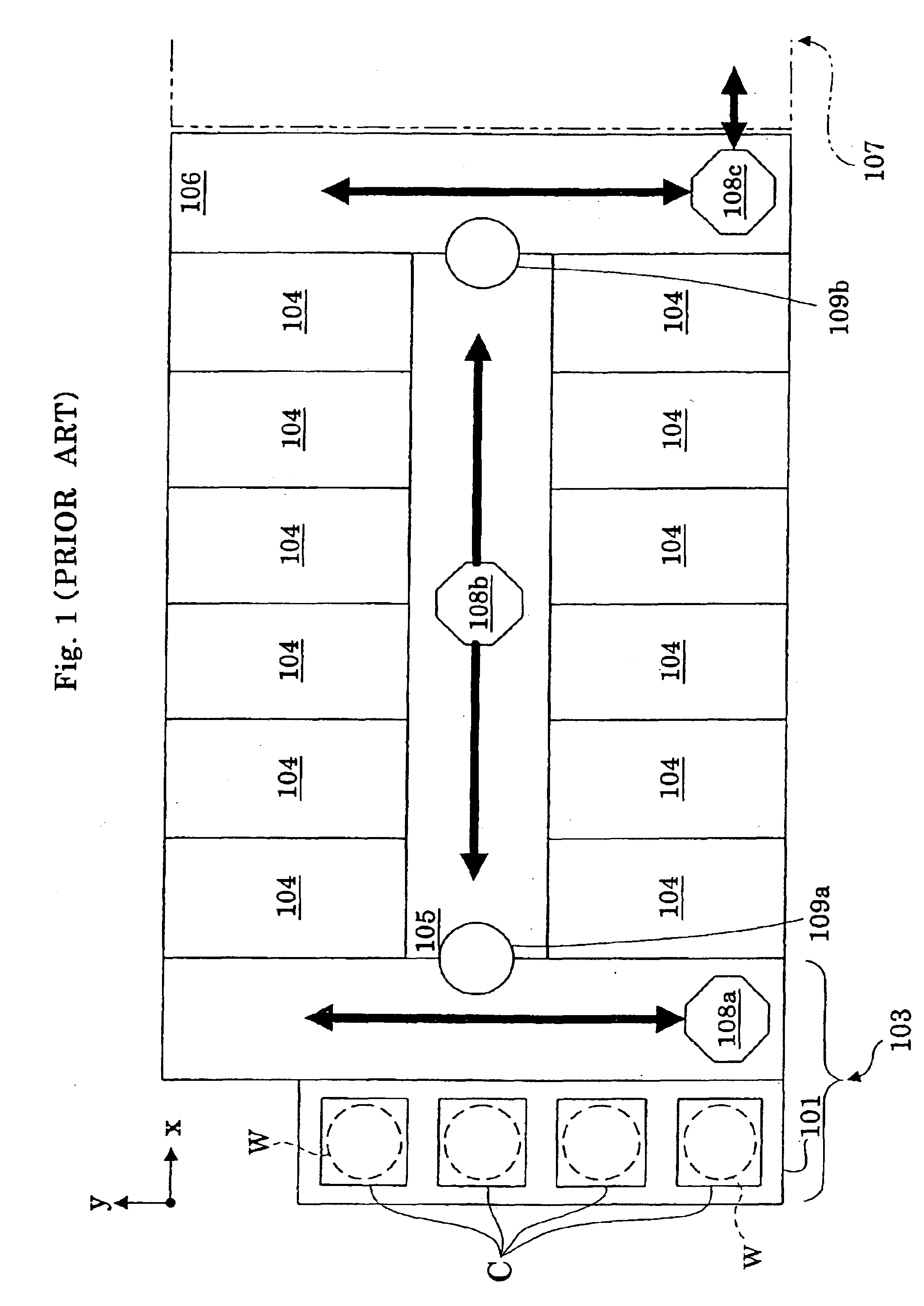

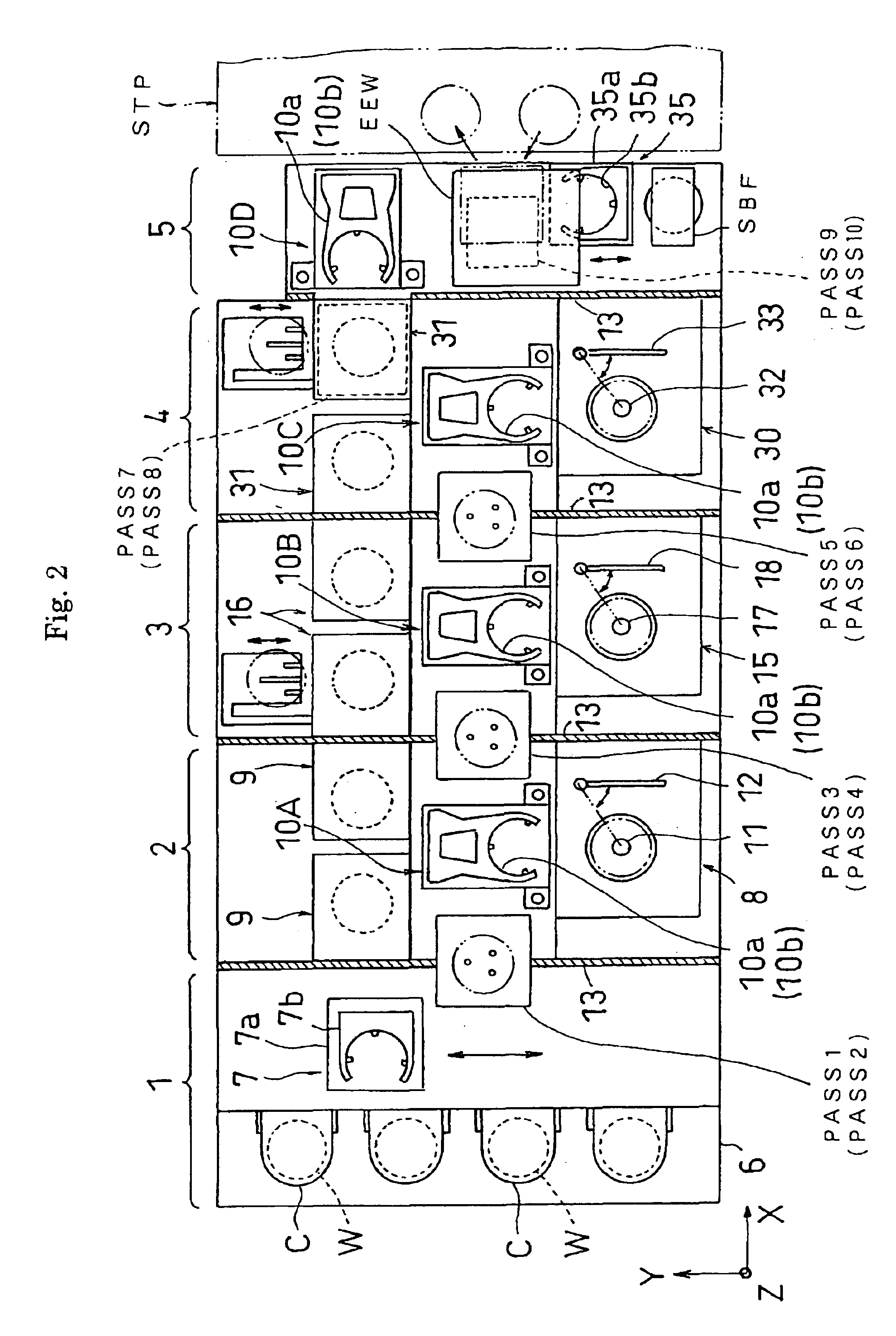

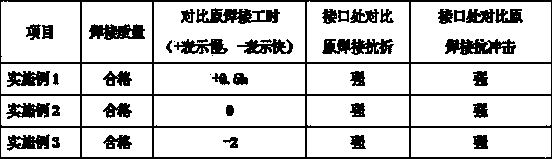

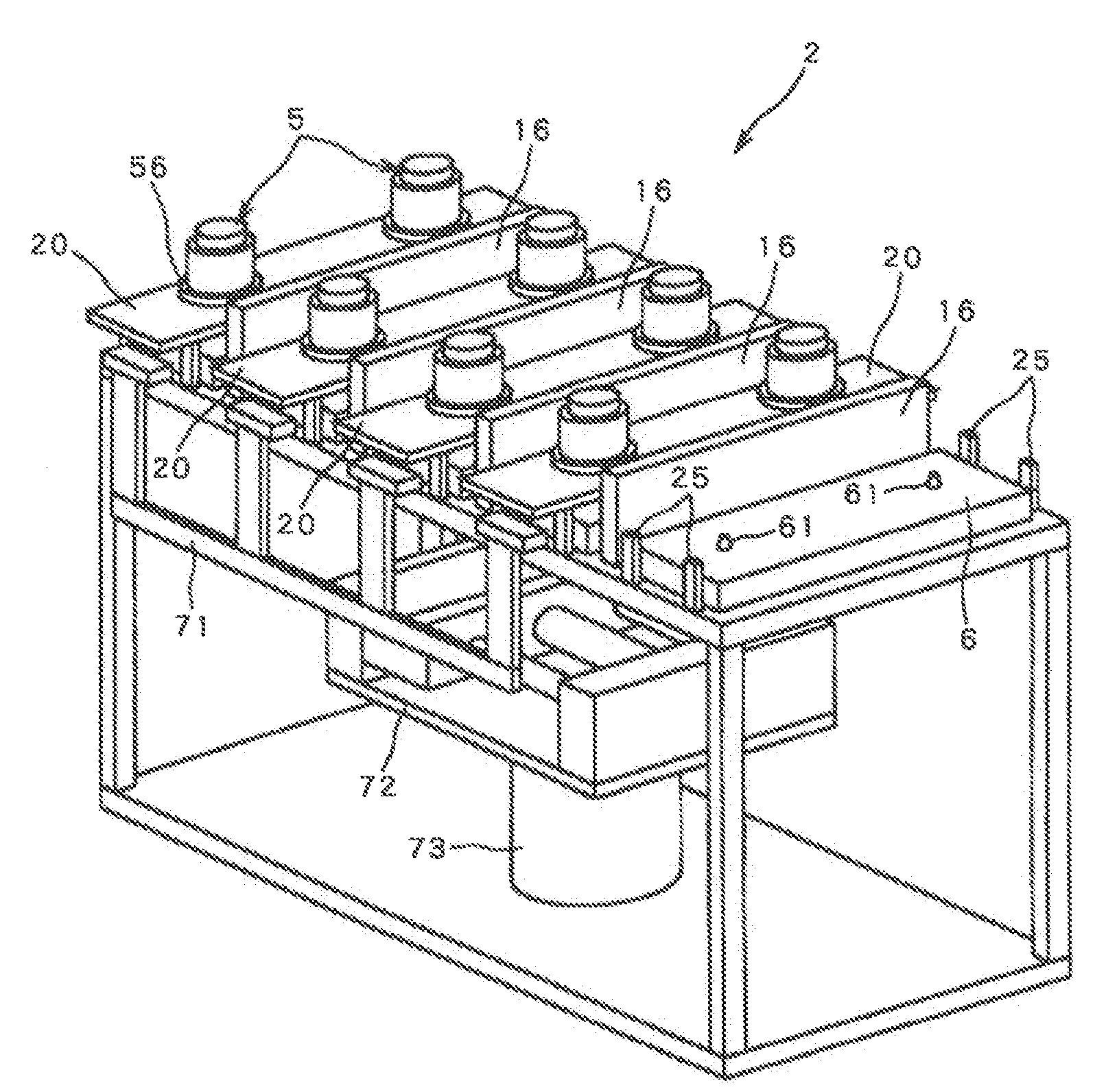

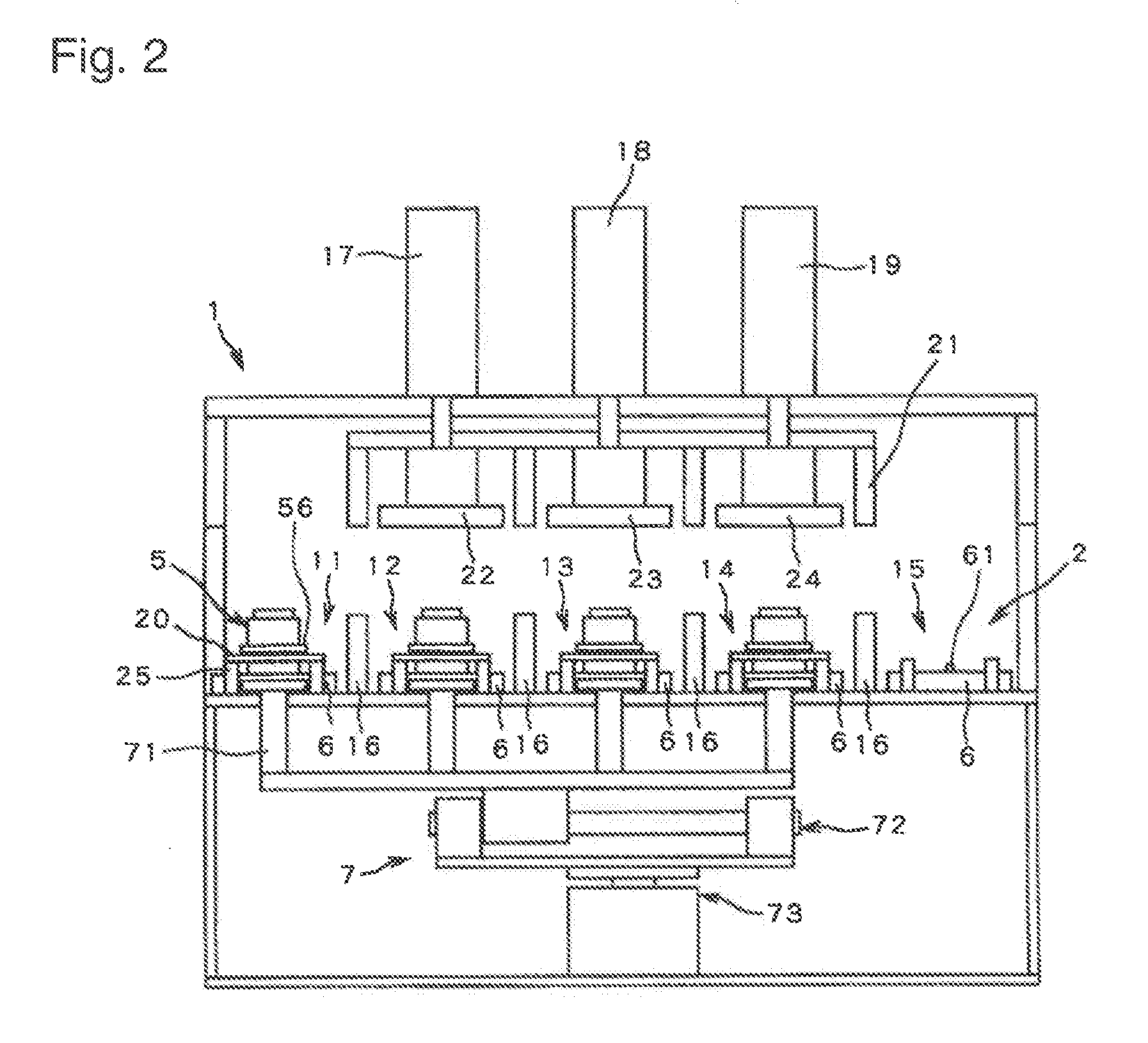

Substrate treating apparatus

ActiveUS6837632B2Efficiently transportAvoid thermal influenceLiquid surface applicatorsLiquid processingResistEngineering

A substrate treating apparatus has an antireflection film forming block, a resist film forming block and a developing block arranged in juxtaposition, each of these blocks including treating modules and a single main transport mechanism. The main transport mechanism transports substrates within each block, and transfers the substrates between the blocks through inlet substrate rests and outlet substrate rests provided as separate components. This construction realizes improved throughput of the substrate treating apparatus.

Owner:SCREEN HLDG CO LTD

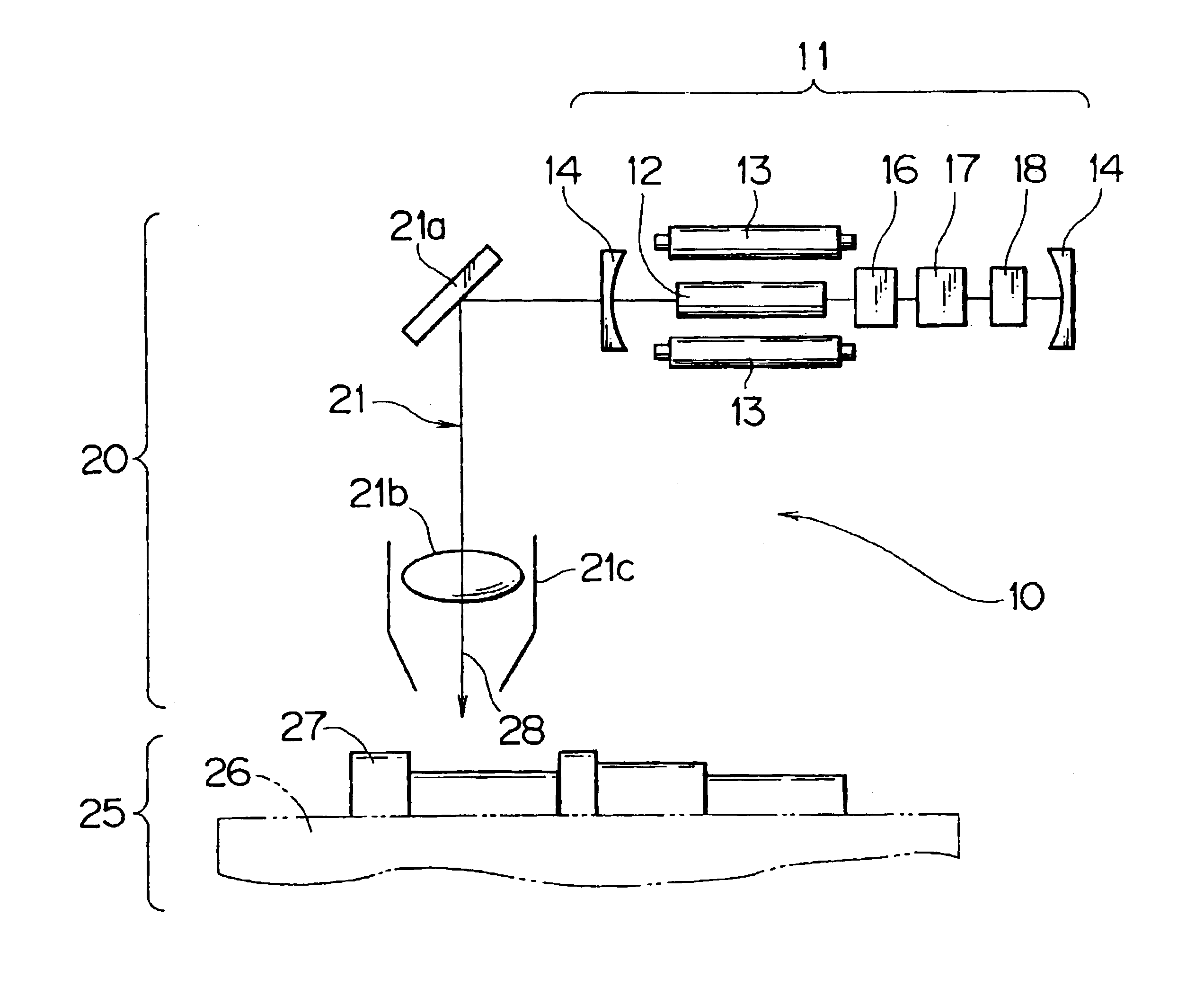

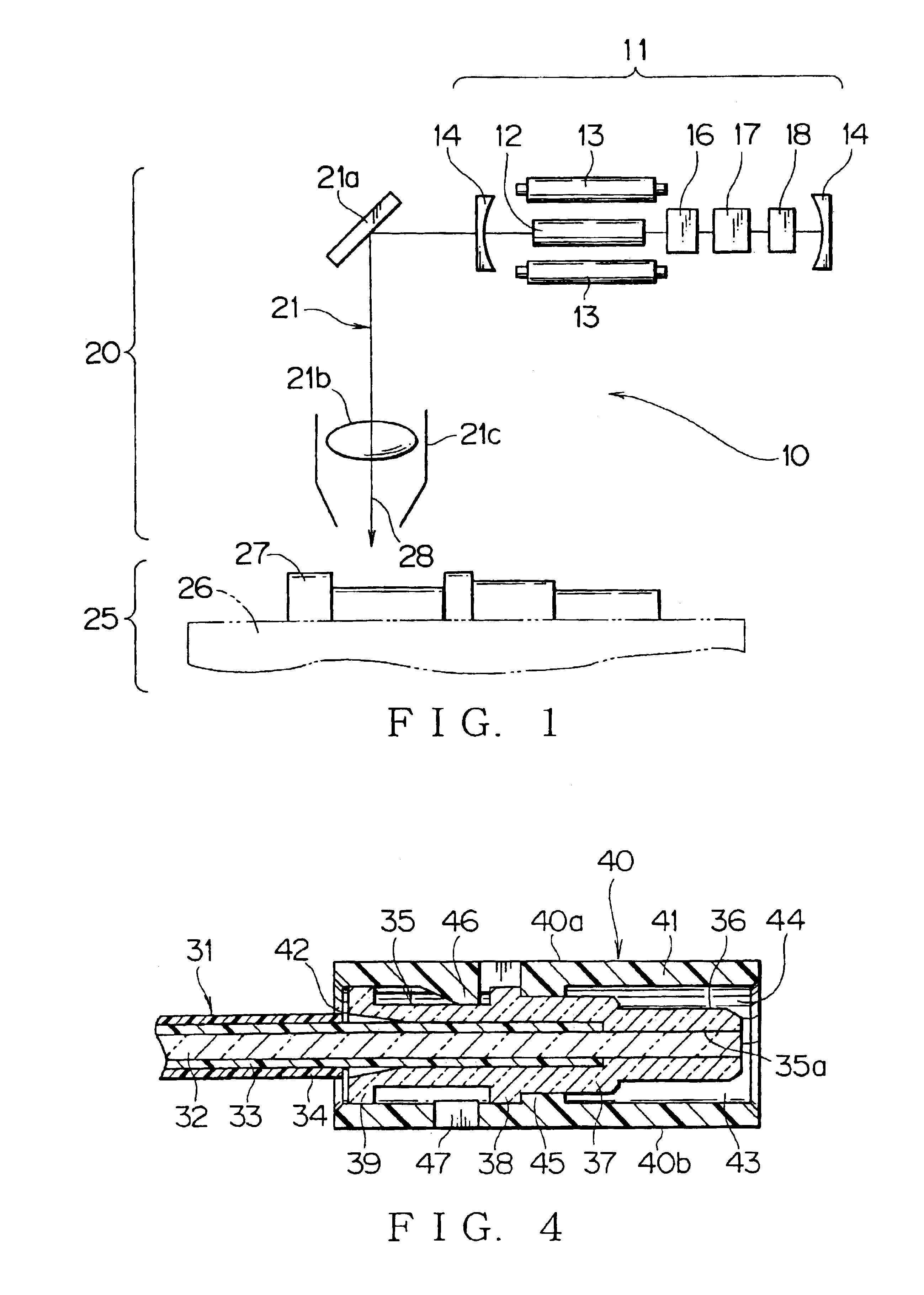

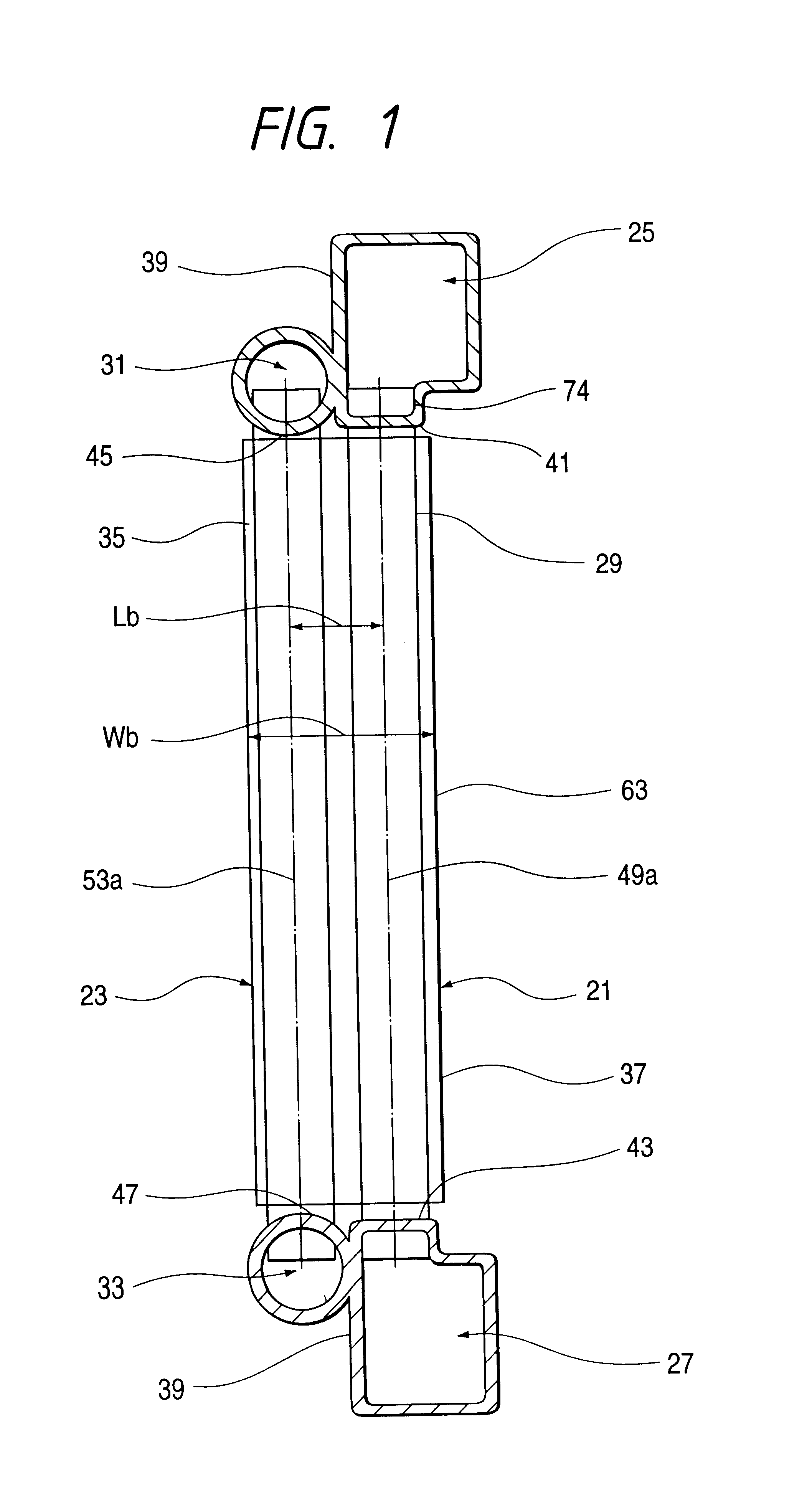

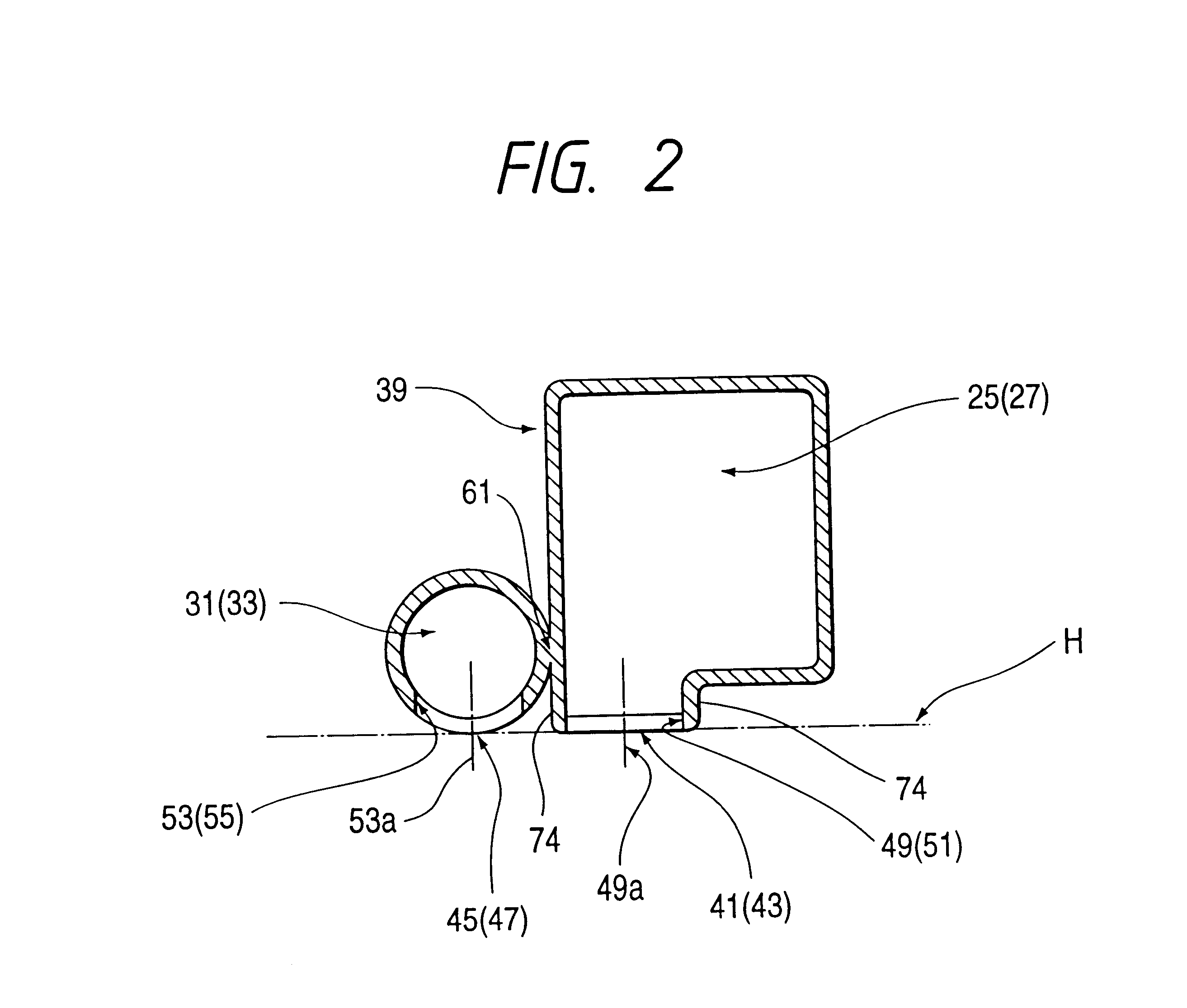

Optical fiber fixing method

InactiveUS6886991B2Less influenceShorten the timeOptical articlesCoupling light guidesPulsed modeSynthetic resin

While a ferrule or a laser beam is being shifted in an axial direction, the laser beam is applied, thereby forming a plurality of welded portions at the boundary between a coating of an optical fiber and the ferrule. A YAG laser in a Q switch pulse mode is used to provide a laser beam. The beam. The YAG laser in the Q switch pulse mode is preferably oscillated in a pulse exciting system. The ferrule is made of transparent or semi-transparent synthetic resin. The coating of the optical fiber is made of translucent synthetic resin. In this way, an optical fiber fixing method can be provided which can surely fix an optical fiber and a ferrule in a shortened time, and minimize the thermal influence on the vicinity of the portion to be processed.

