Connection structure of motion guide rod and rotor and electronic expansion valve

A technology of connecting structure and guide rod, applied in valve details, valve device, engine components, etc., can solve the problems of rotor thermal influence, failure, magnetic intensity change of rotor surface, etc., and achieve good connection quality, accurate positioning, and travel limit. Bit accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

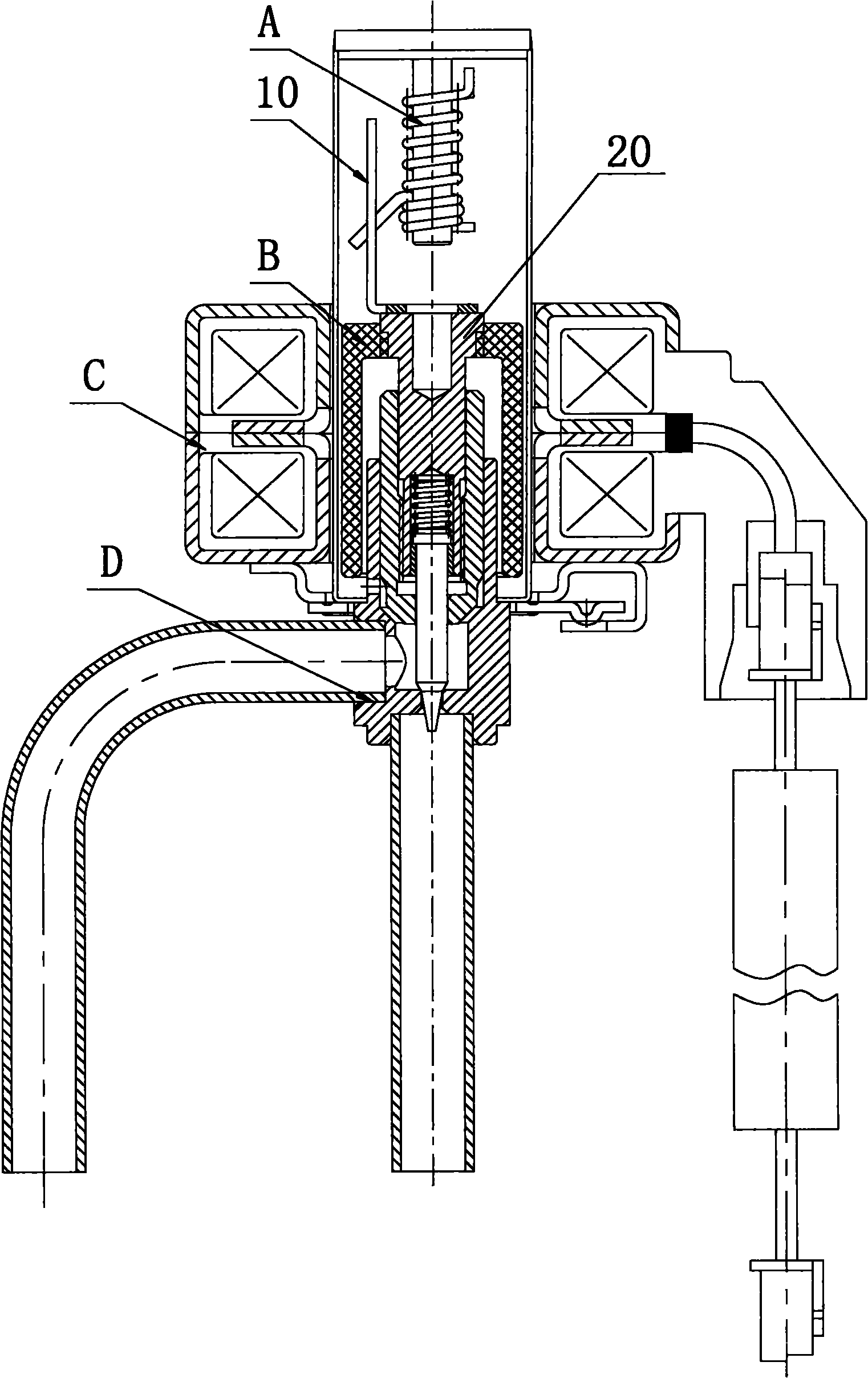

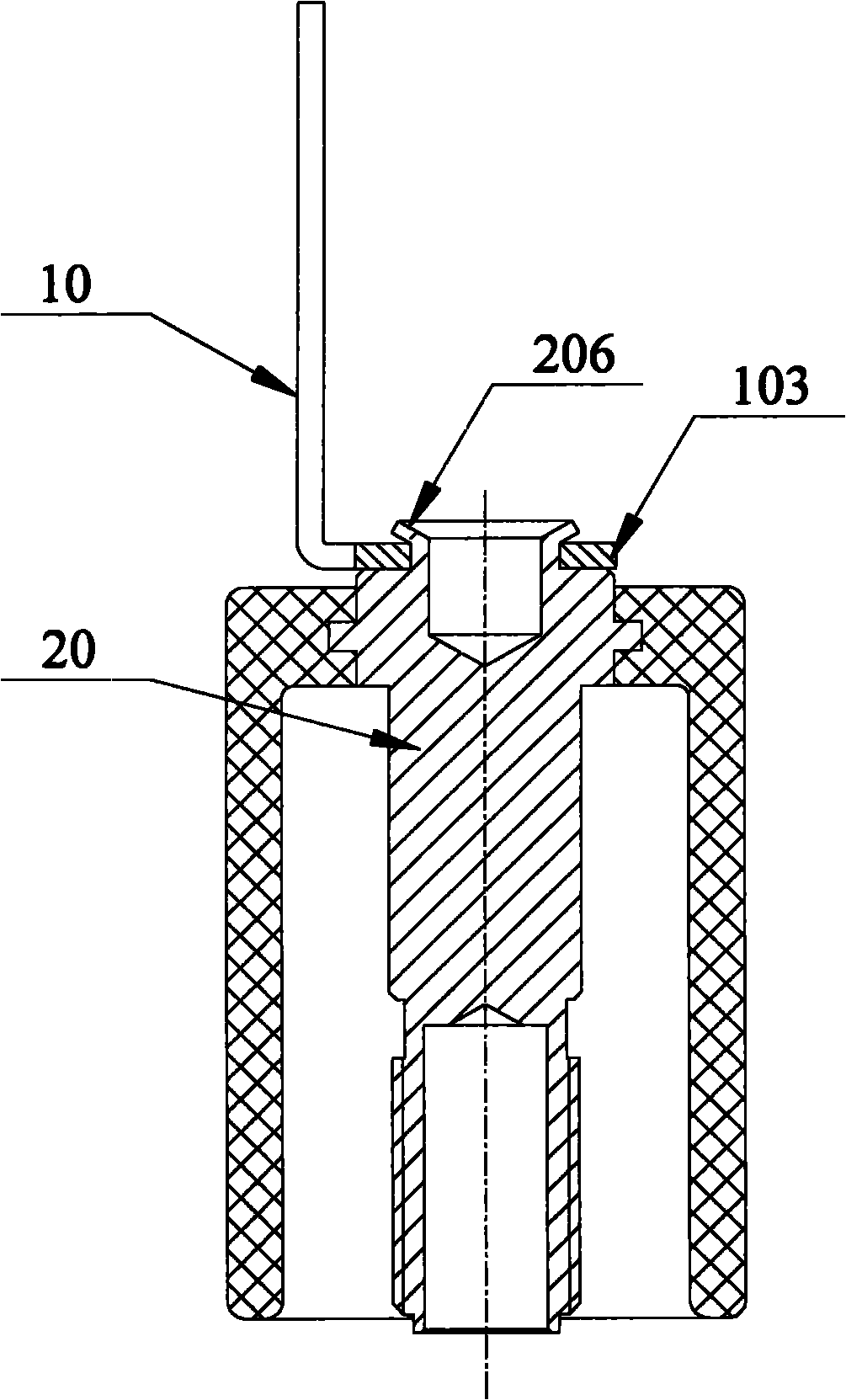

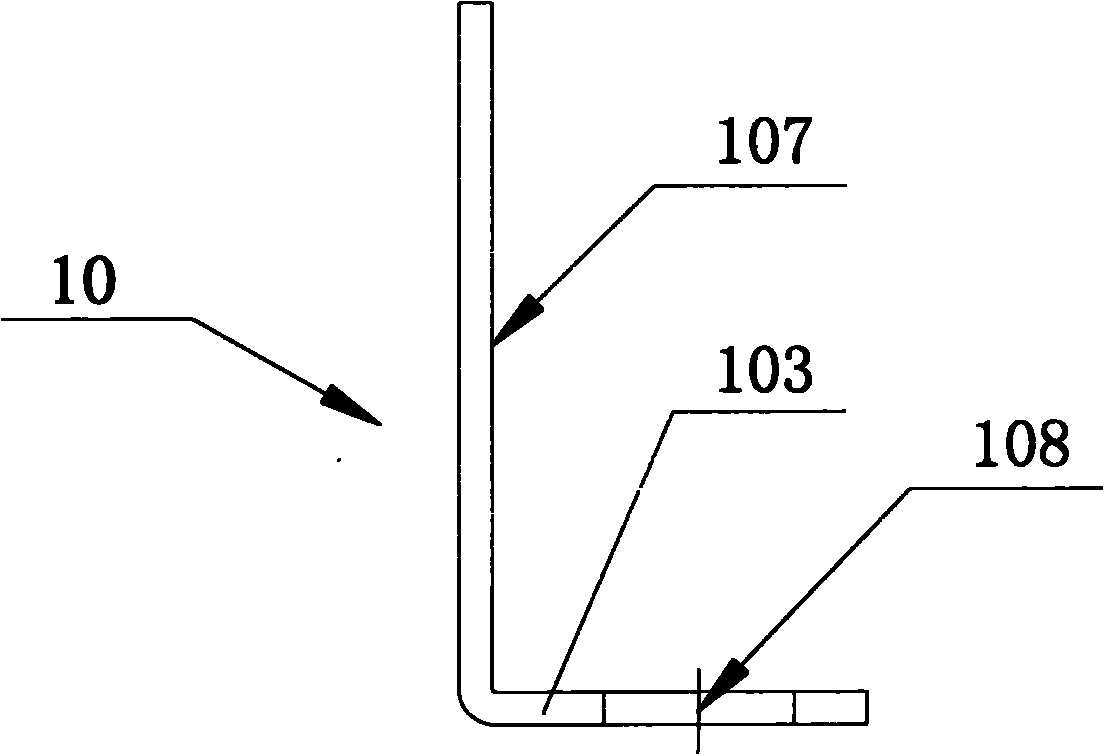

[0042] figure 2 The connection structure between the guide rod and the rotor according to the first embodiment of the present invention is schematically shown in cross-sectional structure. The connection structure between the guide rod and the rotor includes: a guide rod 10 and a rotor screw 20, wherein, as image 3 As shown, the section of the guide rod 10 is L-shaped, such as Figure 4 to Figure 6 As shown, the guide rod 10 includes: a vertical guide rod vertical section 107, a connecting section 103 that is horizontally arranged and connected with the guide rod vertical section 107, and the connecting section 103 can be, for example, a circle with a positioning hole 108. The annular plate can also be a rectangular plate, and the upper end of the rotor screw 20 is riveted with the connecting section 103 , for example, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com