Owner:YAZAKI CORP

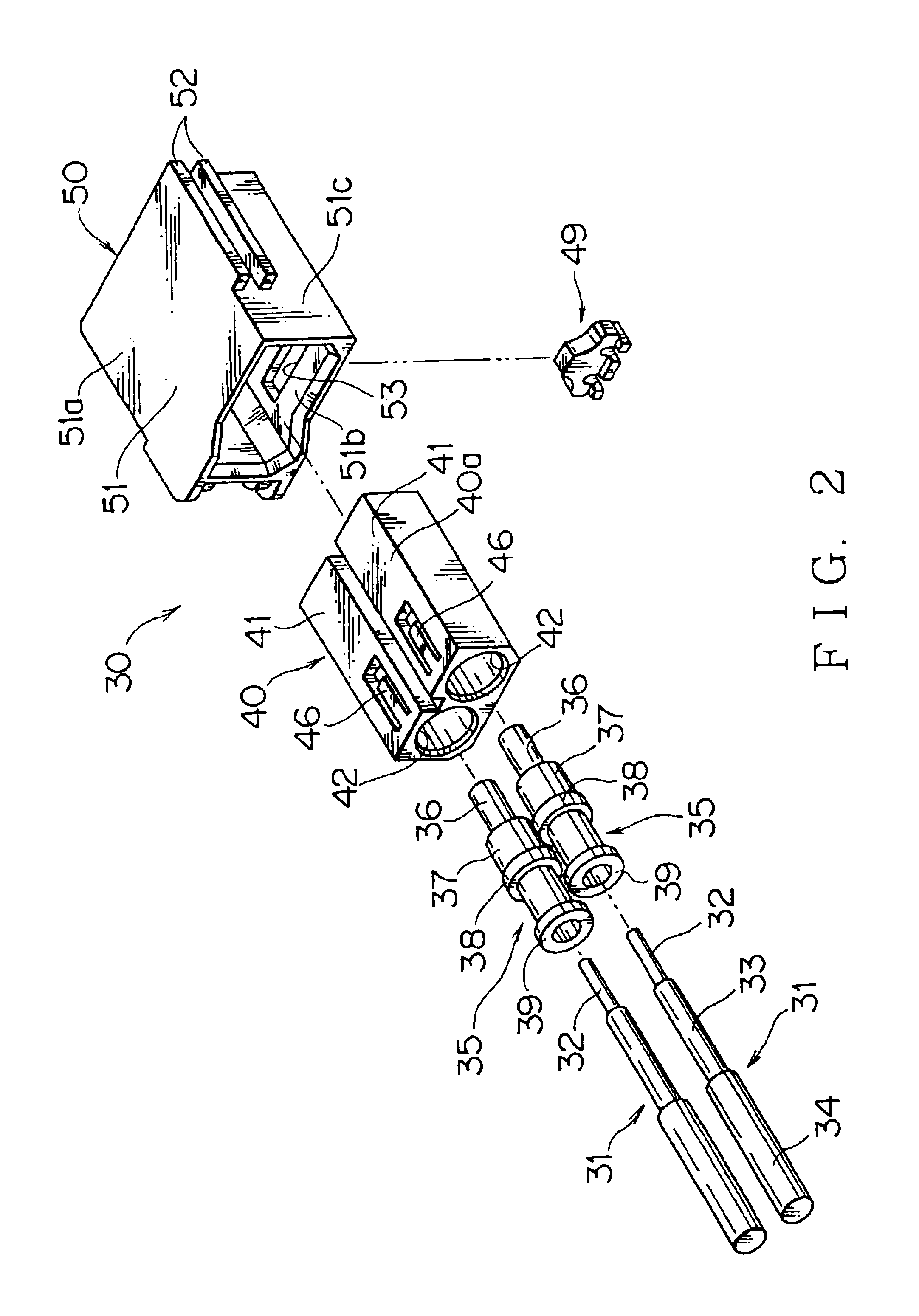

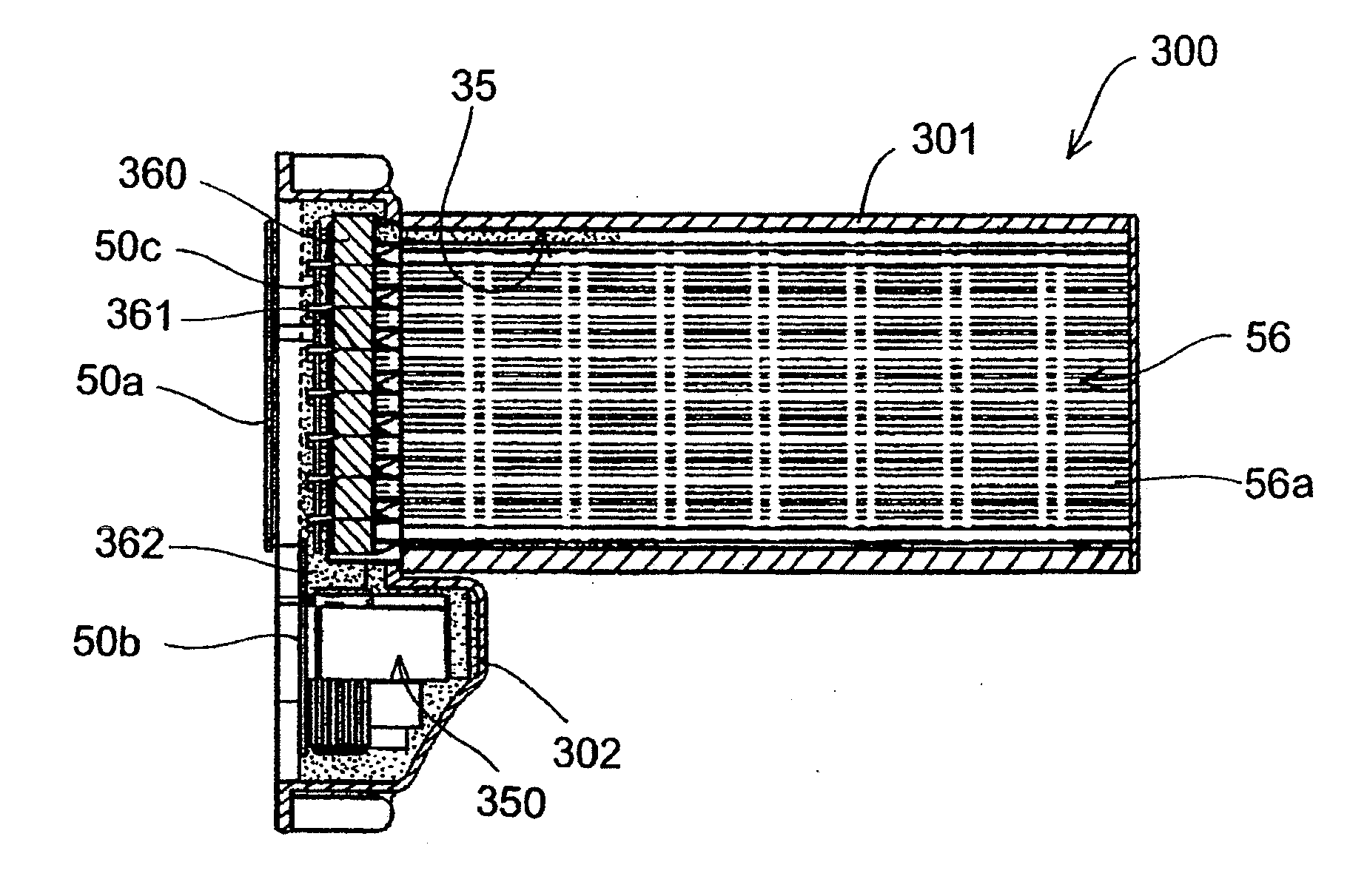

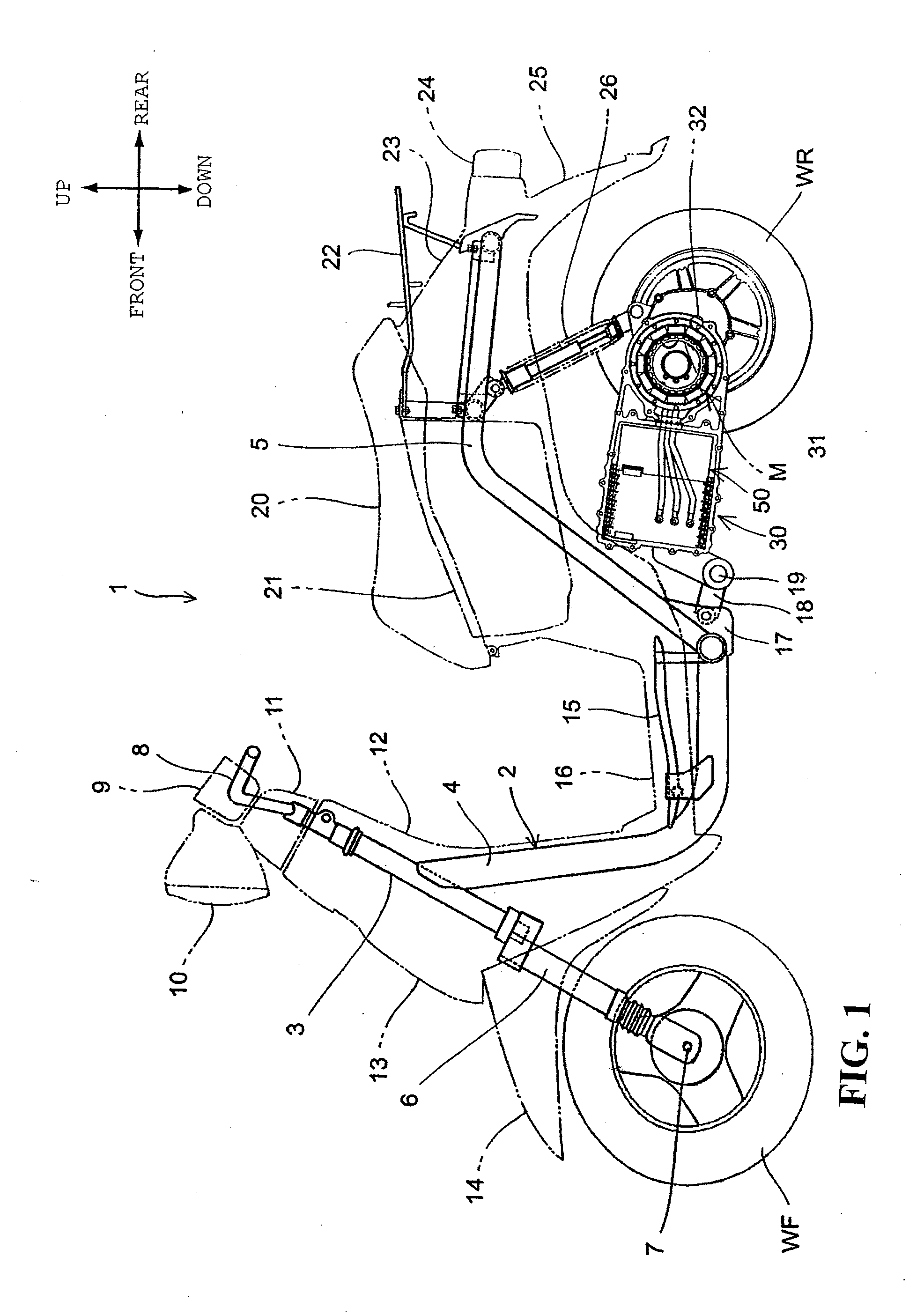

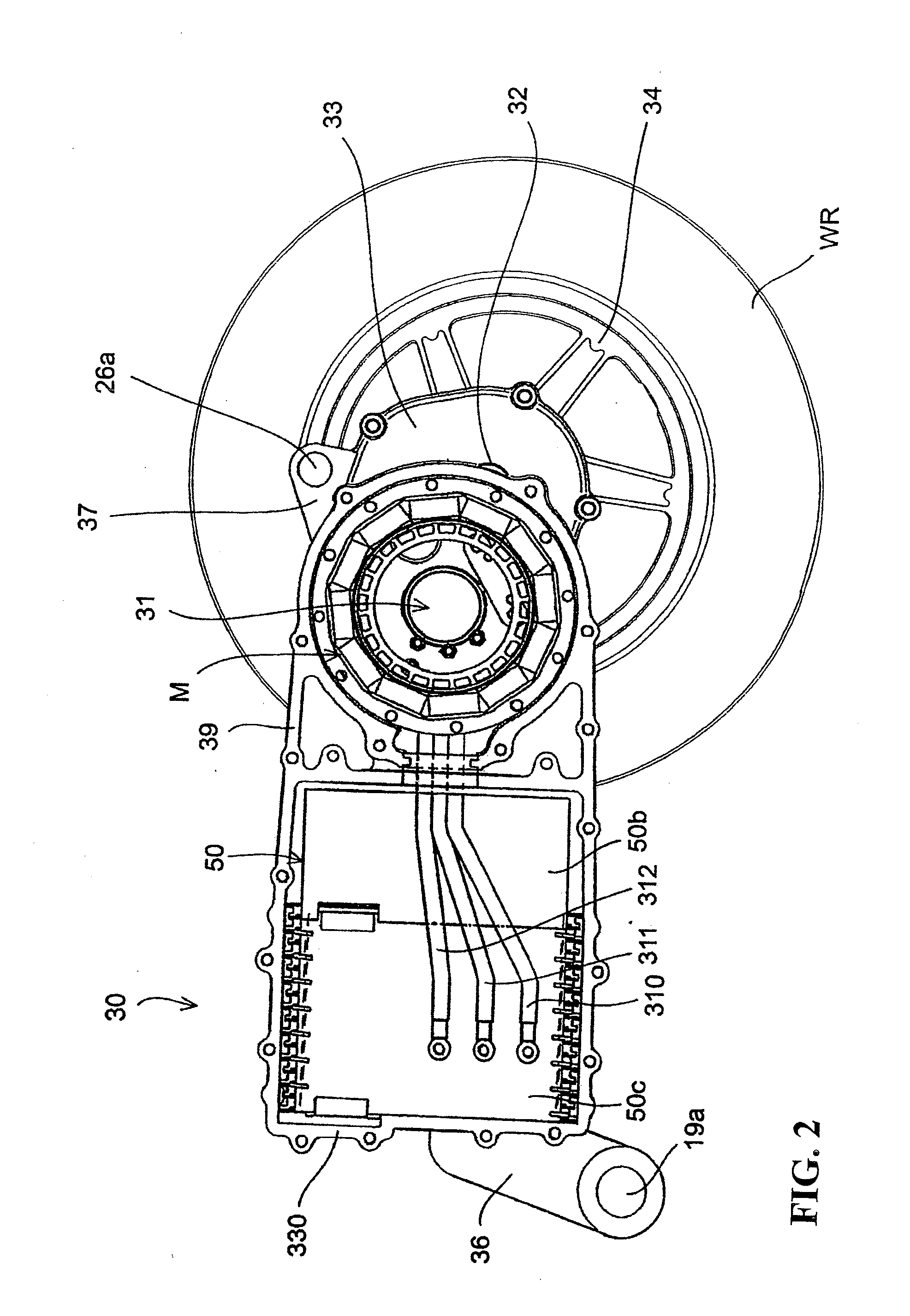

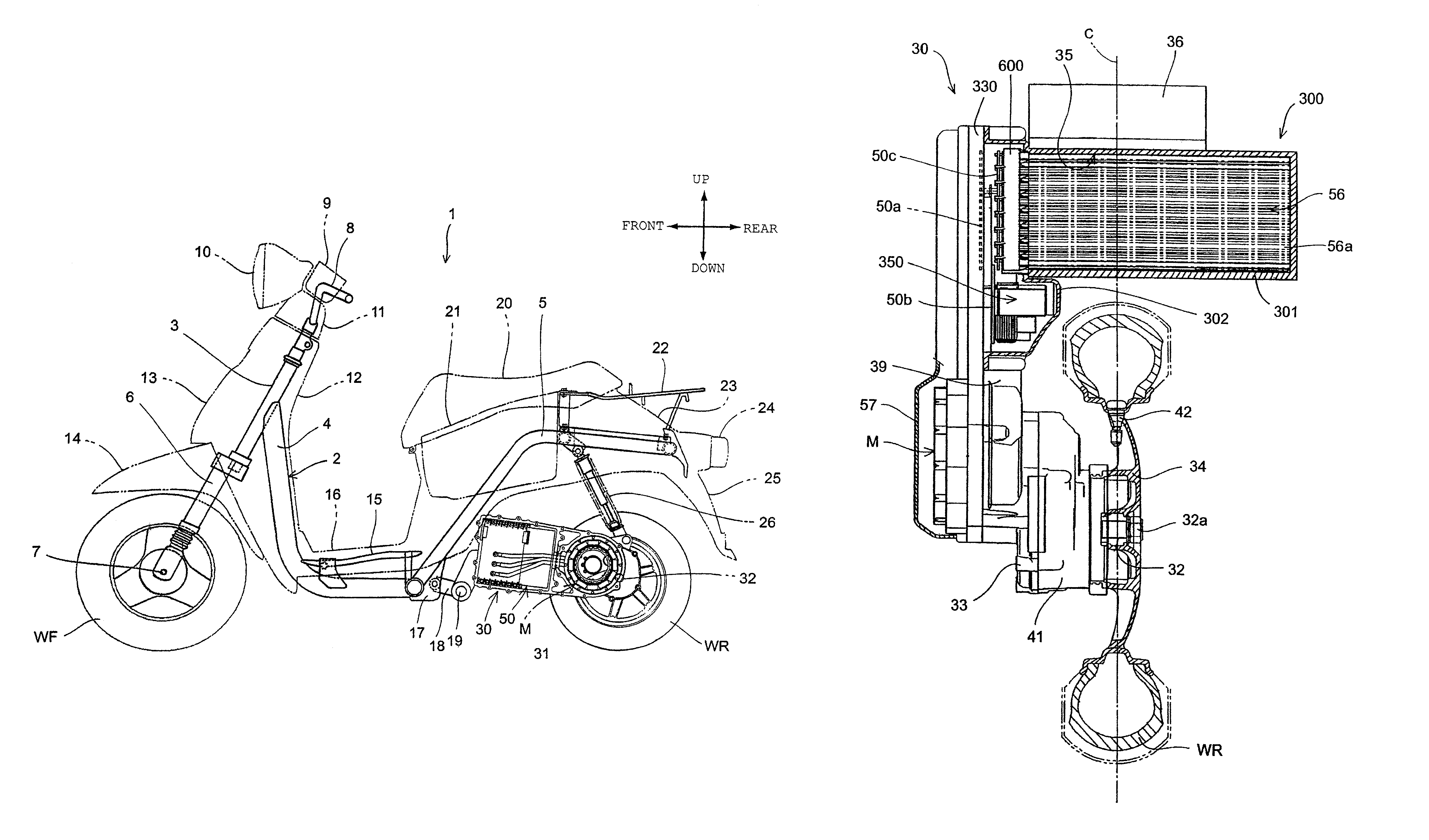

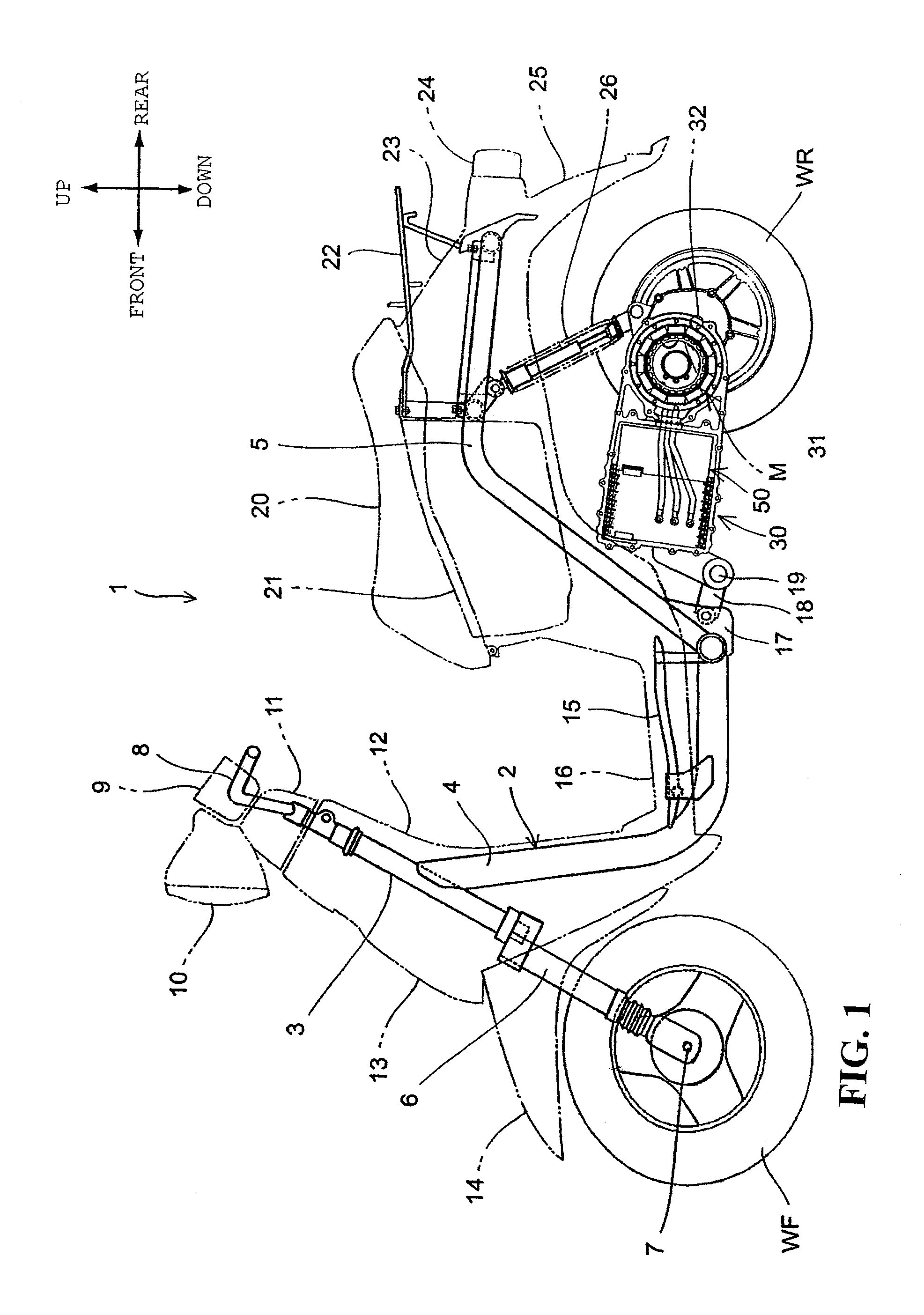

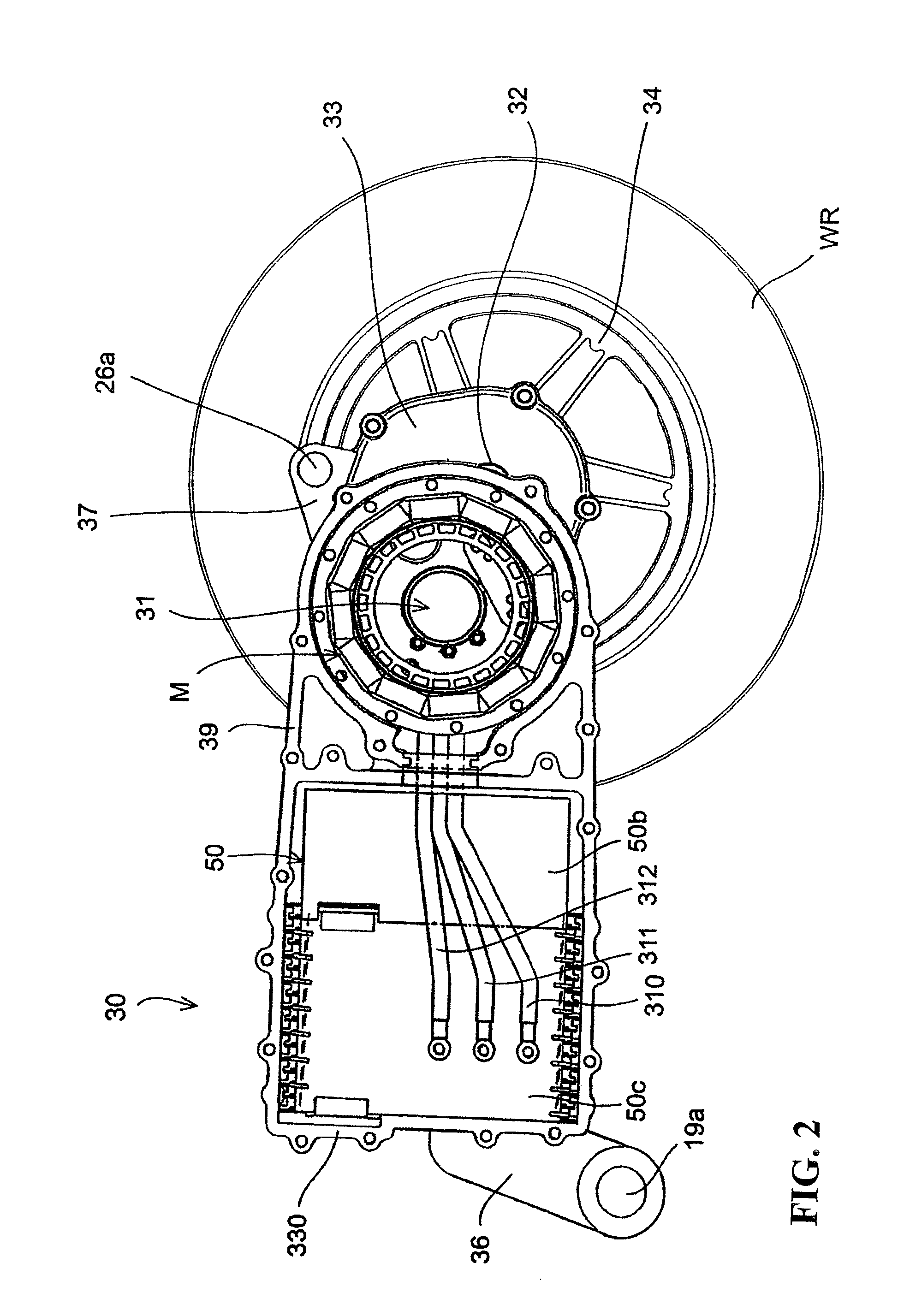

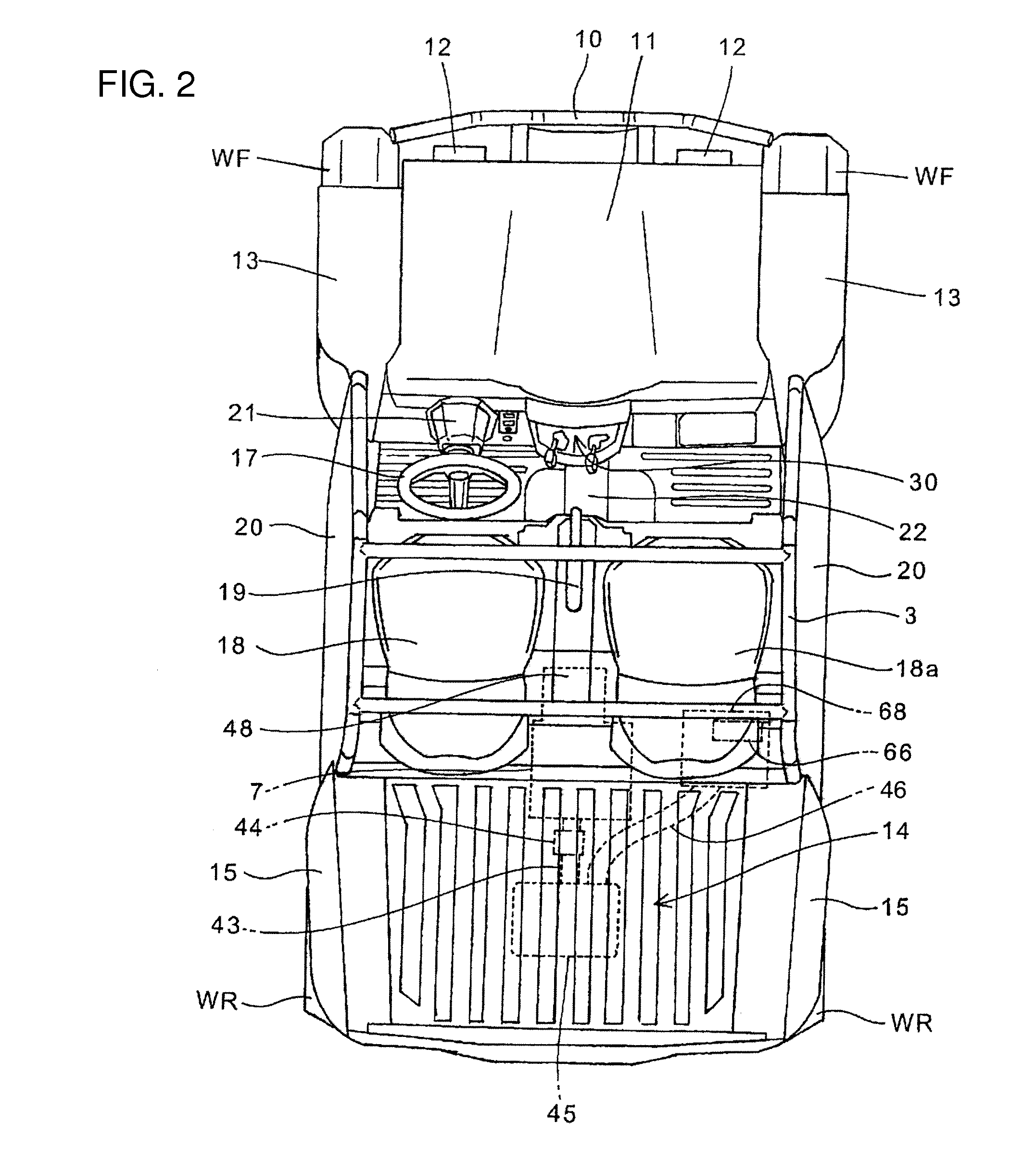

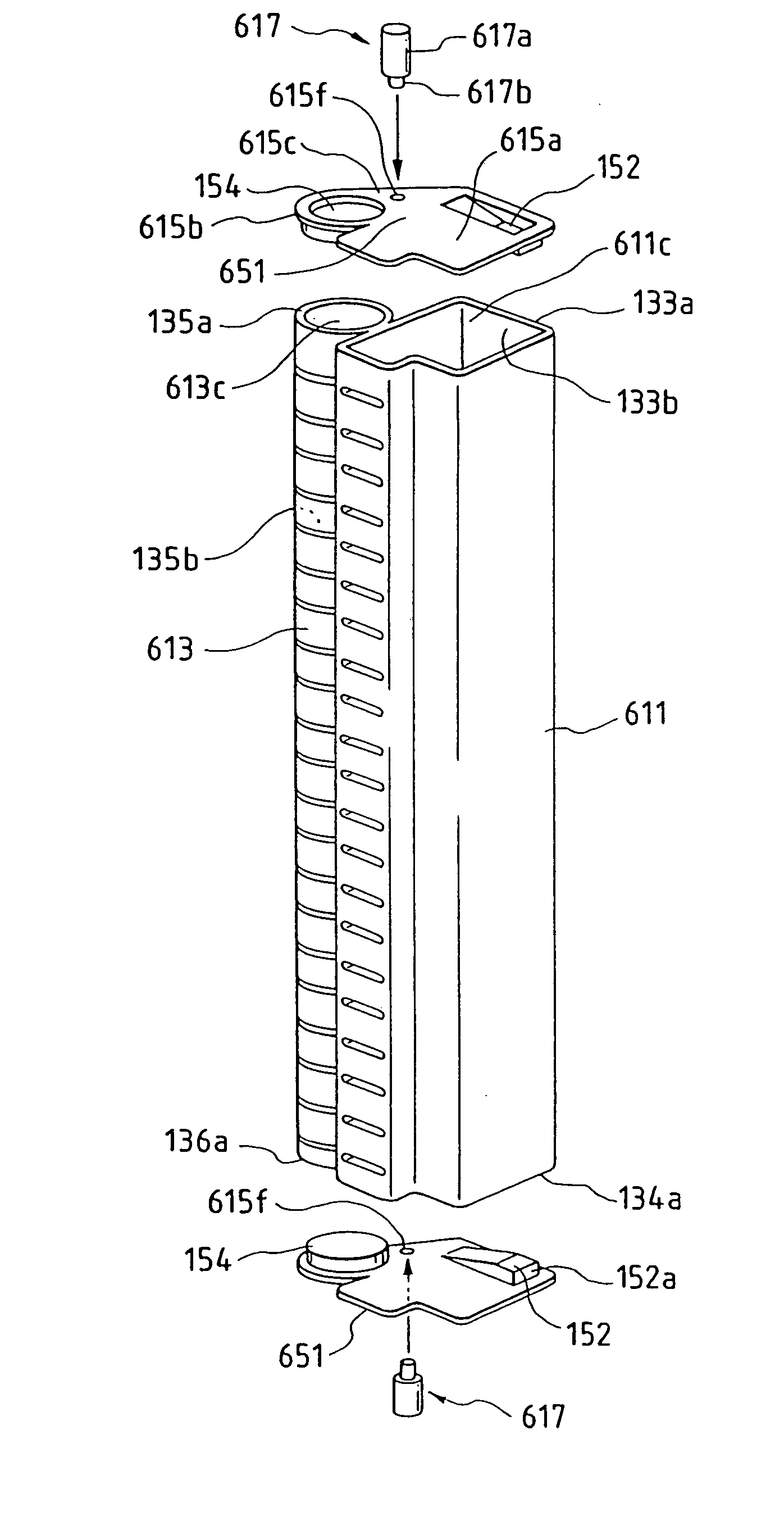

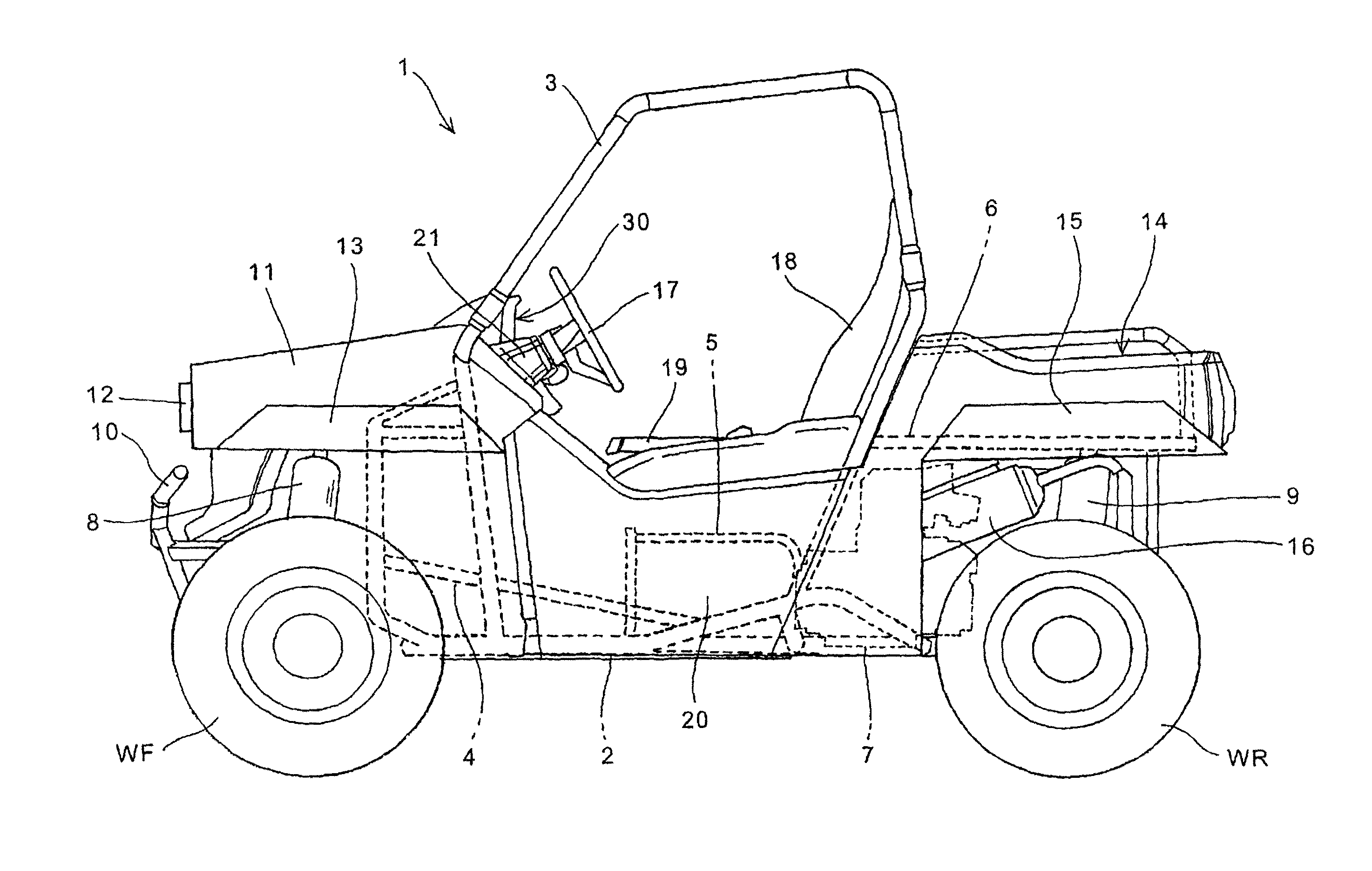

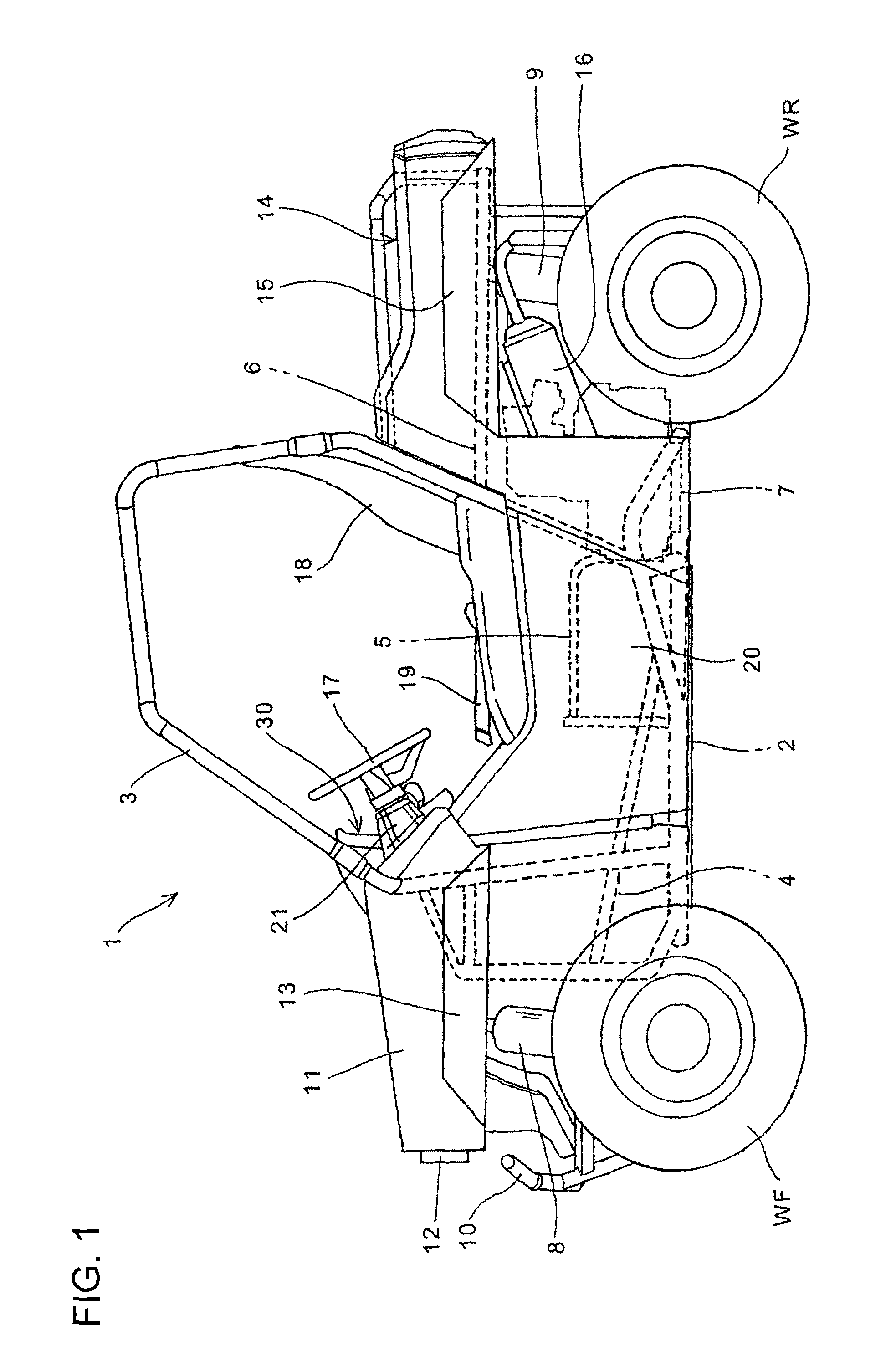

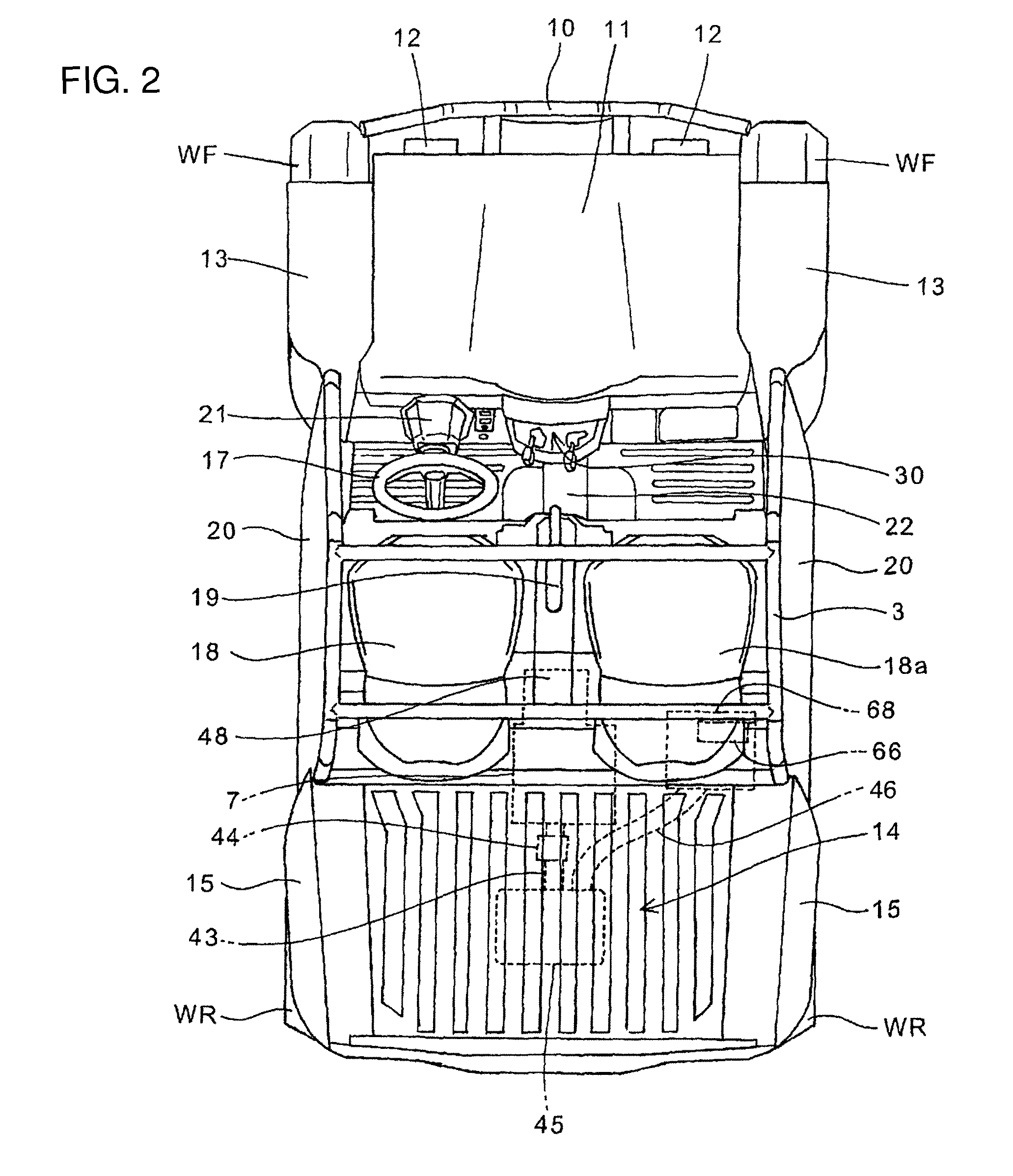

Battery module mounting structure for motor-driven two-wheeled vehicle

InactiveUS20120080254A1Simple designEasy to assembleMotorised scootersVehicle sub-unit featuresMotor driveElectric power

A battery module mounting structure includes a housing structure housing a battery supplying electric power to the electric motor of a motor-driven two-wheeled vehicle and a PDU controlling the electric motor. The housing case is configured to be mountable to and dismountable from the swing arm with the electric motor and a control substrate housed in the housing case. The swing arm is formed as a cantilever type in which an arm portion disposed on the vehicle-widthwise right or left of a rear wheel supports the rear wheel. The battery shaped in a rectangular parallelepiped is housed in the housing case with a longitudinal direction thereof facing in a vehicle-width direction. The housing case is mounted from a vehicle-widthwise inside on a lateral surface of a swing arm housing at a position vehicle-body-forward of the rear wheel and vehicle-body-rearward of a through-hole, the swing arm housing supporting the arm portion.

Owner:HONDA MOTOR CO LTD

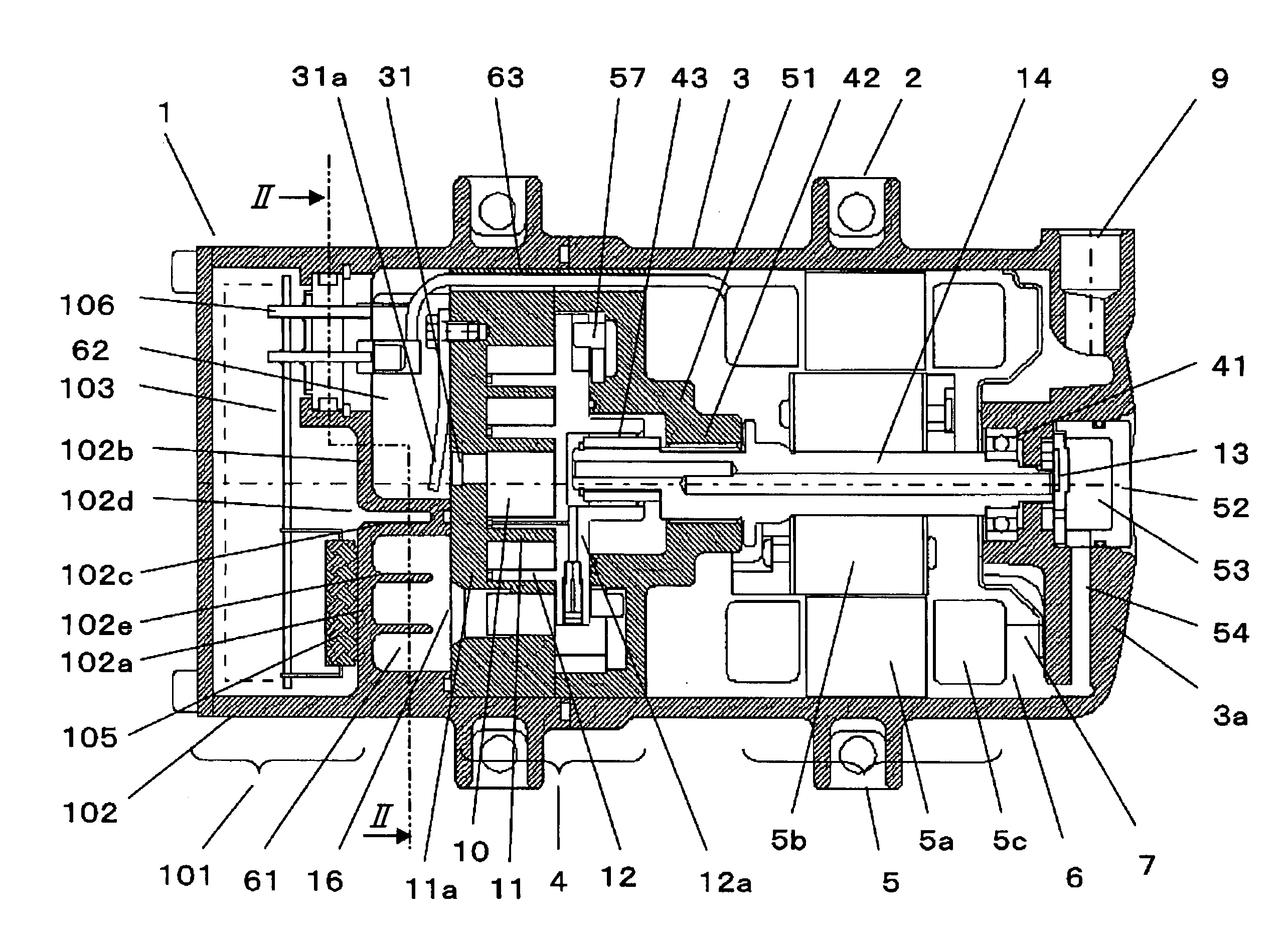

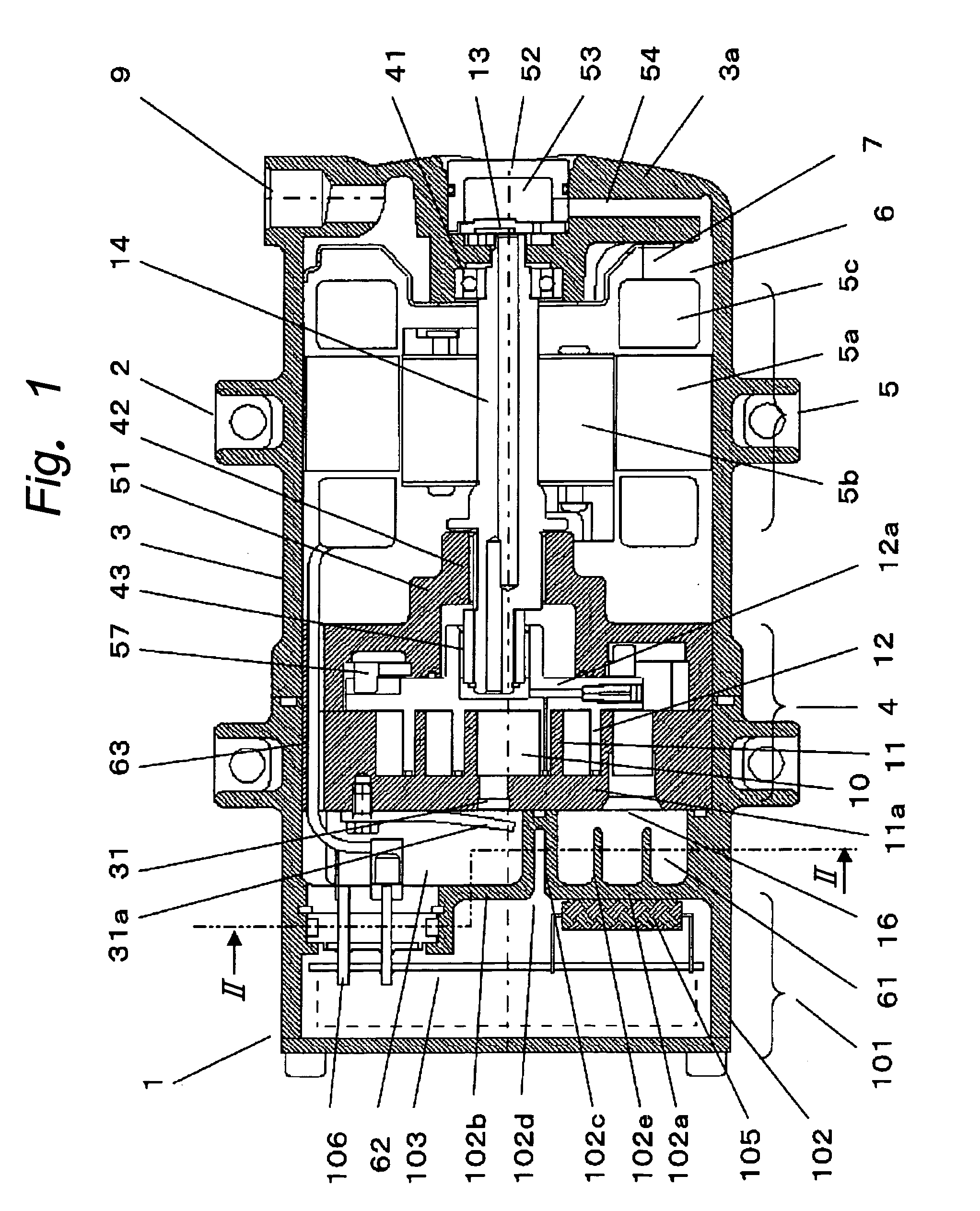

Electric compressor

InactiveUS7147443B2Increase in sizeImprove installabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsMotor driveDriving circuit

Owner:PANASONIC CORP

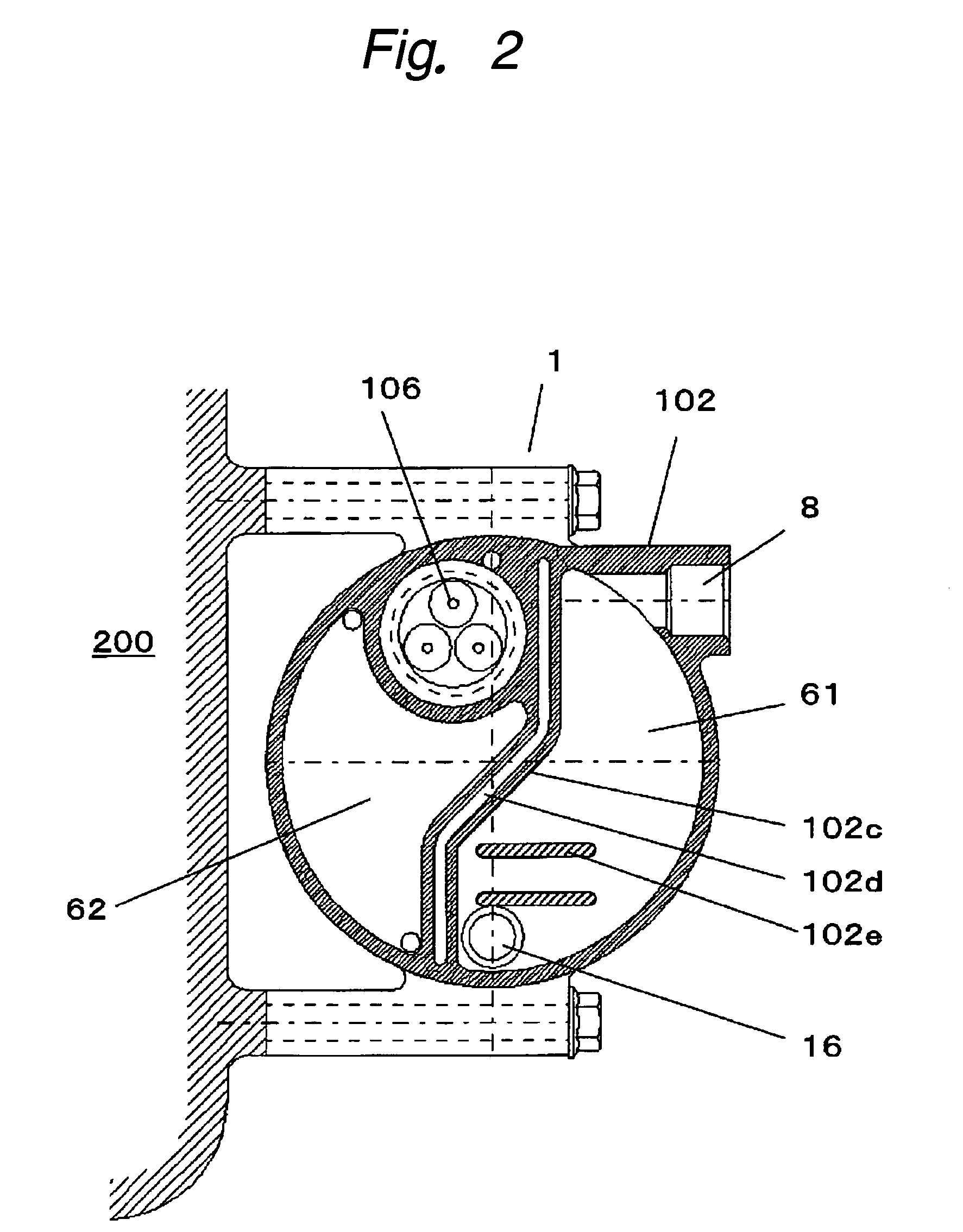

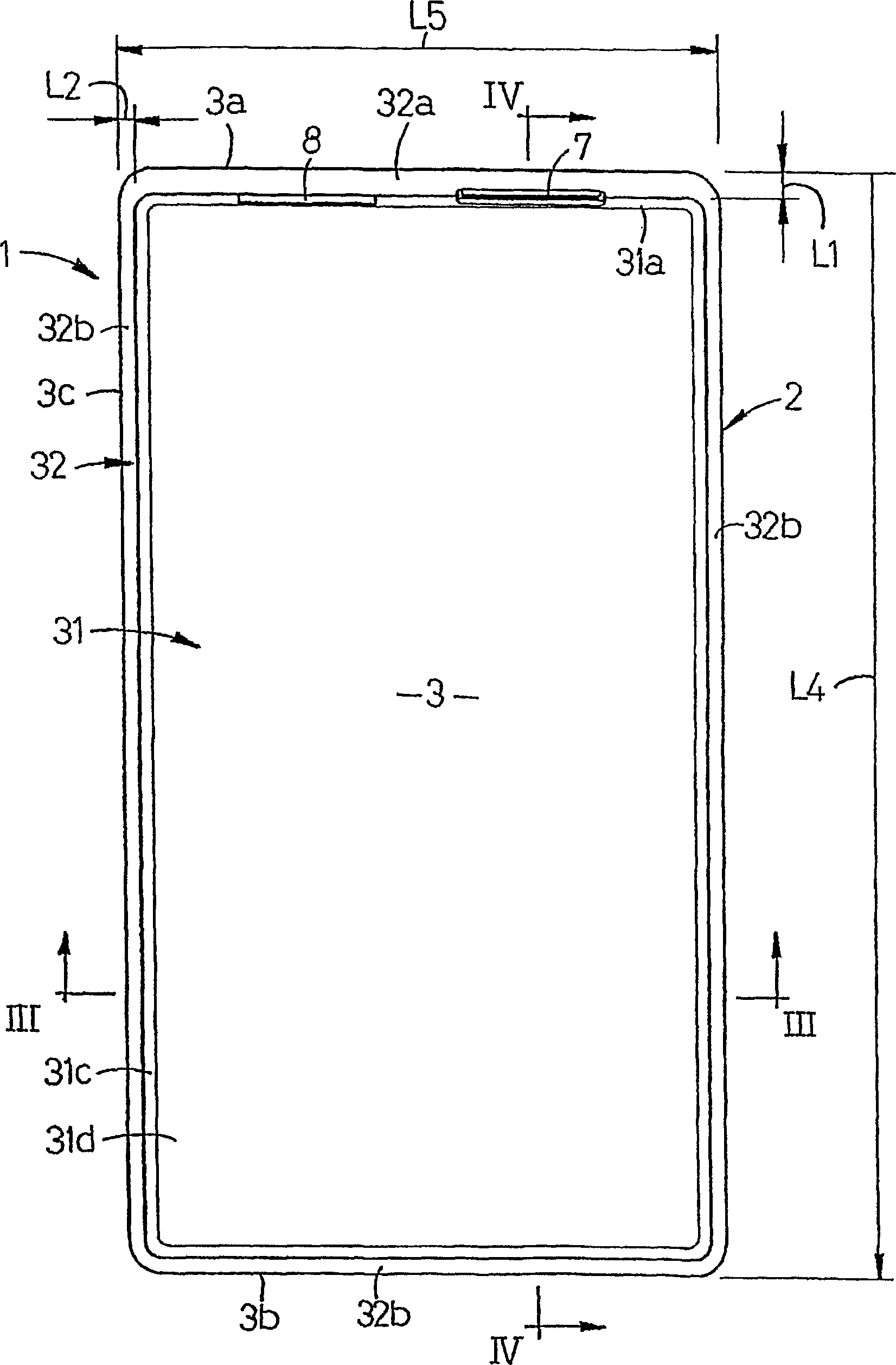

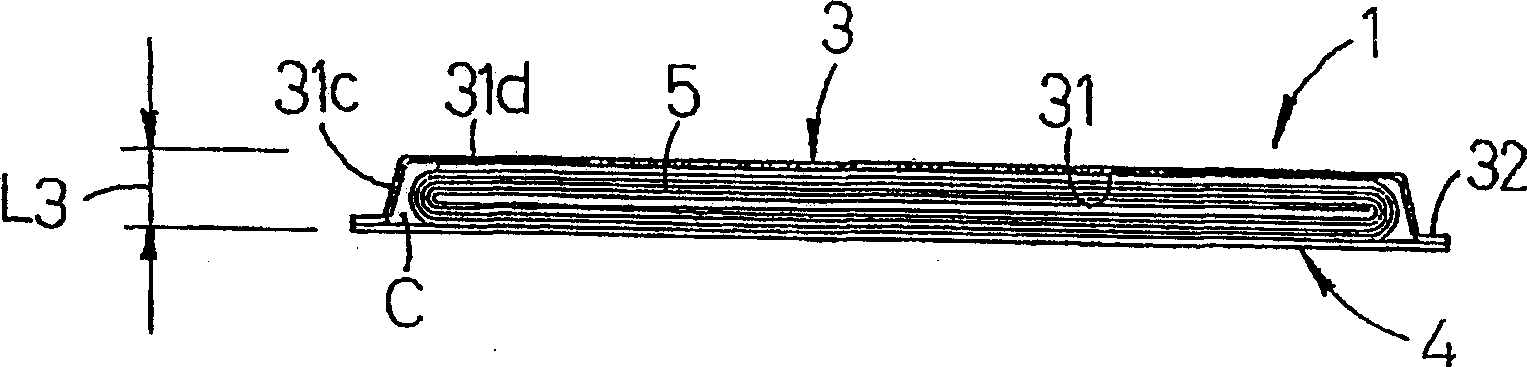

Battery

InactiveCN1526174AEasy to separateImprove installabilityFinal product manufactureCells structural combinationProduction rateMetal sheet

The present invention relates to a battery suitable for use as a power source of small electronic equipment such as portable electronic equipment, and in particular, to a configuration of a thin battery. A battery can (2) is composed of a can main body (3) formed with a recess (31) for receiving electrode bodies (5), and a metal cover (4) sealing the open end of the recess (31) in this can main body (3). The can main body (3) is dish-shaped by shallow-drawing a metal sheet. The peripheral edge of the open end of this can main body (3) is provided with a flange (32) capable of maintaining the interior of the recess (31) gas tight and liquid tight by being integrally joined to the metal cover (4). This makes it possible to provide a battery of novel construction that, in achieving the thinning the battery, is capable of solving the problems liable to occur in all aspects including shape, attachability, strength, and productivity, all at once.

Owner:HITACHI MAXELL ENERGY LTD

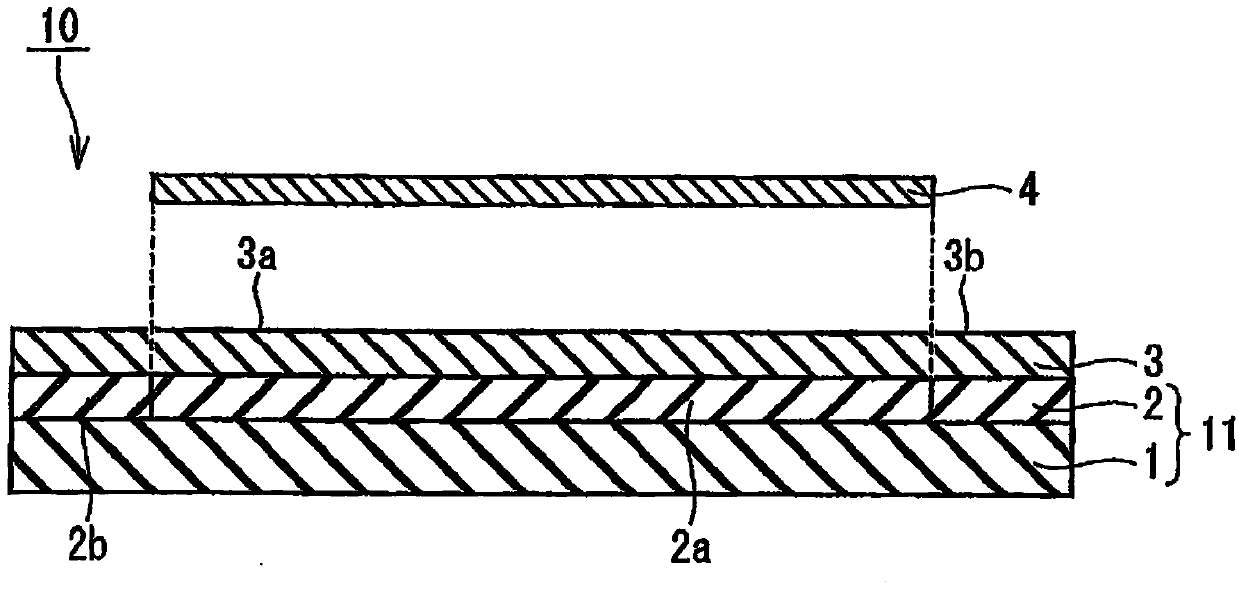

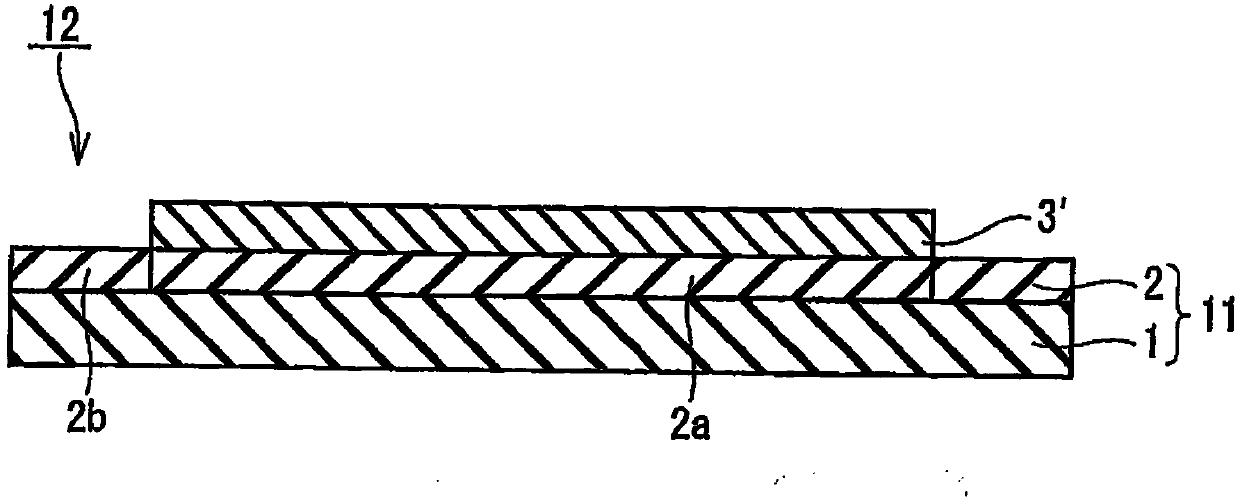

Film adhesive, dicing tape with film adhesive, method of manufacturing semiconductor device, and semiconductor device

InactiveCN103992755AAvoid thermal influenceWarpage suppressionNon-macromolecular adhesive additivesFilm/foil adhesivesDicing tapeDevice material

The present invention provides a film adhesive that can prevent a thermal effect to a semiconductor wafer and that can suppress warping of the semiconductor wafer; a dicing tape with a film adhesive; and a method of manufacturing a semiconductor device. The present invention relates to a film adhesive comprising a thermoplastic resin and electrically conductive particles, the film adhesive having an adhesion strength measured at 25°C after the film adhesive is pasted to a mirror silicon wafer at 40°C of 0.5 N / 10 mm or more.

Owner:NITTO DENKO CORP

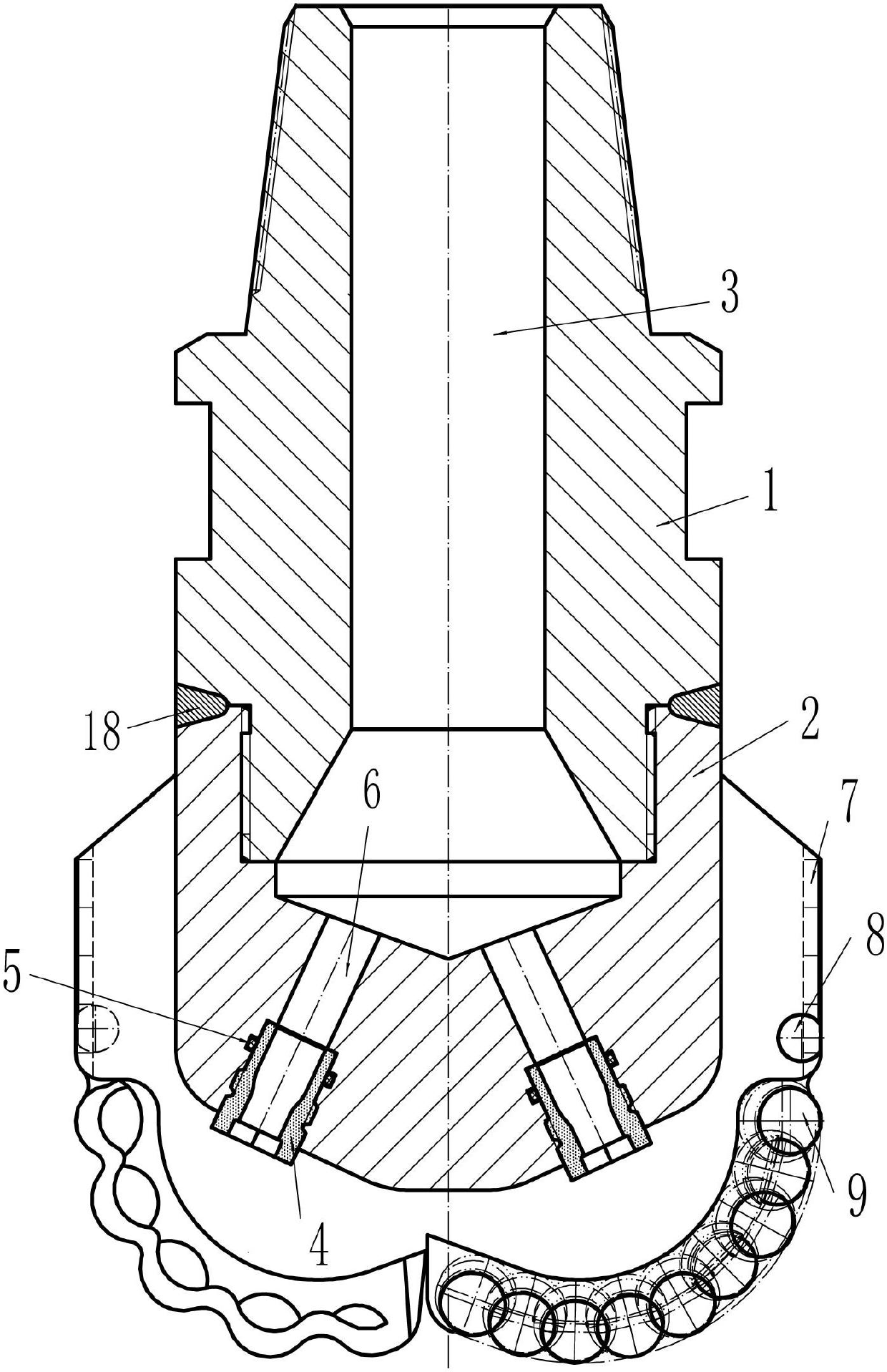

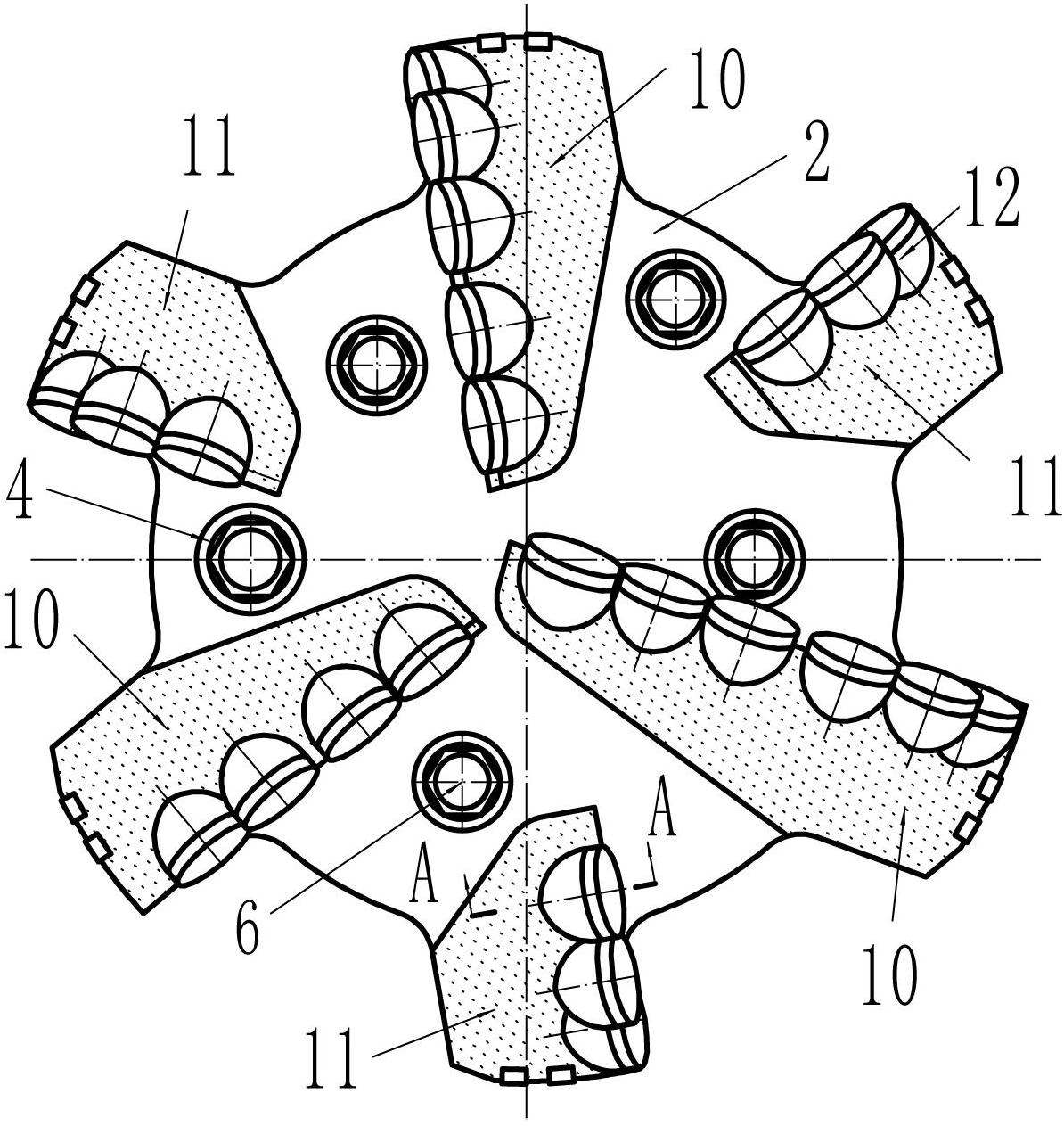

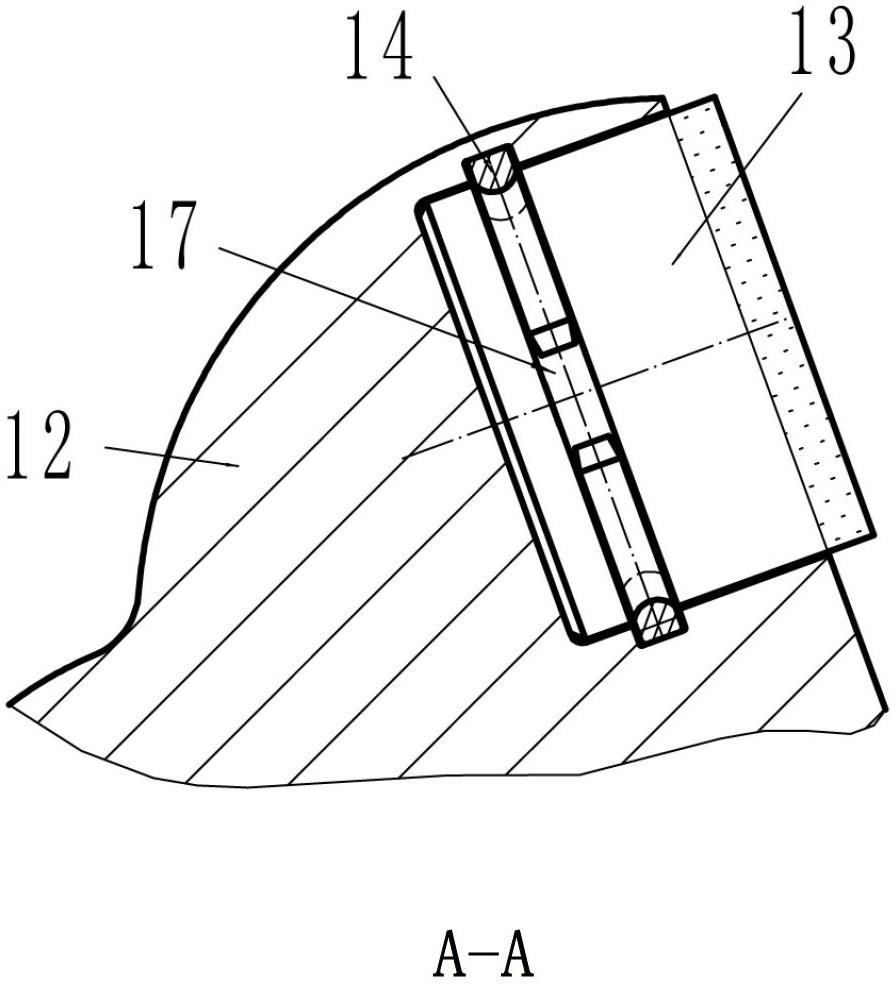

Cold-fixed PDC (polycrystalline diamond compact) bit

ActiveCN102678056AAvoid thermal influenceOvercoming the disadvantages of wear and tearDrill bitsConstructionsPolycrystalline diamondEngineering

The invention discloses a cold-fixed PDC (polycrystalline diamond compact) bit. PDCs with slots are in clearance fit with and fixed in tooth post holes by check rings or stop pins to form cutting teeth, so that the heat influence on the PDCs by the braze welding is avoided, and simple maintenance and replacement of onsite PDCs are realized; when rock is broken in a well, the counter force of the rock drives circumferential conversion working surfaces of the PDCs in the composite tooth posts to rotate, as a result, the defect of abrasion of fixed working surfaces of the PDC bit is overcome, cutting edges are kept sharp during the whole cutting processing, the application stratum scope of the PDC bit is also widened, at the same time, the heat damage on the PDCs during the manufacture process of the bit can be avoided, and the abrasion resistance and the thermal stability of the product are improved. The abrasion resistance of the cutting edges is 13.5 times of that of the standard cutting edge, the whole service life of the bit can be prolonged for 3 to 5 times, and the demand of continuous development in the drilling field is satisfied.

Owner:三原石油钻头厂

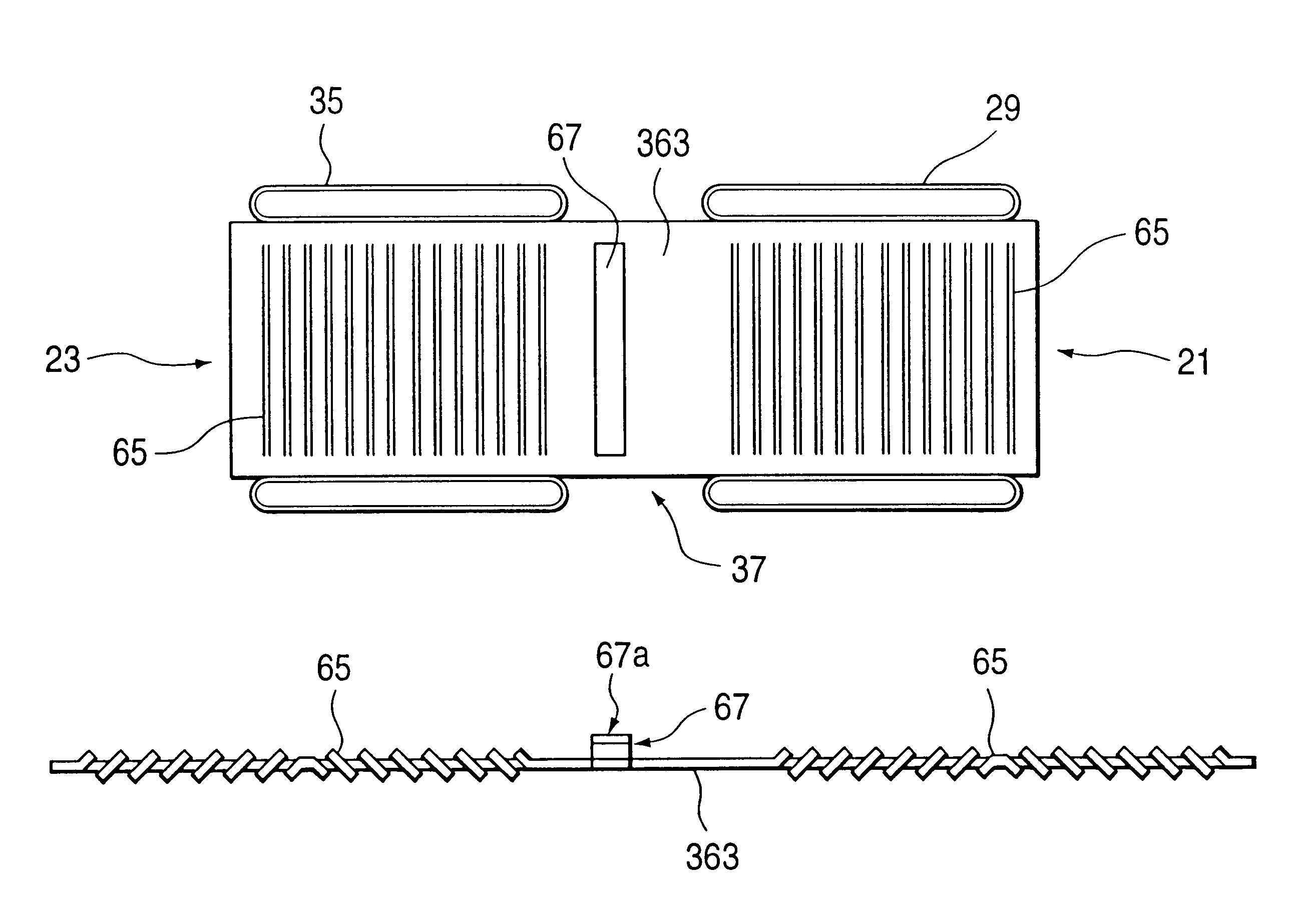

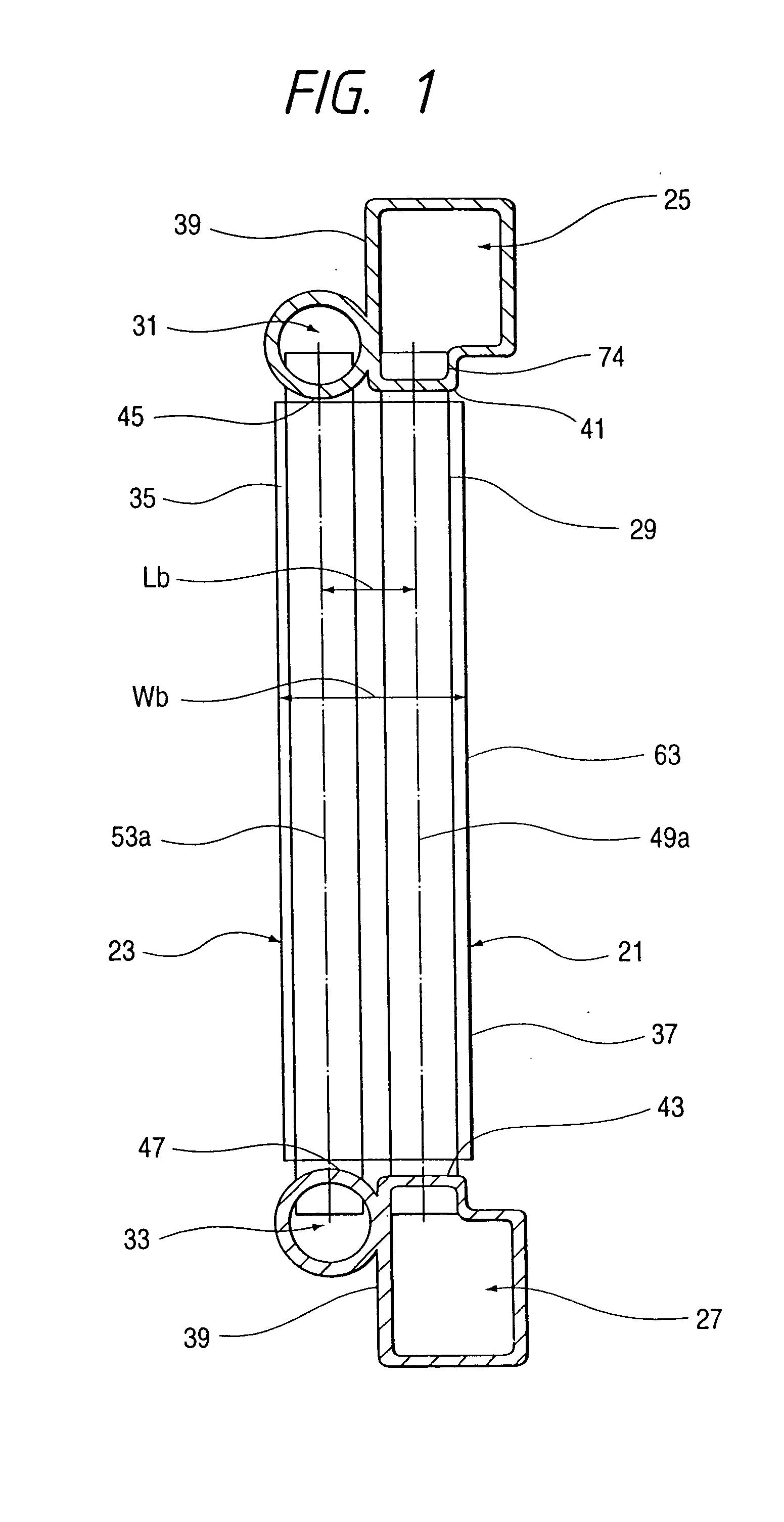

Integral-type heat exchanger

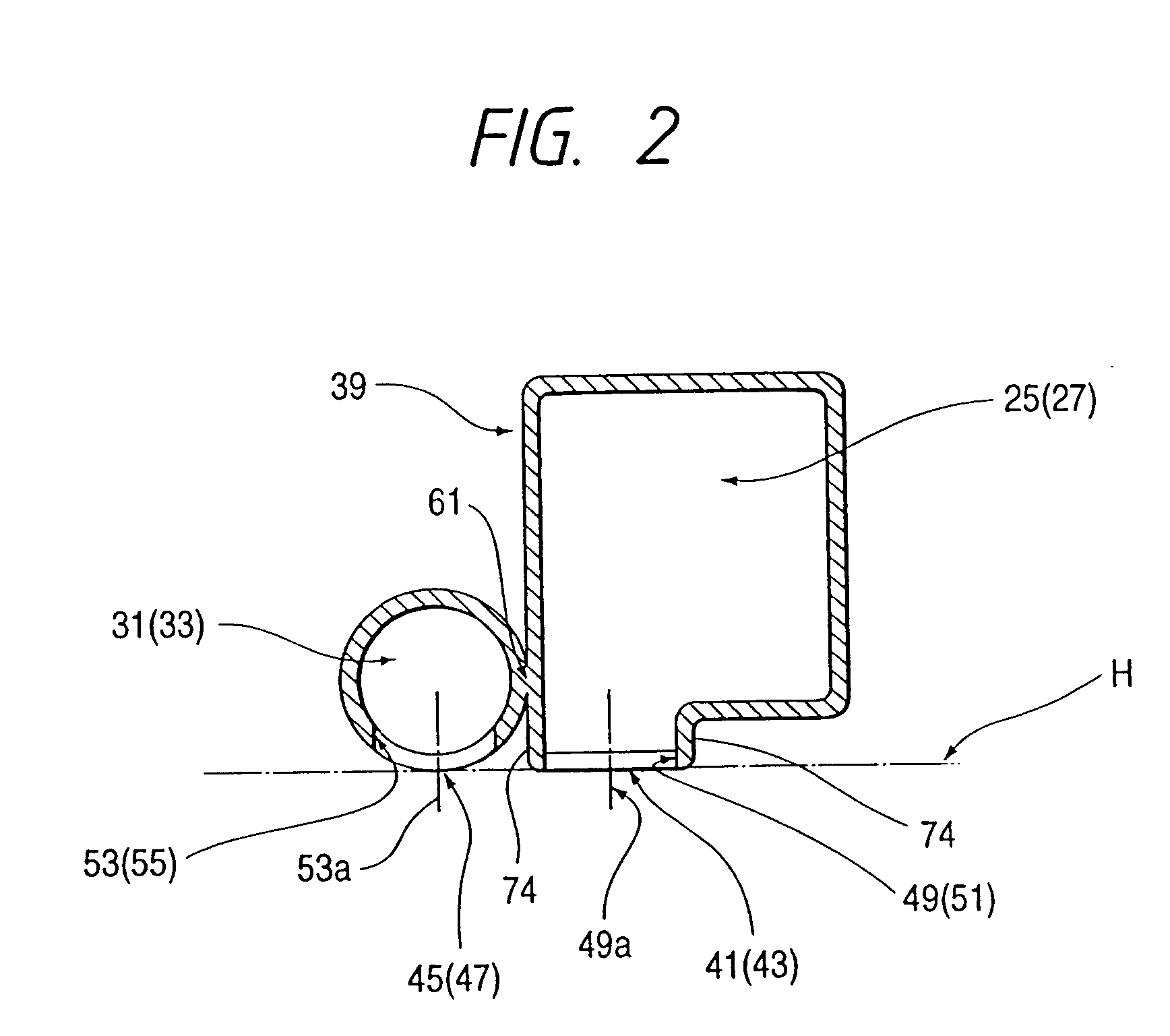

InactiveUS6837304B2Reduce thicknessSimple structureClosure meansHeat exhanger finsPlate heat exchangerEngineering

Tanks of a first heat exchanger have plane sections perpendicular to bottoms having a plurality of tube insertion holes formed therein. Tanks of a second heat exchanger with circular cross sections have bottoms having a plurality of tube insertion holes formed therein. The axes of the tube insertion holes of the first and second heat exchangers are held in parallel with each other. The second heat exchanger is in contact with the plane sections of the first heat exchanger tank.

Owner:CALSONIC KANSEI CORP

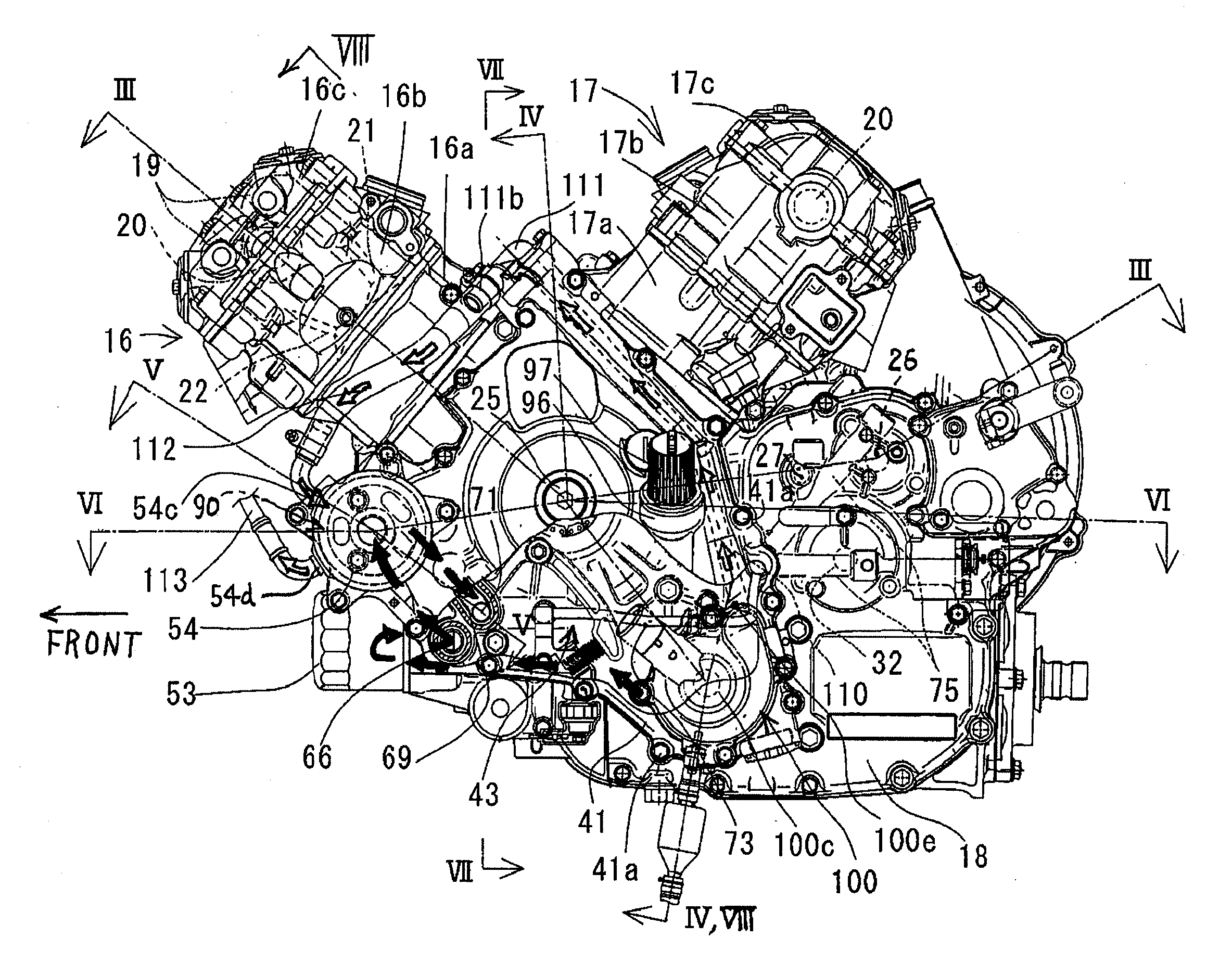

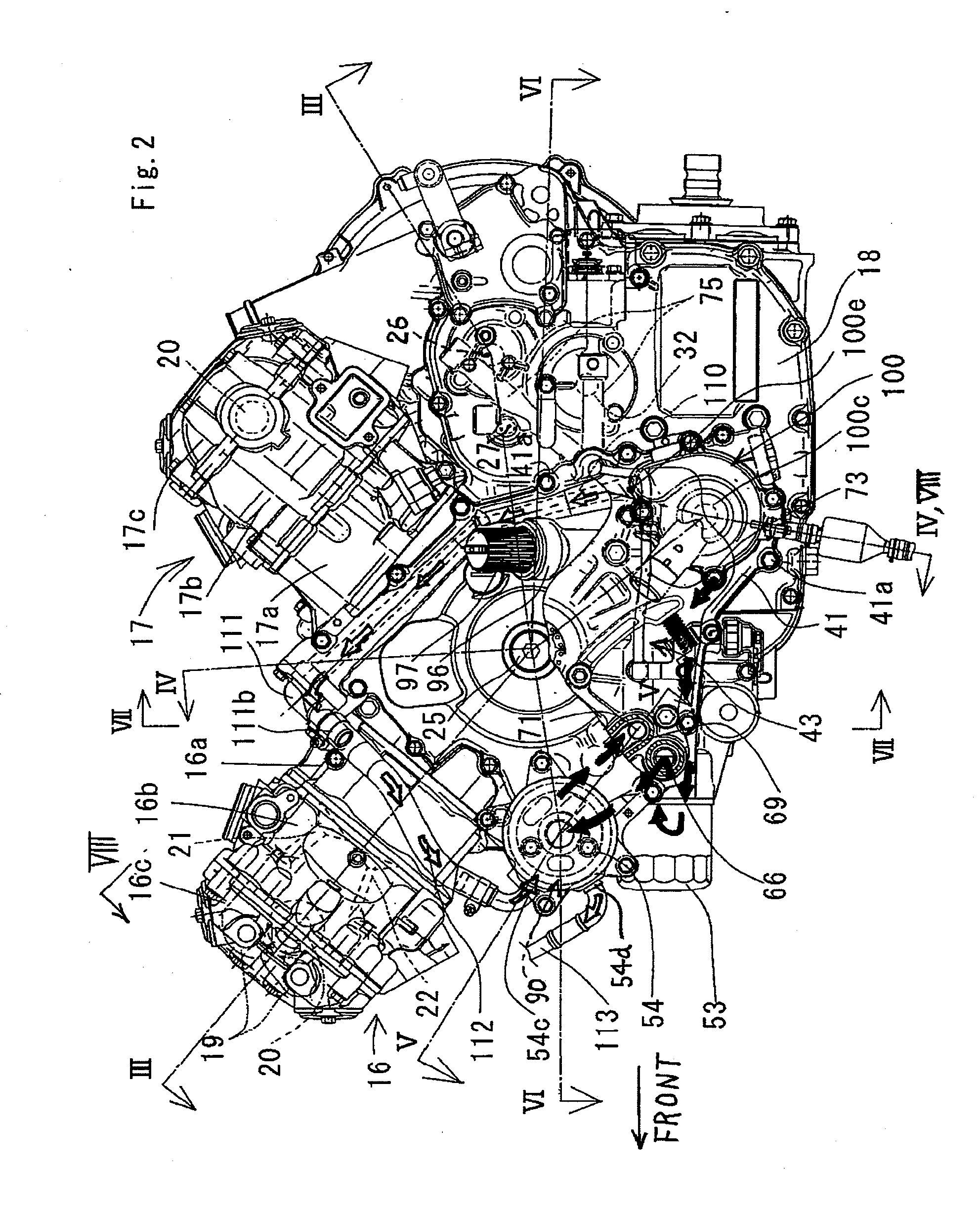

Lubricating oil feeding structure of engine

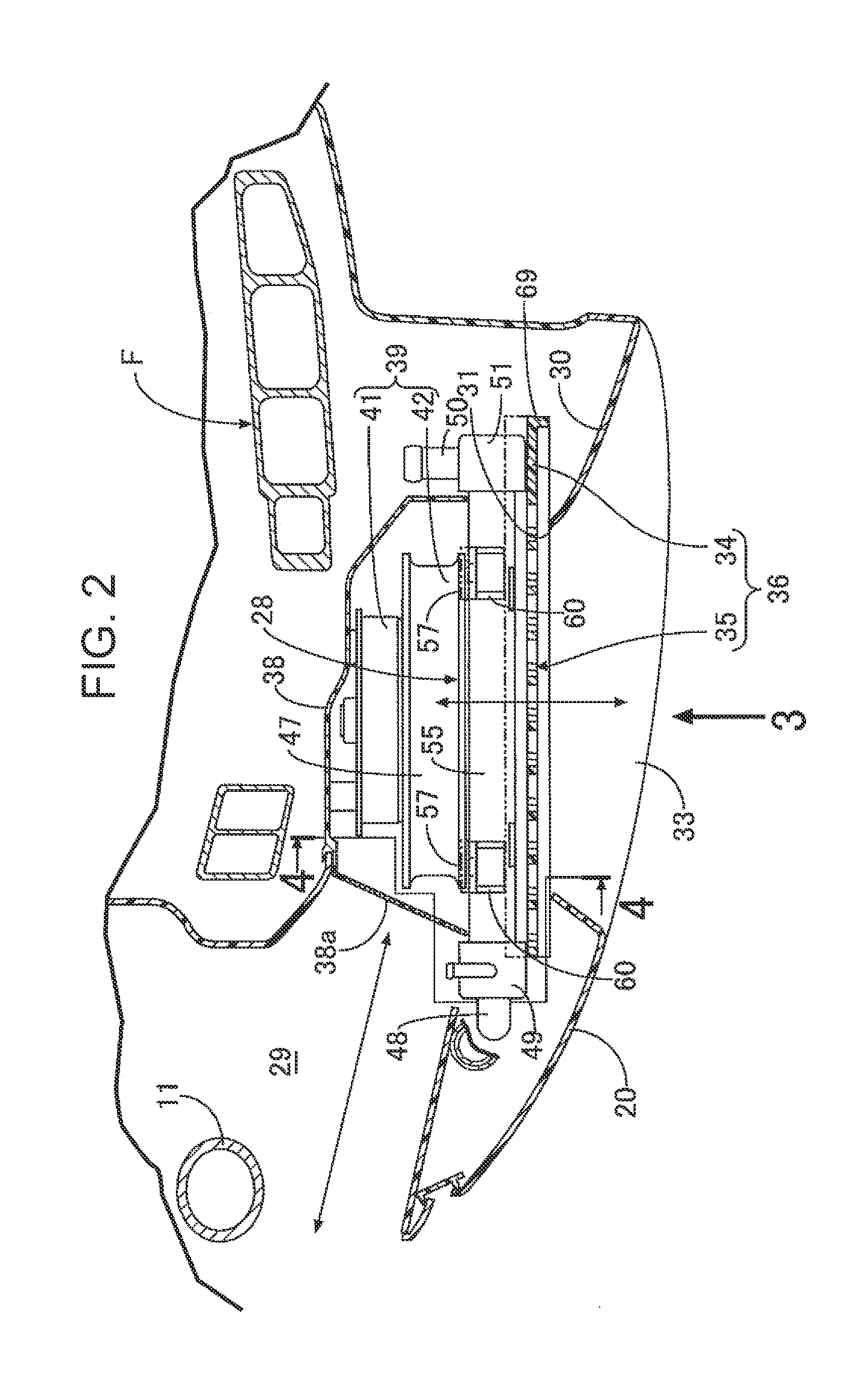

ActiveUS20120160208A1Avoid thermal influenceGood adhesionLubricant conduit arrangementsMachines/enginesFuel tankCrankcase

A lubricating oil feeding structure of an engine includes an oil pump provided in a crankcase for pressurizing and feeding oil in an oil reservoir, an oil filter provided in an outer peripheral wall of the crankcase for purifying the oil fed from the oil pump, and an oil cooler provided in a cover member covering an end of the crankcase in the crankshaft direction for cooling the oil sent from the oil filter. Preferably, the cover member is a generator cover, and the oil cooler is arranged on the outer side in the radial direction of a rotor of the generator.

Owner:KAWASAKI MOTORS LTD

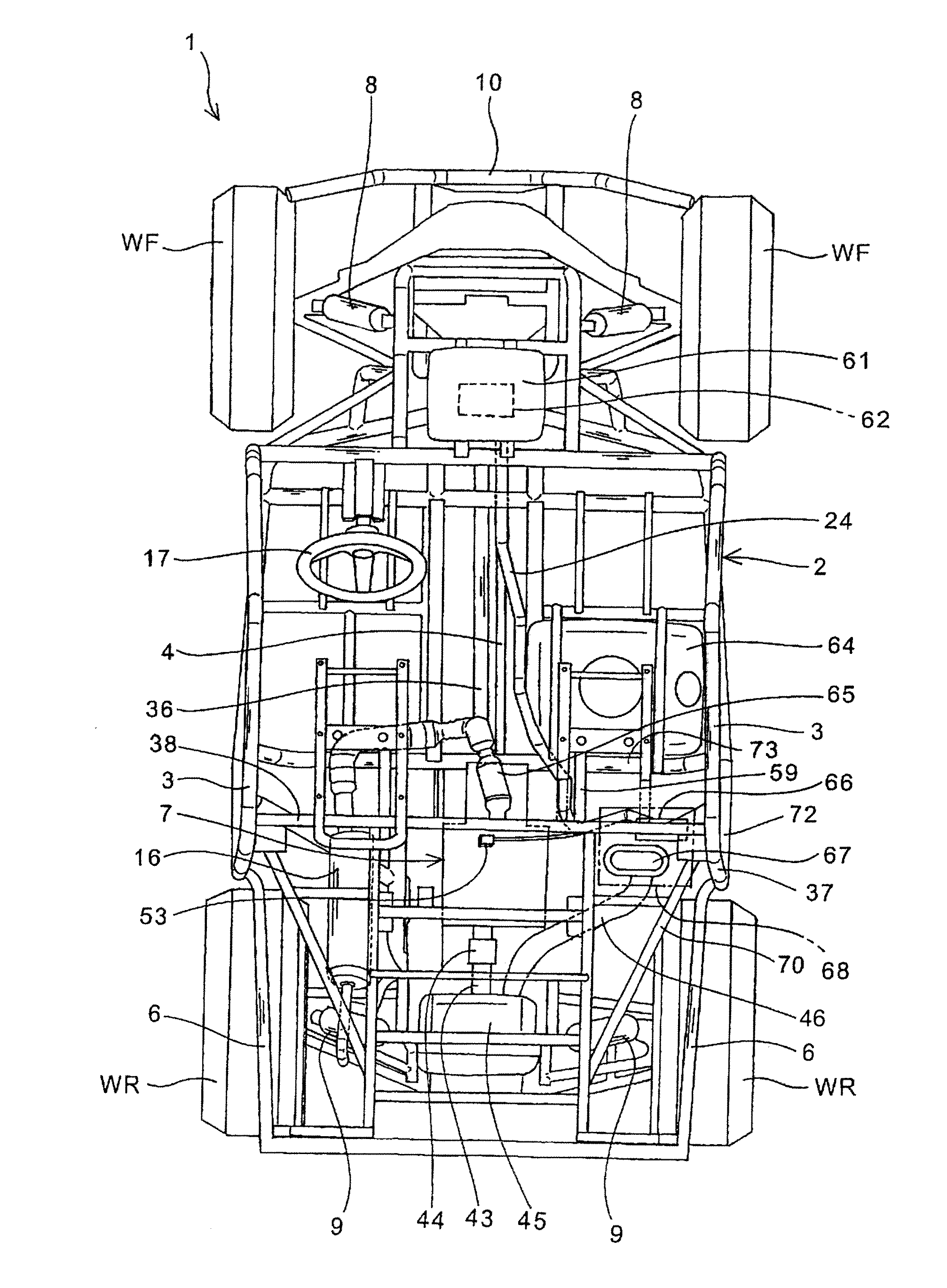

Battery module mounting structure for motor-driven two-wheeled vehicle

InactiveUS8813891B2Simple designEasy to assembleMotorised scootersVehicle sub-unit featuresMotor driveElectric power

A battery module mounting structure includes a housing structure housing a battery supplying electric power to the electric motor of a motor-driven two-wheeled vehicle and a PDU controlling the electric motor. The housing case is configured to be mountable to and dismountable from the swing arm with the electric motor and a control substrate housed in the housing case. The swing arm is formed as a cantilever type in which an arm portion disposed on the vehicle-widthwise right or left of a rear wheel supports the rear wheel. The battery shaped in a rectangular parallelepiped is housed in the housing case with a longitudinal direction thereof facing in a vehicle-width direction. The housing case is mounted from a vehicle-widthwise inside on a lateral surface of a swing arm housing at a position vehicle-body-forward of the rear wheel and vehicle-body-rearward of a through-hole, the swing arm housing supporting the arm portion.

Owner:HONDA MOTOR CO LTD

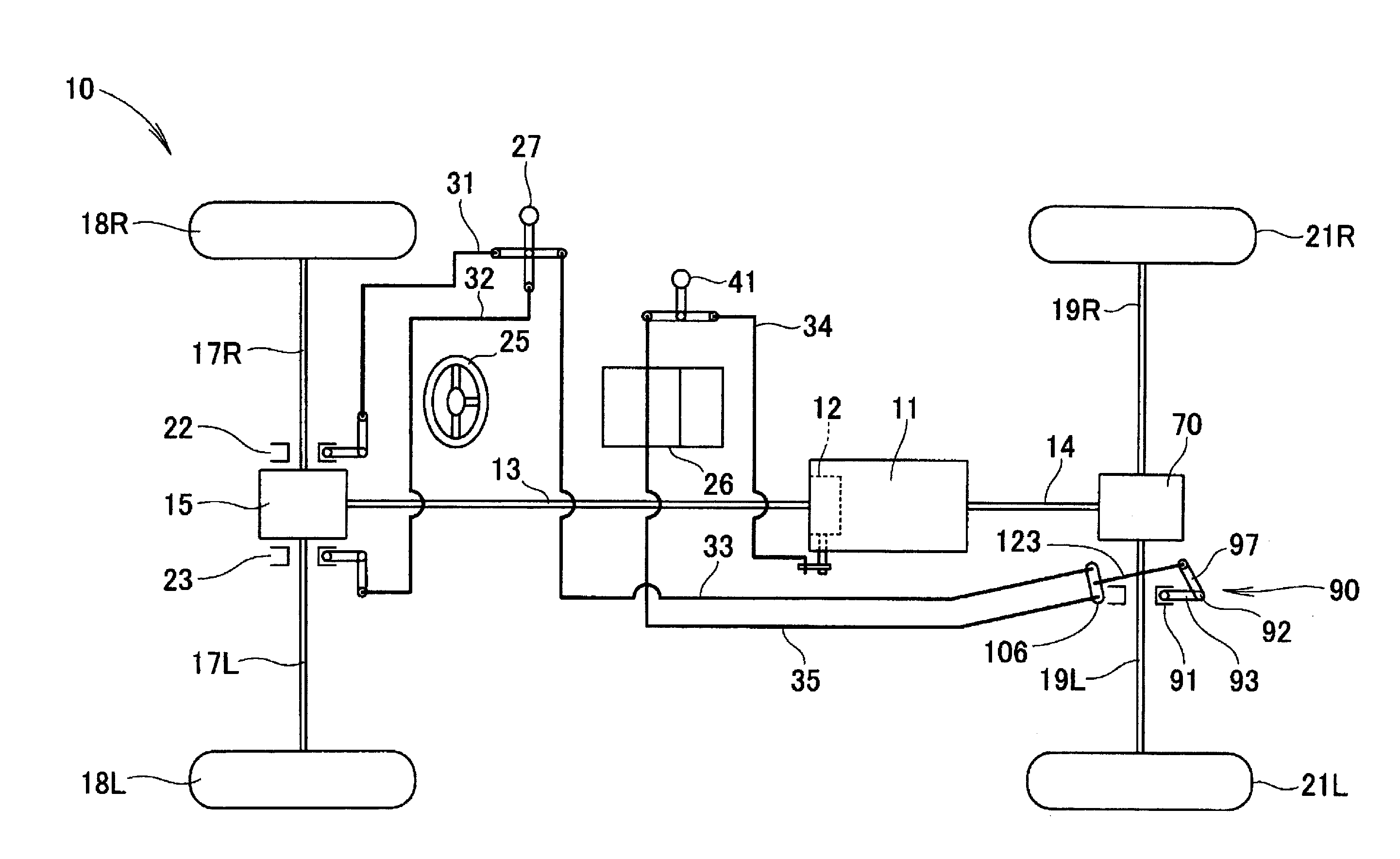

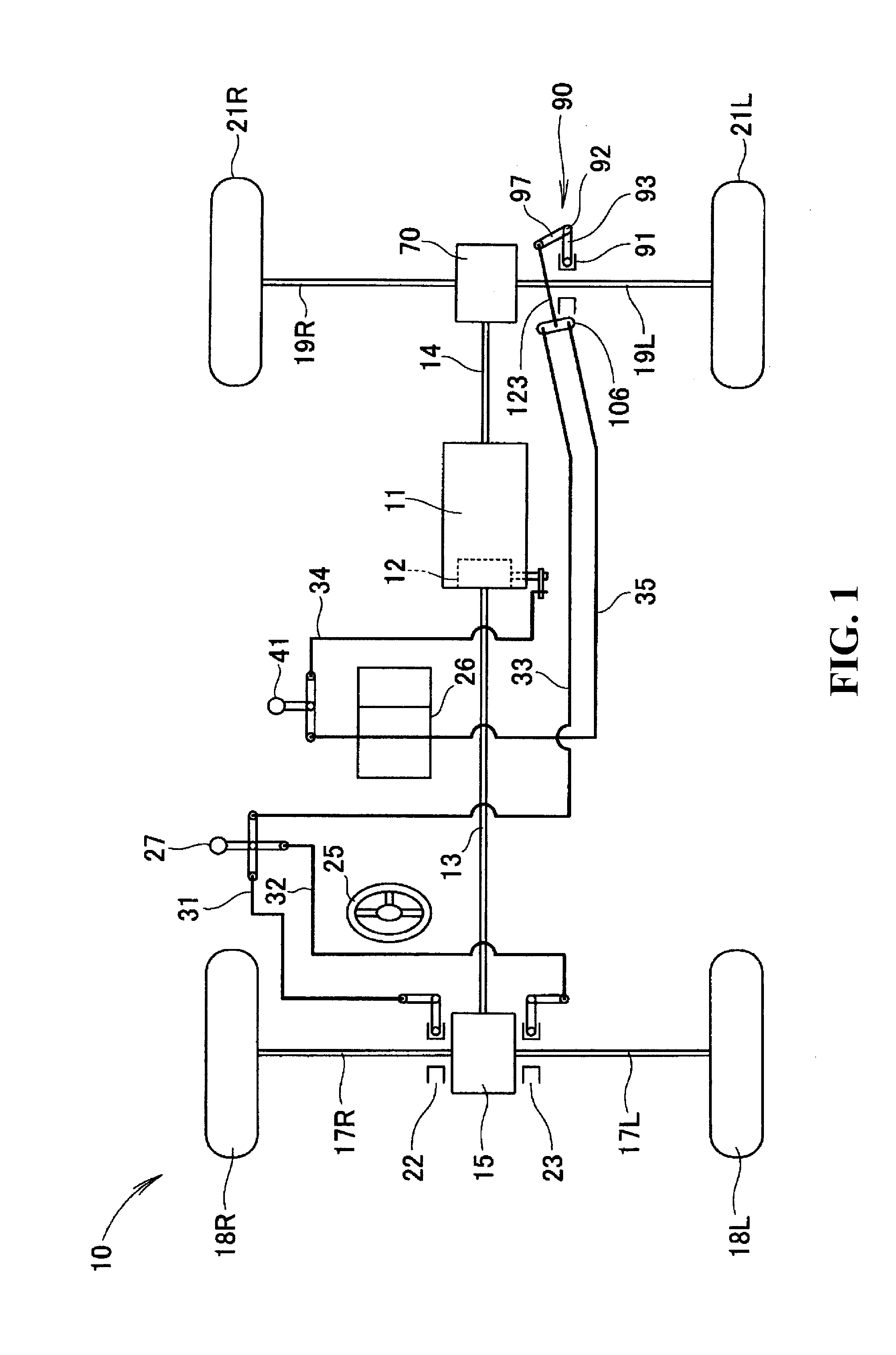

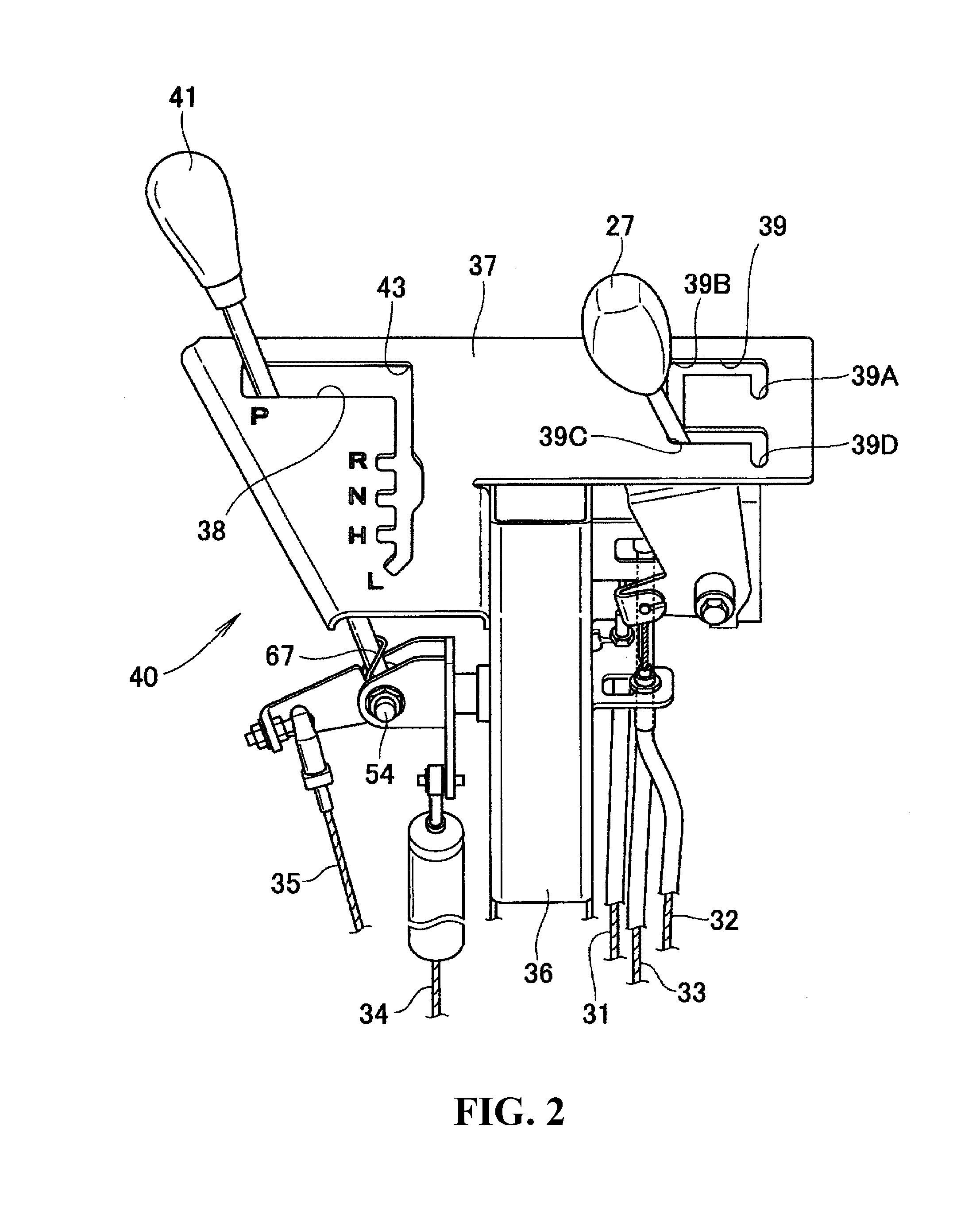

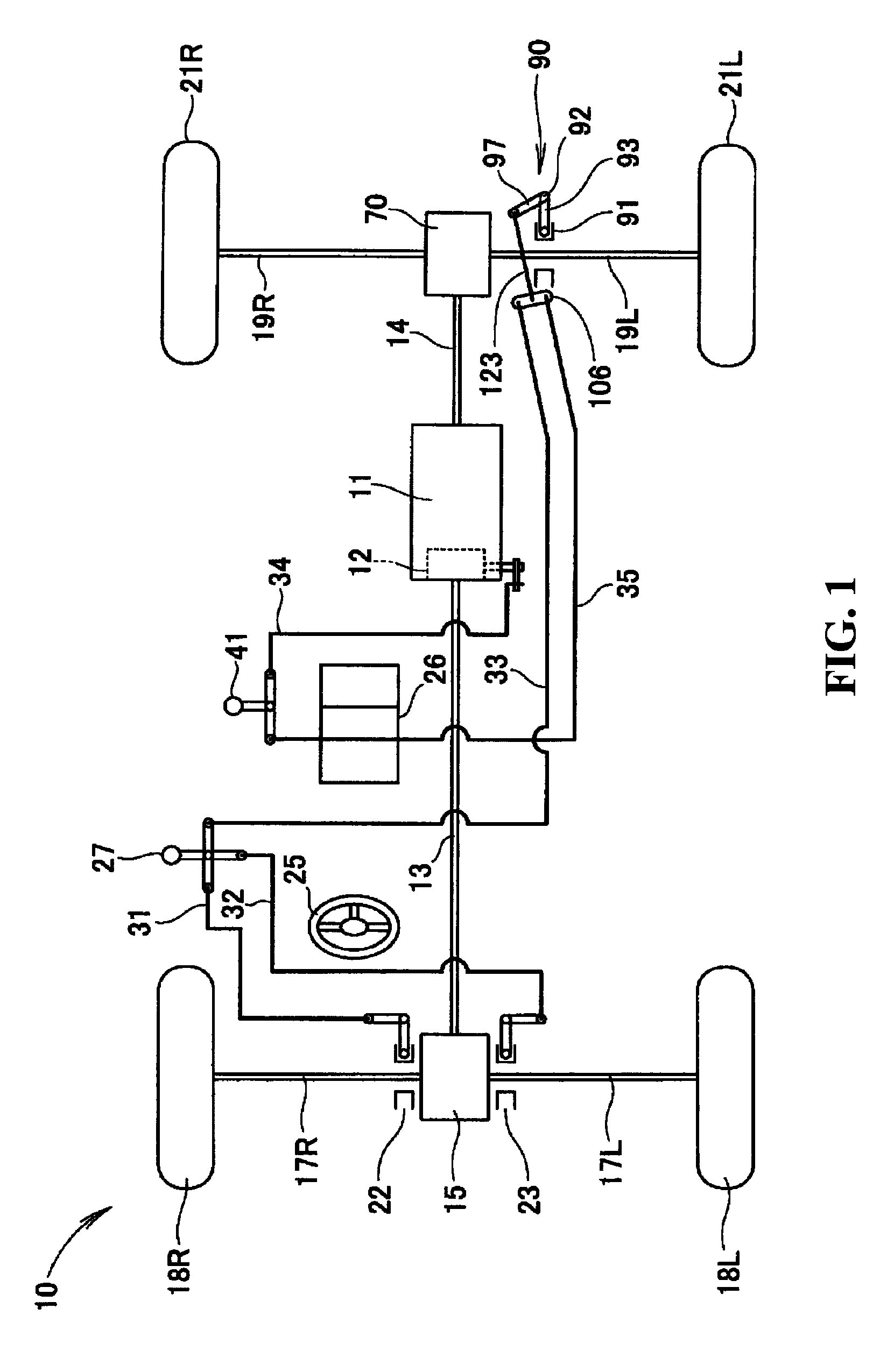

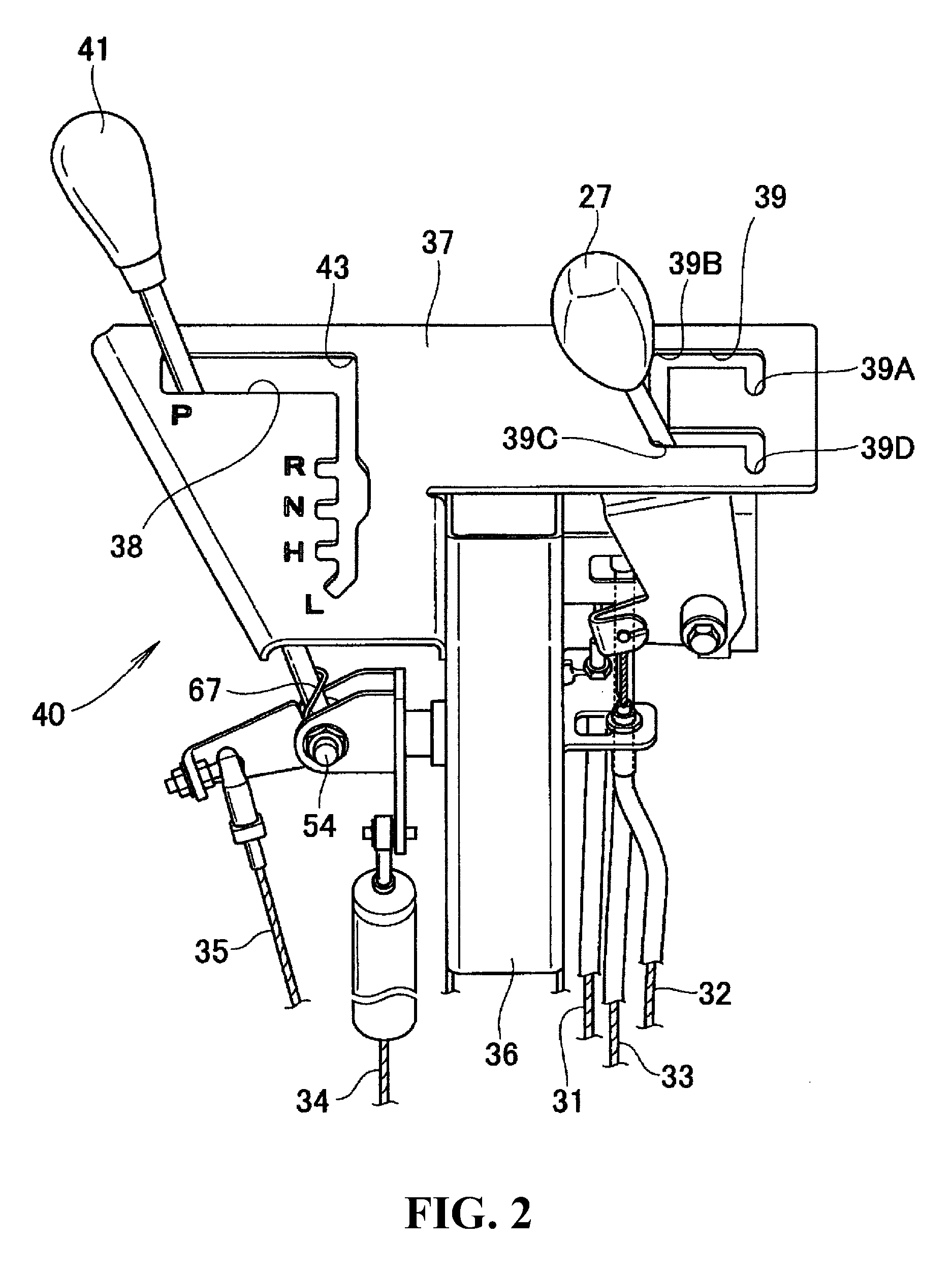

Differential gear provided with differential lock mechanism

ActiveUS20150096822A1Increase in sizeSmall shapeExhaust apparatusSilencing apparatusLocking mechanismMiniaturization

A differential mechanism regulating device which is mechanically connected to two manipulators is miniaturized. When a first cable and a second cable are pulled, a collecting member moves its position. As a result of this movement, the collecting member tilts a portion of an arm by way of a rod. As a result, a differential lock is released. The operation of the first cable and the operation of the second cable can be merged by the collecting member, and it is sufficient to connect only a collecting transmission member to the arm. The connection between the arm and the collecting transmission member can be simplified thus realizing the miniaturization of the differential mechanism.

Owner:HONDA MOTOR CO LTD

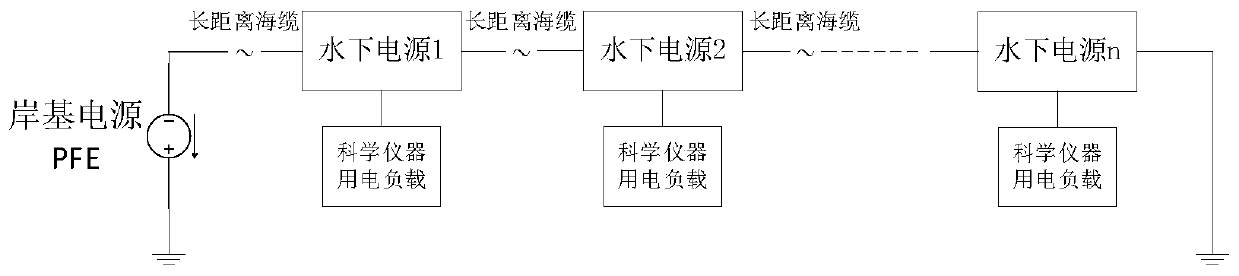

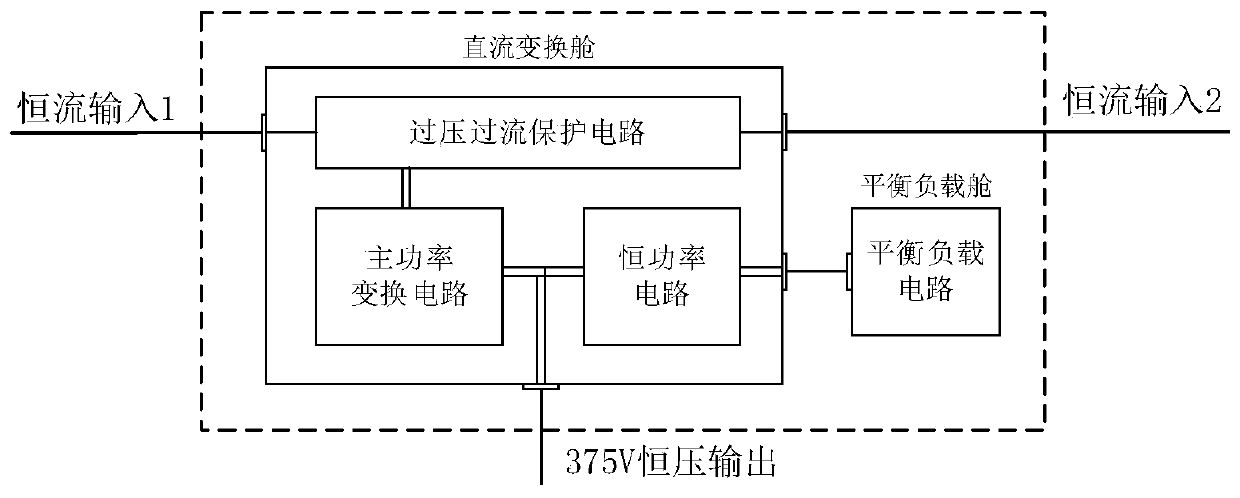

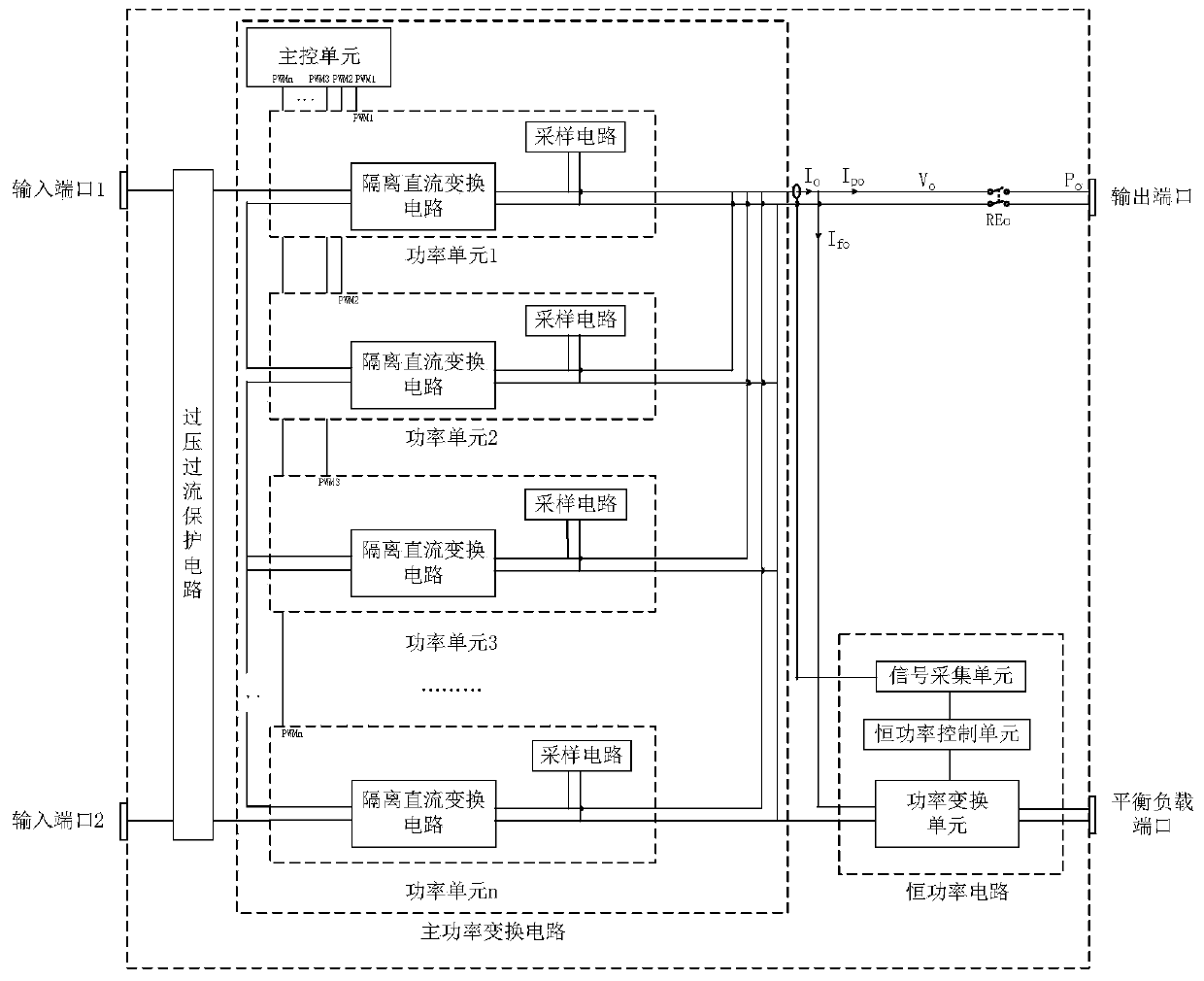

Underwater power supply suitable for constant-current power supply type seabed observation network

ActiveCN111490533AGuaranteed isolation voltageSolve pressure requirementsConstant-current supply dc circuitLoad circuitConstant power

The invention discloses an underwater power supply suitable for a constant-current power supply type seabed observation network. The underwater power supply comprises a direct-current conversion cabinand a balance load cabin which are independent of each other, a main power conversion circuit and a constant power circuit are arranged in the direct-current conversion cabin; a balance load circuitis arranged in a balance load; an output end of the main power conversion circuit is connected with an input end of the constant power circuit, and an output end of the constant power circuit is connected with the balance load cabin, the main power conversion circuit is used for receiving electric energy provided by a shore base station through a submarine cable, converting constant current into constant voltage and supplying power to an electric load for a scientific instrument; the constant power circuit is used for controlling the constant-power output of the underwater power supply when load switching occurs in the electric load for the scientific instrument; and the balanced load circuit is used for converting redundant electric energy of the direct-current conversion cabin into heatenergy and dissipating the heat energy. The high common-mode voltage isolation and heat dissipation of an underwater power supply input port are realized by adopting encapsulation oil filling and a ceramic gasket, and the power supply is more suitable for a multi-seabed main base station and a long-distance large constant-current power supply network.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

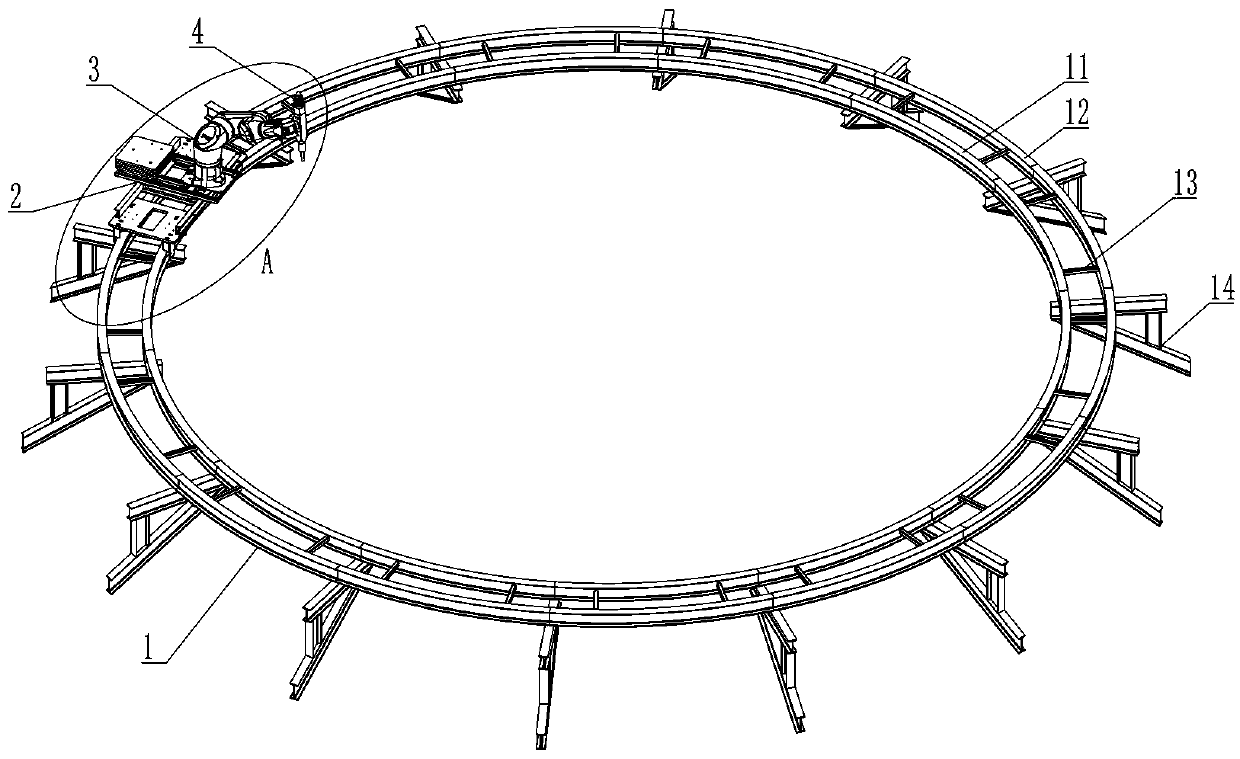

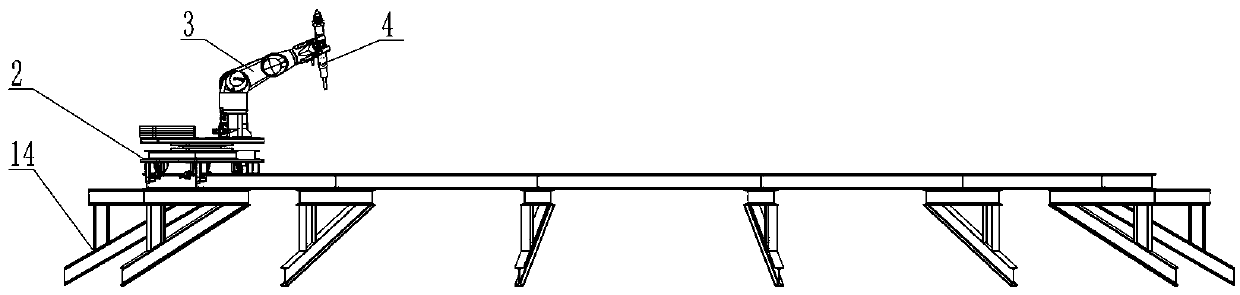

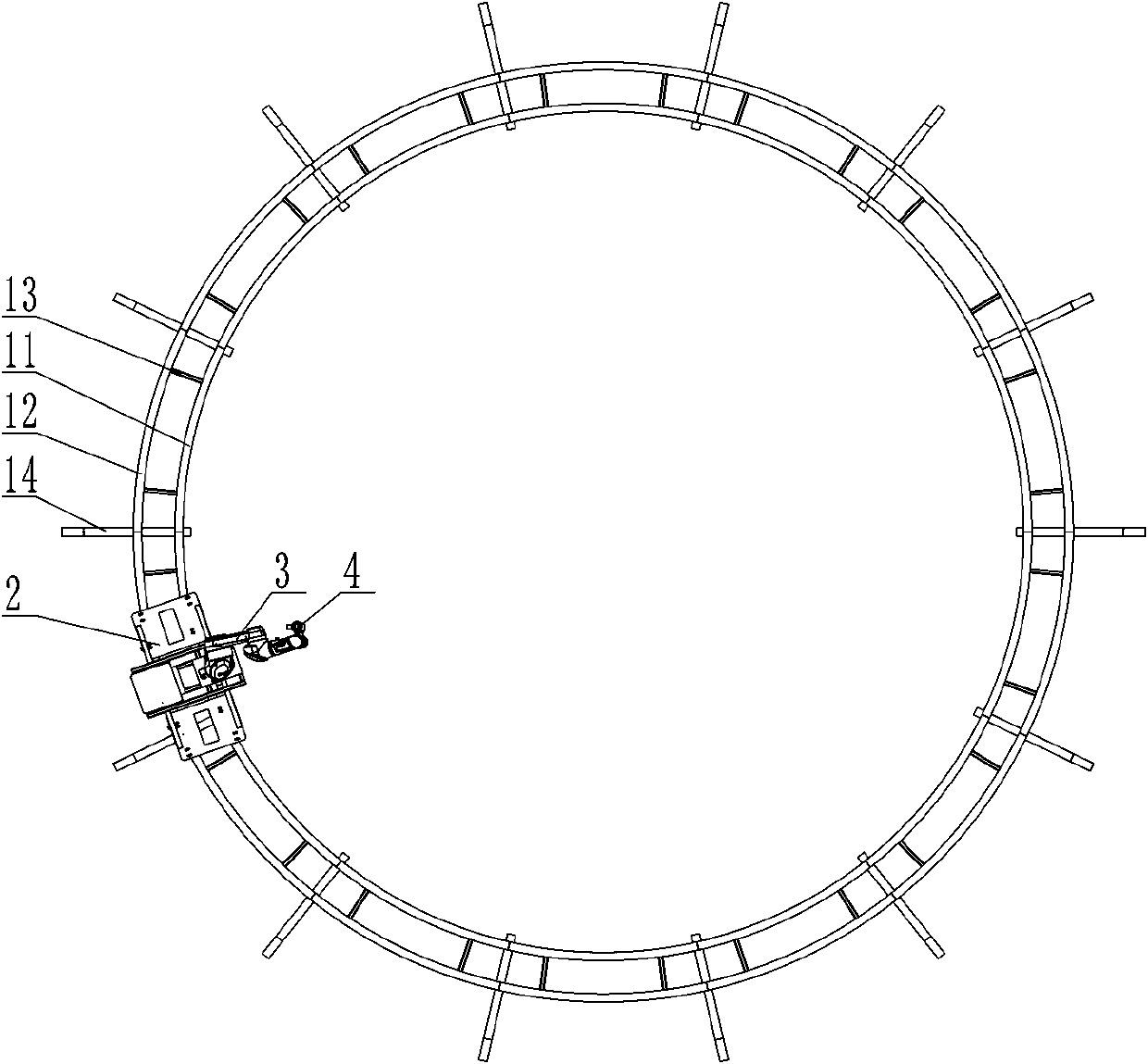

On-line laser reinforcing device for hydraulic turbine blades

PendingCN109868471ASimple structureLittle thermal impactMetallic material coating processesRobot controlAerospace engineering

The invention provides an on-line laser reinforcing device for hydraulic turbine blades. The on-line laser reinforcing device comprises a track, a traveling mechanism, a robot and laser cladding complete equipment; and the annular track is arranged in a rotating wheel chamber of a hydraulic turbine, the traveling mechanism is arranged on the track, the robot is connected with the traveling mechanism, the laser cladding complete equipment is connected with the robot, the traveling mechanism is pushed to move along the track to drive the robot to arrive at the operation area, and the robot controls the laser cladding complete equipment to repair the cladding part. According to the on-line laser reinforcing device, the problems that in the traditional electric-arc welding defect repair process of original hydraulic turbine blades, the heat effect on substrates is large, the binding strength is low, the thickness is not easily controlled, environmental protection is not achieved, the operation space is large, and the repairing efficiency is low are solved; and the on-line laser reinforcing device has the characteristics of being simple in structure, small in heat effect on substrate, high in binding strength, controllable in thickness, environmentally friendly, capable of being suitable for small space operation, high in repairing efficiency, and easy and convenient to operate.

Owner:CHINA YANGTZE POWER +1

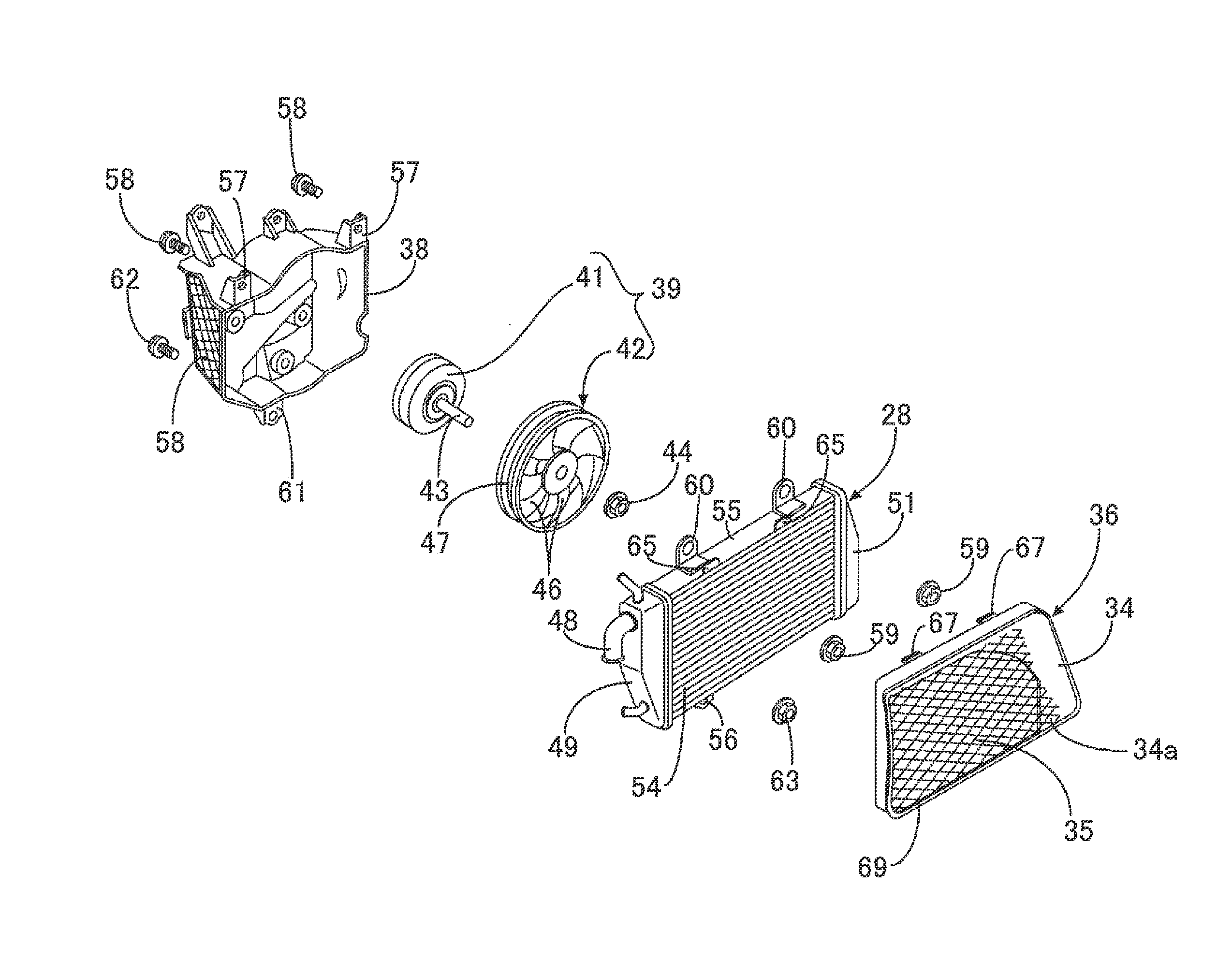

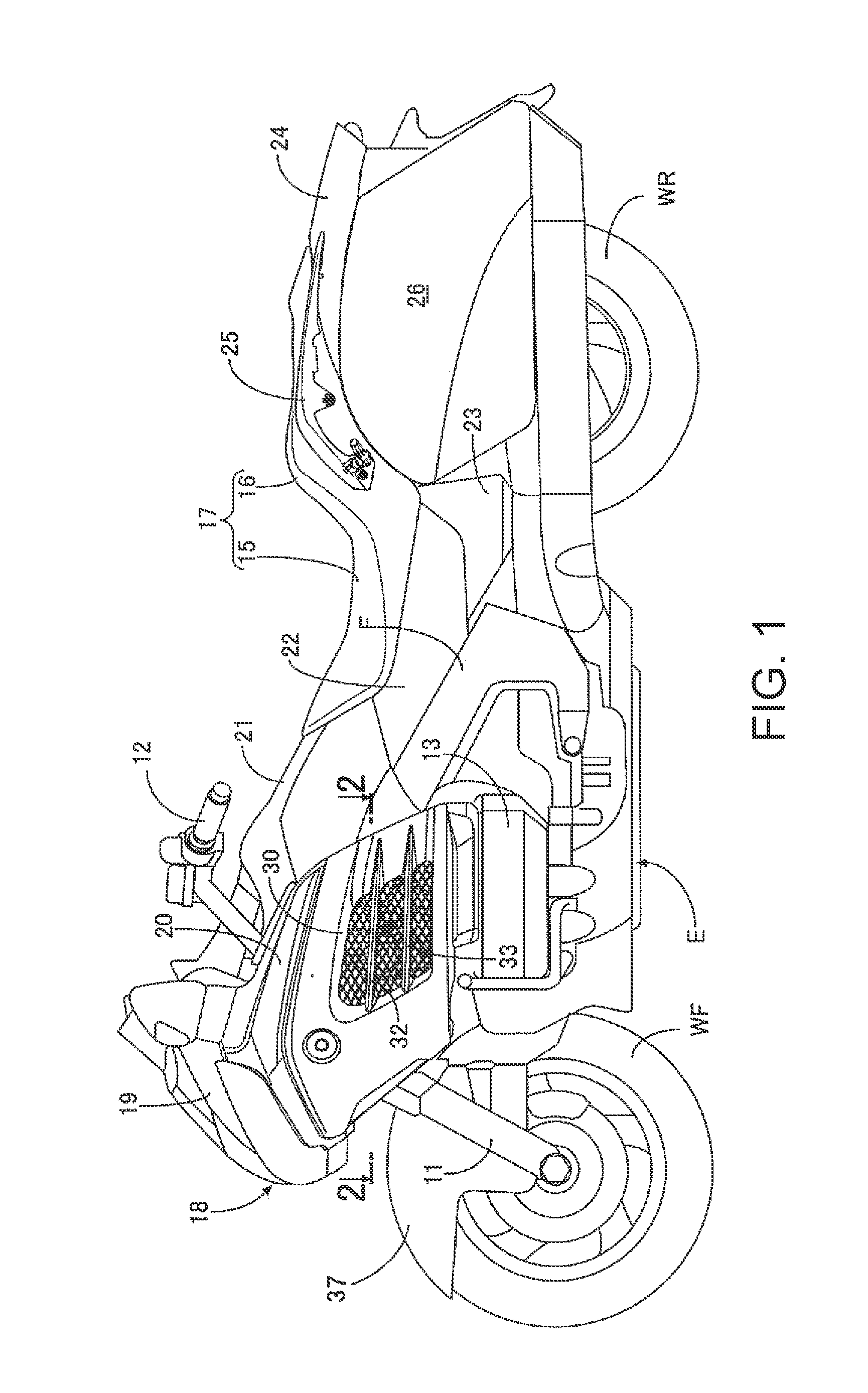

Ventilation structure of radiator in straddle type vehicle

ActiveUS20140034267A1Inhibition is effectiveMaintain performanceAir-treating devicesExhaust apparatusControl of respirationHeat spreader

In a straddle type vehicle in which a radiator is covered with a cover member, and an air guide duct for guiding hot air from the radiator to an outside of the vehicle is formed integral with the cover member, the hot air is restrained from staying within the cover member even in the case where the air guide duct of the cover member covering the radiator must be opened face-to-face with only a portion of a core of the radiator. A ventilation control member for controlling cooling air passing through the core of the radiator so as to flow toward an inner opening of the air guide duct is provided in the vicinity of the radiator.

Owner:HONDA MOTOR CO LTD

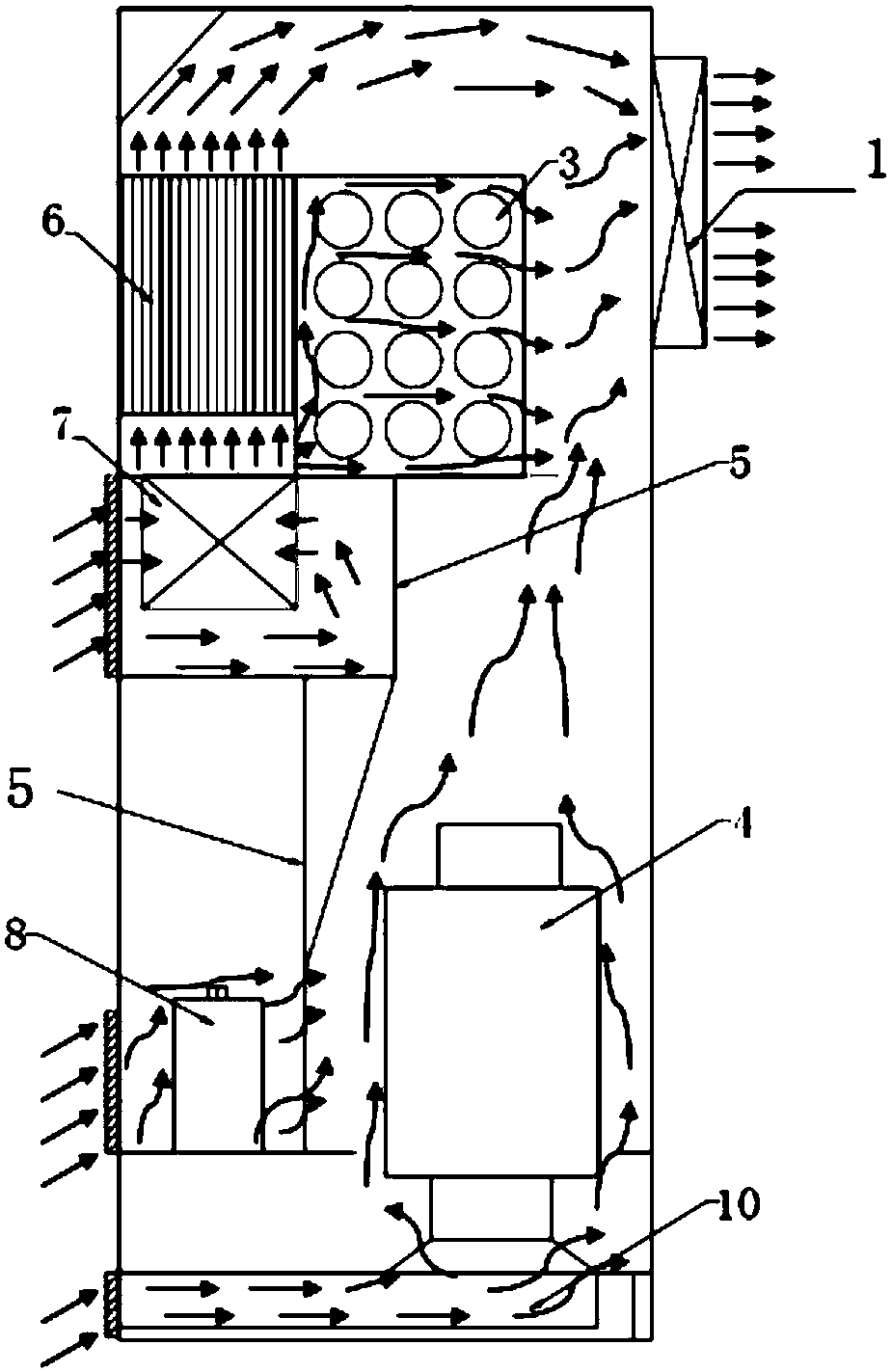

Power cabinet with partitioning heat dissipation function

InactiveCN108092490AAvoid thermal influenceEfficient heat dissipationCooling/ventilation/heating modificationsPower conversion systemsHeat sensitiveBack door

The invention discloses a power cabinet with a partitioning heat dissipation function. The power cabinet comprises a cabinet body, and a power module, an electric reactor and a filtering capacitor arranged in the cabinet body, and also comprises an air channel partition plate arranged in the cabinet body; the cabinet body is divided into a first heat dissipation region and a second heat dissipation region by the air channel partition plate and a front door plate of the cabinet body; and the air channel partition plate and a back door plate of the cabinet body form a third heat dissipation region which is on the upper parts of the first heat dissipation region and the second heat dissipation region. By virtue of the power cabinet with the partitioning heat dissipation function, partitioningheat dissipation can be realized, so that thermal influence of a high-power heating device electric reactor on a heat sensitive device can be avoided, and efficient heat dissipation can be achieved.

Owner:RENERGY ELECTRIC TIANJIN

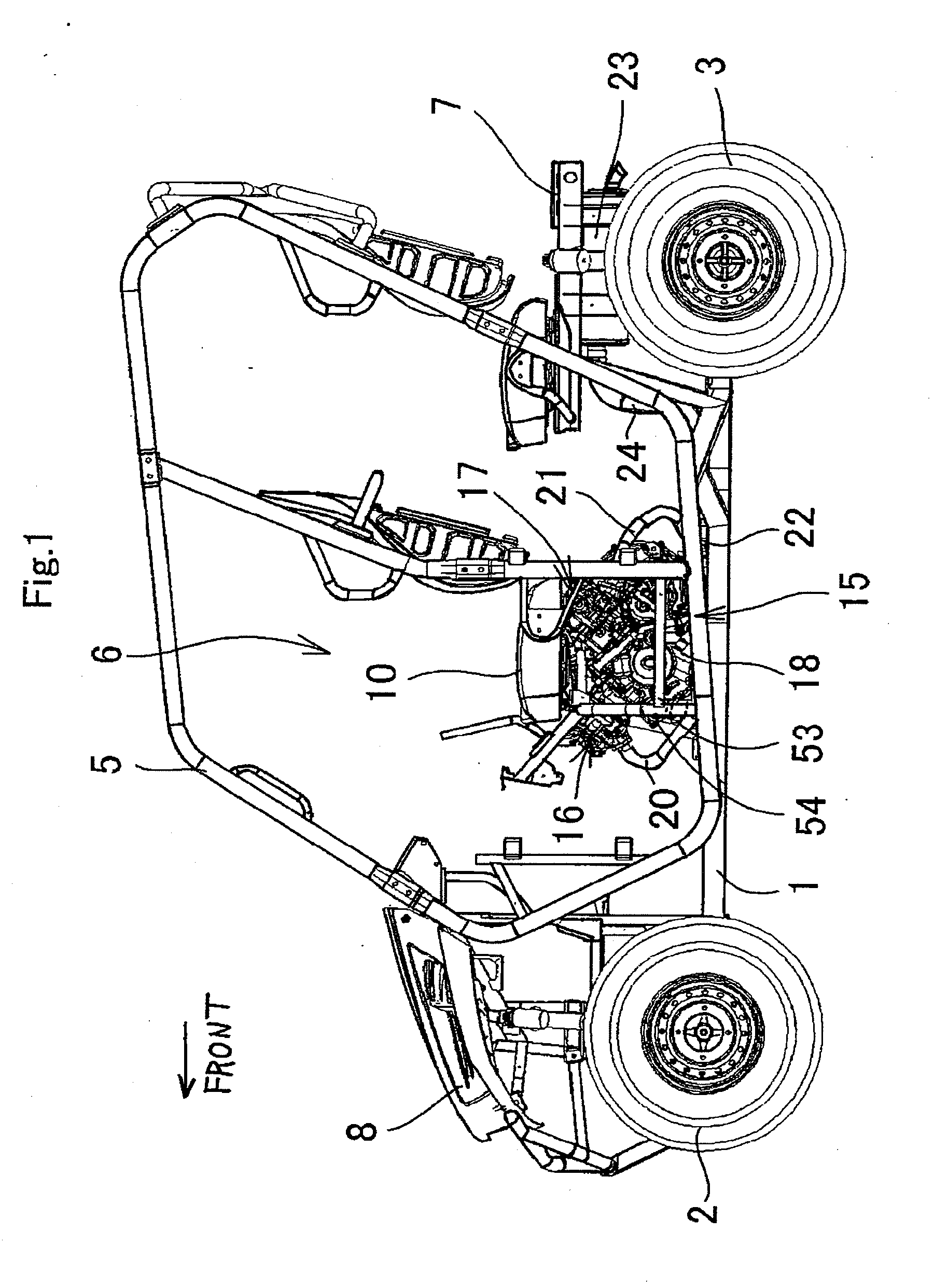

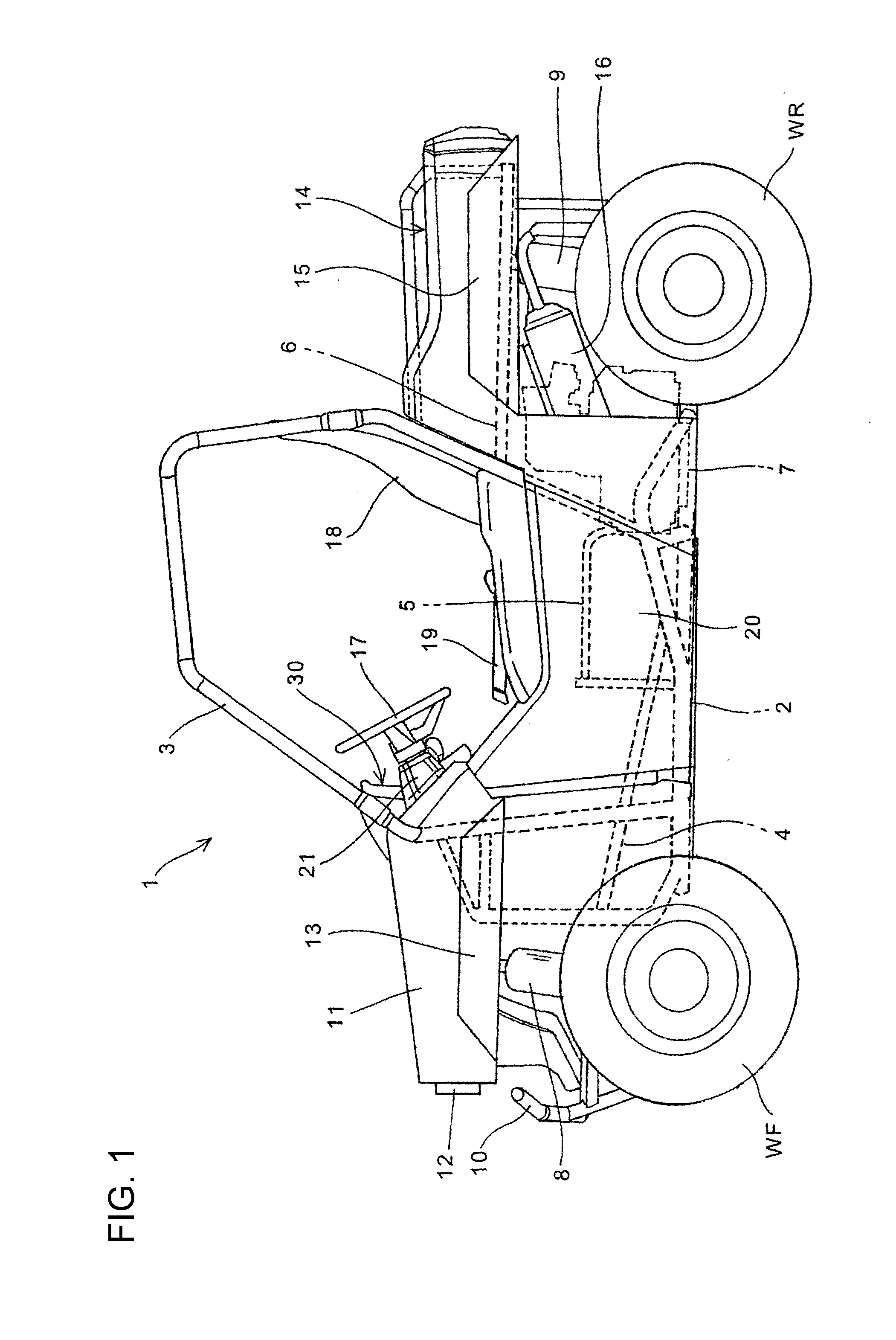

Ecu arrangement structure for a vehicle

ActiveUS20100236852A1Reduce weightImprove the ease of assemblyRace vehiclesPropulsion coolingAir cleanersEngine control unit

An engine controller structure for a vehicle, can include a duct cover having a box-like portion on a vehicle body front side thereof. The box-like portion can include an opening formed therein, and can be configured to have an intake duct of an engine connected thereto. The duct cover can be configured to be positioned sidewardly of an engine. An engine control unit can be disposed on the inside of the duct cover. The opening, configured to be connected to the intake duct, can be configured such that the intake duct is connected to an air cleaner box attached to a vehicle body rear side of the engine. The intake duct can shaped so as to be extended to a vehicle body front side from the air cleaner box.

Owner:HONDA MOTOR CO LTD

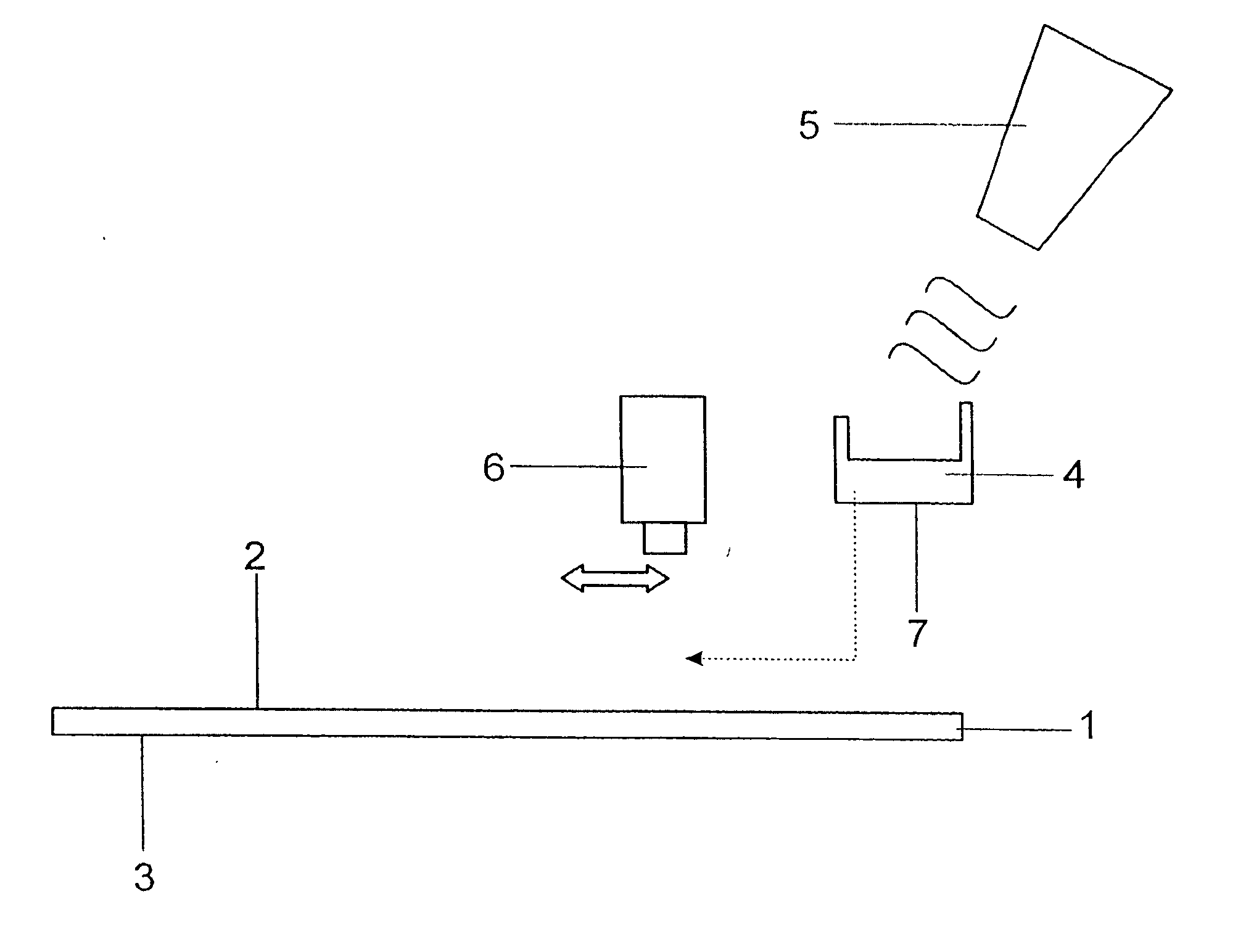

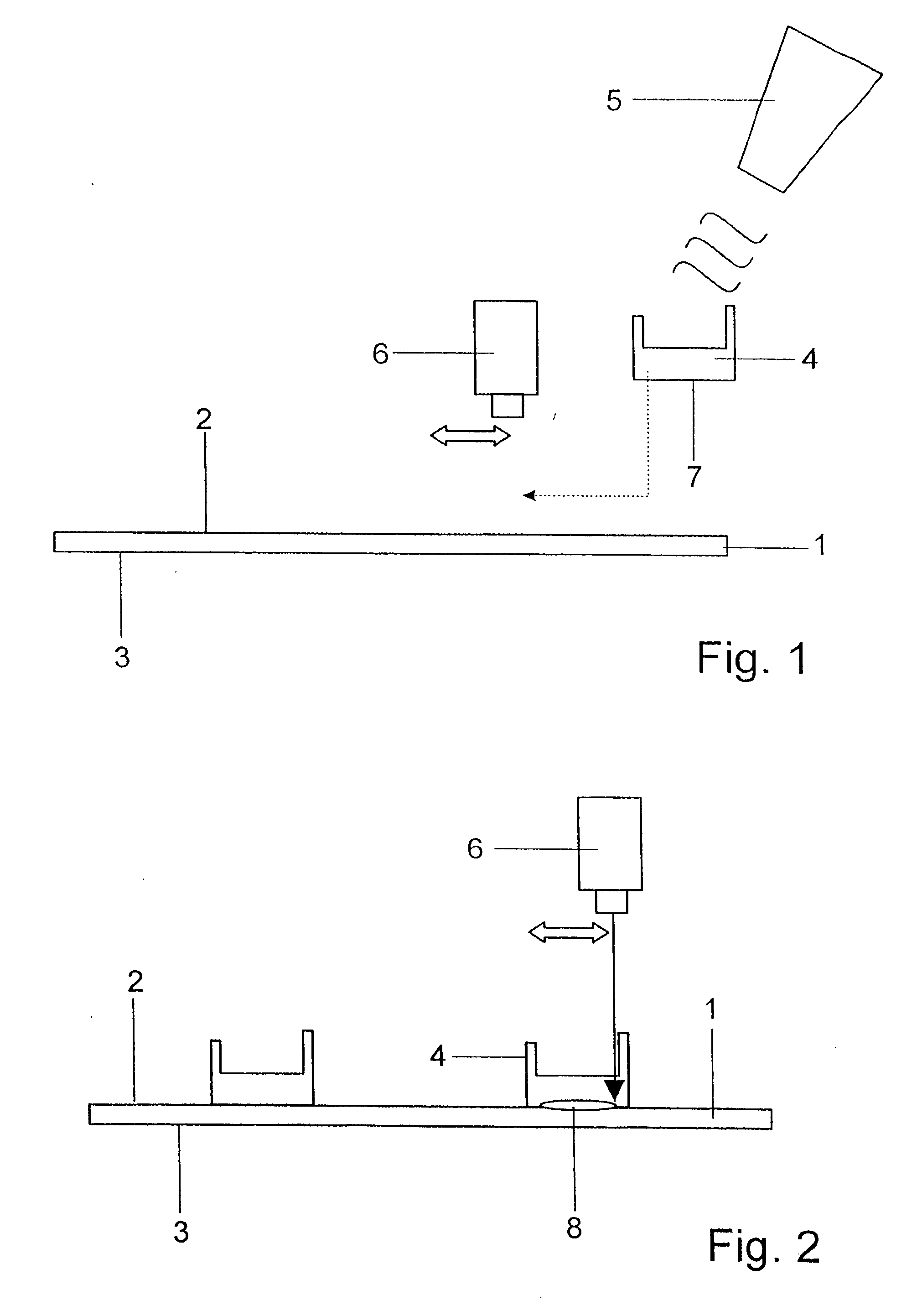

Method for joining plastic structural component parts by means of laser radiation

InactiveUS20050000618A1Avoid damage to surface qualityAvoid thermal influenceMechanical working/deformationSlide fastenersThermal expansionMechanical engineering

In a method for joining plastic structural component parts by laser radiation, it is the object of the invention to prevent impairment of the surface quality by the falling in of material of the quality surface in thin-walled plastic structural component parts when the latter are connected to another part. A first thin-walled plastic structural component part having a quality surface is formed so as to be absorbent for the laser radiation and is welded by the transmission radiation method on a side located opposite from the quality surface to a second plastic structural component part which is transparent to the laser radiation. The transparent plastic structural component part is heated beforehand in order to reduce the temperature gradient between the plastic structural component parts when joining, so that a faster melting of the transparent plastic structural component part is carried out by heat conduction during joining, and a thermal expansion in the absorbing plastic structural component part in the direction of the quality surface is limited.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

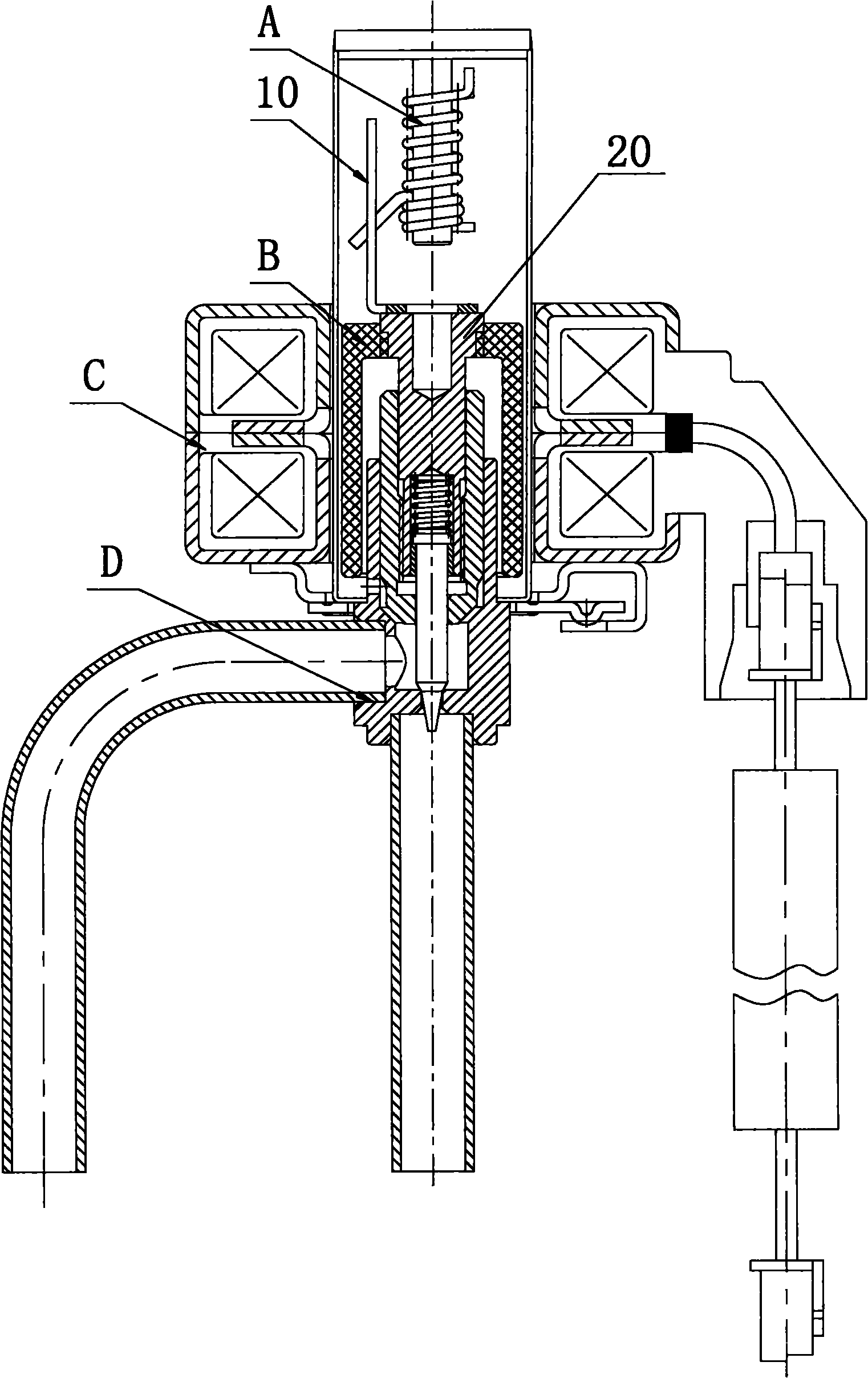

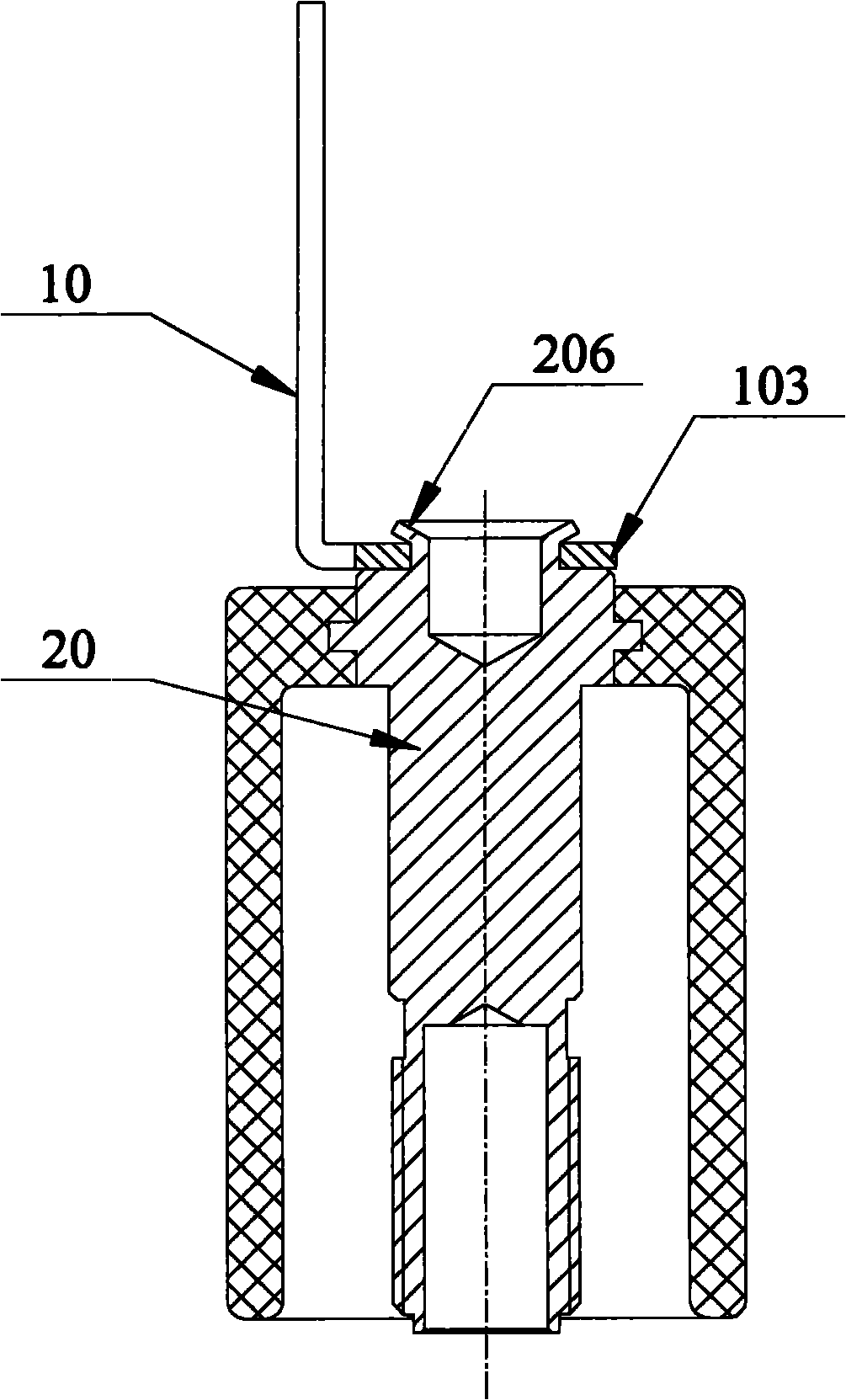

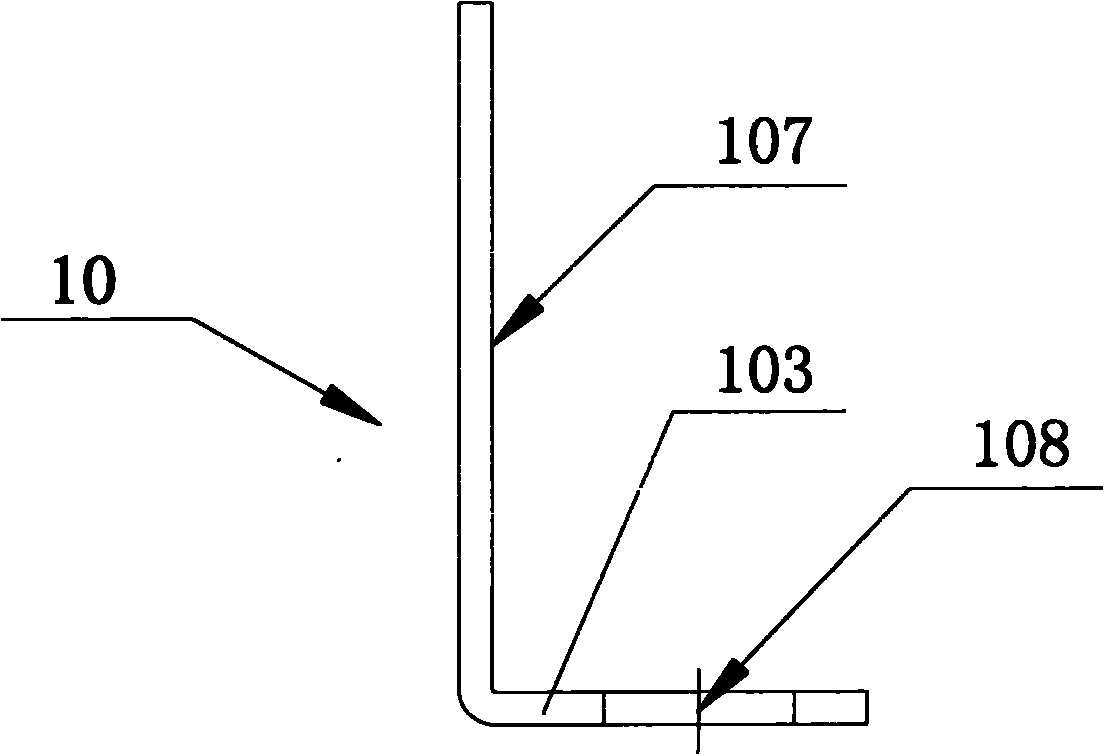

Connection structure of motion guide rod and rotor and electronic expansion valve

ActiveCN101776171AAvoid thermal influenceOvercome the problem of surface magnetic intensity change or even failureOperating means/releasing devices for valvesEfficient regulation technologiesStator coilMechanical engineering

The invention provides a connection structure of a motion guide rod and a rotor, comprising the motion guide rod and a rotor screw, wherein the section of the motion guide rod is in an L shape; the motion guide rod comprises a motion guide rod vertical segment and a connection segment, wherein the motion guide rod vertical segment is vertically arranged, and the connection segment is horizontally arranged and is connected with the motion guide rod vertical segment; and the upper end of the rotor screw is riveted with the connection segment. The invention also provides an electronic expansion valve comprising a limiter assembly A, a rotor assembly B, a stator coil C and a valve body assembly D, wherein the limiter assembly A comprises the connection structure of the motion guide rod and the rotor. The invention solves the problem that the magnetic strength of the surface of the rotor is changed and even loses efficacy directly because the motion guide rod and the rotor are mutually welded to generate heat influence on the rotor in the prior art, thereby achieving the effects of good connection quality, simple and convenient connection process, stable connection, convenient processing, accurate stroke limit of the limiter assembly A and accurate positioning of the electronic expansion valve.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

Integral-type heat exchanger

InactiveUS20050092462A1Reduce thicknessSimple structureClosure meansHeat exhanger finsEngineeringHeat exchanger

Owner:CALSONIC KANSEI CORP

ECU arrangement structure for a vehicle

ActiveUS8336656B2Avoid thermal influenceImprove cooling effectRace vehiclesPropulsion coolingAir cleanersEngine control unit

An engine controller structure for a vehicle, can include a duct cover having a box-like portion on a vehicle body front side thereof. The box-like portion can include an opening formed therein, and can be configured to have an intake duct of an engine connected thereto. The duct cover can be configured to be positioned sidewardly of an engine. An engine control unit can be disposed on the inside of the duct cover. The opening, configured to be connected to the intake duct, can be configured such that the intake duct is connected to an air cleaner box attached to a vehicle body rear side of the engine. The intake duct can shaped so as to be extended to a vehicle body front side from the air cleaner box.

Owner:HONDA MOTOR CO LTD

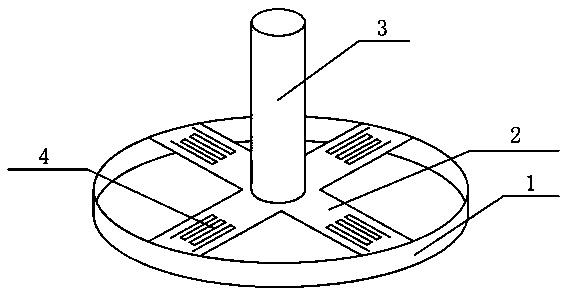

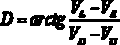

Strain-type wind direction sensor

InactiveCN105372448AAvoid interferenceAvoid consistencyIndication/recording movementEngineeringStrain type

The invention relates to a strain-type wind direction sensor, which belongs to the technical field of atmospheric sounding. The strain-type wind direction sensor comprises a supporting base, strain beams, a wind pole, and strain sensors, wherein the strain beams are arranged on the supporting base; the wind pole is arranged in the center of the supporting base; the strain beams are radially arranged along the supporting base with the wind pole as the center; and the strain sensors are arranged on the strain beams. According to the strain-type wind direction sensor provided by the invention, one wind pole is adopted, mutual interference between wind poles and inconsistency of wind effects can be effectively prevented, the strain sensor and the wind pole are separated, and wind effects on the strain sensor are reduced.

Owner:PLA UNIV OF SCI & TECH

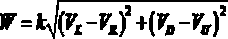

Differential gear provided with differential lock mechanism

ActiveUS9200699B2Miniaturizing connectionImprove maintainabilityExhaust apparatusGearing controlLocking mechanismMiniaturization

A differential mechanism regulating device which is mechanically connected to two manipulators is miniaturized. When a first cable and a second cable are pulled, a collecting member moves its position. As a result of this movement, the collecting member tilts a portion of an arm by way of a rod. As a result, a differential lock is released. The operation of the first cable and the operation of the second cable can be merged by the collecting member, and it is sufficient to connect only a collecting transmission member to the arm. The connection between the arm and the collecting transmission member can be simplified thus realizing the miniaturization of the differential mechanism.

Owner:HONDA MOTOR CO LTD

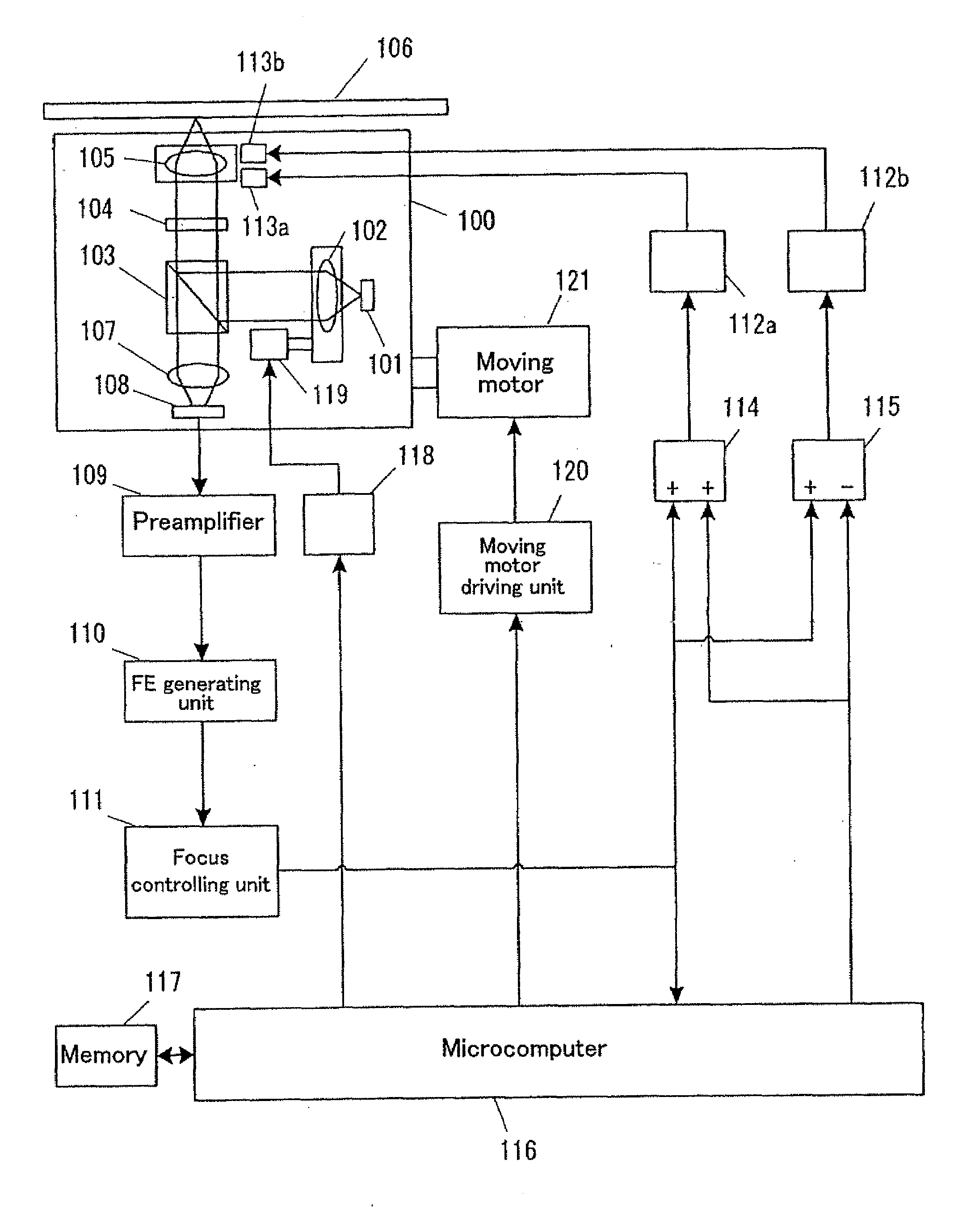

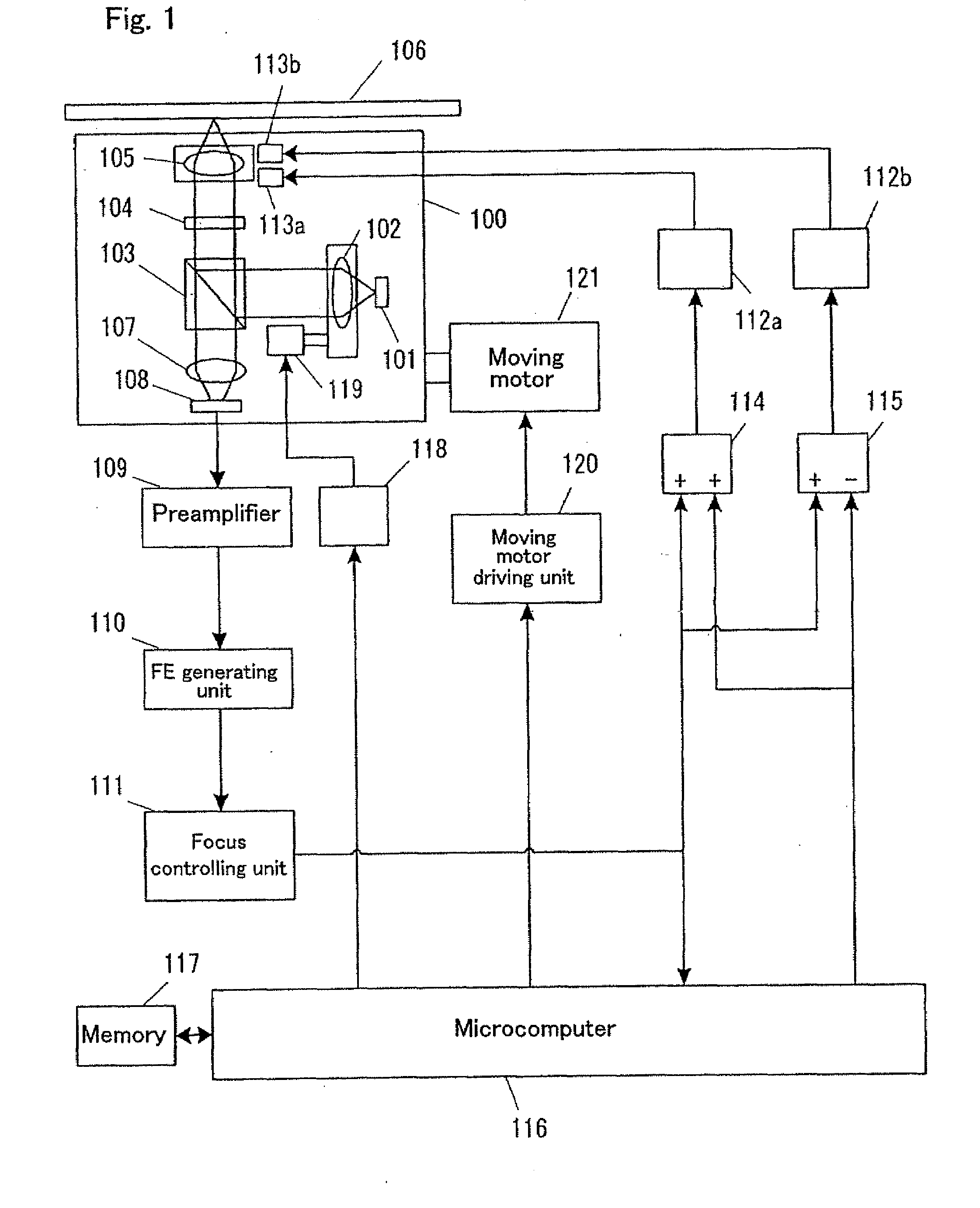

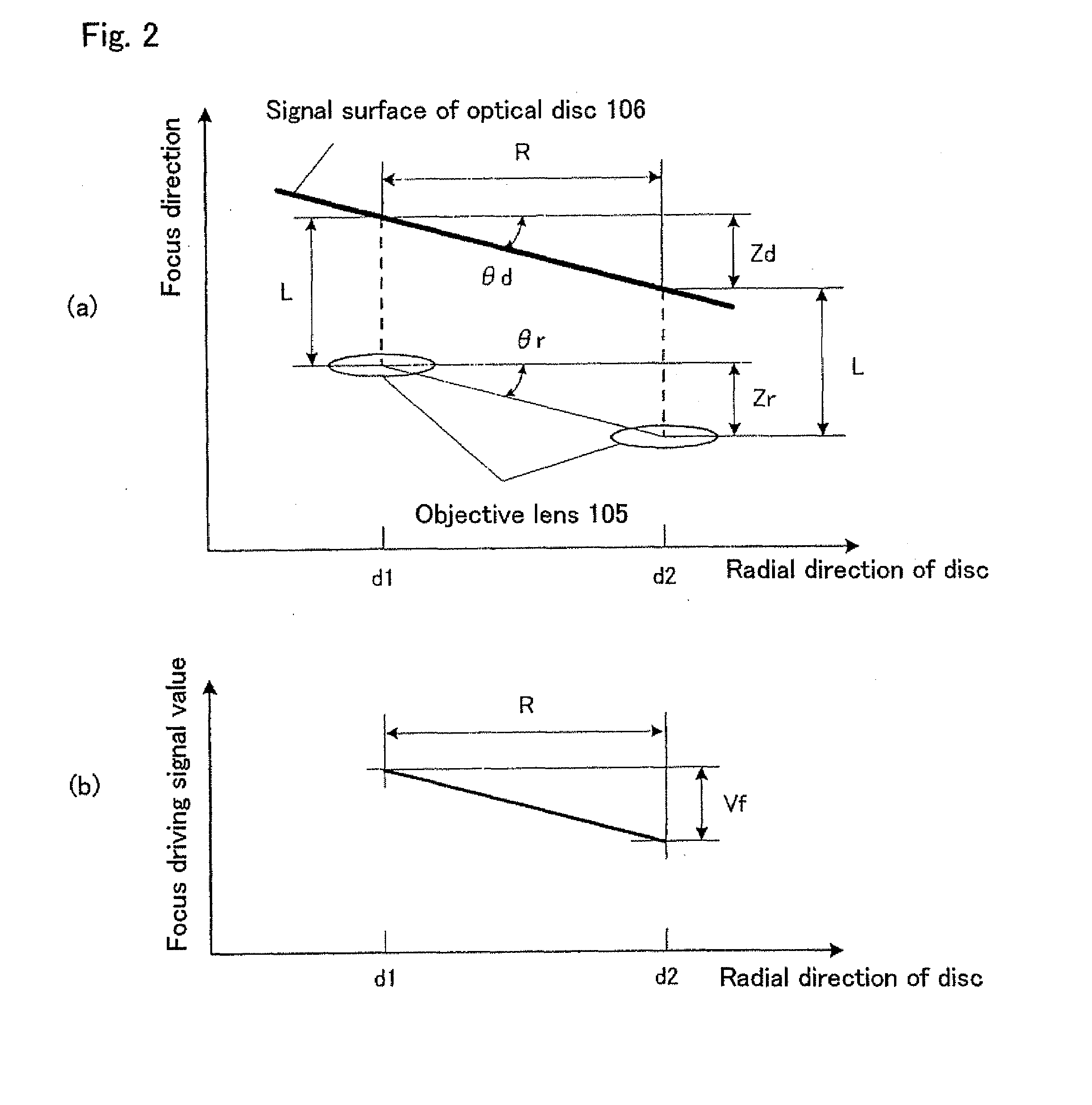

Optical Disk Device

InactiveUS20090122663A1Improve reliabilityTilt marginCombination recordingRecord information storageComputational physicsBiological activation

The optical disc apparatus according to the present invention includes a tilt detecting means; a coma aberration correcting means; and a spherical aberration correcting means. Based on the result of a tilt detection, the amount of the correction performed by the coma aberration correcting means is determined so that the amount of correction is constant for the whole circumference of an optical disc, and then a spherical aberration is corrected by the spherical aberration correcting means. Thus, it is possible to correct the spherical aberration that has occurred due to the coma aberration correcting means, while the tilt margin is secured, thereby improving the reliability of reproduction and recording by the optical disc apparatus. Further, the optical disc apparatus according to the present invention is configured, in the case where a thermal shock tilt has occurred during the activation of the apparatus, to wait until the thermal shock tilt has settled. Thus, it is possible to perform the activation while the influence of the thermal shock tilt is avoided, thereby improving the reliability of the recording and reproduction operations by the optical disc apparatus.

Owner:PANASONIC CORP

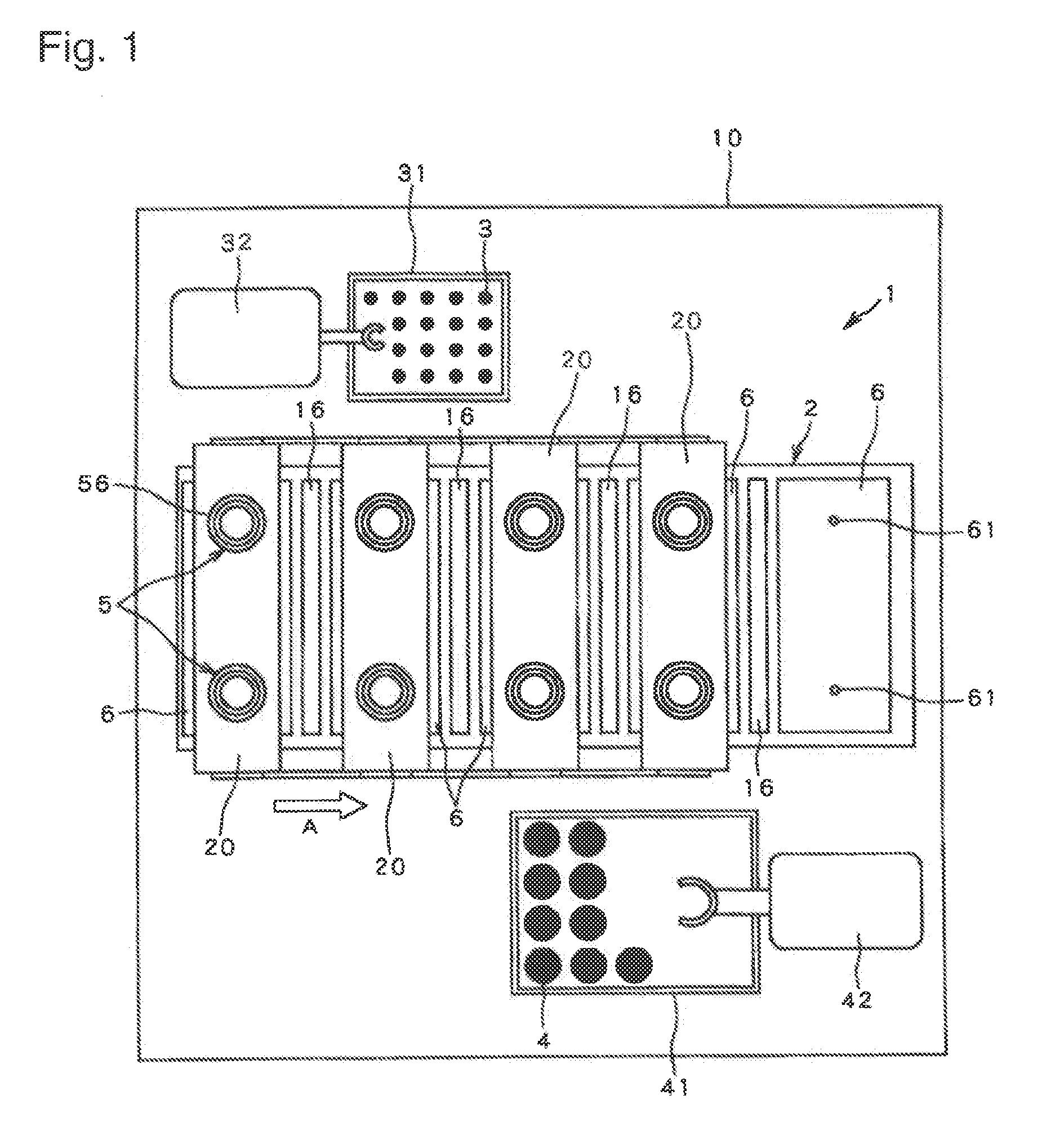

Welding method for low-carbon high-strength steel

ActiveCN103008846AImprove efficiencyHas a stirring effectArc welding apparatusLaser beam welding apparatusStress concentrationGas metal arc welding

The invention provides a welding method for low-carbon high-strength steel. The welding method for the low-carbon high-strength steel comprises the following steps of: 1) forming a welding groove on the low-carbon high-strength steel with a laser blanking method, and forming a welding line between the welding grooves of two pieces of low-carbon high-strength steel to be welded; and 2) welding the welding line by consumable electrode mixed gas metal arc welding, filling a welding wire in the welding process, and ensuring that the welding environment temperature is higher than 5DEG C. Specifically, the step 2) comprises the following steps of: 21) carrying out backing weld to the welding line by non-pulse consumable electrode mixed gas metal arc welding, forming a backing weld layer on the bottom of the welding line, and filling the welding wire in the welding process; and 22) carrying out cosmetic welding to the welding line by pulse consumable electrode mixed gas metal arc welding, forming a plurality of cosmetic layers above the backing weld layer, ensuring that two adjacent cosmetic layers are provided with overlay regions, and filling welding wire in the welding process. According to the welding method for the low-carbon high-strength steel, the stress concentration is lowered, and the welding quality of the low-carbon high-strength steel is improved.

Owner:青岛中车四方轨道车辆有限公司

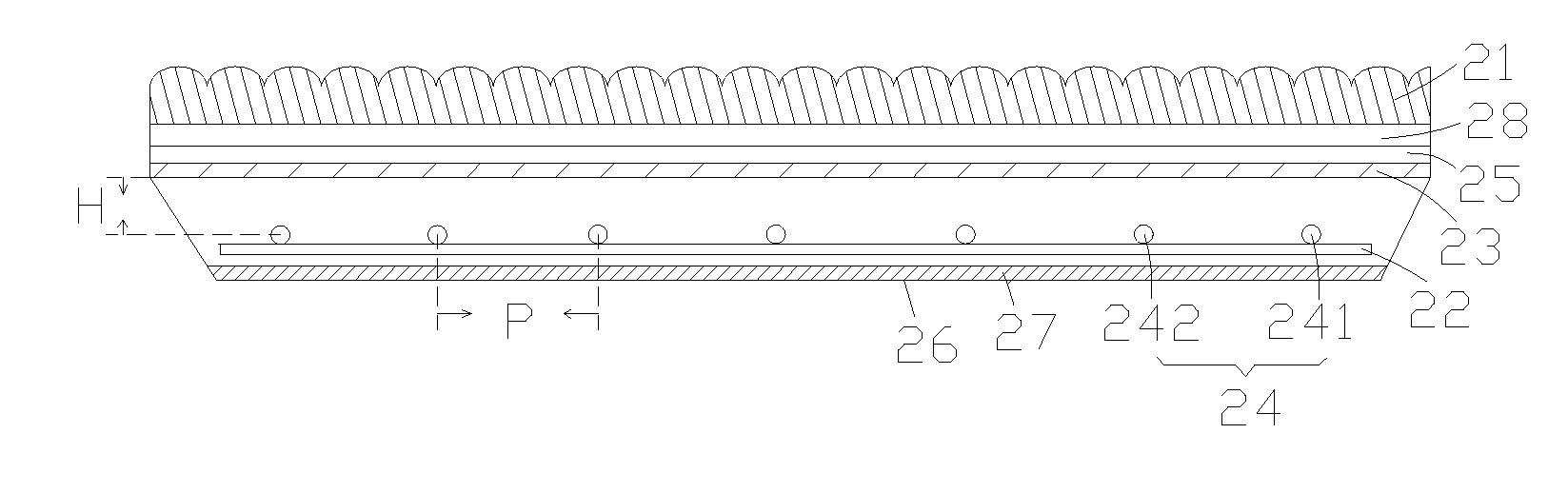

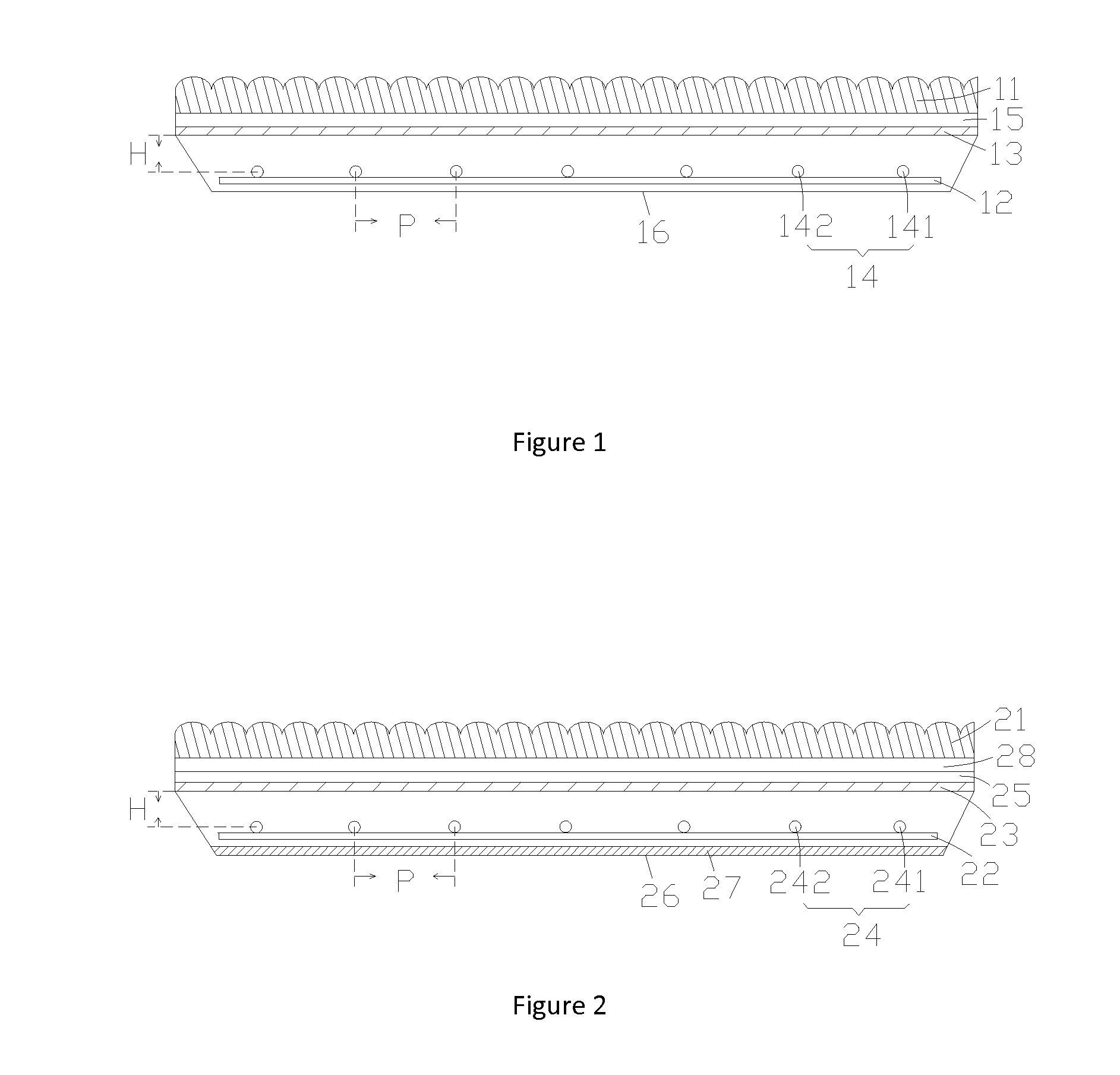

Backlight Module and Liquid Crystal Display Device

ActiveUS20140211448A1Reduce thicknessSave energySpectral modifiersNon-linear opticsColor saturationLiquid-crystal display

The present invention provides a backlight module and liquid crystal display device. The backlight module includes diffuser plate, substrate, fluorescent layer and light-emitting chip. The fluorescent layer is disposed on a light-entering surface of diffuser plate, and the fluorescent layer includes quantum dot (QD). The light-emitting chip is disposed on the substrate and the light-emitting chip is between substrate and fluorescent layer for irradiating on the fluorescent layer to excite the quantum dots to emit light to form white backlight source. The present invention uses quantum dots to effectively increase luminance, color saturation and avoid chroma offset. The quantum dots can emit uniform light and reduce thickness of the backlight module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

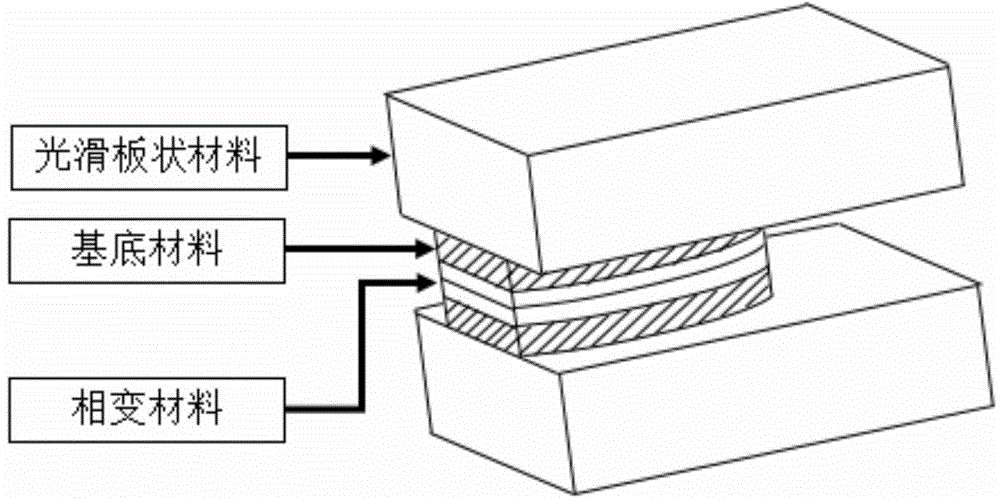

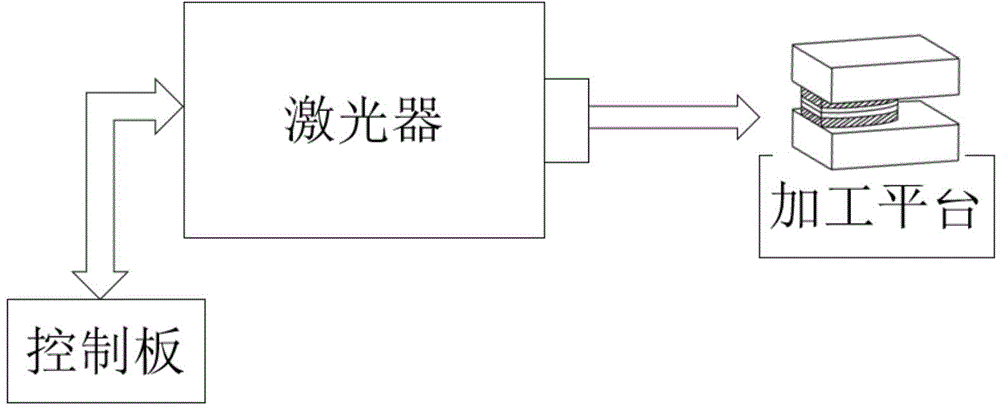

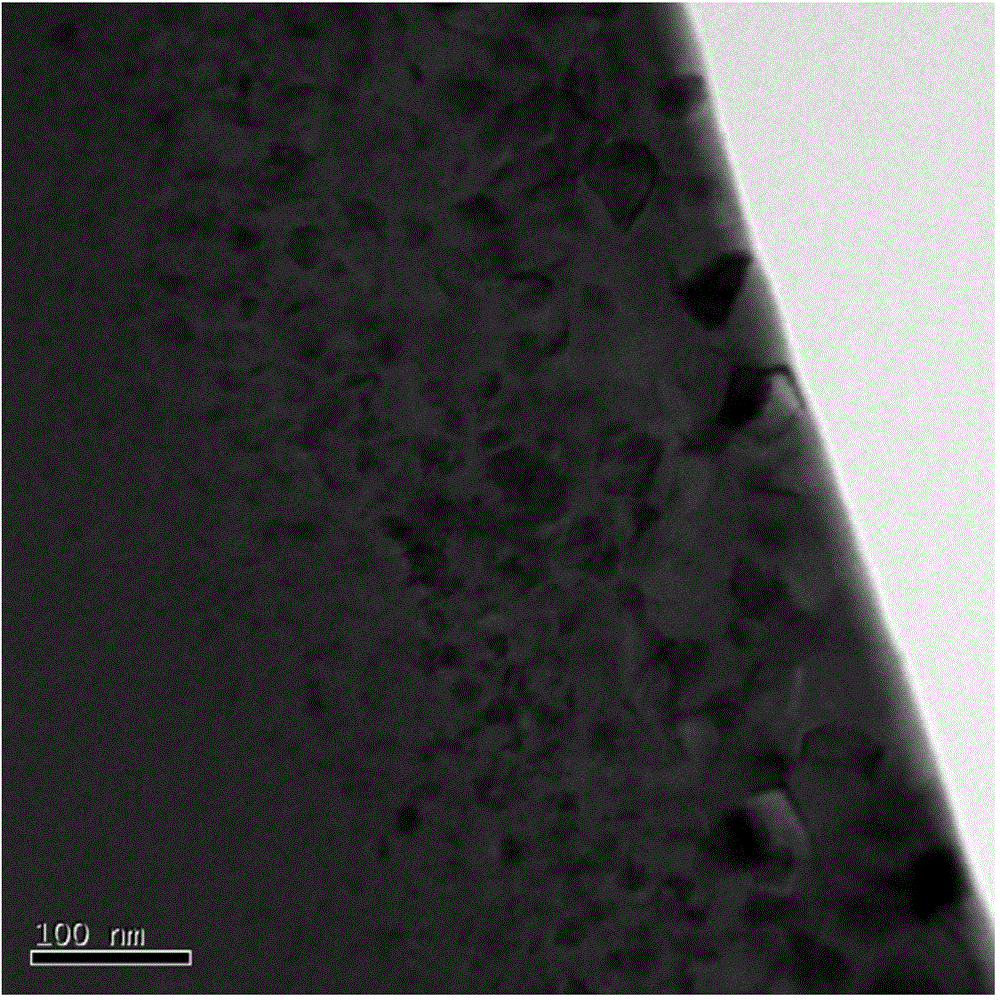

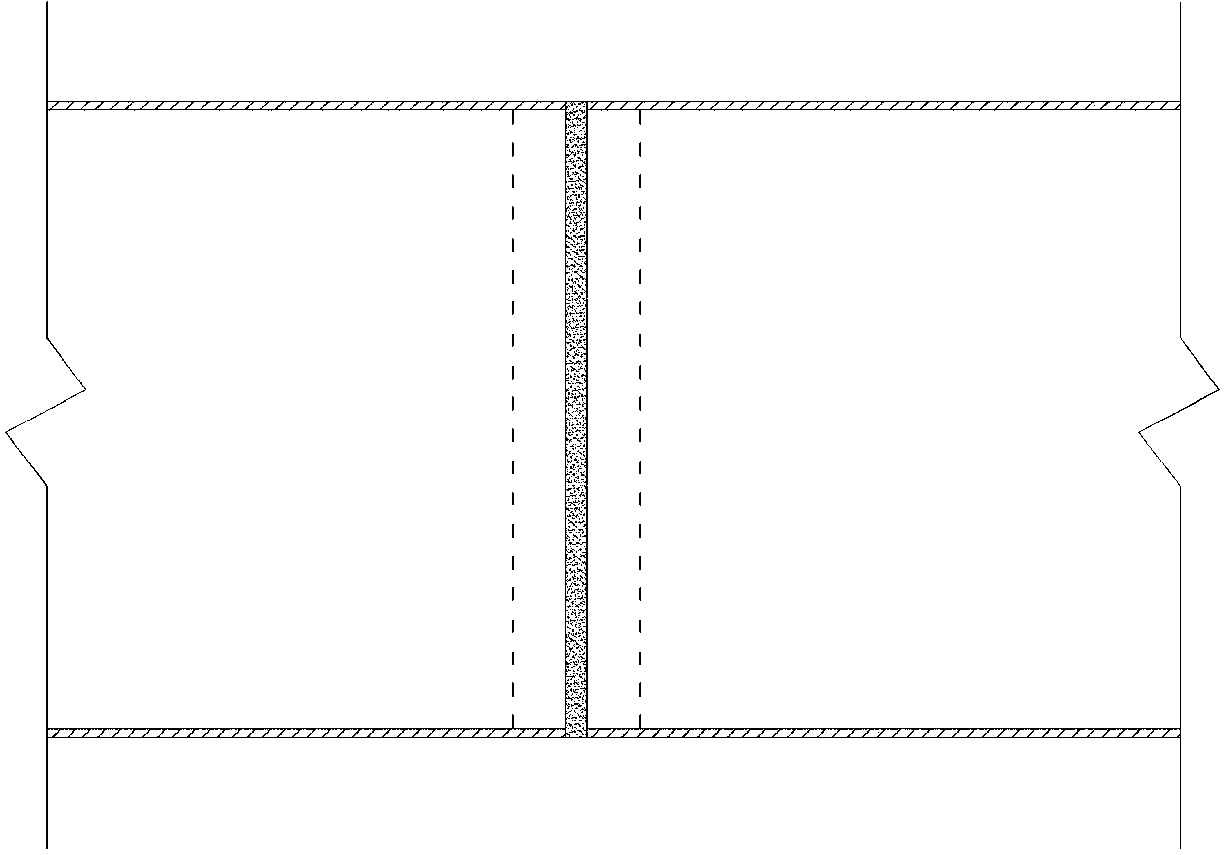

Transmission electron microscope-based Sample preparation method for observing section grain characteristics of laser-induced crystallized nano-film

InactiveCN104596818AAvoid pollutionAvoid thermal influencePreparing sample for investigationMaterial analysis by transmitting radiationPhase-change materialAtomic physics

The invention relates to a transmission electron microscope-based sample preparation method for observing the section grain characteristics of a laser-induced crystallized nano-film. The sample preparation method comprises the following steps: 1, plating a layer of film on a substrate for observing by adopting a transmission electron microscope by using a magnetron sputtering method; 2, oppositely gluing film coated surfaces of two films, fixing, and cutting one part; 3, clamping the cut films by using two plate materials, so that the section is in a gap of the edges of the two plate materials; 4, carrying out single-pulse irradiation on the section by using a laser; and 5, observing one film by flatly putting the film under the transmission electron microscope, wherein the crystallization area at the section edge is the grain growth morphology of a laser irradiated section to be observed. The sample preparation in the invention is carried out without a series of complex methods, such as mounting, grinding of a sample, and ion thinning, and therefore, the process time is greatly shortened; the pollution is very low; furthermore, the reliability of a result is relatively high; and the sample preparation method has the important significance for researching crystallization behaviours of a phase-change material in the thickness direction.

Owner:BEIJING UNIV OF TECH

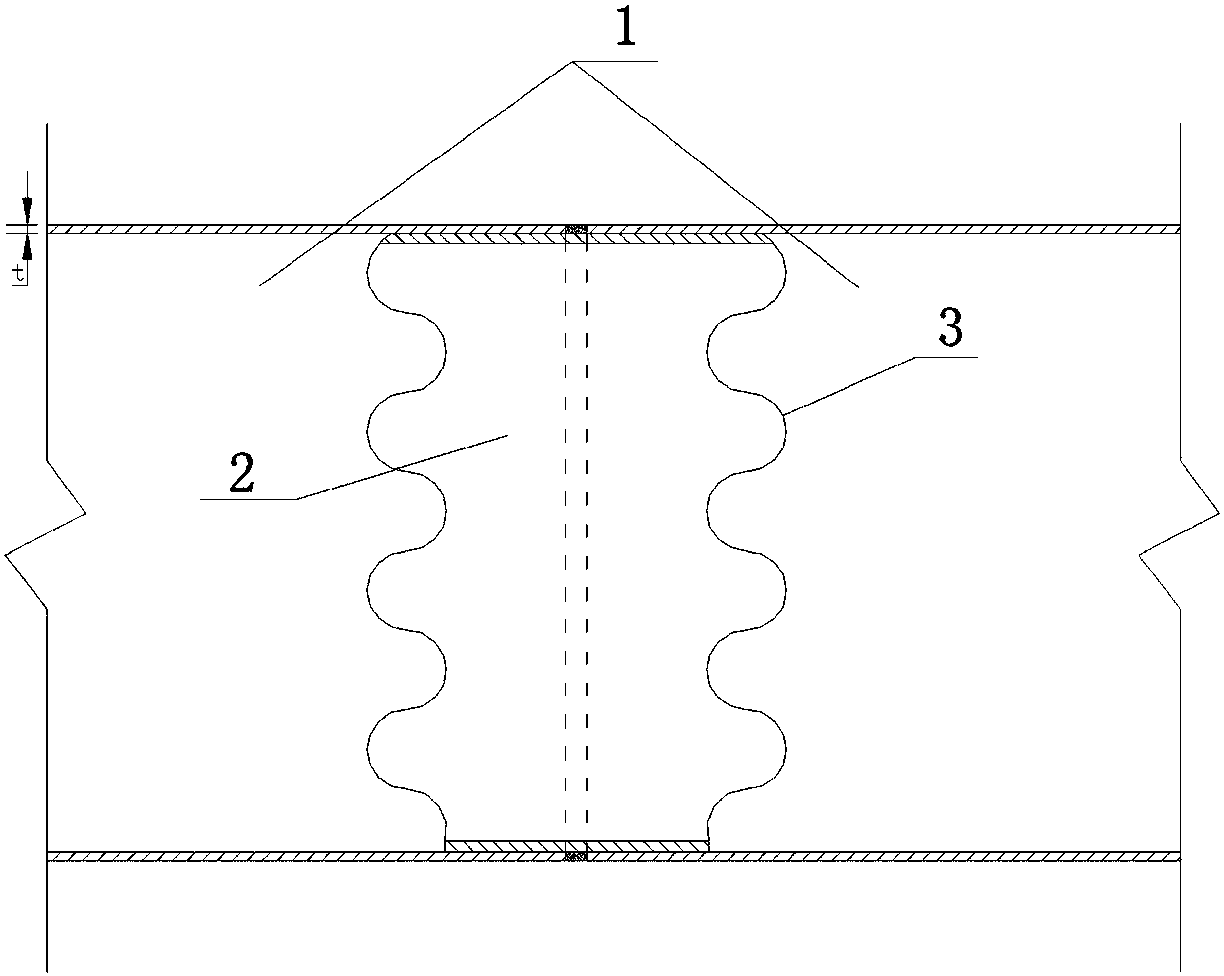

Butt joint connecting device and method for large-scale steel pipe columns under circumstance of vibration load

ActiveCN103801846AAvoid thermal influenceAvoid it happening againWelding/cutting auxillary devicesAuxillary welding devicesButt weldingButt joint

The invention relates to a large steel structure building, particularly to a butt joint connecting device and method for large-scale steel pipe columns under the circumstance of vibration load. A steel pipe interface of a large-scale steel pipe support column is usually processed via a butt joint mode, but the butt joint mode for processing has the following defects that the requirement on the welding quality in an interface position is extremely strict, so that quality acceptance requirements are difficult to achieve; the organizational structure of steel pipe column parent materials within the range of 50 mm on the both sides of the steel pipe interface position is changed, and crystal particles are coarsened, so that welding heat influence lines are generated; under the action of the mechanical vibration load, the steel pipe column parent materials in welded junction positions are cracked to cause accidents. In order to solve the technical problems and enable the butt joint welding of the large-scale steel pipe support columns to achieve the requirements on safety, economy and reliability in use, a wave-shaped bushing pipe is mounted in the large-scale steel pipe column interface. The wave-shaped bushing pipe is mounted in the steel pipe column interface, wave shapes at the both ends of the wave-shaped bushing pipe are welded on the inner sides of two steel pipe columns, and the steel pipe column interfaces and the outer side of the wave-shaped bushing pipe are welded together.

Owner:湖南金海现代建筑科技有限公司

Apparatus for molding optical element

InactiveUS20080209946A1Convey evenlyAvoid thermal influenceGlass pressing apparatusGlass reforming apparatusEngineeringMechanical engineering

Owner:ASAHI GLASS CO LTD

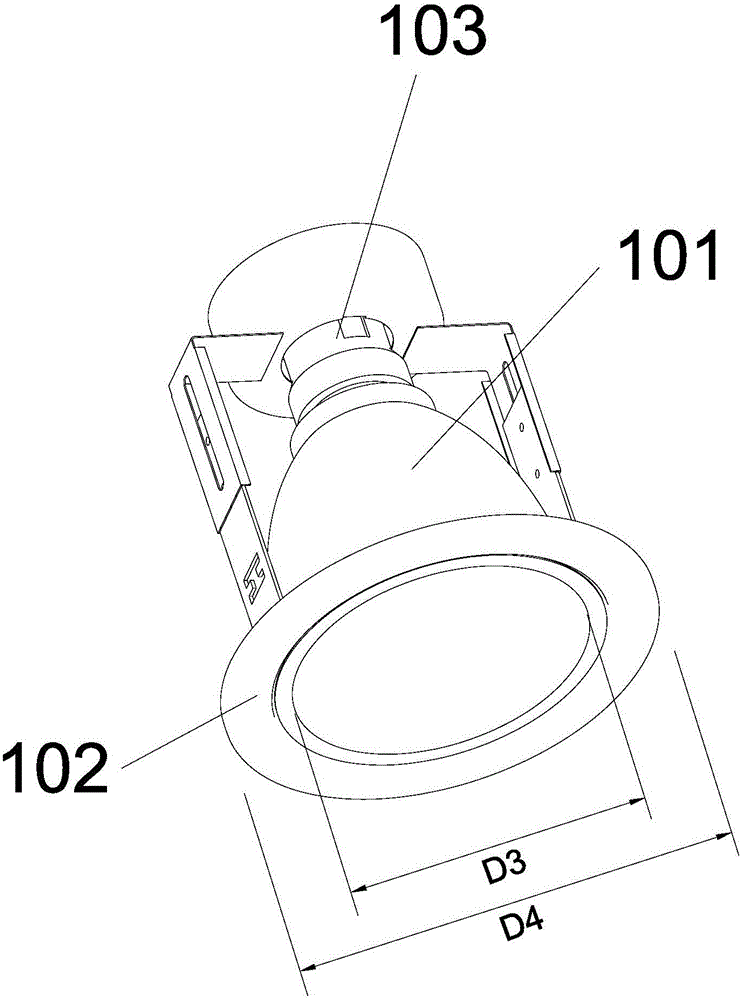

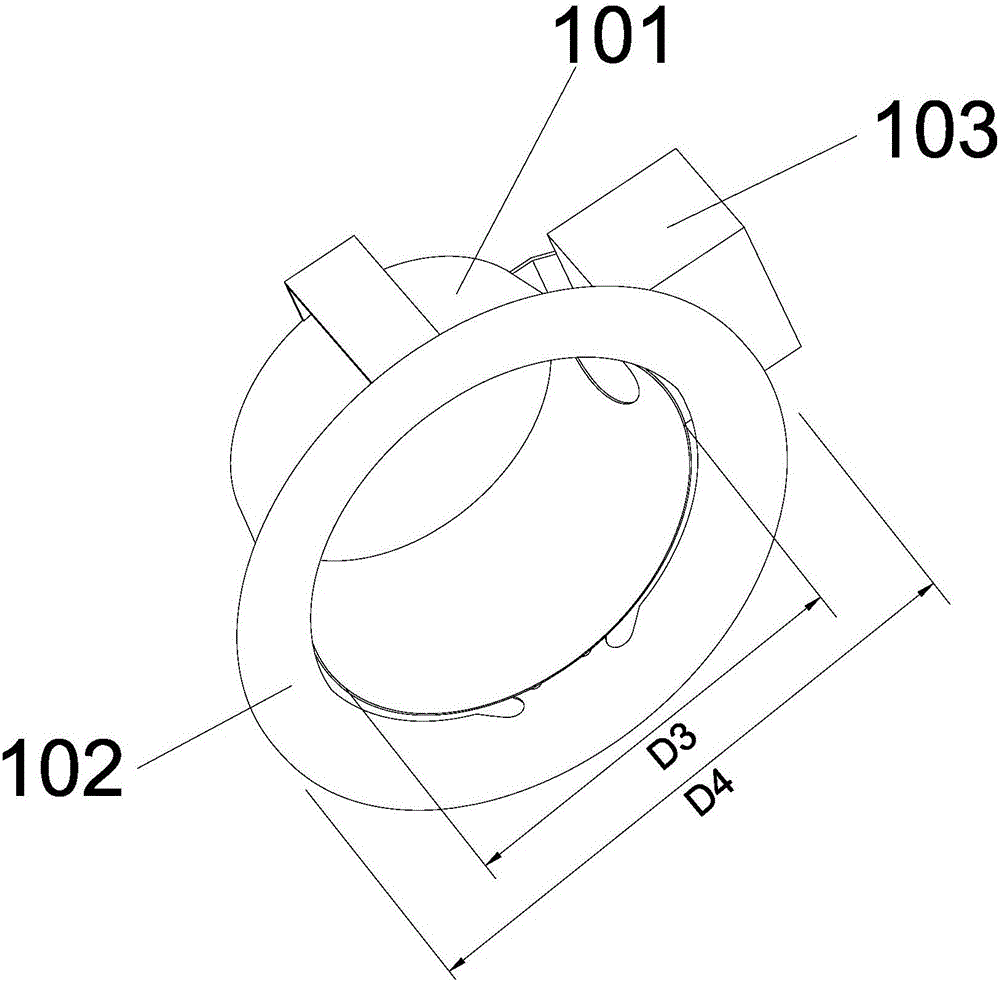

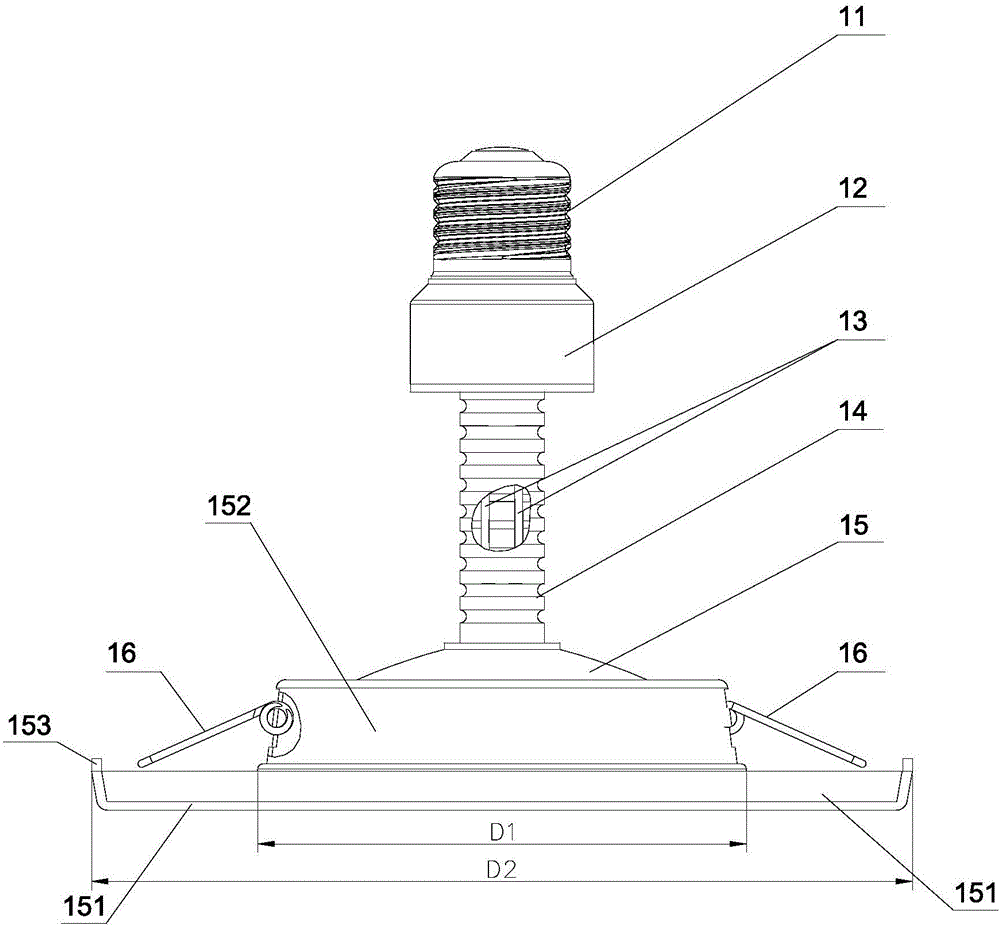

LED replacement light source matched with traditional tube light and LED ceiling light

ActiveCN105972518AEasy to installEasy to replaceElectric circuit arrangementsProtective devices for lightingPhysicsLight source

The invention discloses an LED replacement light source matched with a traditional tube light. The LED replacement light source comprises a light holder, a driving power source, an LED light source plate and an LED light source plate supporting piece. The light holder is fixedly connected with a shell body of the driving power source. An electrode of the light holder is in internal wire connection with an input electrode of the driving power source. An output electrode of the driving power source is in external wire connection with a light source electrode of the LED light source plate. The LED light source plate is provided with the LED light source plate supporting piece and is of a cap structure with a brim. The size of a cap opening of the LED light source plate is smaller than the hole diameter of a traditional tube light decoration ring matched with the LED light source plate. The outer diameter size of the cap edge of the LED light source plate is larger than the hole diameter of the traditional tube light decoration ring matched with the LED light source plate. The LED replacement light source matched with the traditional tube light can directly replace traditional light sources in existing traditional tube lights huge in stock and has great significance to acceleration of application and popularization of LED lighting, energy saving and environmental protection.

Owner:FUJIAN YDJ LIGHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com